Palm wood plywood and preparation method thereof

A palm wood and plywood technology, applied in the field of palm wood plywood and its preparation, can solve the problems of poor product quality, poor mechanical properties and low dimensional stability of the palm wood veneer, and achieve enhanced modified palm veneer, good Promoting and commercial prospects, good effect of dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

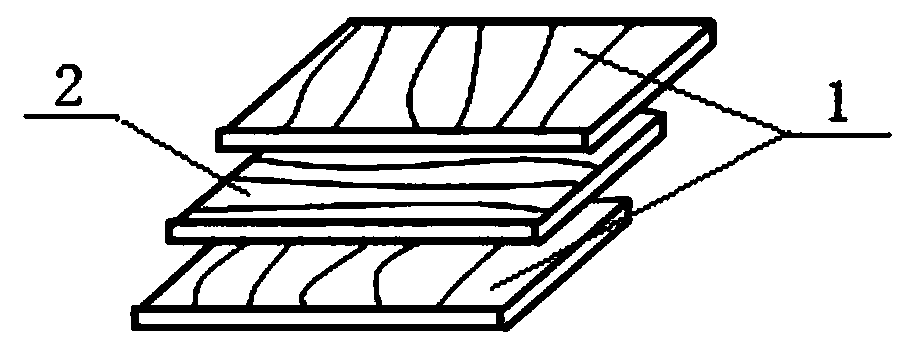

[0036] Such as figure 1 As shown, a palm wood plywood includes a surface board and a core board, the surface board is made of high-density impregnated palm wood veneer, and the core board is made of low-density impregnated palm wood veneer.

[0037] Preparation:

[0038] S1. Rotary cutting of veneer: use a rotary cutting machine to process palm wood into palm wood veneer, and the thickness of palm wood veneer is 3.0mm;

[0039] S2. Primary drying of the veneer: Dry the palm wood veneer in step S1 with a roller dryer, the drying temperature is 150°C-180°C, the drying time is 3-5min, and the moisture content of the dried palm wood veneer Control it at around 12%;

[0040] S3, veneer grading: remove the cracked veneers in the dried palm wood veneers in step S2, and divide them into high-density palm wood veneers and low-density palm wood veneers, and the density level of low-density veneers Use 0.35-0.45g / cm 3 , high-density veneer density grade adopts 0.45-0.56cm 3 ;

[00...

Embodiment 2

[0049] A palm wood plywood, comprising a surface board and a core board, the surface board is made of high-density impregnated palm wood veneer, and the core board is made of low-density impregnated palm wood veneer.

[0050] Preparation:

[0051] S1. Rotary cutting of veneer: use a rotary cutting machine to process palm wood into palm wood veneer, and the thickness of palm wood veneer is 5mm;

[0052] S2. Primary drying of the veneer: drying the palm wood veneer in step S1 with a roller dryer, the drying temperature is 150°C-180°C, and the drying time is 3-5min;

[0053] S3, veneer grading: remove the cracked veneers in the dried palm wood veneers in step S2, and divide them into high-density palm wood veneers and low-density palm wood veneers, and the density level of low-density veneers Use 0.35-0.45g / cm 3 , high-density veneer density grade adopts 0.45-0.56cm 3 ;

[0054] S4. Impregnation of the veneer: The high-density palm wood veneer and the low-density palm wood ve...

Embodiment 3

[0062] A palm wood plywood, comprising a surface board and a core board, the surface board is made of high-density impregnated palm wood veneer, and the core board is made of low-density impregnated palm wood veneer.

[0063] Preparation:

[0064] S1. Rotary cutting of veneer: use a rotary cutting machine to process palm wood into palm wood veneer, and the thickness of palm wood veneer is 8.0mm;

[0065] S2. Primary drying of the veneer: drying the palm wood veneer in step S1 with a roller dryer, the drying temperature is 150°C-180°C, and the drying time is 3-5min;

[0066] S3, veneer grading: remove the cracked veneers in the dried palm wood veneers in step S2, and divide them into high-density palm wood veneers and low-density palm wood veneers, and the density level of low-density veneers Use 0.35-0.45g / cm 3 , high-density veneer density grade adopts 0.45-0.56cm 3 ;

[0067] S4. Impregnation of the veneer: The high-density palm wood veneer and the low-density palm wood ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Bonding strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com