Core sample testing protocol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

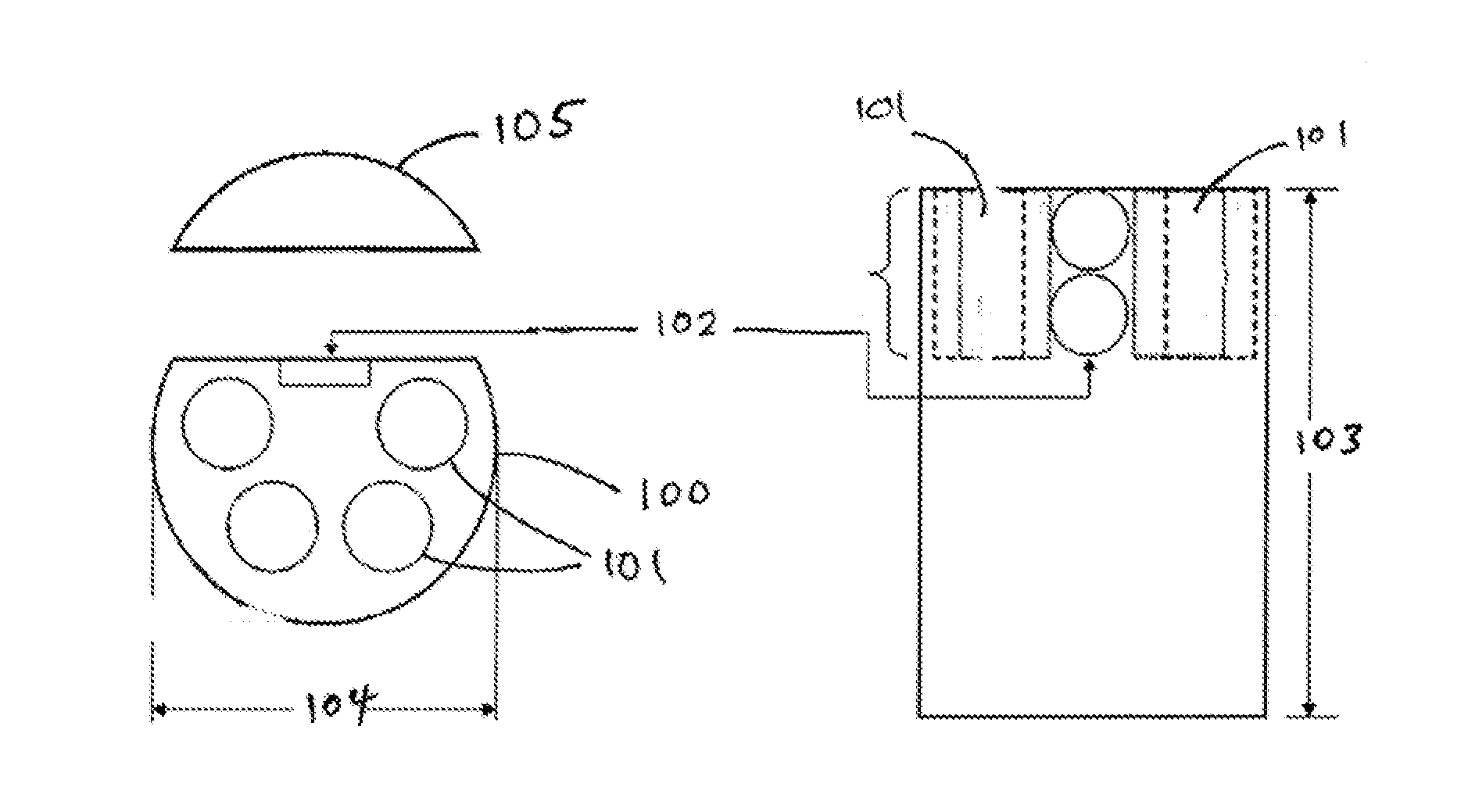

[0059]This example describes a protocol for preparing and analyzing core sample according to an embodiment of the present invention. A schematic of the sampling protocol along with the various measurements is shown in FIG. 1. A standard procedure is for a bulk sample having length 103 of 6 inches (15 cm) and diameter 104 of 4 inches (10 cm) to be cut along its axis so that a quarter 105 of the core is removed and submitted for archiving, whilst the remaining three quarter core 100 is available for testing.

[0060]The core analysis process begins when the preserved core samples arrive at the lab for testing. The preserved ¾whole core sample 100 is first CT scanned to validate the preserved rock material is suitable for core plugging and mechanical testing. This step is required to identify fractured, broken or desiccated core that might not be suitable for mechanical testing.

[0061]After the CT scan, the sample is prepared for plugging. A total of 4—1″×2″ (2.5 cm by 5 cm) plugs 101 are ...

example 2

[0072]This example illustrates some of the differences between single stage triaxial testing of an embodiment and multistage triaxial testing. FIG. 6 shows a sample graph plotting deviatory stress versus strain of multistage triaxial testing where confining pressure increased at each imminent failure point. There are at least three imminent failure points represented by the plateaus in the axial strain. Success of multistage triaxial testing is largely dependent on the experimenter's ability to determine the imminent failure point for each confining stress. It is not uncommon to misplace the appropriate termination point (imminent failure) for each loading cycle thereby introducing significant error in determining Mohr-Coulomb yield parameters. By contrast, FIG. 7 shows a sample graph plotting deviatory stress versus strain of single stage triaxial testing where confining pressure is constant throughout the entire test. No human error is introduced in the form of judging where the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com