Production process for cotton paper

A production process and technology of tissue paper, applied in papermaking, textiles and papermaking, pulping of cellulose raw materials, etc., can solve the problems of easy wrinkling, not smooth enough paper surface, difficult papermaking, etc., and achieve strong tensile strength, high toughness, Good water absorption and hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

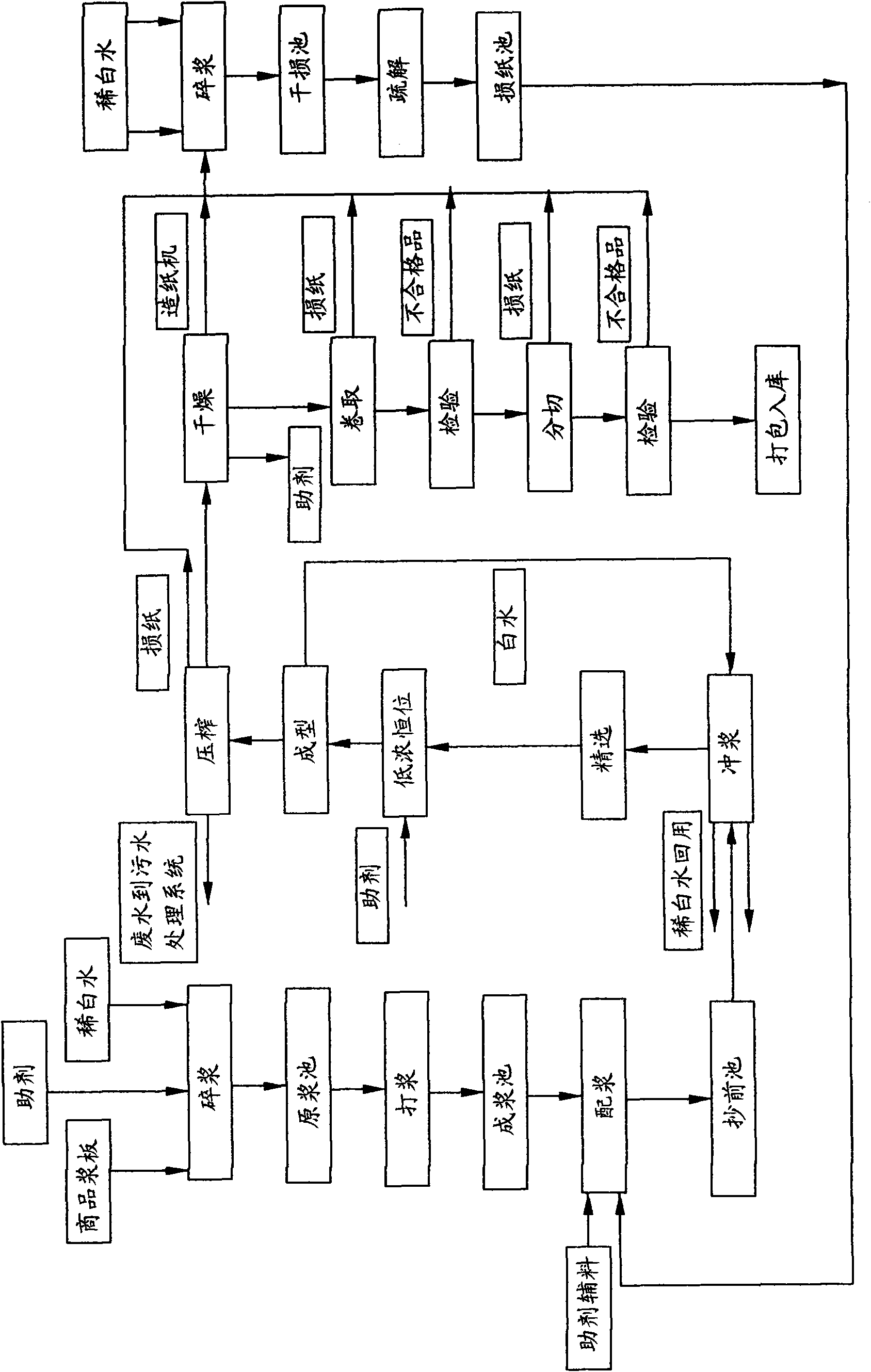

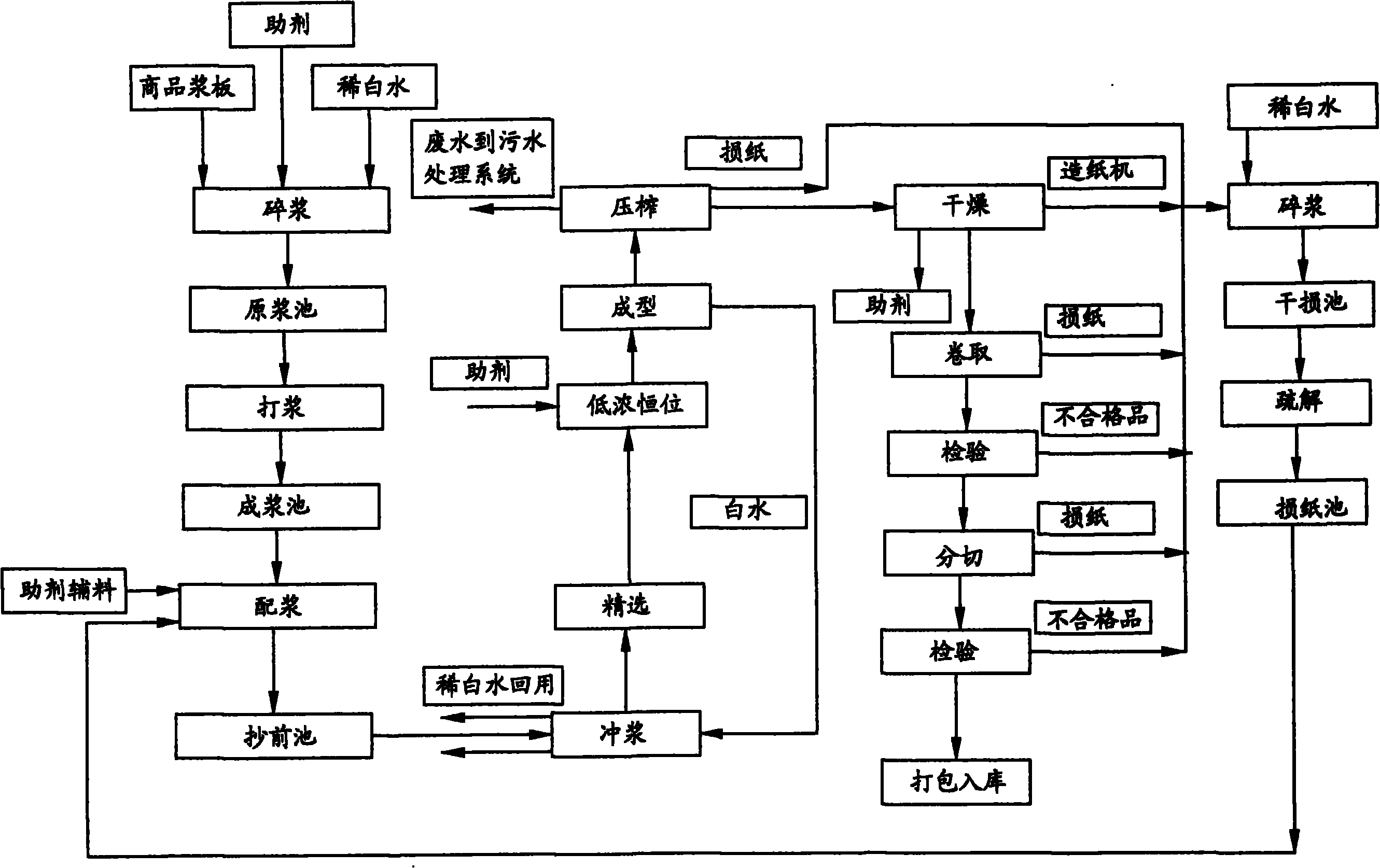

[0012] Example: A production process of cotton paper, using long-fiber wood pulp to be disintegrated by a hydraulic crusher and adding chemical additives to make raw pulp, and then through a toothed disc deflaker and a refiner connected in series with a low-current semi-viscous beating , the beating concentration of the beater used is 4.2-5.5%, and the beating ampere is 46-58A; after the beating is completed, the pulp should be mixed, and 1% whitening agent should be added and filtered through a 90-mesh screen, and it should be evenly matched with the above-mentioned slurry; the above-mentioned mixed slurry should be copied After the paper is formed and dried, it is taken up by the rewinder, and the broken paper is detected in the drying and winding process. Please refer to the specific operation figure 1 .

[0013] Pulp forming includes pulping process, high-efficiency sand removal process, high-low-consistency high-level overflow and paper forming. The pulping process is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com