Method for three-layer unblocking for immovable string

A technology for removing blockage and moving pipes, which is applied in earth-moving drilling, cleaning equipment, and production of fluids, etc., can solve problems such as production decline and oil pressure sudden drop, and achieve the effects of cost saving, solving large area and simple construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

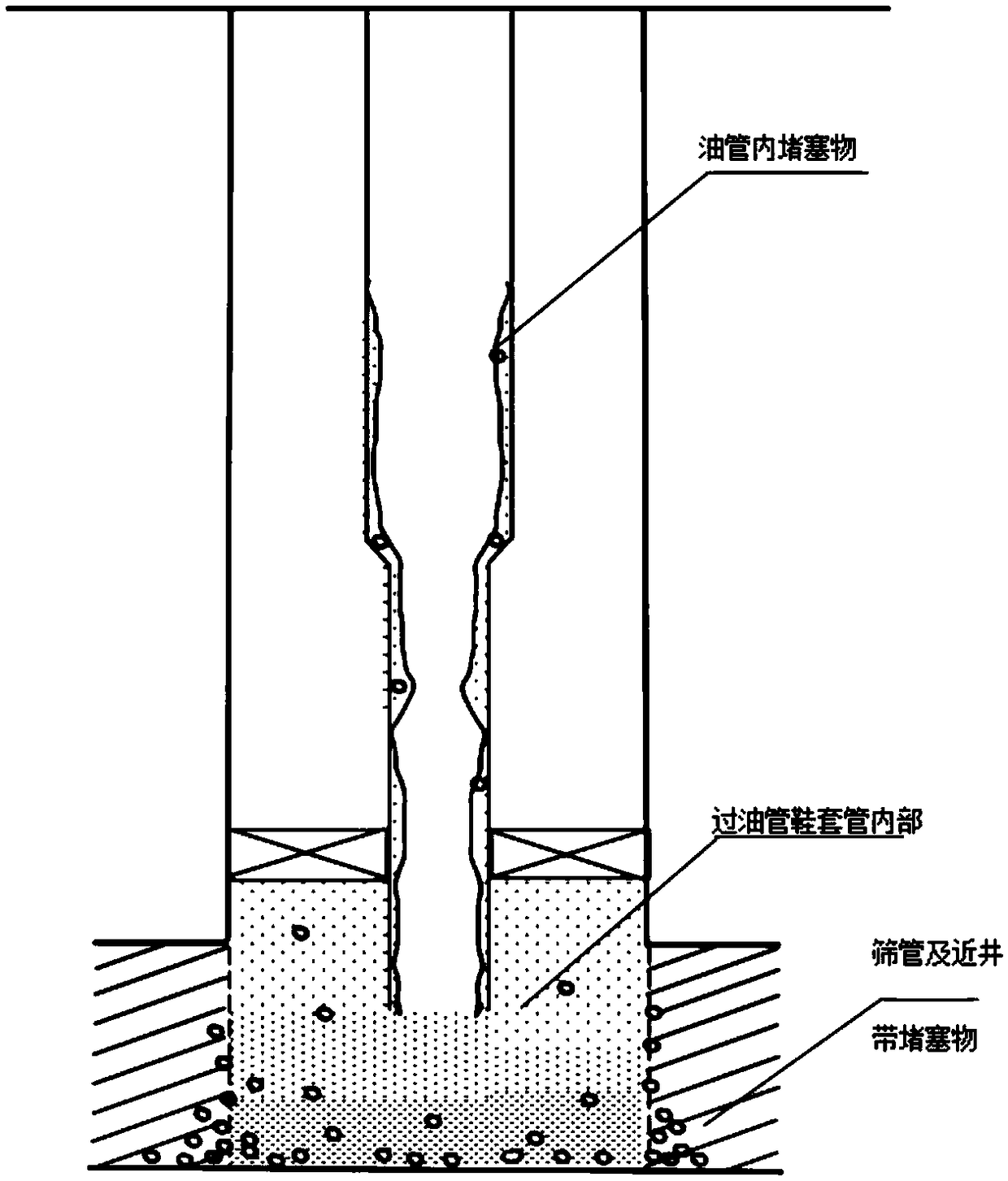

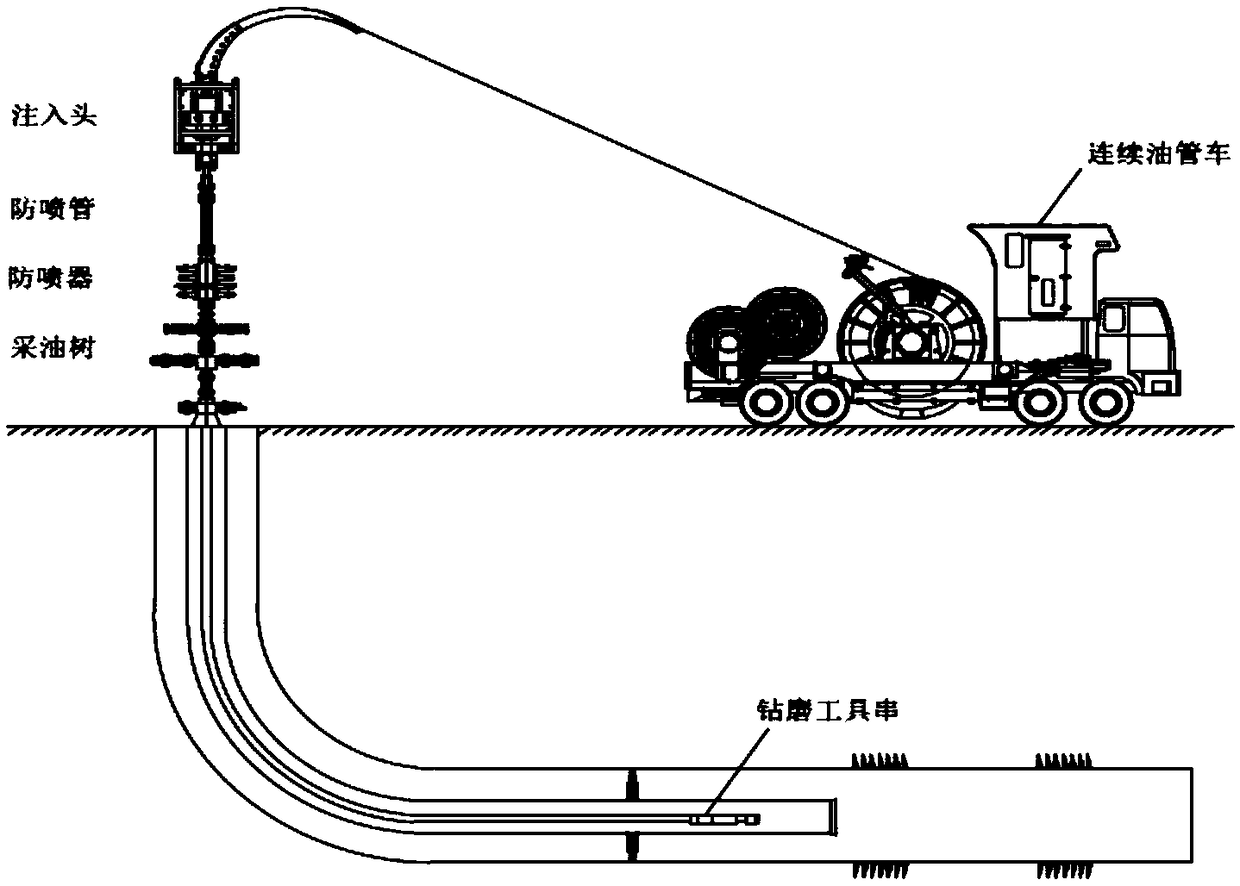

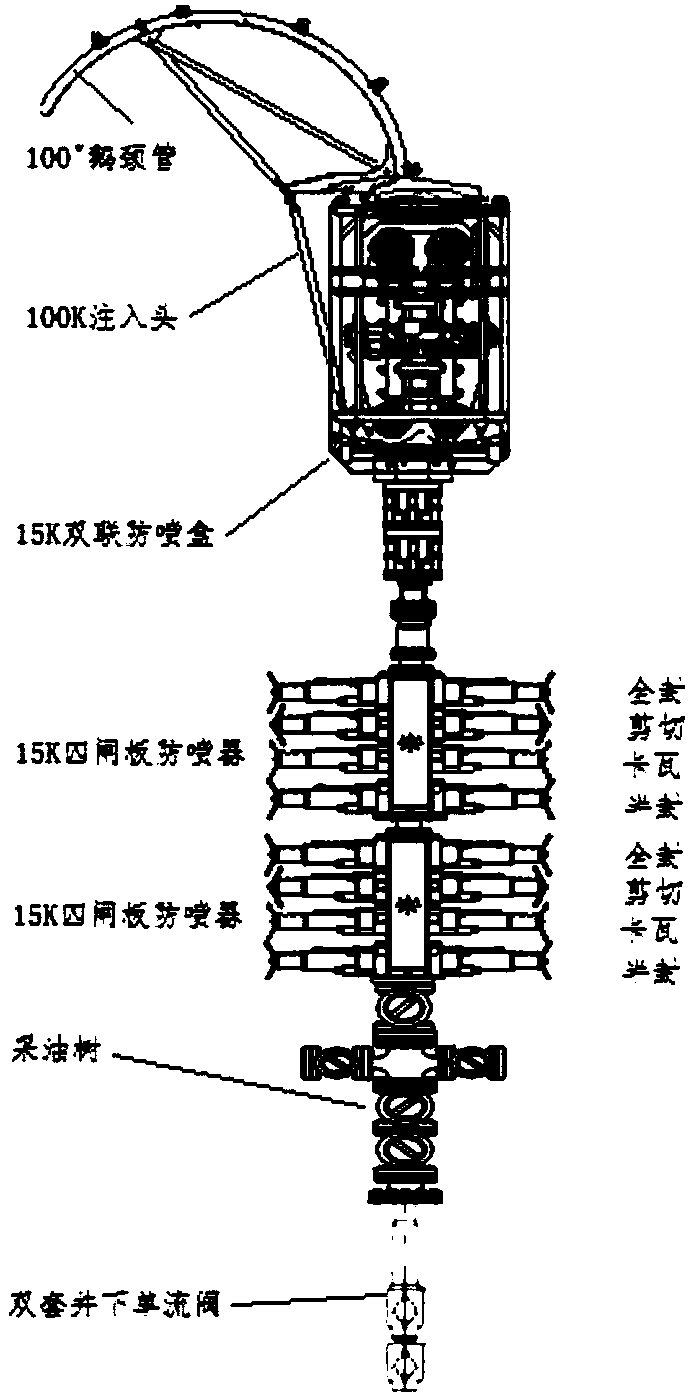

[0033] A method for three-layer plugging removal without moving the string. The three-layer plugging removal includes plugging removal in the tubing, plugging removal in the tubing casing, and plugging removal near the wellbore; specifically, coiled tubing well control equipment is installed at the entrance of the high-pressure gas well. , A circulating working fluid desanding system is set up on the ground, and downhole tools and plugging liquid are transported through coiled tubing to realize three-layer plugging removal.

[0034]Downhole tools include special tool strings, venturi overshots, screw drilling tools, small diameter sand pumps or any combination of special nozzles.

[0035] The operation steps of unblocking in the tubing are as follows: downhole tools are installed at the bottom of the coiled tubing, and the 1050-type pump truck on the ground circulates the sand washing fluid to provide power for the downhole drilling tools. The three-stage sand removal and filt...

Embodiment 2

[0046] A method for three-layer plugging removal without moving the string. The three-layer plugging removal includes plugging removal in the tubing, plugging removal in the tubing casing, and plugging removal near the wellbore; specifically, coiled tubing well control equipment is installed at the entrance of the high-pressure gas well. , A circulating working fluid desanding system is set up on the ground, and downhole tools and plugging liquid are transported through coiled tubing to realize three-layer plugging removal.

[0047] Further, the downhole tools include special tool strings, Venturi overshots, screw drill tools, small diameter sand pumps or any combination of special nozzles.

[0048] The operation steps of unblocking in the tubing are as follows: downhole tools are installed at the bottom of the coiled tubing, and the 1200-type pump truck on the ground circulates the sand flushing fluid to provide power for the downhole drilling tools. The three-stage sand remo...

Embodiment 3

[0059] A method for three-layer plugging removal without moving the string. The three-layer plugging removal includes plugging removal in the tubing, plugging removal in the tubing casing, and plugging removal near the wellbore; specifically, coiled tubing well control equipment is installed at the entrance of the high-pressure gas well. , A circulating working fluid desanding system is set up on the ground, and downhole tools and plugging liquid are transported through coiled tubing to realize three-layer plugging removal.

[0060] Further, the downhole tools include special tool strings, Venturi overshots, screw drill tools, small diameter sand pumps or any combination of special nozzles.

[0061] The operation steps of unblocking in the tubing are as follows: downhole tools are installed at the bottom of the coiled tubing, and the 1050-type pump truck on the ground circulates the sand washing fluid to provide power for the downhole drilling tools. The three-stage sand remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com