Anti-slip sole and shoe employing same

A non-slip and outsole technology, applied in the direction of shoe soles, footwear, clothing, etc., can solve the problem of reducing the contact area between the pattern surface and the ground, reducing the friction between the pattern and the ground, reducing the anti-skid performance of the sole surface, etc. Problems, to achieve the effect of improving diffusion fluidity, ensuring straight line fluency, and improving fluency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

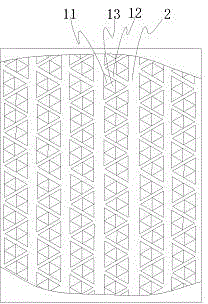

[0013] refer to figure 1 , the embodiment of the present invention discloses that an anti-slip shoe sole includes a large bottom, and the large bottom has a plurality of anti-slip protrusion rows 1 evenly arranged in its length direction, and the adjacent anti-slip protrusion rows 1 Form a linear drainage gap 2 between them; the anti-slip protrusion row 1 is composed of a plurality of triangular anti-slip protrusions 11, and adjacent triangular anti-slip protrusions 11 will form a parallelogram structure together, and the adjacent triangular anti-slip protrusions 11 will form a parallelogram structure, and the adjacent triangular anti-slip protrusions 11 will form a parallelogram structure. There is also a communication gap 12 connected to the drainage gap 2 between the sliding protrusions 11; a triangular groove 13 is also provided on the surface of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com