Composite facer for wallboards

a technology of composite facing and wallboard, which is applied in the direction of process and machine control, natural mineral layered products, instruments, etc., can solve the problems of reducing the structural integrity of paper, reducing the quality of paper, and generally flammable paper facing, so as to facilitate the folding of the facing material, reduce the likelihood of yarn loss, and increase the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

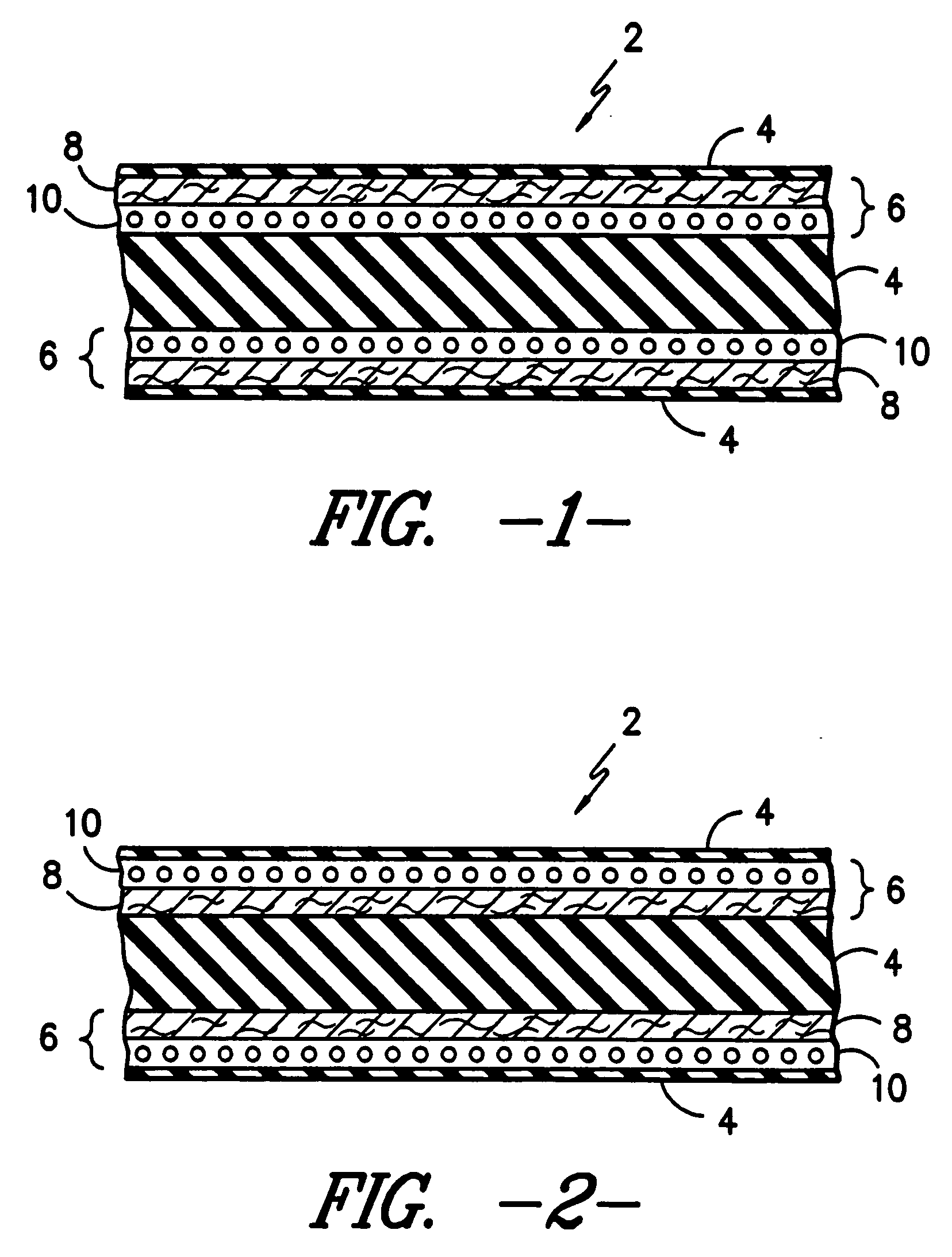

[0022] A facer material was constructed from a laid scrim of G150 glass yarn in a triaxial configuration laminated to a 0.5 ounce / square yard carded polyester mat bonded with an acrylic adhesive. The yarn frequency was 4 yarns per inch in each direction. The facer was laid into a silicone mold 3 inches by 11 inches and 0.5 inches deep. The mold was filled with gypsum slurry covering the facer. In one trial, the facer was placed with the scrim facing the gypsum (as shown in FIG. 1), in another, the mat was facing the gypsum (as shown in FIG. 2). The slurry was allowed to set for 20 minutes after which the composites were removed from the mold and cured at 40.degree. C. for 24 hours.

[0023] The flexural break strength was measured according to ASTM C473. The break strength of the composite with the scrim facing the gypsum (FIG. 1) was 21.4 pounds. The break strength of the composite with the mat facing the gypsum (FIG. 2) was 29.4 pounds.

[0024] Thus, it can be seen that the orientation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com