Method for quickly acclimatizing active sludge mixed flora to prepare polyhydroxyalkanoate (PHA) by using aerobic dynamic drainage method

A technology of polyhydroxyalkanoate and activated sludge, which is applied in the direction of fermentation, etc., can solve the problems of unstable operation of the reactor, high cost of the production method, and low PHA content, and achieve the promotion of industrial application, multiple cycles, and high synthesis speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Embodiment 1: The aerobic dynamic drainage method of this embodiment is used to quickly domesticate the mixed flora of activated sludge to prepare polyhydroxyalkanoate. The specific steps are as follows:

[0020] 1. Put the activated sludge in the SBR reactor with a height-to-diameter ratio of 10:1, so that the sludge concentration in the reactor reaches 3000-5000mg / L;

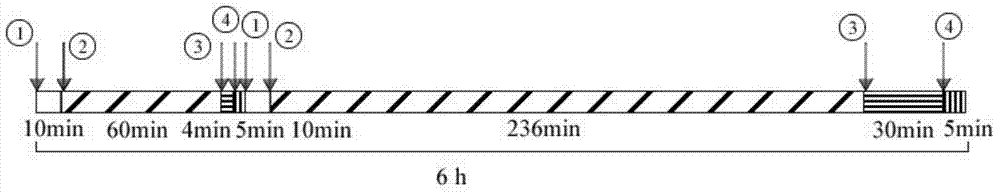

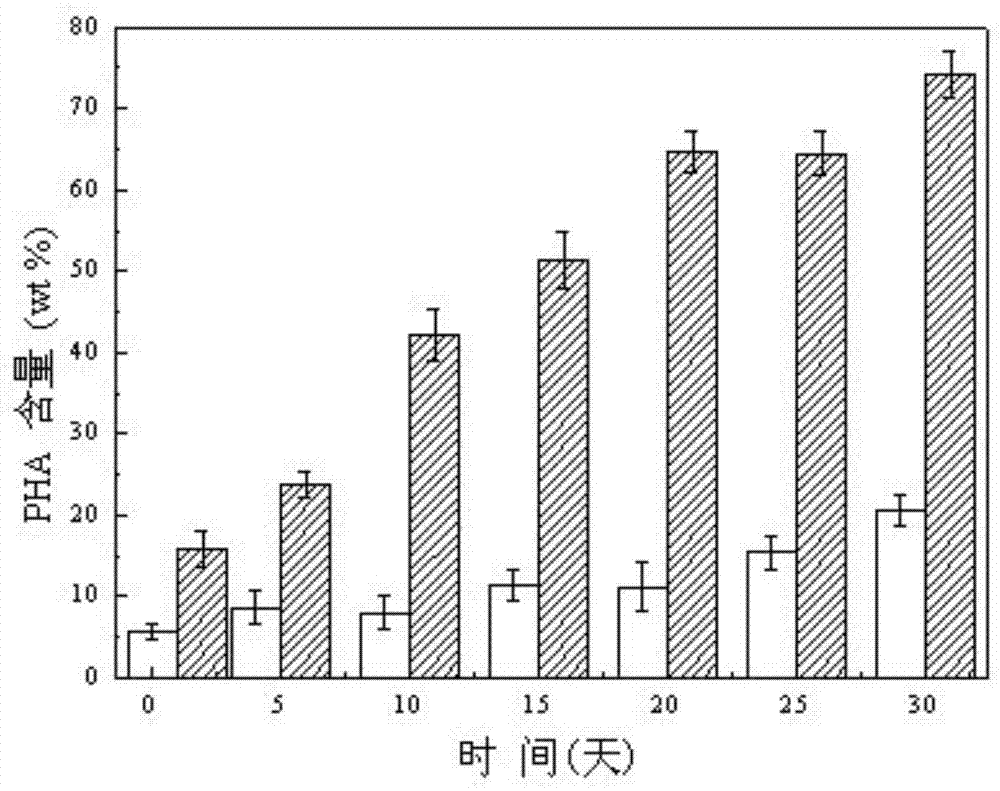

[0021] Two, take 6~12h as an operation cycle, run the SBR reactor, the operation process of a cycle of the SBR reactor is as follows: firstly carry out the first water inflow, after the first water inflow is completed, in the SBR reactor When the temperature is 20 ℃ ~ 25 ℃, start aeration, after the dissolved oxygen in the SBR reactor jumps from 2 ~ 3mg / L to 6 ~ 7mg / L, stop the aeration, and then carry out precipitation for 3 ~ 5min. Drainage; carry out the second water intake, continue to aerate for 5-11 hours, and drain after 30 minutes of sedimentation; among them, the first water intake contains car...

specific Embodiment approach 2

[0032] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the aeration is started when the temperature of the reactor is 23° C. as described in step 2. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0033] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the carbon sources are all small molecule organic acids. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com