Patents

Literature

71results about How to "Achieving safe operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

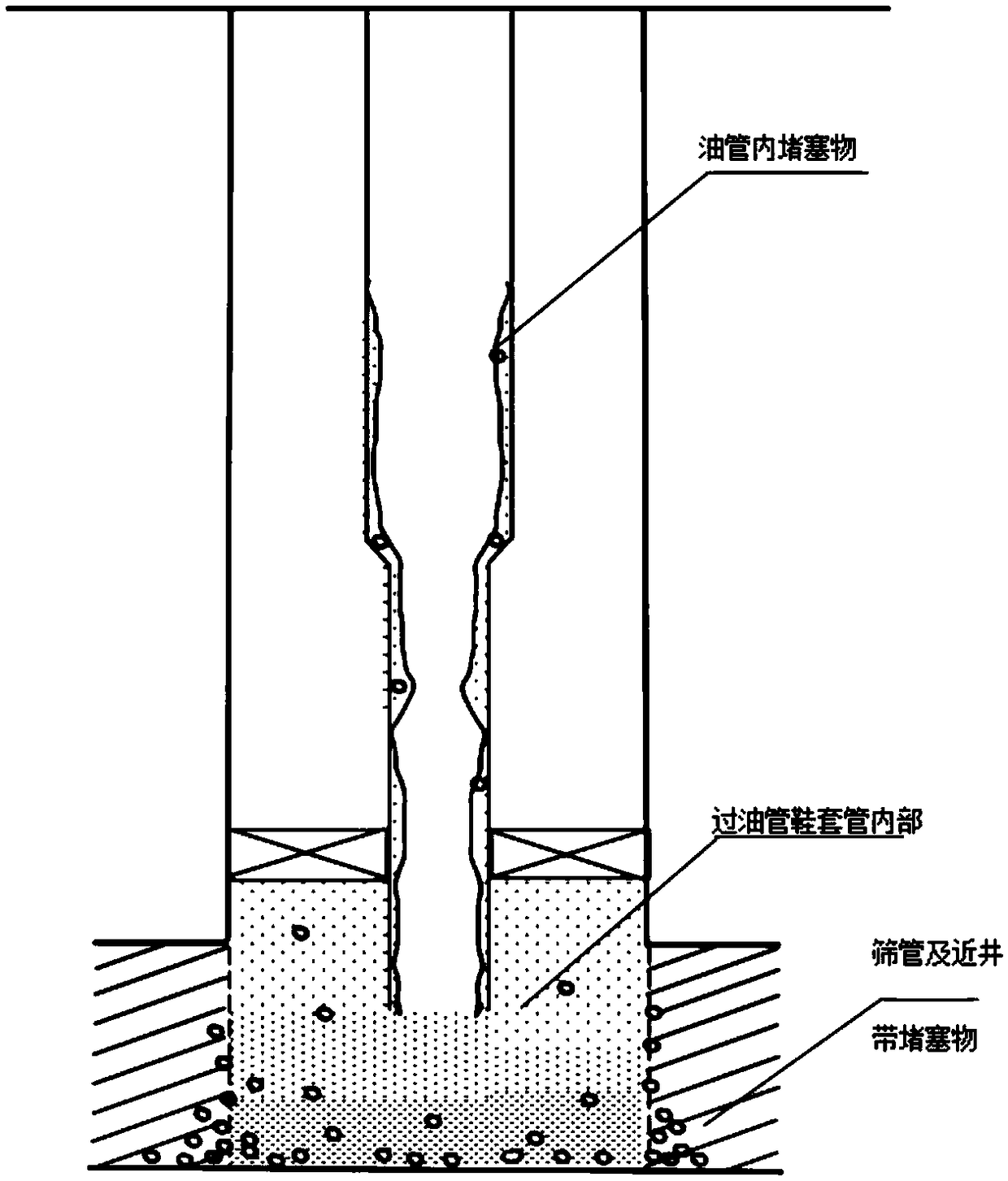

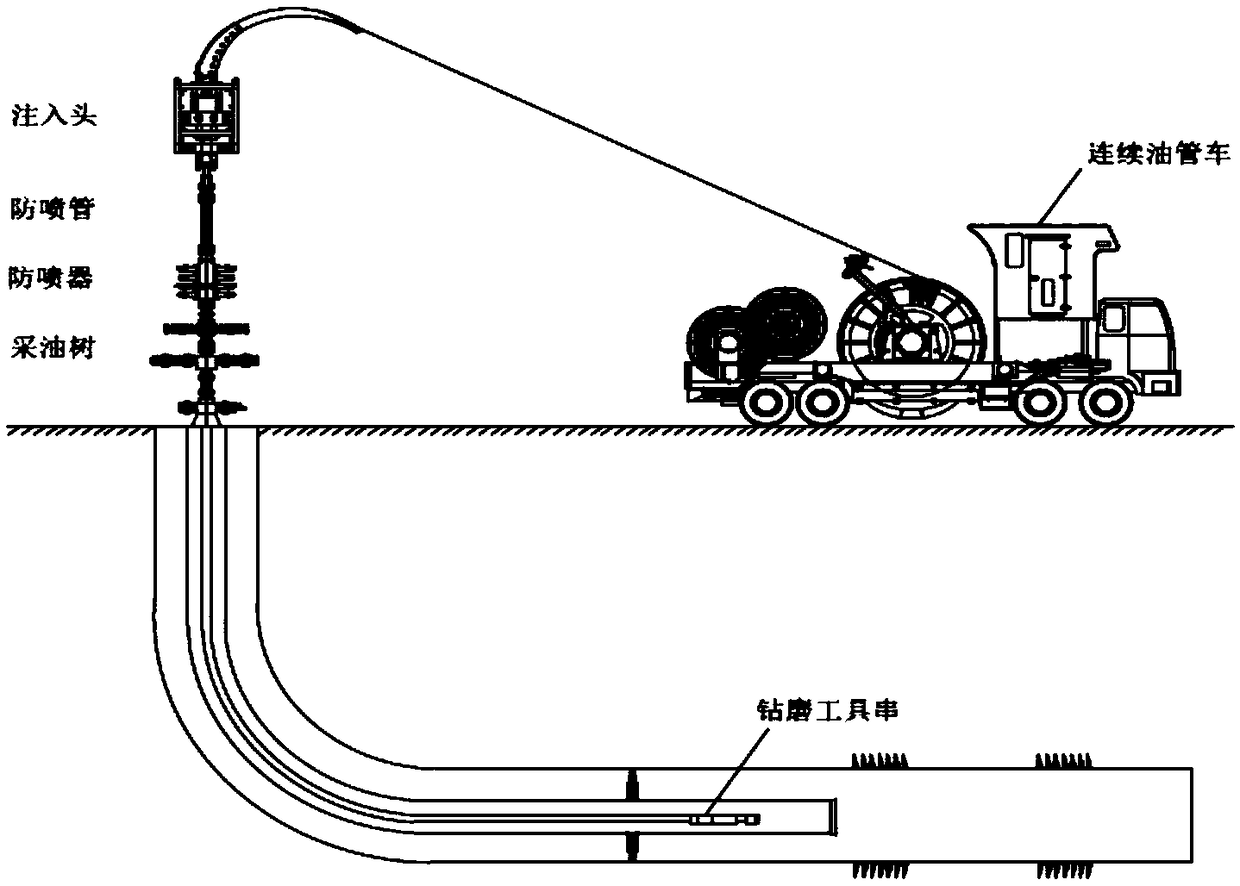

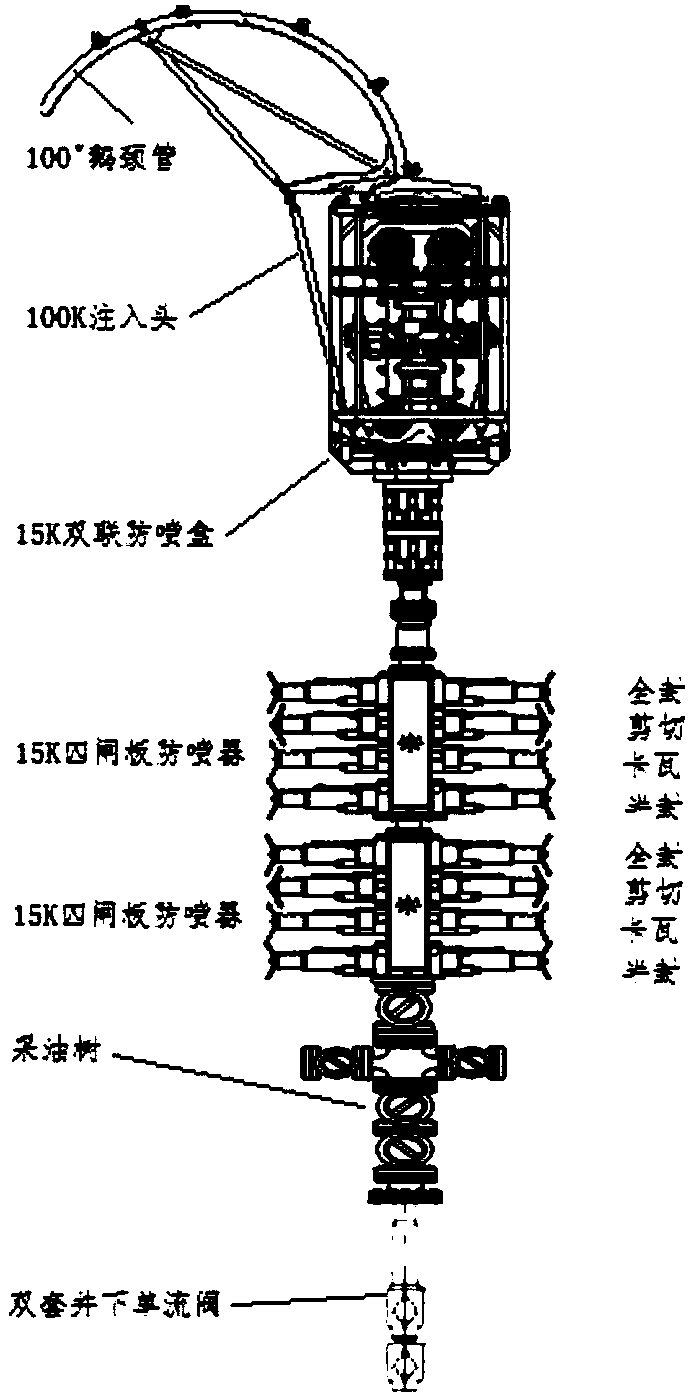

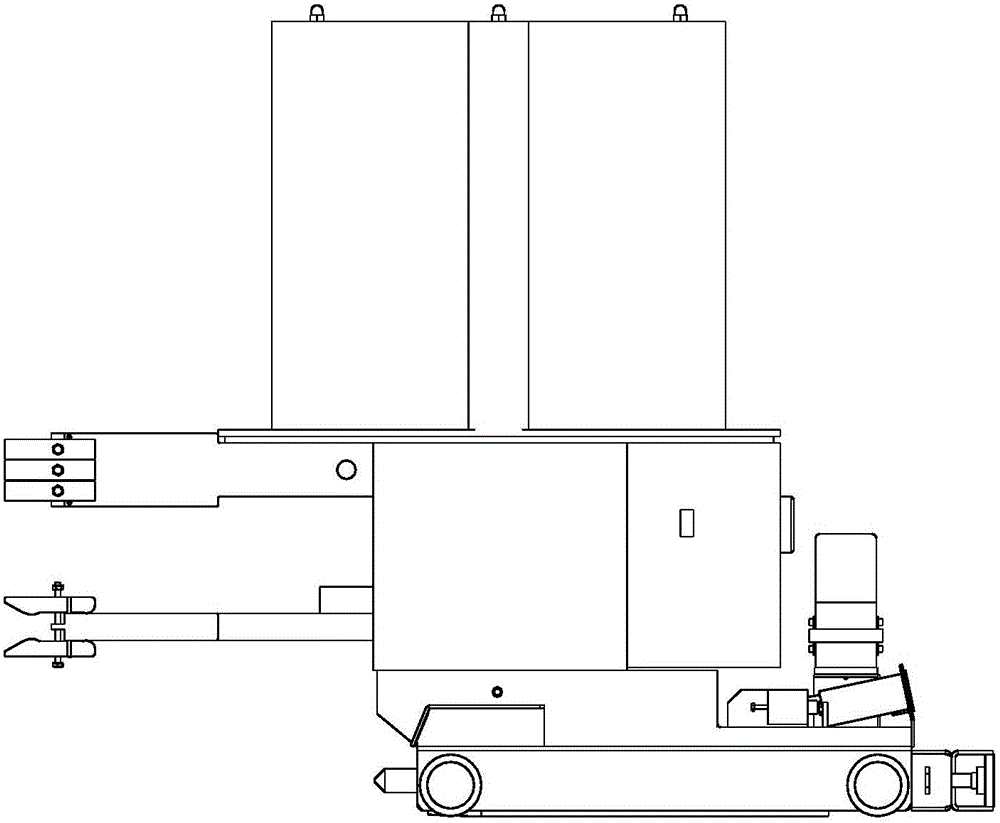

Method for three-layer unblocking for immovable string

InactiveCN108979569AEasy constructionLow costCleaning apparatusFluid removalCoiled tubingEngineering

The invention relates to the technical field of unblocking of oilfield gas wells, in particular to a method for three-layer unblocking for an immovable string. The three-layer unblocking includes oiltube internal unblocking, through-tubing casing internal unblocking and unblocking of immediate vicinity of a wellbore. The method comprises the following specific steps: arranging coiled tubing wellcontrol equipment at the position of an inlet of a high-pressure gas well; arranging a circulating working liquid sand removal system on the ground; and carrying downhole tools and delivering unblocking liquid by coiled tubing to realize three-layer unblocking. The method is proposed for a blocked gas well of an oilfield, the coiled tubing is used as a carrier of unblocking tools, and used as a deliverer for unlocking liquid. The method is simple to construct, the cost is saved, well control is safe, reservoir protection is implemented, occupied area is small, the method runs safely and reliably, and the requirements for unblocking operation of a high-pressure gas well of an oilfield can be met completely.

Owner:JEREH ENERGY SERVICES

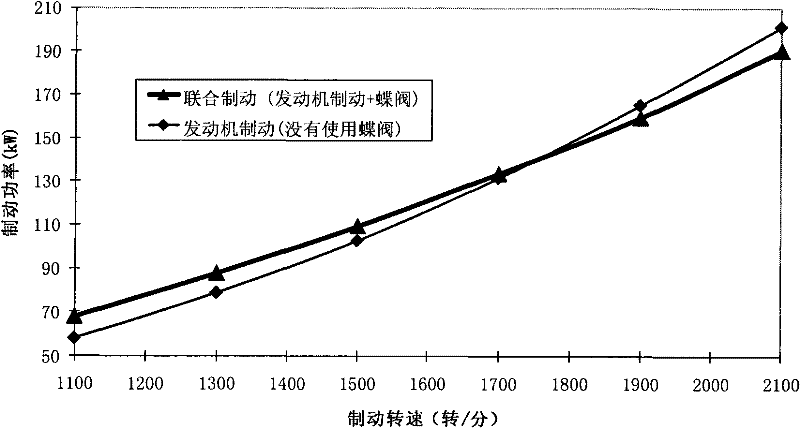

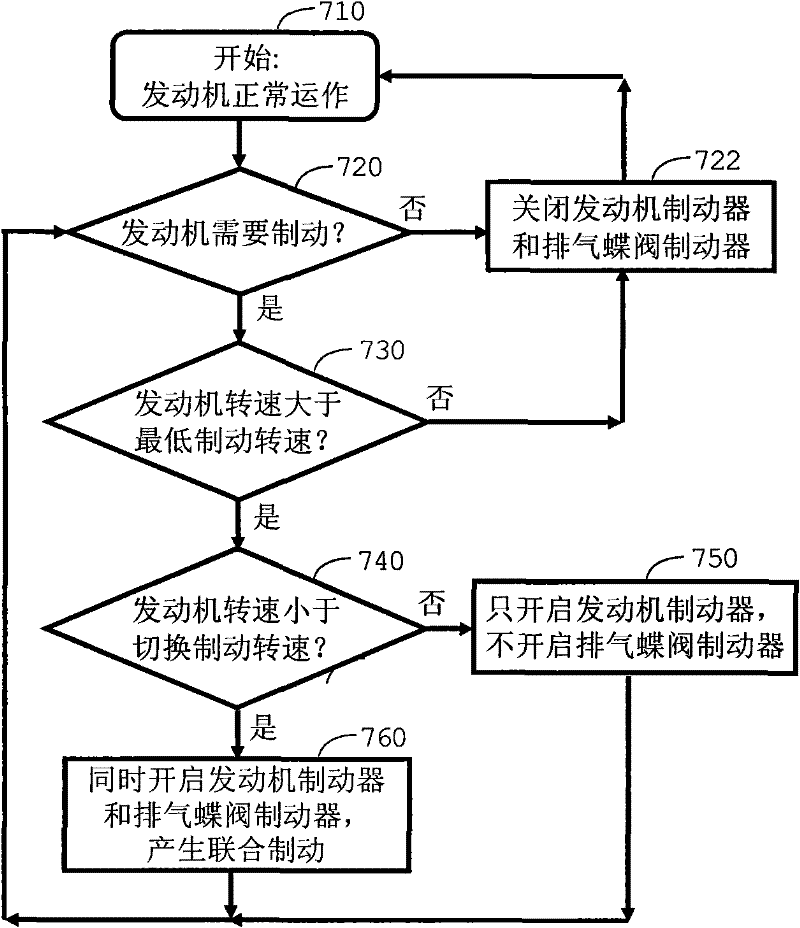

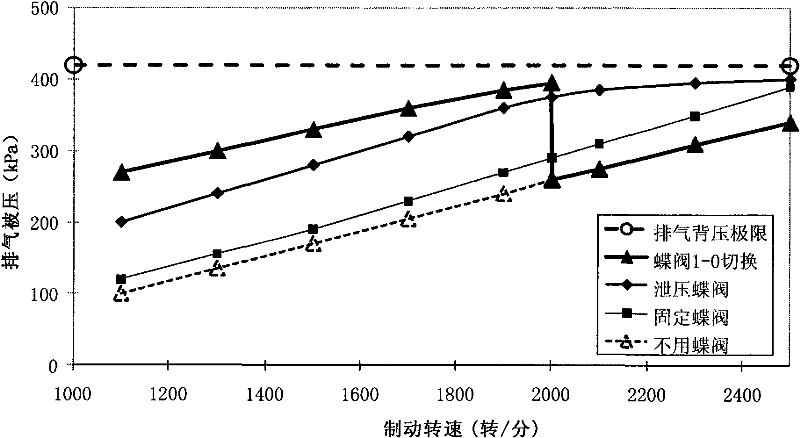

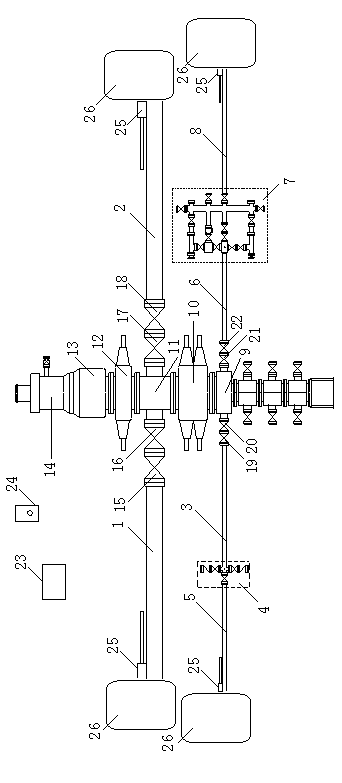

Engine combined brake control method

ActiveCN102220907AOptimizing braking powerSimplify the braking systemValve arrangementsOutput powerAutomotive engineeringBrake control

The invention relates to an engine combined brake control method which comprises the steps of controlling the action process of an engine brake and controlling the action process of an exhaust butterfly valve brake. The engine brake is arranged on an engine, and the exhaust butterfly valve brake is arranged in an exhaust system of the engine. The braking speed of the engine is detected, and the braking speed of the engine is compared with one switching braking speed. When the braking speed of the engine is lower than the switching braking speed, the engine brake and the exhaust butterfly valve brake are started. When the braking speed of the engine is higher than or equal to the switching braking speed, the engine brake is started, and the exhaust butterfly valve brake is remained to be closed. According to the engine combined brake control method disclosed by the invention, the optimization of braking power and the safe operation of the engine are realized, no complex and expensive variable exhaust butterfly valve brake or pressure relief exhaust butterfly valve brake is needed to control the exhaust back pressure of the engine, the braking system is simplified, and the cost is reduced.

Owner:SHANGHAI UNIVERSOON AUTOPARTS CO LTD

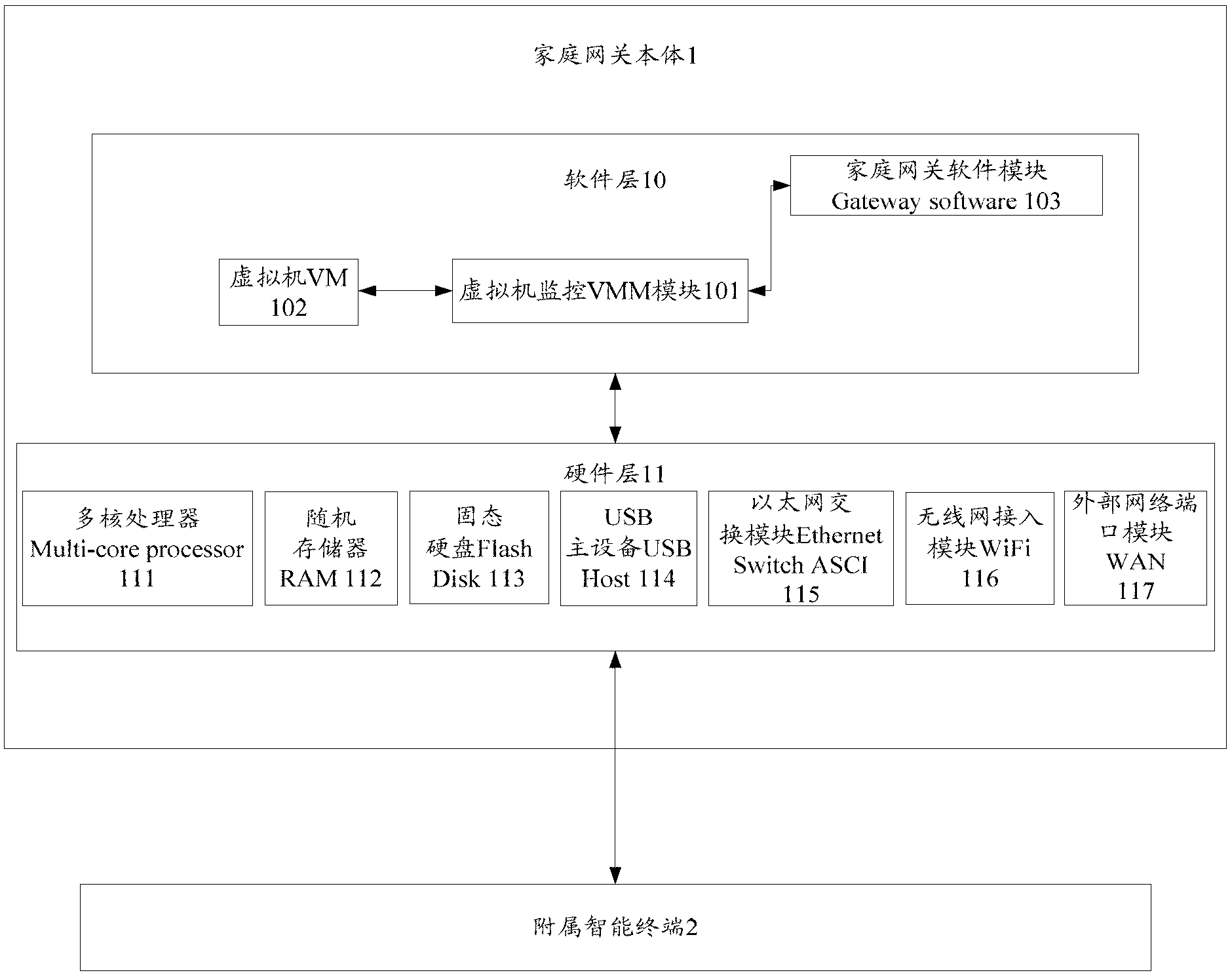

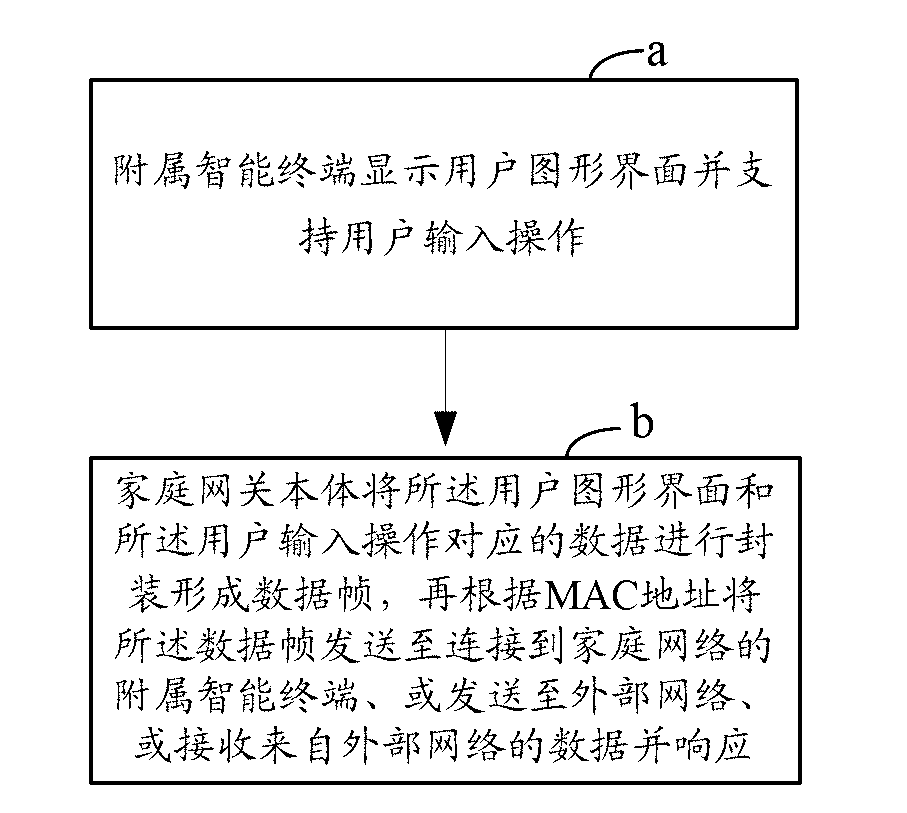

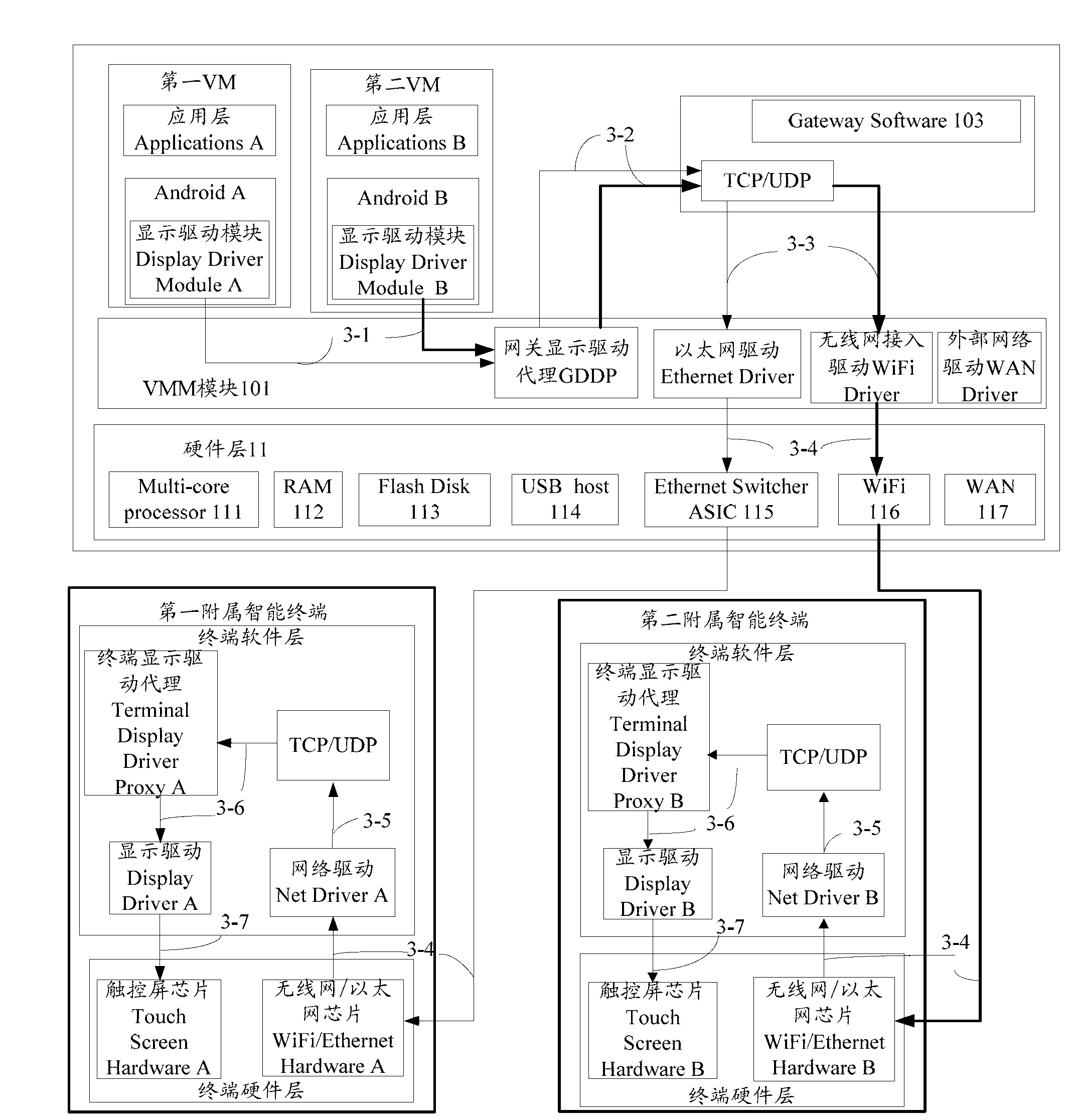

Home gateway and intelligent terminal integrated system and communication method thereof

ActiveCN102938718AAchieving safe operationAbundant software and hardware resourcesProgram controlNetwork connectionsVirtualizationTerminal equipment

The invention discloses a home gateway and intelligent terminal integrated system. The integrated system comprises a home gateway body and a subsidiary intelligent terminal, wherein the home gateway body adopts a multi-core processor architecture and a virtualization technology and has abundant software and hardware resources, so that besides the routing and forwarding functions of the existing home gateway, the function of the home gateway body can be expanded through installing application software; and due to the subsidiary intelligent terminal, users can safely operate household smart terminals by using the software and hardware resources. Intelligent terminals are not required for being purchased for every family member, so that the defects that intelligent terminal equipment is low in utilization ratio, the existing home gateway is single in function, and the like are overcome.

Owner:ZTE CORP

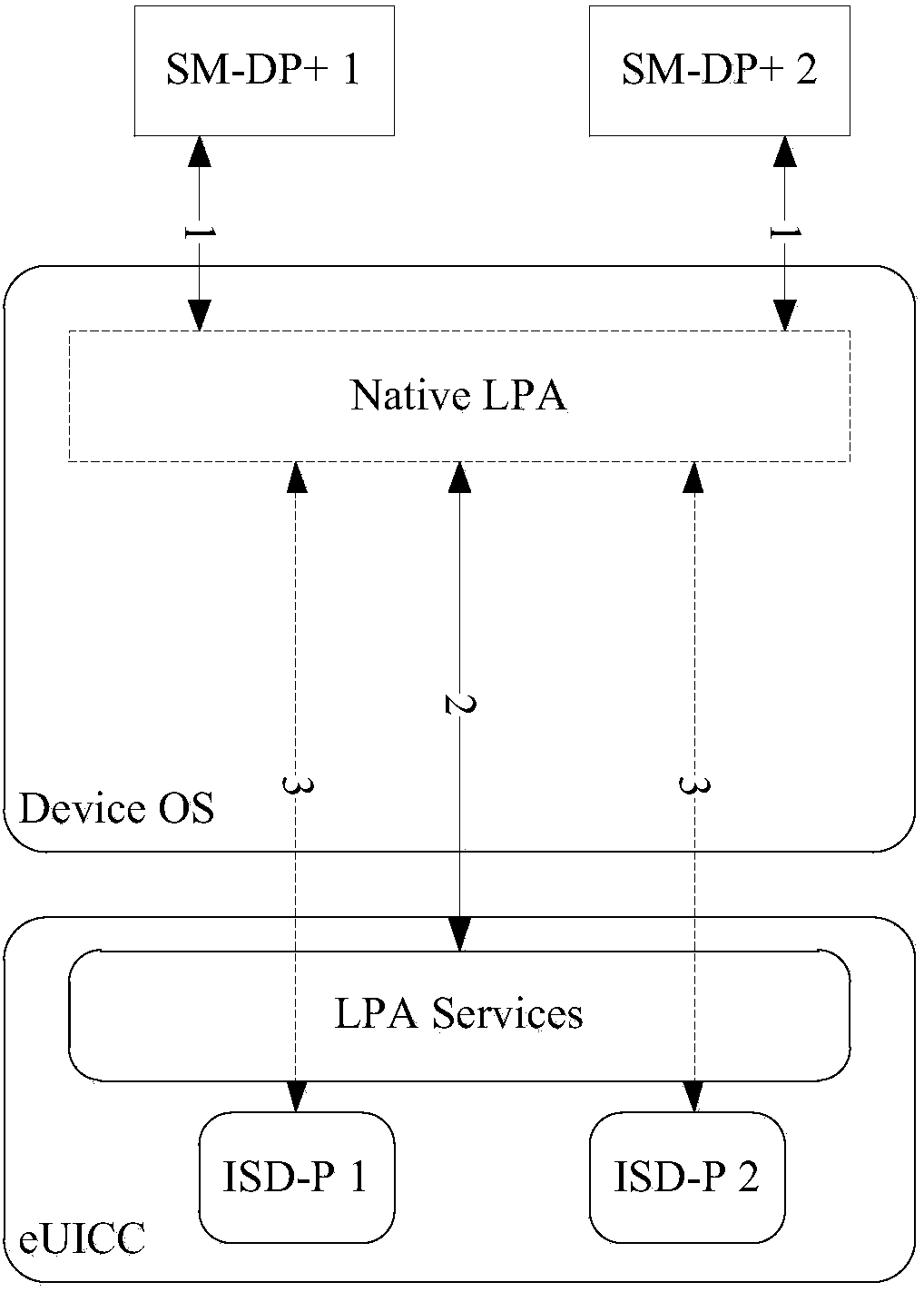

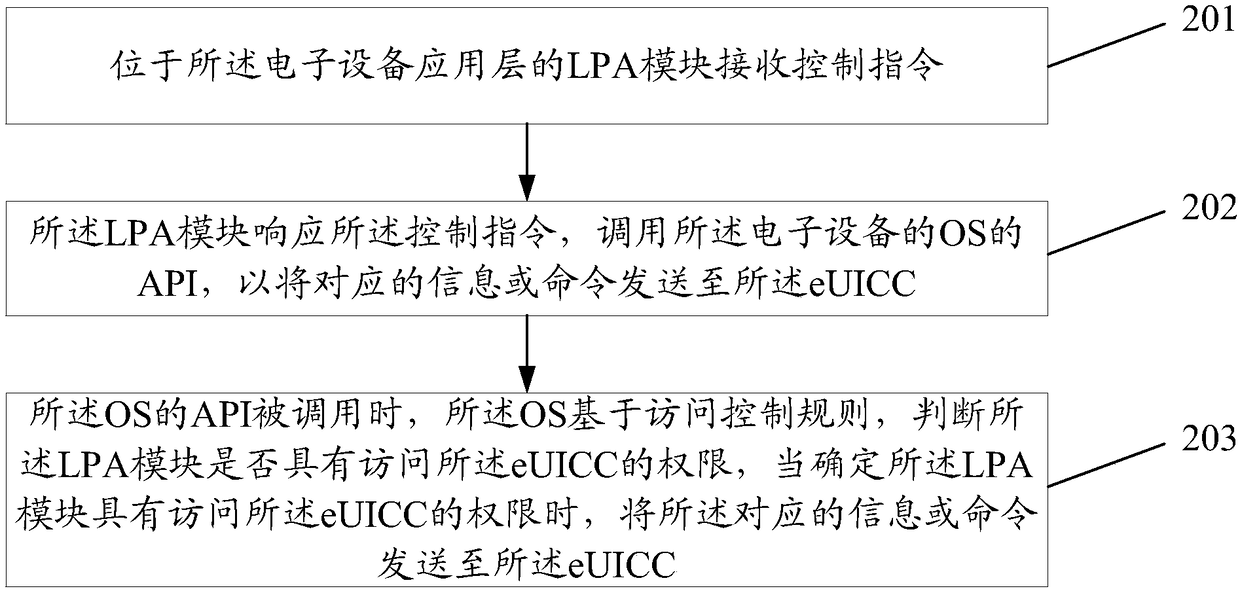

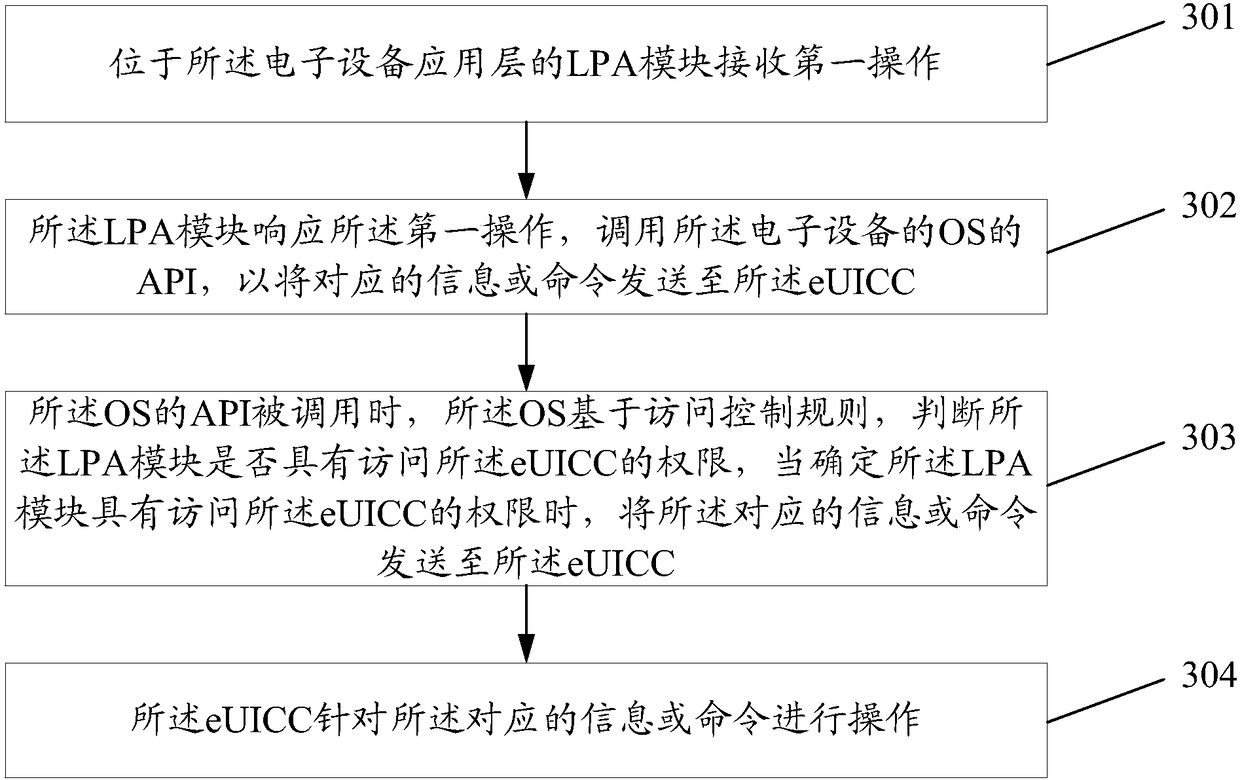

Access control method and system and electronic equipment

ActiveCN108229213AAchieving safe operationInternal/peripheral component protectionSecurity arrangementIntegrated circuit cardMedia access control

The invention provides an access control method. The method comprises the steps that a local path administration (LPA) module located on an electronic equipment layer receives a control instruction; the control instruction is used for indicating an embedded universal integrated circuit card (eUICC) to perform a control operation; the LPA module responds to the control instruction and calls an application program programmatic interface (API) of an operating system (OS) of electronic equipment so as to send the corresponding information or instruction to the eUICC; when the API of the OS is called, the OS judges whether the LPA module has the authority for accessing the eUICC or not on the basis of access control rules, and when it is determined that the LPA module has the authority for accessing the eUICC, the corresponding information or instruction is sent to the eUICC, and operation is performed by the eUICC for the corresponding information or instruction. The invention further discloses the electronic equipment and an access control system.

Owner:CHINA MOBILE COMM LTD RES INST +1

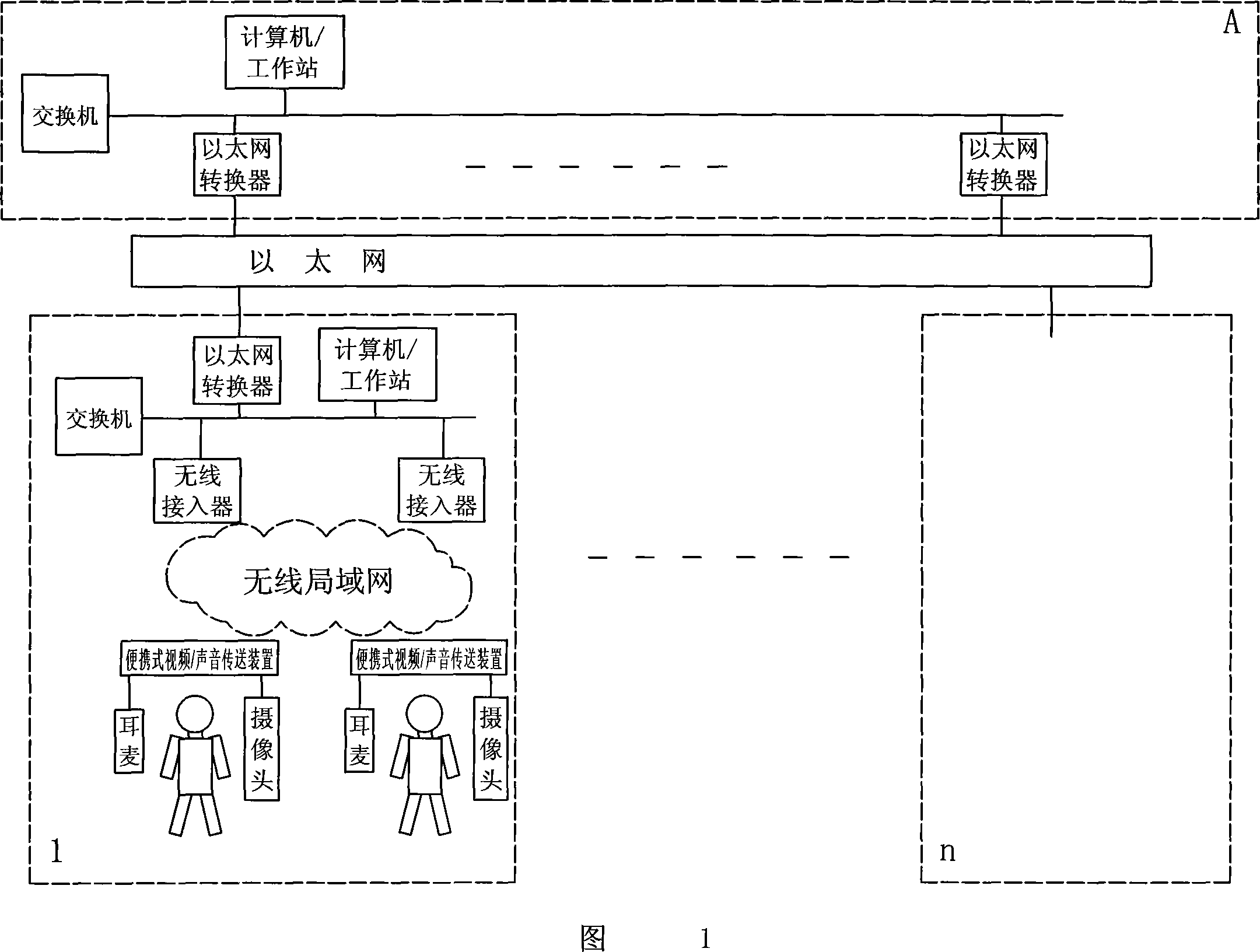

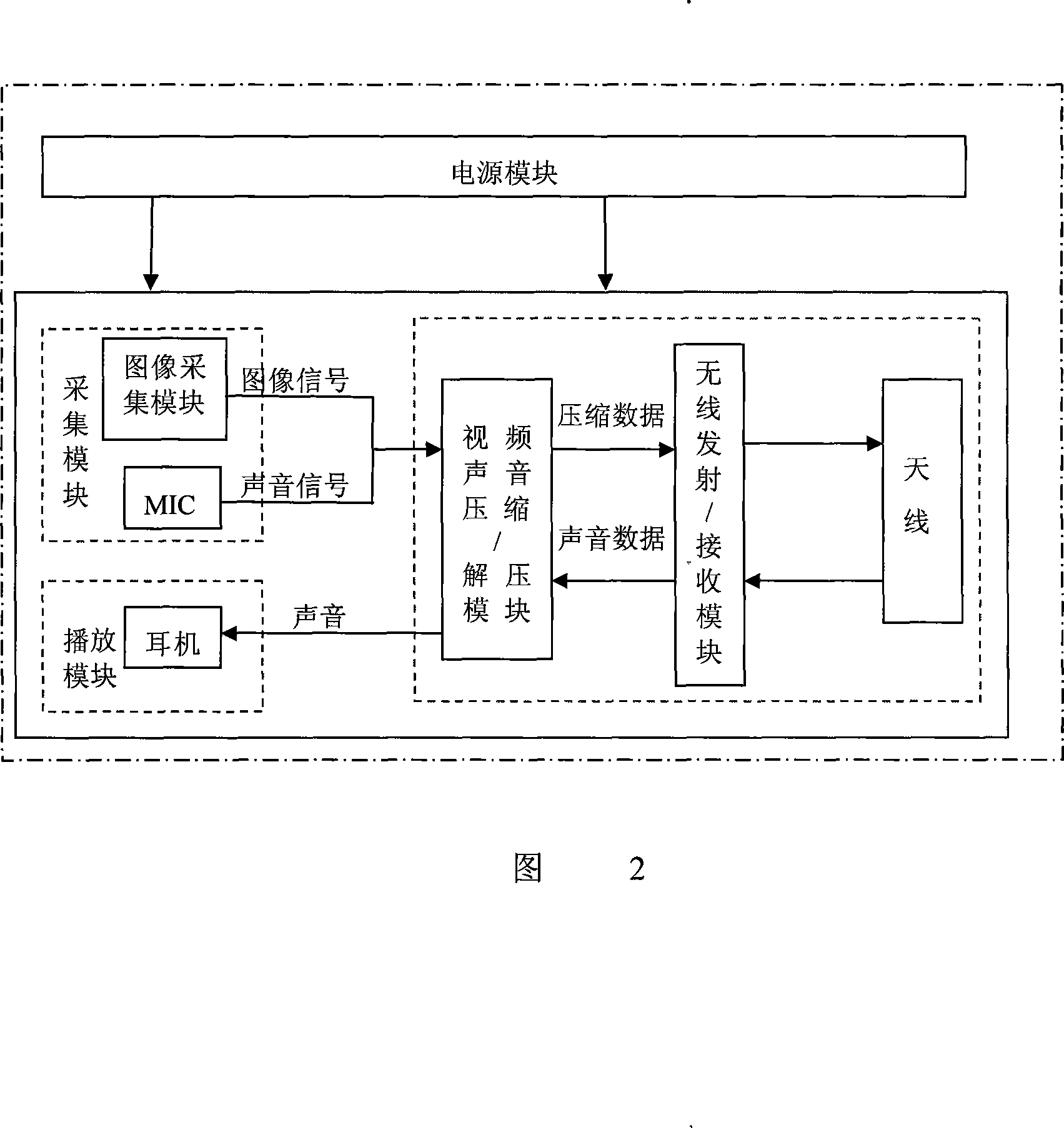

Unattended transforming plant single operation safety monitoring system

ActiveCN101183803AEasy to carryFlexible layoutPower network operation systems integrationCircuit arrangementsSound imageLocal area network

The invention discloses a safe monitoring system without duty and with one person for operation, belonging to the technical field of audio / image signal transmission, which is characterized in that: two wired local area networks are respectively arranged at a central control room and at the front-end transformer station; a video receiving device and audio receiving / sending device connected with the wired local area networks is arranged at the central control room; a wired Ethernet is arranged between the central control room and the front-end transformer station; a portable video / audio sendingdevice is arranged at the front-end transformer station and is connected with the wired local area network of the front-end transformer station through a wireless local area network. The invention has the advantages of meeting the purpose of realizing safe operation for equipments at the front-end transformer station under the precondition of low cost due to adopting wireless local area network for transmitting sound image signal, not producing interruption for equipments of prior transformer station, realizing safe monitoring of single personnel operating process, being widely applied in areas such as operation, maintenance and safe production of transformation and distribution systems.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

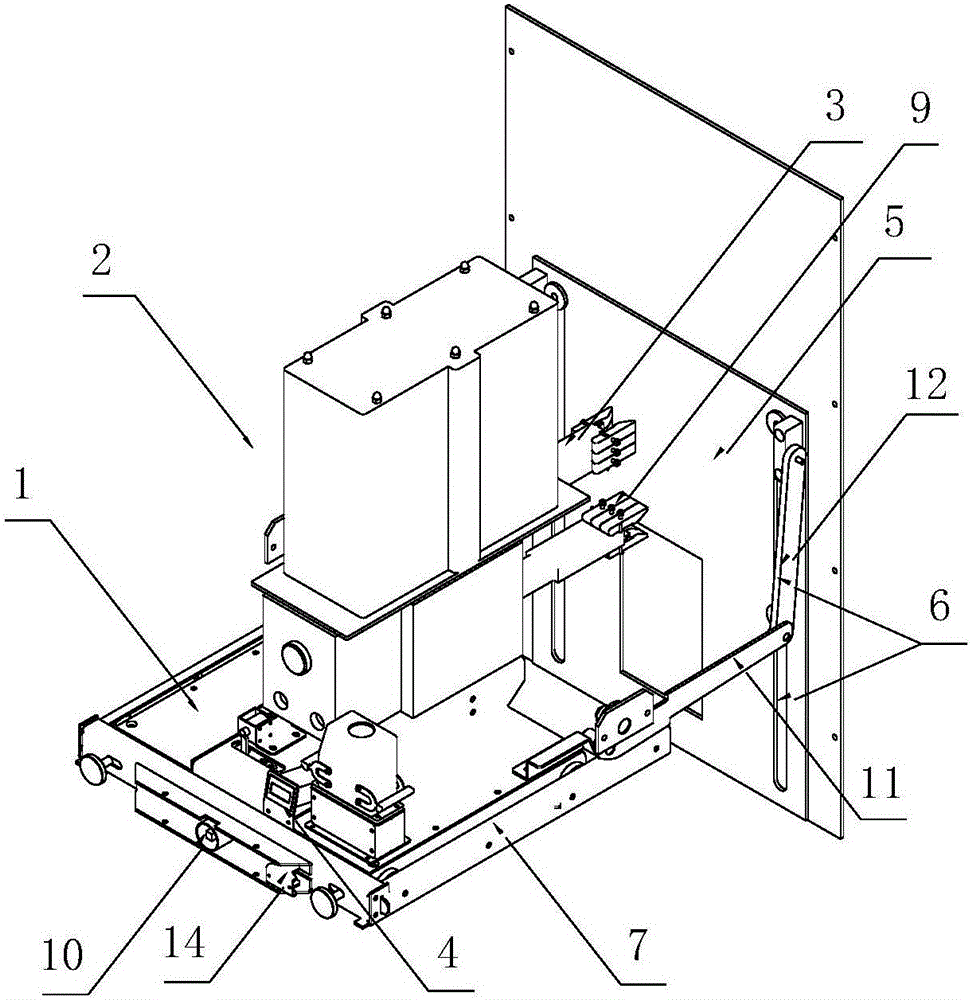

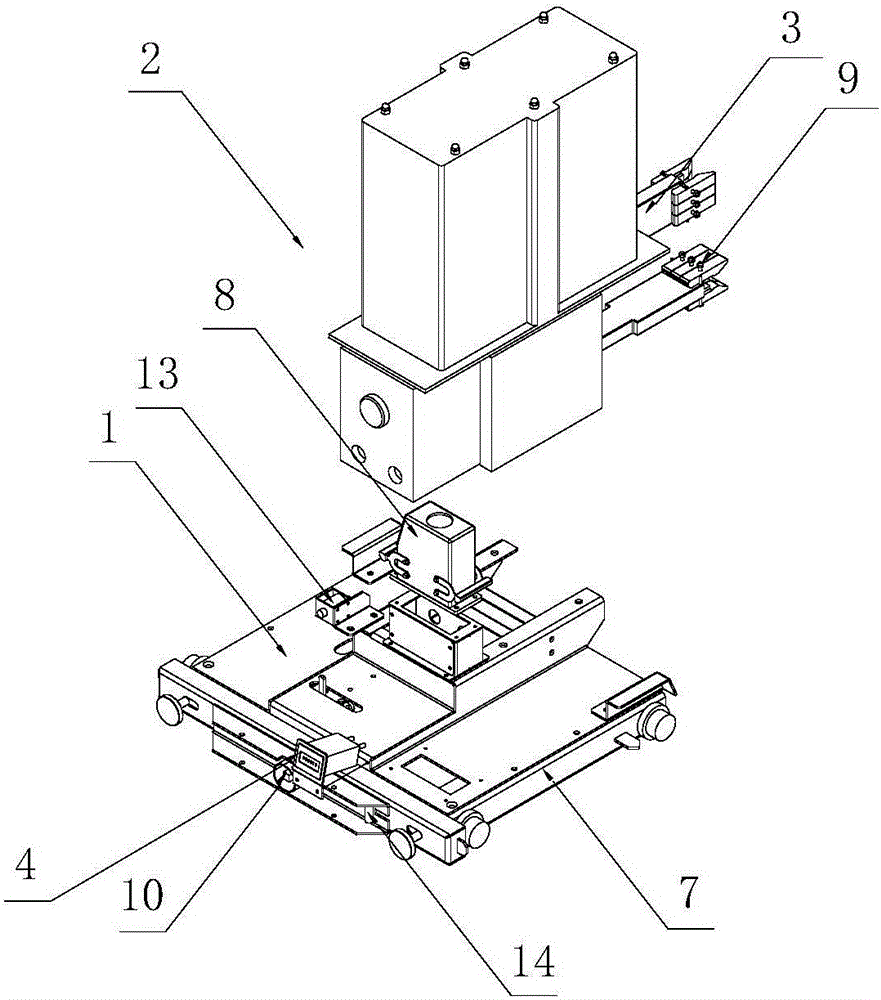

DC fast circuit breaker trunk

InactiveCN105932587ACompact structureReduce space consumptionSwitchgear with withdrawable carriageElectricityDc circuit breaker

The invention relates to a DC fast circuit breaker trunk, which is arranged in a switch cabinet and comprises a chassis, a breaker, a contact, a counter and a valve. The chassis is arranged between the inner sidewalls at the left side and the right side of the switch cabinet and can move in the switch cabinet; the breaker and the counter are respectively arranged on the chassis and can move along with the chassis; the counter is electrically connected to the breaker; and the back side of the breaker extends to form the contact. The valve is embedded into the back sidewall of the switch cabinet; the upper edge of the valve is hinged to the back sidewall of the switch cabinet and can turn around the upper edge thereof; and the chassis is movably connected to the valve through a valve propulsion mechanism. The DC fast circuit breaker trunk has compact structure and small occupied space; in comparison with other integrated circuit breaker trunks, the manufacturing and the installation are more convenient and the cost is lower; through the valve propulsion mechanism, the circuit breaker trunk can be quickly and easily pushed into or exited to a working position or an experiment position, the operations are simple, safe and more reliable, and the replacement is faster.

Owner:WUHAN ZHONGZHI ELECTRIC

Medical waste treatment system and application process thereof

ActiveCN106949477AOperational securityAvoid secondary pollution sourcesIncinerator apparatusAtmospheric pollutantsRotary furnace

The invention provides a medical waste treatment system and an application process thereof. The medical waste treatment system sequentially comprises a pretreatment device, a carbonization device, a waste gas cracking device and a tail gas treatment device. The pretreatment device is connected with a feeding cover of the carbonization device through a screw conveying device. The carbonization device comprises a rotary furnace body and a shell. The rotary furnace body is arranged in the shell, and a closed cavity is formed between the shell and the rotary furnace body. Heat supply equipment for heating the rotary furnace body is arranged on the shell. The two ends of the rotary furnace body are in rotary sealed connection with a discharging cover and the feeding cover. One end of the waste gas cracking device is connected with the discharging cover of the rotary furnace body through a vent pipe. The other end of the waste gas cracking device is connected with the tail gas treatment device through a gas outlet pipe. According to the medical waste treatment system, secondary pollution sources such as dioxin and other air pollutants generated in the process that a traditional incinerator treats medical waste are completely eliminated, and therefore better fuel use efficiency and environmental protection efficiency are achieved.

Owner:LIUHEFENG TIANJIN TECH CO LTD

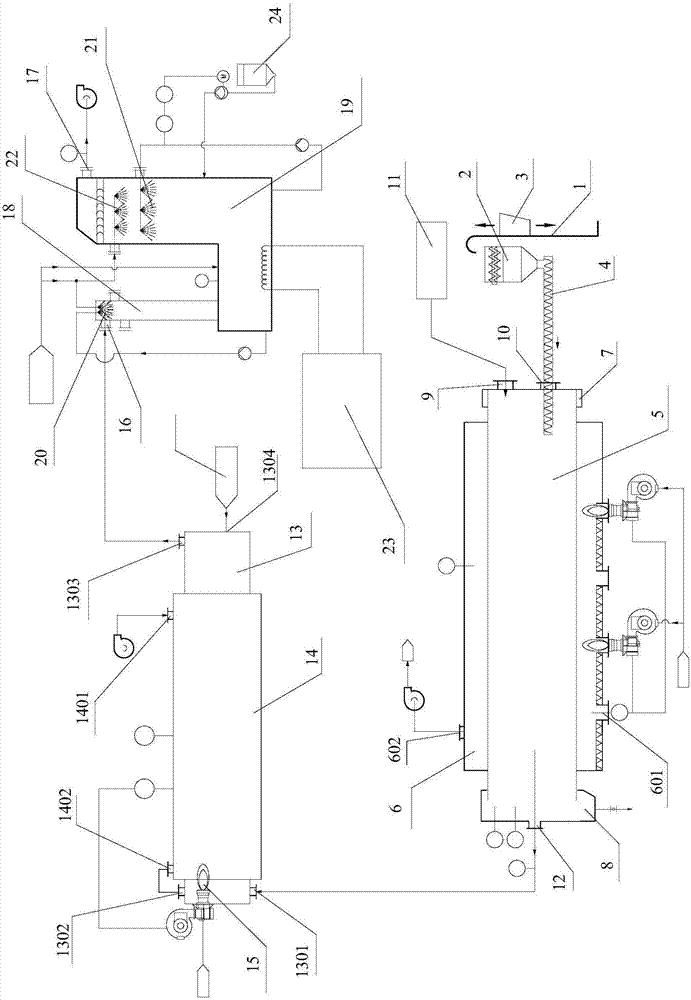

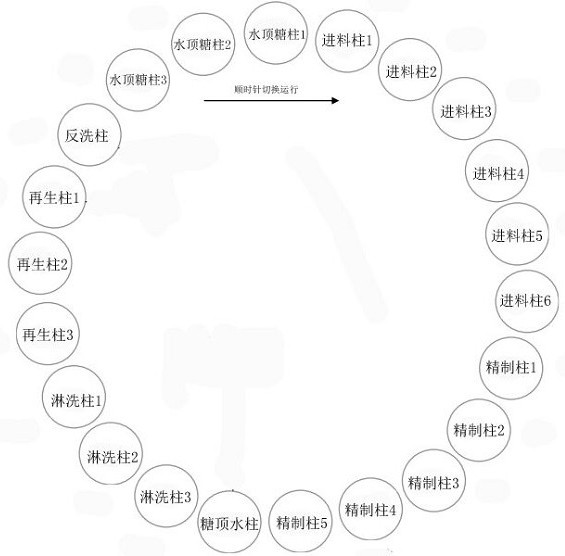

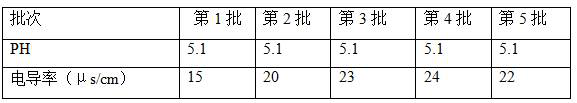

Ion exchange system for producing functional oligosaccharide and using method thereof

PendingCN112619713AReduce processing costsContinuous operationIon-exchange process apparatusAmphoteric ion-exchangersIon exchangeEnvironmental engineering

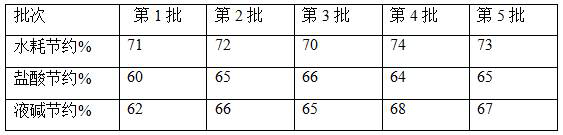

The invention discloses an ion exchange system for producing functional oligosaccharide and a using method thereof. The ion exchange system comprises a plurality of groups of cation exchange resin systems and anion exchange resin systems which are distributed in a staggered manner, wherein each group of ion exchange resin system comprises a feeding column, a refining column, a sugar top water column, a leaching column, a regeneration column, a back-washing column and a water top sugar column which sequentially move and circularly operate, and the ion exchange systems are connected in parallel for feeding, connected in series for cleaning, regenerated and subjected to water top sugar. According to the present invention, with the application of the system to refine and treat functional oligosaccharide, the water consumption is saved by 70-75%, the hydrochloric acid unit consumption is saved by 50-70%, the liquid caustic soda unit consumption is saved by 50-70%, the treatment cost of the waste liquid is reduced while the cost is saved, the conductivity and the pH color value of the product are stable, and the system is suitable for wide industrial popularization.

Owner:BAOLINGBAO BIOLOGY

Internet IC card safety processing system

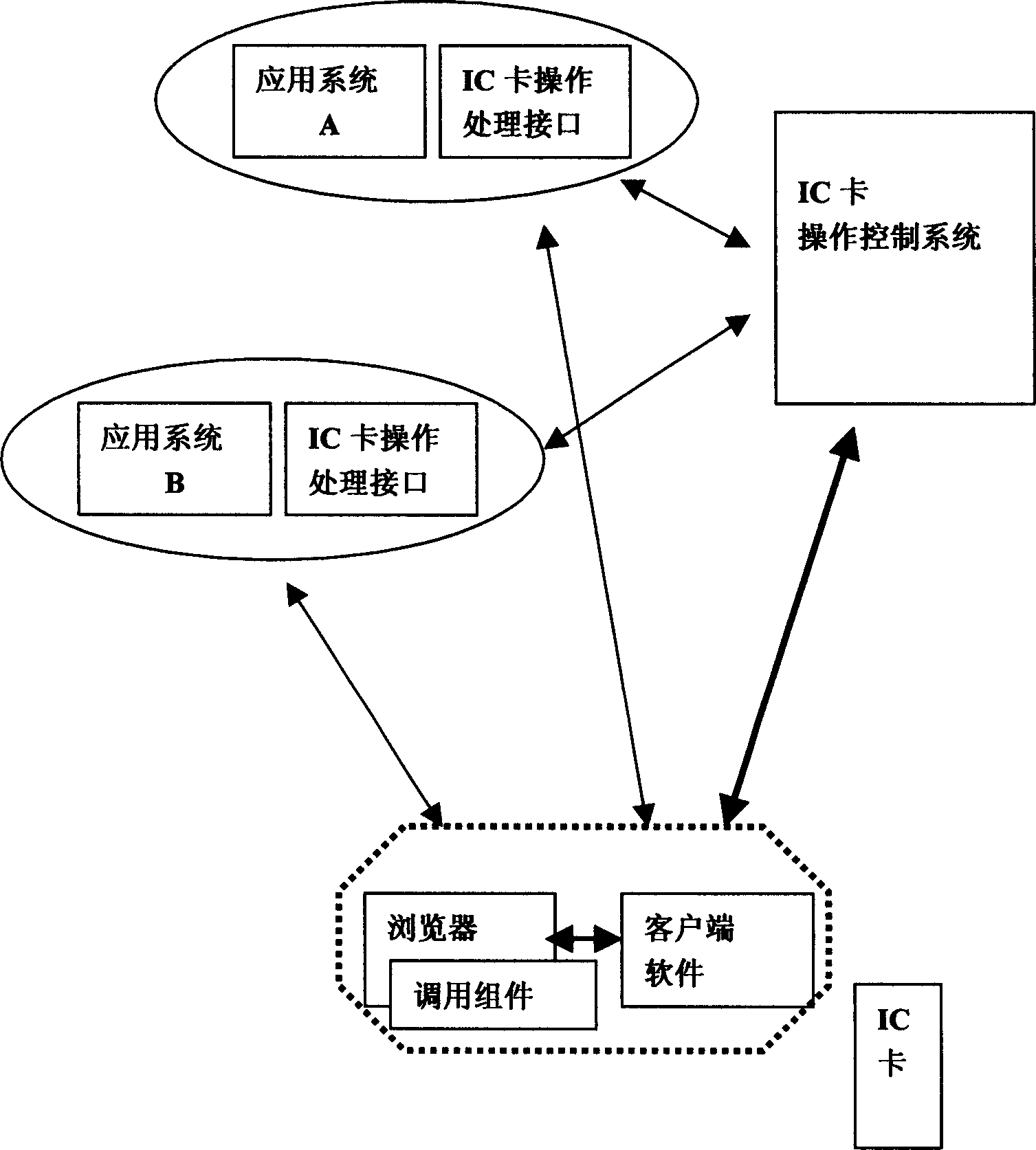

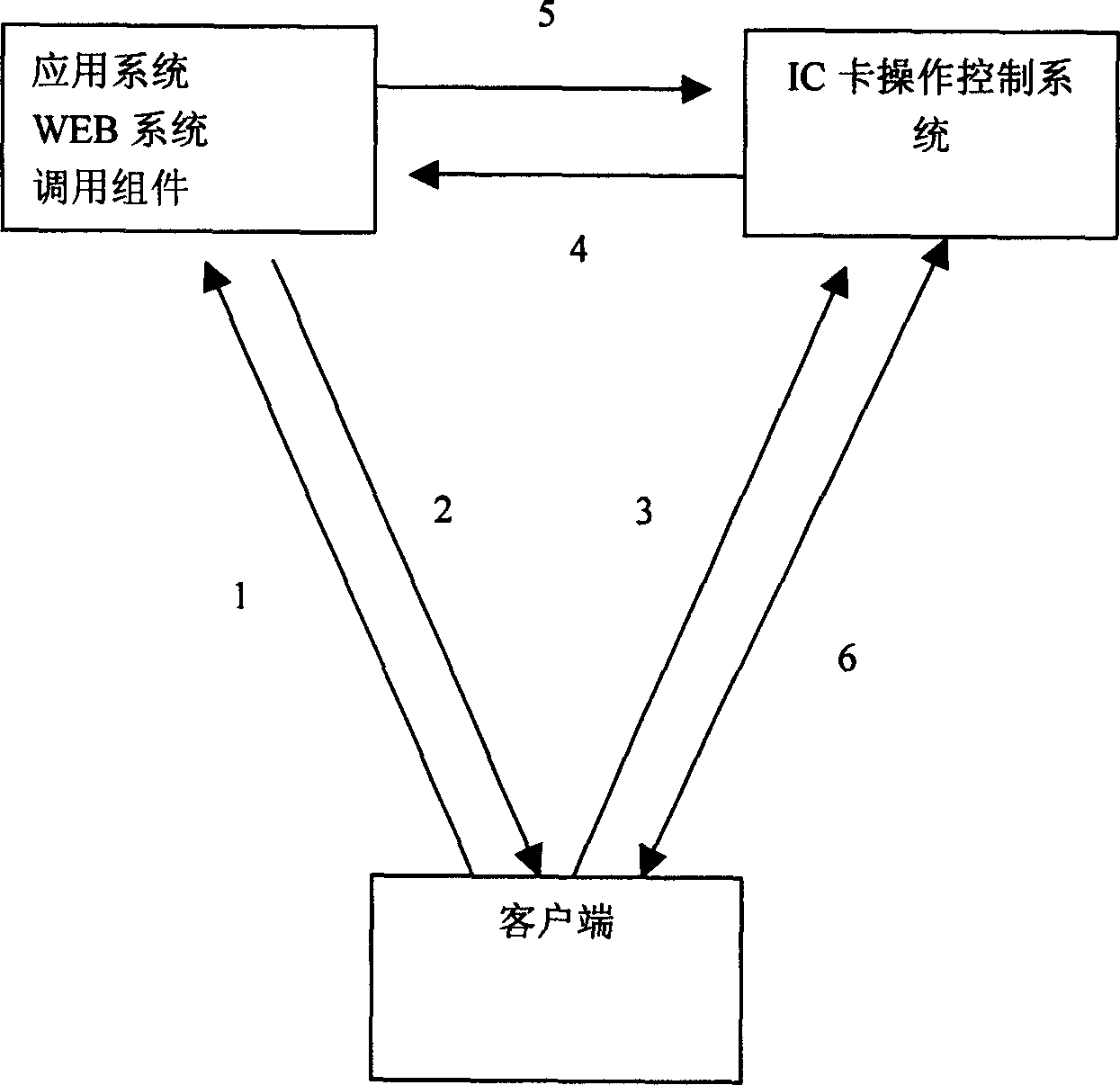

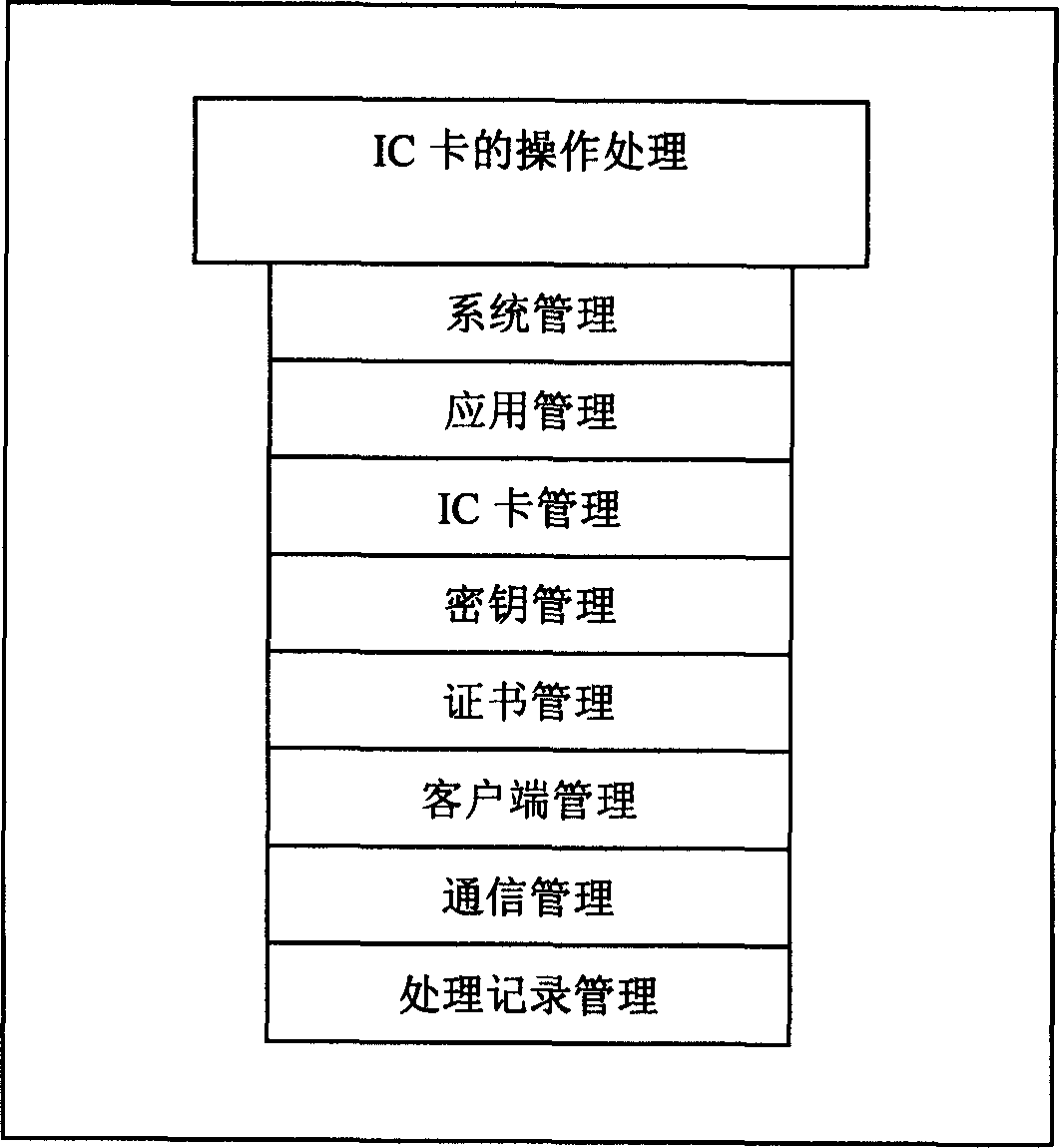

The Internet IC card safety processing system consists of application system, IC card operating and controlling system, client end software, web page calling module and other parts. The communication between the client end software and the web page calling module and between the client end and the IC card operating control system is completed via universal module and by means of public key certificate confirmation and enciphered communication. The IC card operating control system is customized based on the application system, and centralizes the processing and management of IC card. The present invention makes it possible to perform IC card payment and recharging in network for easy use and facilitates the multifunctional use of one identical card and the module sharing.

Owner:北京矽谷学人科技有限公司

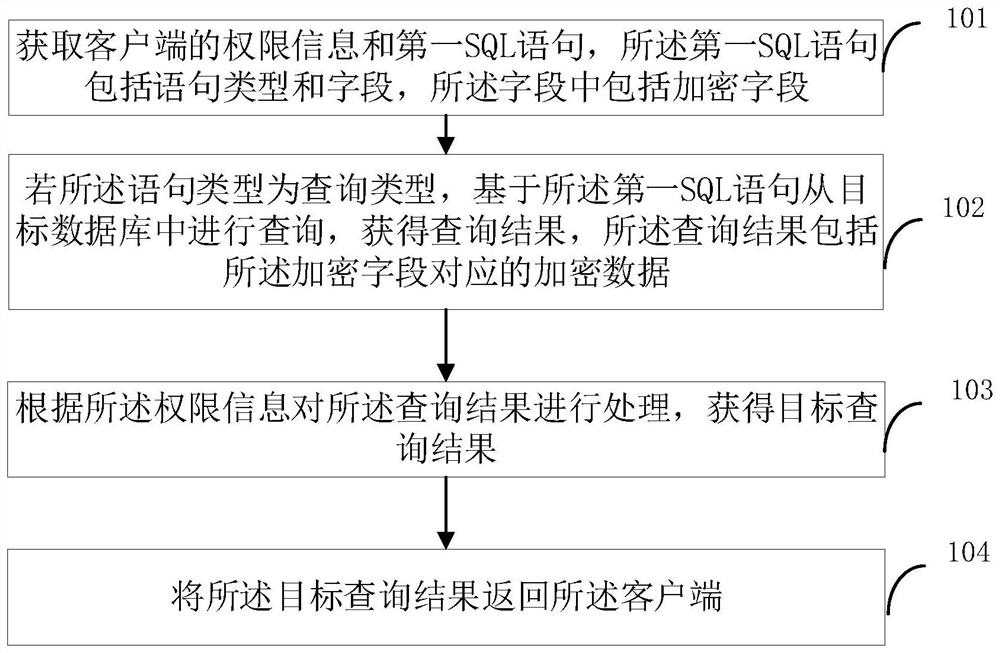

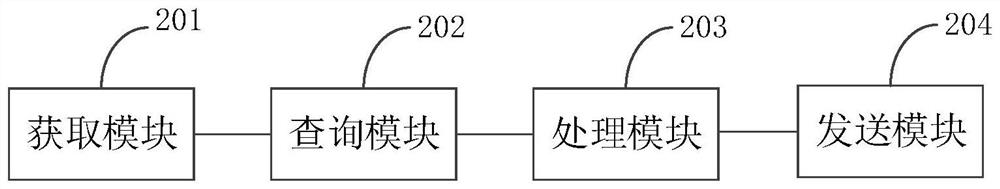

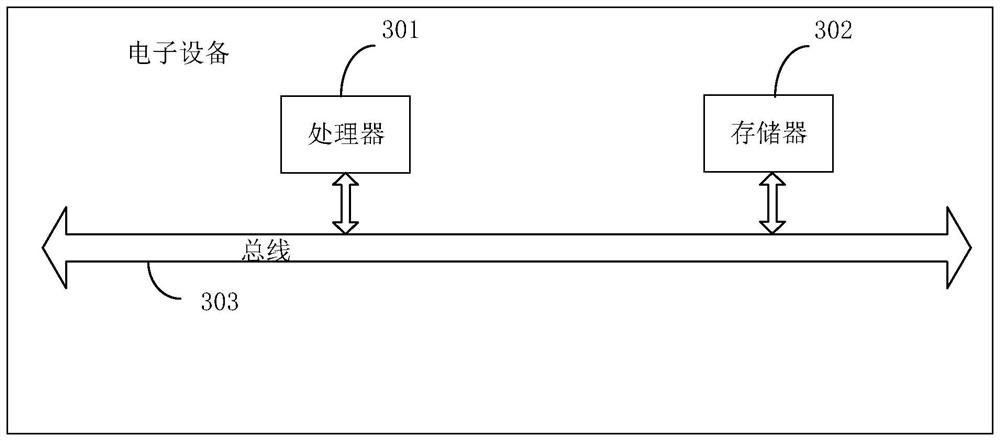

Data security protection method and device, electronic equipment and storage medium

PendingCN114372276AAchieving safe operationEnsure safetyRelational databasesDigital data protectionUser PrivilegeEngineering

The invention provides a data security protection method and device, electronic equipment and a storage medium. The method comprises the steps that permission information of a client side and a first SQL statement are obtained, the first SQL statement comprises a statement type and a field, and the field comprises an encrypted field; if the statement type is a query type, querying from a target database based on a first SQL statement to obtain a query result, the query result comprising encrypted data corresponding to an encrypted field; processing the query result according to the permission information to obtain a target query result; and returning the target query result to the client. The query result queried by the SQL statement is processed according to the obtained client permission information, so that data security access of different user permissions is realized, and a safer data security protection means is provided.

Owner:闪捷信息科技有限公司

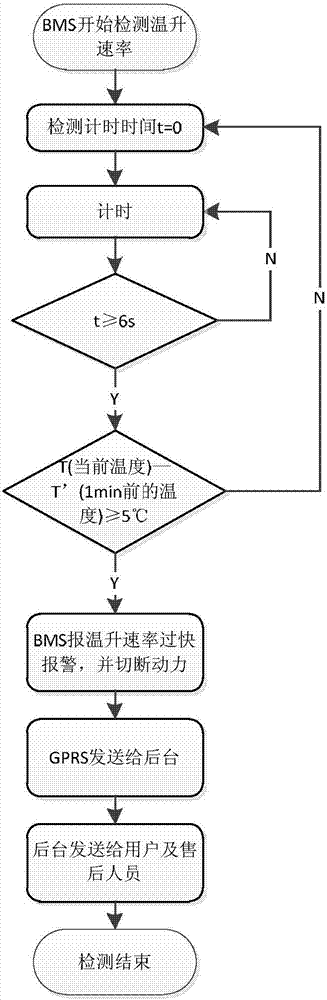

Battery temperature rise rate alarm method

The invention discloses a battery temperature rise rate alarm method. The defects of the prior art are solved. The method comprises the following steps: S1, a BMS (Battery Management System) starts detecting the rate of temperature rise; S2, the BMS starts timing (the timing time t=0), and records the current temperature values T of all single batteries; S3, timing starts; S4, when t is greater than or equal to a set interval length, the temperature values T' of all the single batteries at the time are recorded; S5, T-T' is calculated according to the current temperature values, S6 is performed if T-T' is greater than or equal to a calibrated temperature value, and S2 is performed if T-T' is smaller than the calibrated temperature value; S6, the BMS raises the alarm to remind that the temperature rises too fast, and performs a safety protection action; S8, an electric vehicle sends an alarm signal indicating that the temperature rises too fast to the background through a wireless network; S8, the background sends the alarm signal to users and after-sales personnel; and S9, the BMS ends detection.

Owner:ZHIDOU ELECTRIC VEHICLE CO LTD

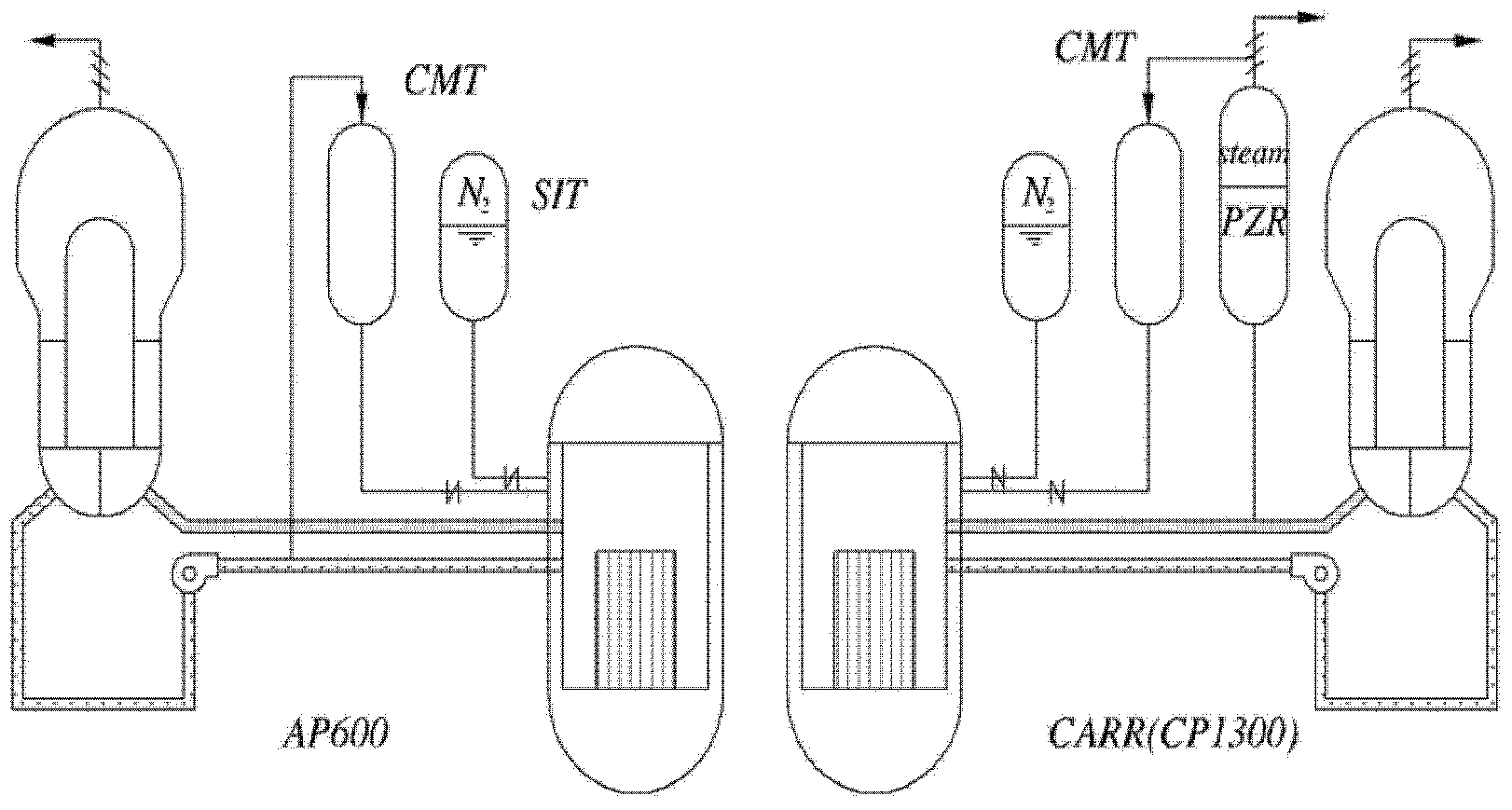

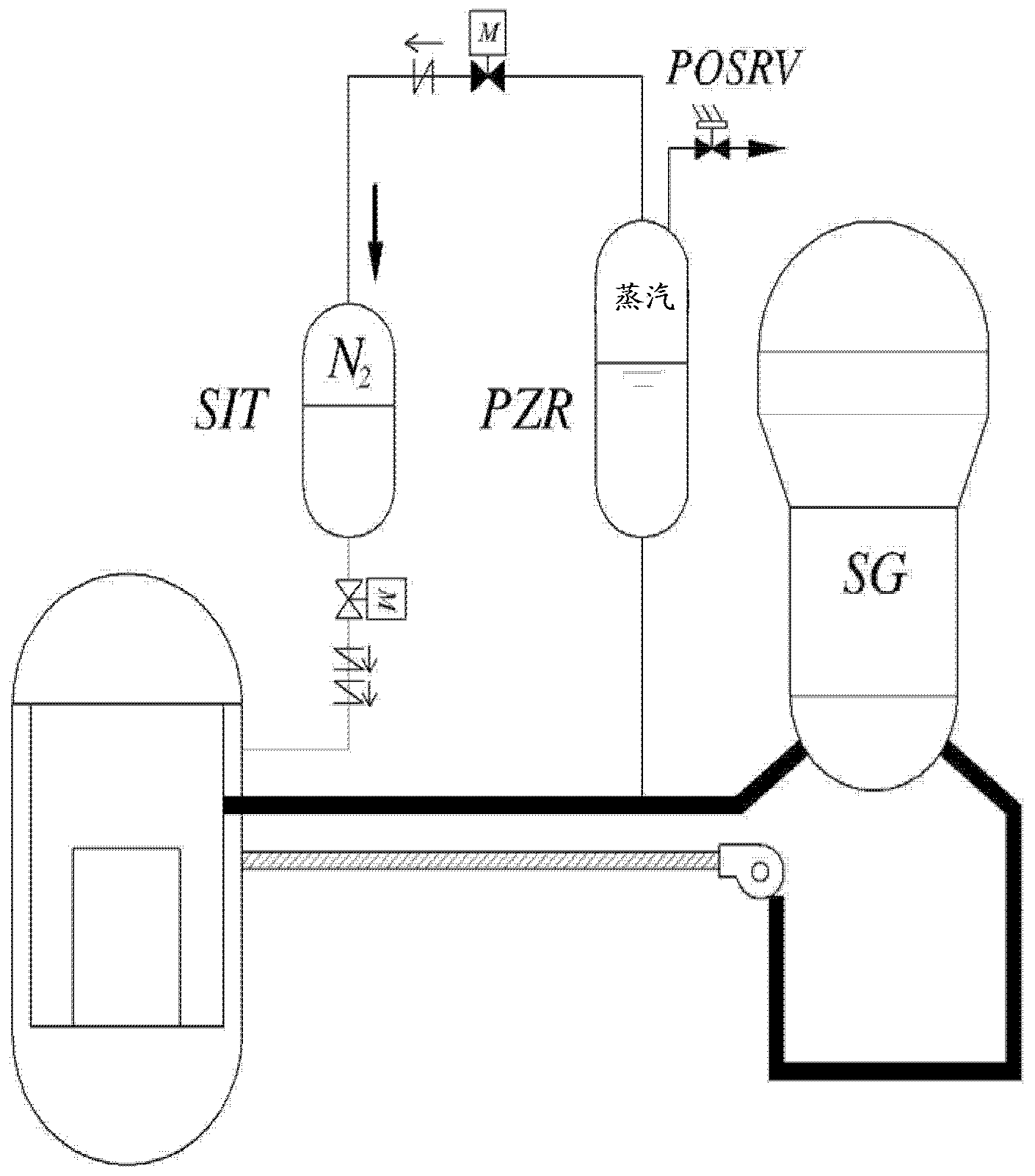

Hybrid safety injection tank system pressurized with safety valve of pressurizer

InactiveCN103578582AEasy to operateImproved emergency core cooling capabilitiesPower plant safety arrangementNuclear energy generationHybrid typeElectricity

A hybrid safety injection tank system pressurized with a safety valve of a pressurizer. The hybrid safety injection tank system has functions of a low pressure safety injection tank and a high pressure reactor core injection tank of a nuclear reactor emergency reactor core cooling system, in the hybrid safety injection tank system, an electrically operated valve or a pneumatic valve mounted in a conventional hybrid safety injection tank system and requiring use of an attached special battery for preventing power failure of a nuclear power plant is replaced, a safety valve allowing automatic operation in response to pressure difference is mounted on a pressure-equalizing pipe capable of realizing balance of pressure between the low pressure safety injection tank and the high pressure pressurizer, the hybrid safety injection tank system does not use electricity, so that even if under the circumstance of the occurrence of power failure of the nuclear power plant, effectively operation is still realized and the possibility of reactor core damage is reduced.

Owner:KOREA ATOMIC ENERGY RES INST

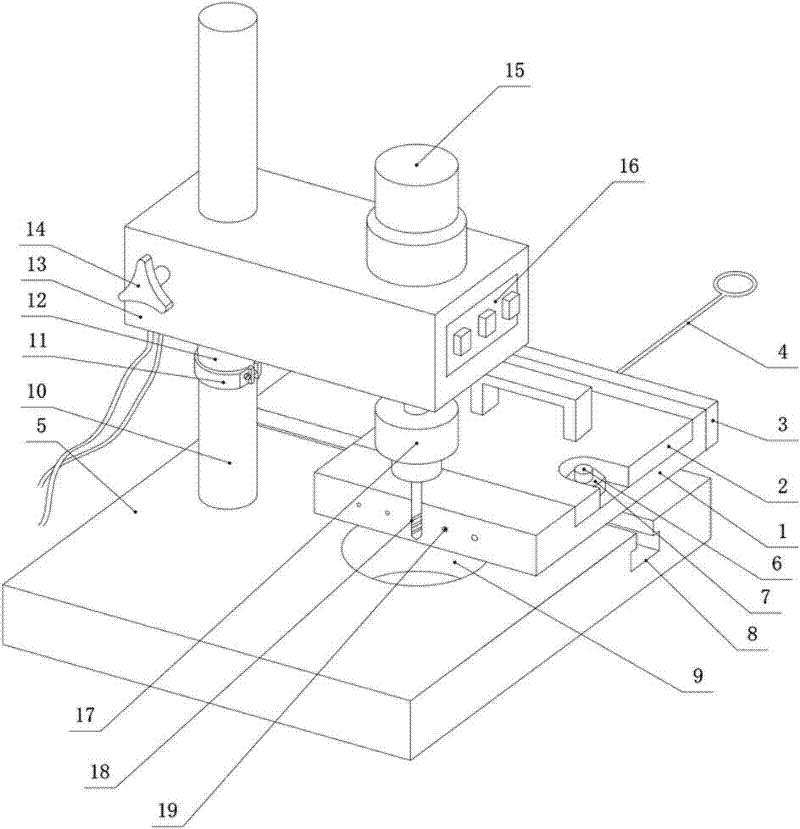

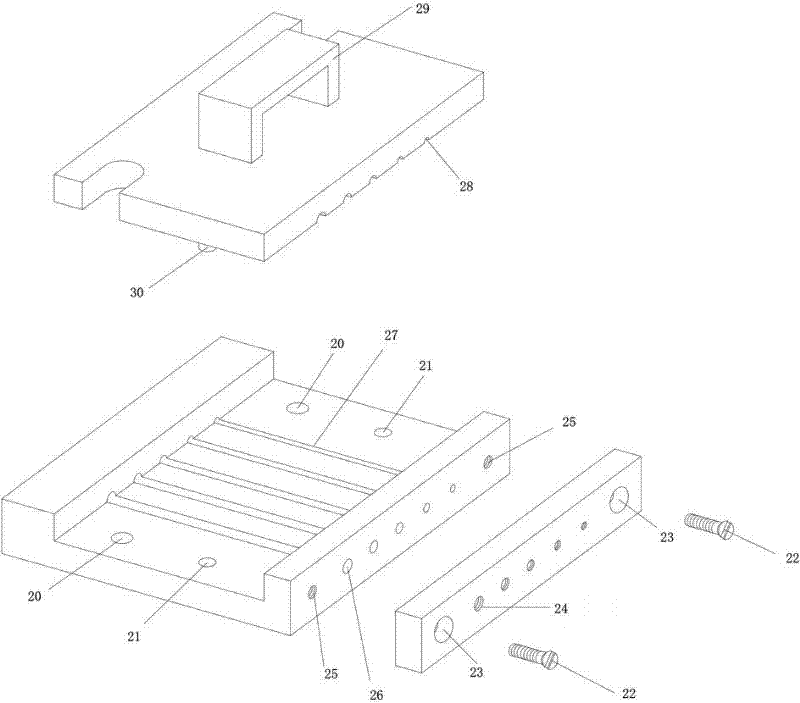

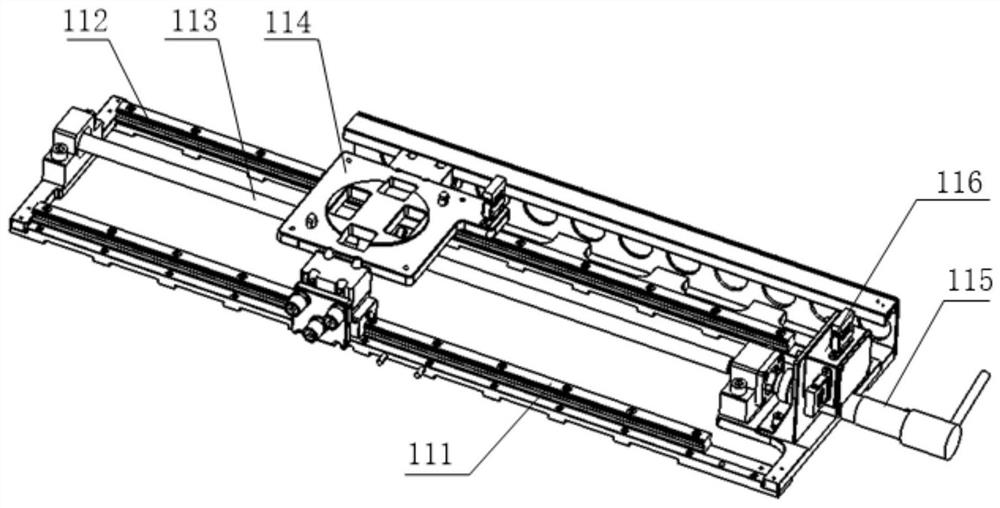

Rapid preparation device for small particle size gunpowder stabilizer content analysis sample

ActiveCN102288463AScientific evaluation of storage lifeNo pollution in the processPreparing sample for investigationMechanical engineeringMaterials science

The invention discloses a device for quickly preparing a stabilizer content analysis sample of small-grain-size gunpowder. A semi-circular material groove is formed at the bottom of a U-shaped feeder base of the device; the material groove passes through two sides and forms a discharge hole and a screw channel; a feeding screw bracket is in fastening connection with one side of the screw channel of the feeder base; an internal thread through hole which corresponds to the discharge hole is formed in the feeding screw bracket; a feeding screw is screwed in the internal thread through hole and corresponds to the discharge hole; a semi-circular upper material groove with corresponding hole diameter is formed on the lower part of a feeder upper cover and matched with the feeder base to form a hole channel in which powder grains are accommodated; and a cutter is arranged in the discharge hole of the feeder base. The invention has the advantages that: the small-grain-size gunpowder can be continuously cut in a continuous feeding and discontinuous cutting mode; by designing the discharge hole and the material groove with different hole diameters, gunpowder with different diameters can be processed; and the device is applicable to preparation of a plurality of kinds of gunpowder.

Owner:XIAN MODERN CHEM RES INST

A method for evaluating the purity of electronic grade trichlorosilane

ActiveCN103454377BEasy to observe growthPurity is obtained quicklySilicon compoundsMaterial analysisEngineeringProduct gas

Owner:青海黄河上游水电开发有限责任公司新能源分公司 +1

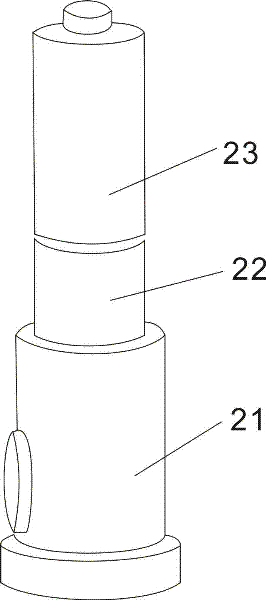

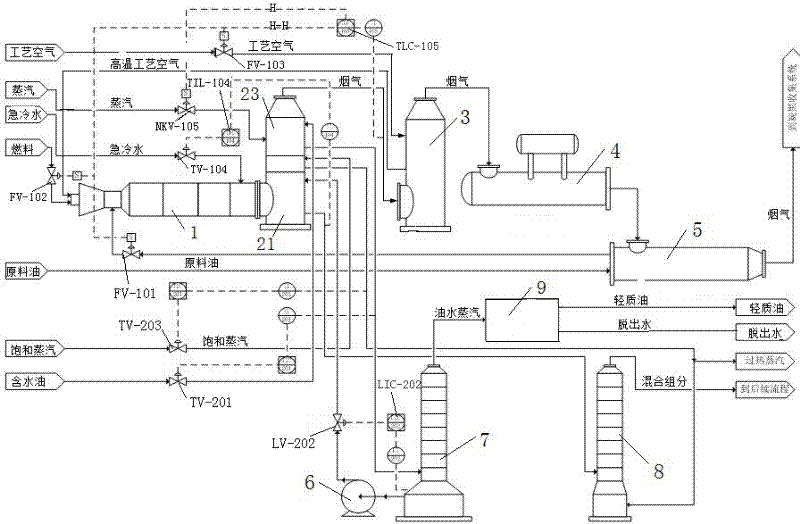

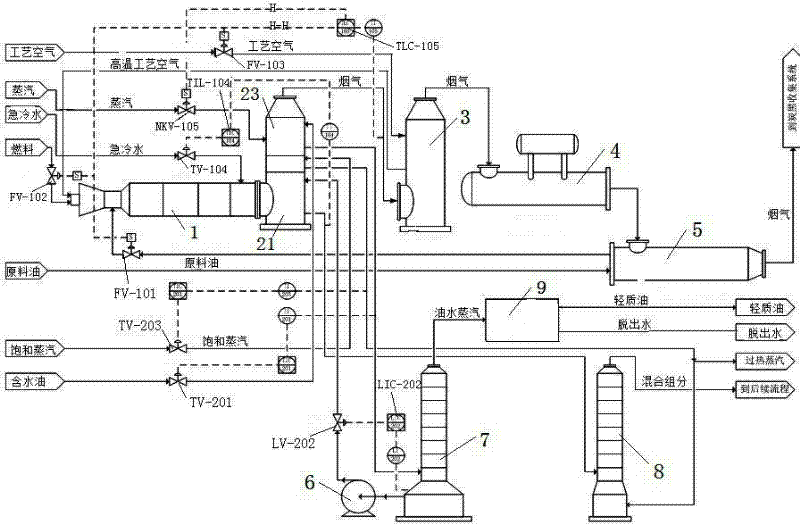

Co-production processing method and equipment for carbon black and oil

ActiveCN102226044ALess quantityRealize expansionPigmenting treatmentTar working-up by distillationAir preheaterOil processing

The present invention discloses a co-production processing method and equipment for carbon black and oil. The co-production processing method and equipment are characterized in that: an online tubular furnace is arranged between a carbon black reaction furnace and an air preheater; the online tubular furnace is divided into, from the bottom to top in turn, a radiation section, an overheating section and a convection section; a water-containing oil heating temperature adjusting system, a superheated steam temperature adjusting system, a water-free oil heating temperature adjusting system, a temperature alarm interlock system and other systems are also arranged; the physical heat of high-temperature carbon black flue gas is used as a heat source for heating raw oil, so that the water-containing oil and water-free oil are heated to the required temperatures; saturated steam is superheated to a specified temperature, thus meeting the feed requirements of an oil processing unit; and simultaneously the oil-containing water discharged from the top of a first-stage evaporator of the oil processing unit can be directly mixed with chilling water of a carbon black device, thereby solving thedifficulty of oil-containing wastewater treatment, effectively reducing the addition amount of the chilling water, decreasing the amount of exhaust gases, increasing the chemical heat value of the exhaust gases, reducing energy consumption in exhaust gas transport, reducing the requirement capacity of processing equipment and simultaneously achieving the security operation.

Owner:中昊黑元化工研究设计院有限公司

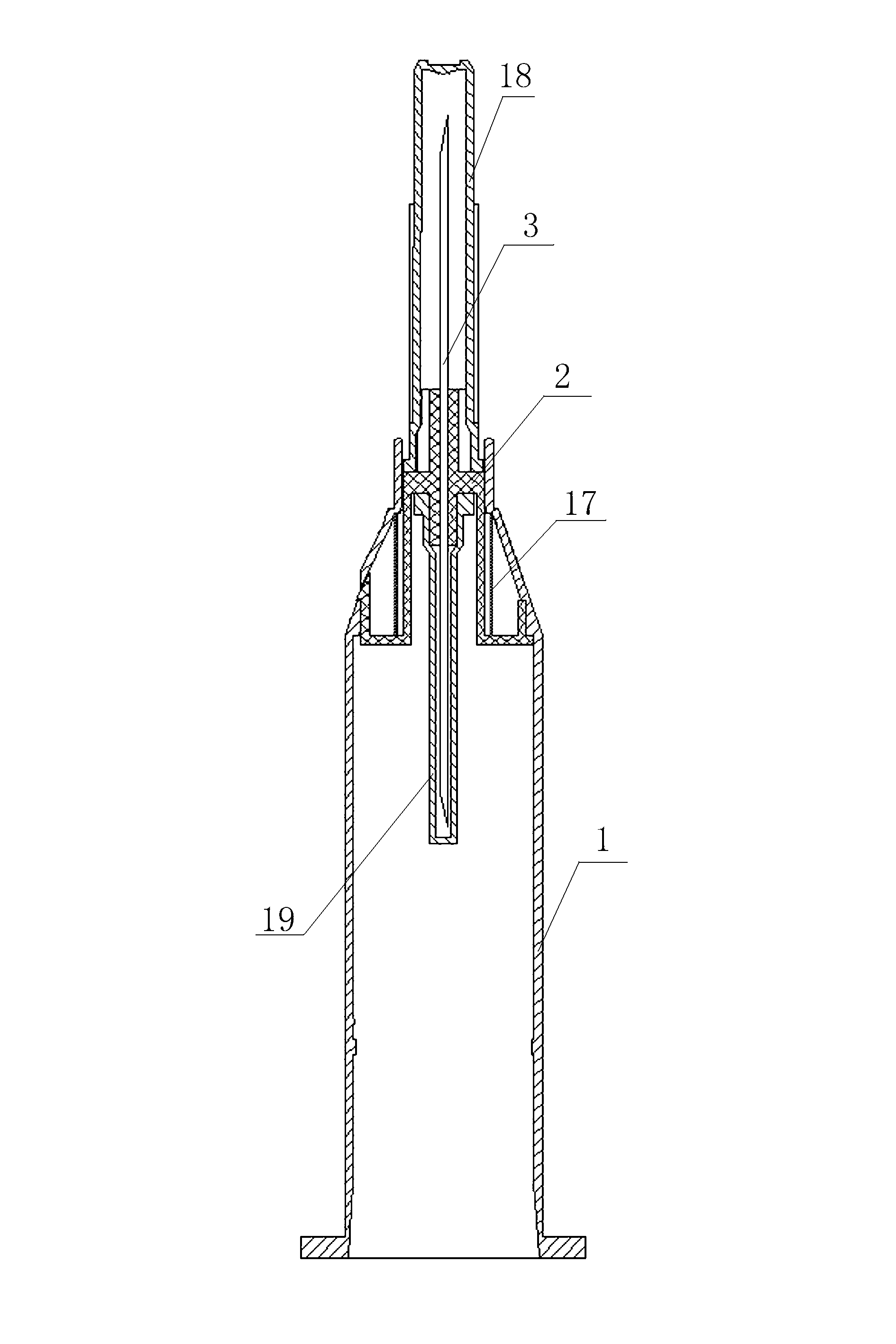

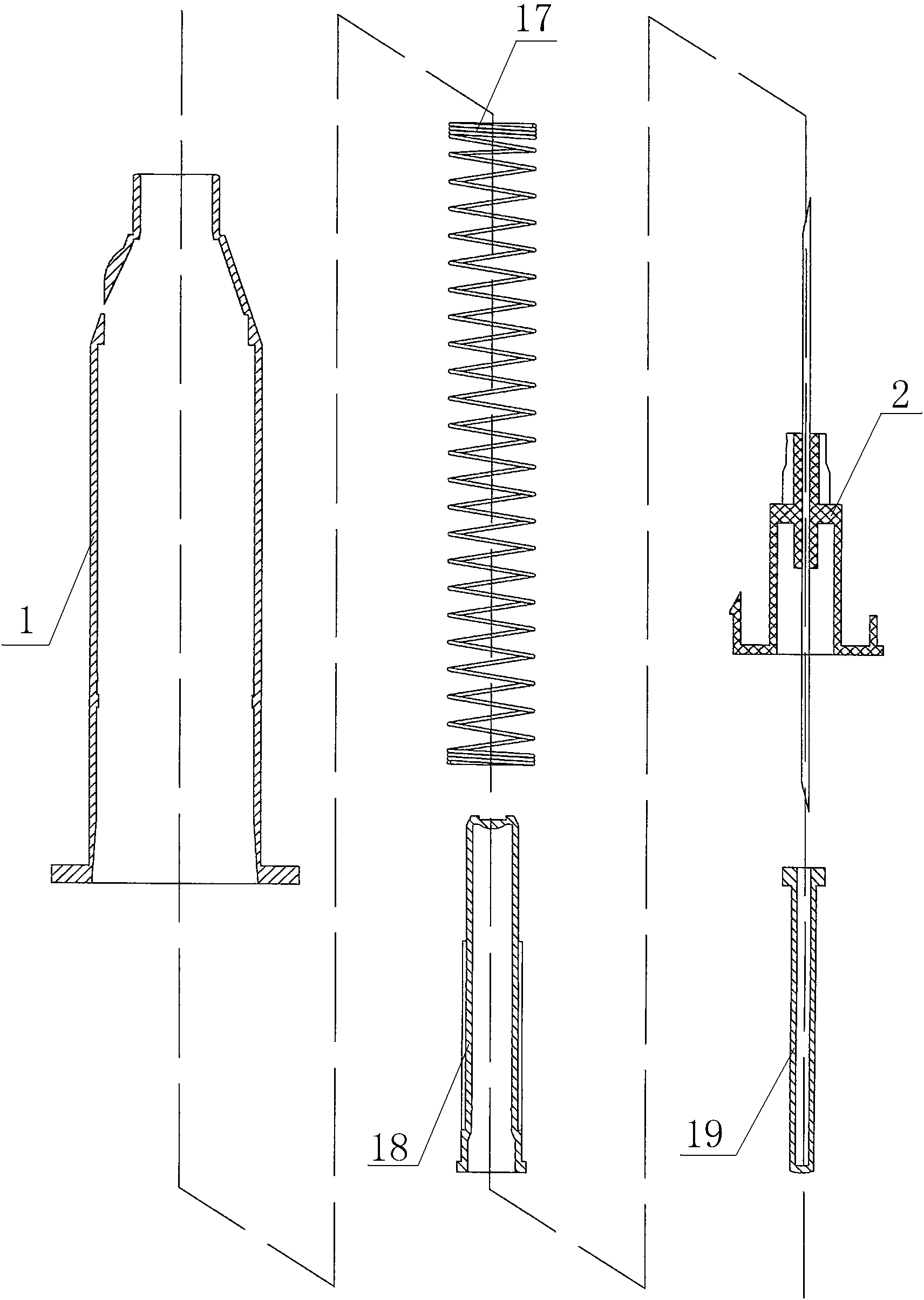

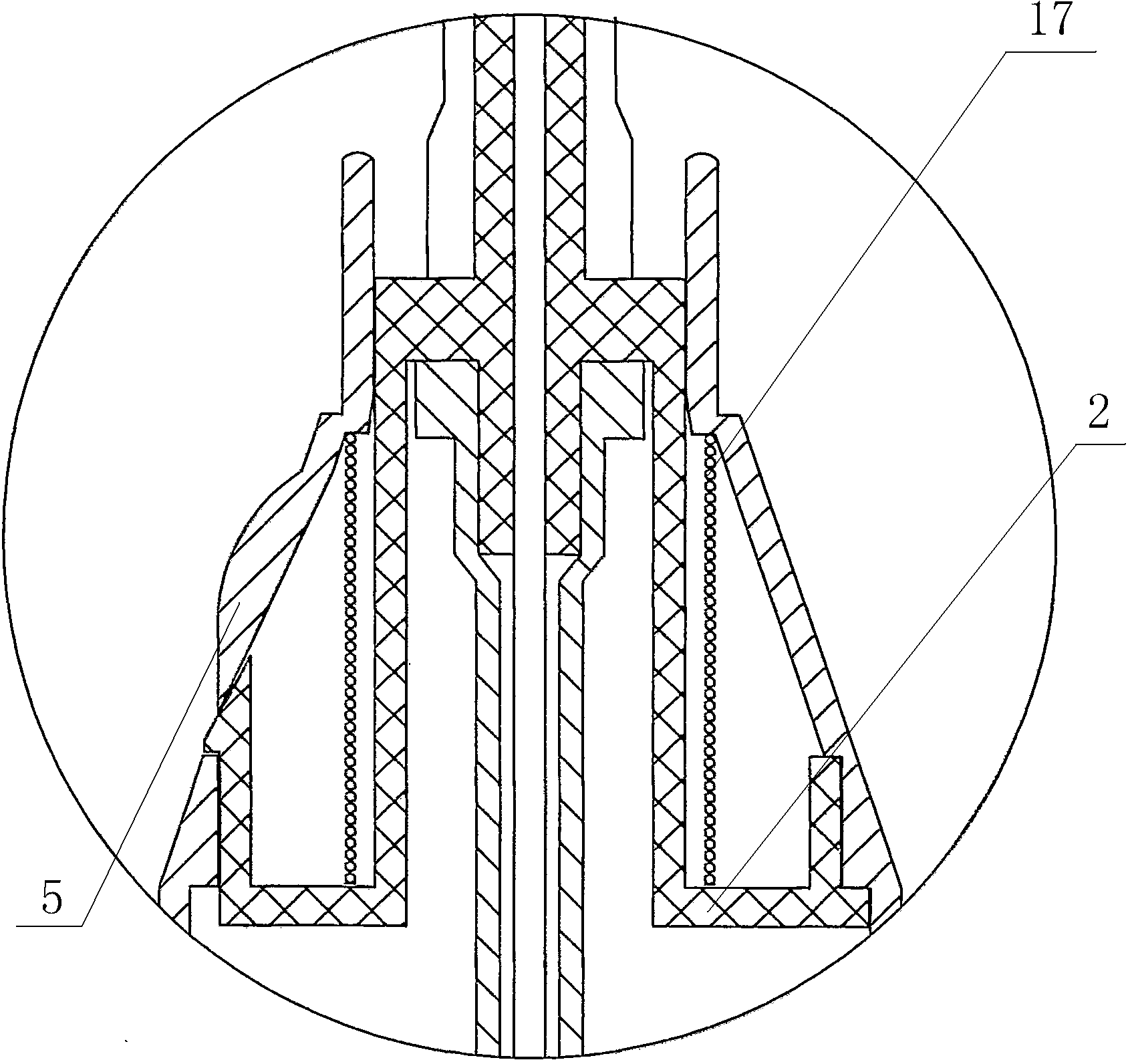

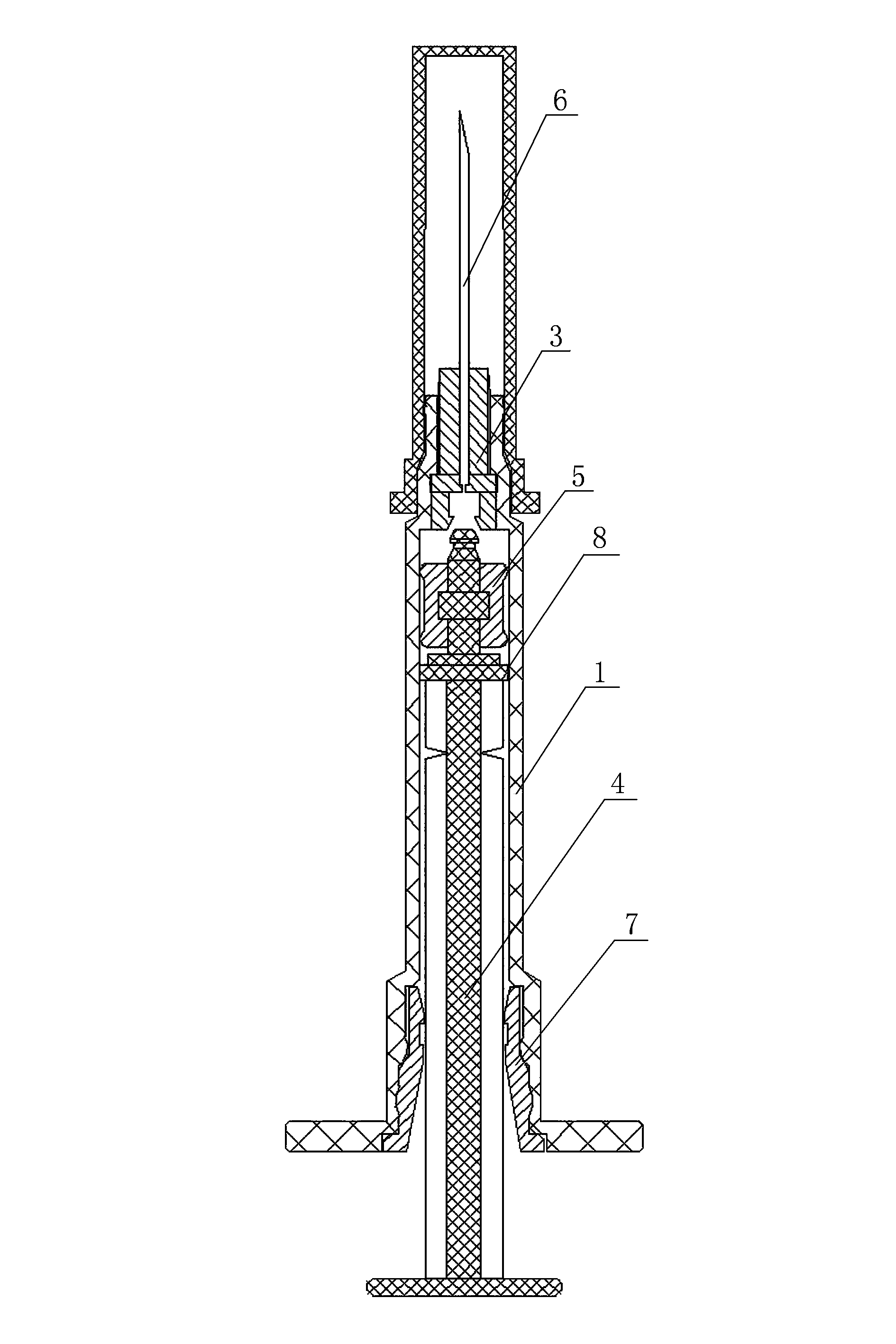

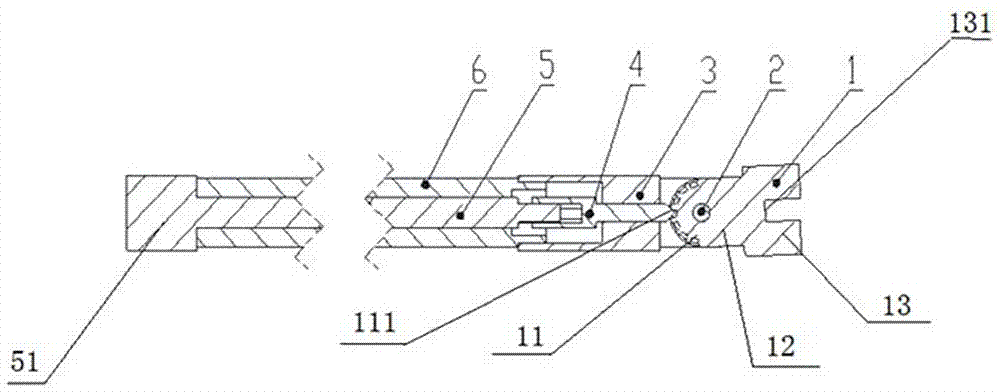

Safe blood taking needle

InactiveCN103006241AWith precisionReasonable designDiagnostic recording/measuringSensorsLocking mechanismSafe operation

The invention discloses a safe blood taking needle, which is characterized in that the upper part of a barrel body is a cone; the cone is provided with a press key; a strip-shaped gap is formed on the barrel body wall on the lower part of the press key; the barrel body on the upper part of the cone is cylindrical; a cylinder is formed in the center of a needle bed; a spring assembling platform is formed on the bottom of the cylinder; a spacing ring body is formed on the surface of the spring assembling platform; an annular step is formed on the edge of the spring assembling platform on the outer side of the spacing ring body; a notch is formed on the spring assembling platform; and an elastic stator is formed in the notch. According to the safe blood taking needle, an individual built-in spring is adopted, the integral retraction of the needle bed part is realized by the expansion force of the spring, the static locking structure of the needle bed is damaged in a pressing mode, and the safe blood taking needle can be operated with one hand. The inside of the barrel body is provided with a needle bed locking mechanism which can be used for spacing and fixing the retracted needle bed so as to realize the safe operation of the blood taking needle. The product has the advantages of reasonable integral design and artful concept, each component is precisely cooperated, automatic assembling in one time can be realized, and the safe blood taking needle has a good practicality.

Owner:SHANGHAI LANYINTONG MEDICAL TECH

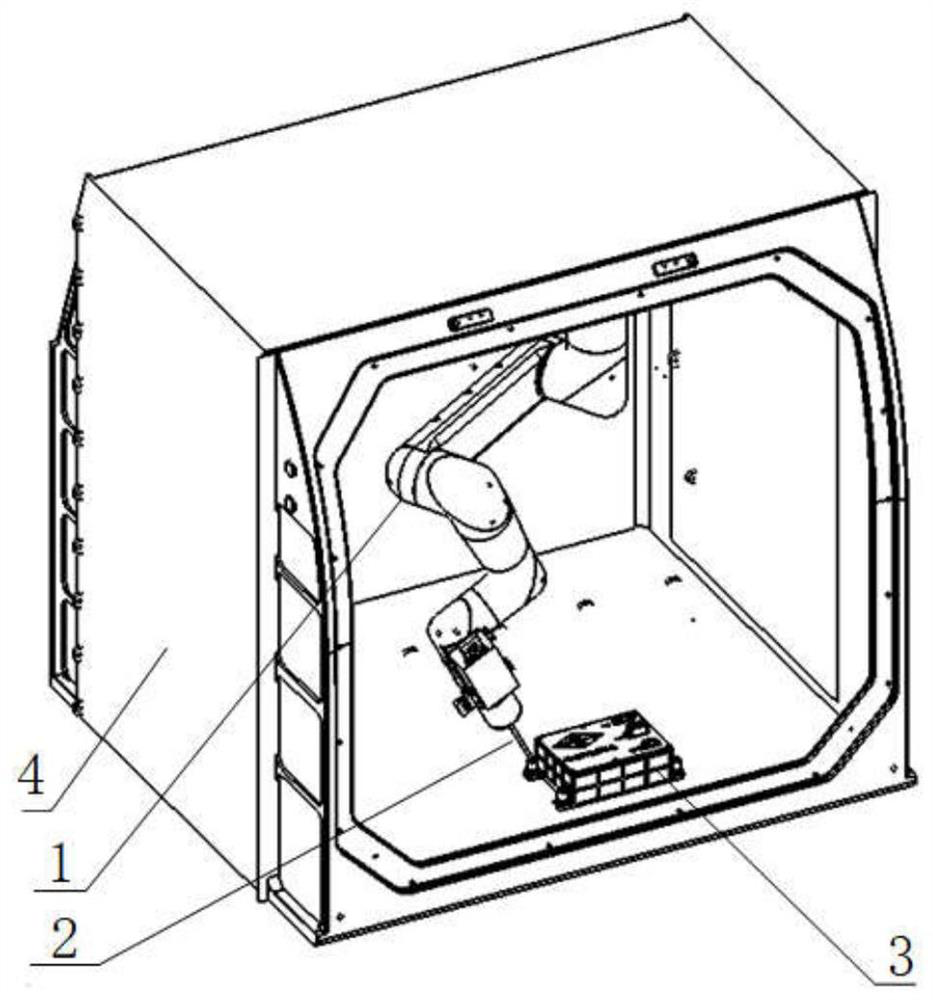

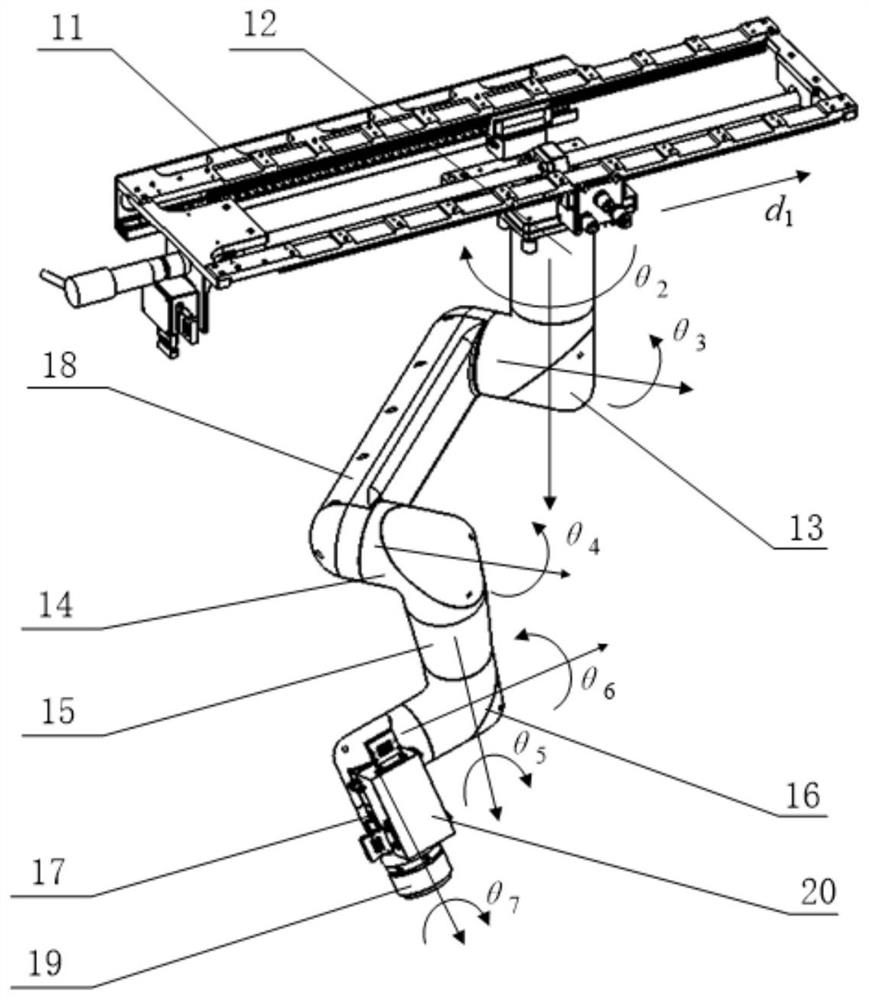

Mechanical arm used for space station load on-orbit maintenance

The invention relates to manned aerospace space station scientific experiment operation equipment, in particular to a mechanical arm used for space station load on-orbit maintenance. The mechanical arm comprises a maintenance box and a load maintenance mechanical arm body hung upside down in the maintenance box. The load maintenance mechanical arm body has seven degrees of freedom, a quick locking mechanism and a camera module are arranged at the execution tail end, the quick locking mechanism is used for being connected with a maintenance tool, and the camera module is used for collecting image information of to-be-maintained loads. According to the mechanical arm, the minimization design of the size, weight and energy consumption can be realized, the functional requirement of carrying out load maintenance on a space station is met, and an astronaut autonomously completes or is assisted in completing load on-orbit in-place maintenance.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Well control method for high-pressure reservoir nitrogen well drilling

InactiveCN109577902AQuick controlMeet the needs of drilling well control safetyConstructionsFlushingNitrogen gasHigh pressure

The invention discloses a well control method for high-pressure reservoir nitrogen well drilling, and belongs to the technical field of well drilling engineering. The well control method is characterized by comprising steps of a, connecting large-drift-diameter multifunctional spools in well control equipment with double-ram blowout preventers and single-ram blowout preventers; b, pushing well shut-in buttons of driller emergency button boxes when high-pressure and high-yield natural gas is drilled in nitrogen drilling periods, issuing well shut-in instructions, receiving the well shut-in instructions by PLC (programmable logic control) master control boxes, shutting down annular blowout preventers, turning on blowout valves, and starting up igniters to carry out blowout ignition; c, lowering pressure values of the annular blowout preventers until the pressure values reach 6 MPa, adjusting the heights of drilling tools, shutting down the single-ram blowout preventers, turning on the annular blowout preventers and completing well shut-in actions. The well control method has the advantages that wellheads can be quickly controlled by the aid of the well control method, multi-channel blowout and sluice valves can be remotely manipulated by the aid of the well control method, accordingly, the high-pressure reservoir nitrogen well drilling well control safety requirements can be met,and well control method is quite easy to operate and high in efficiency and is convenient and speedy.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

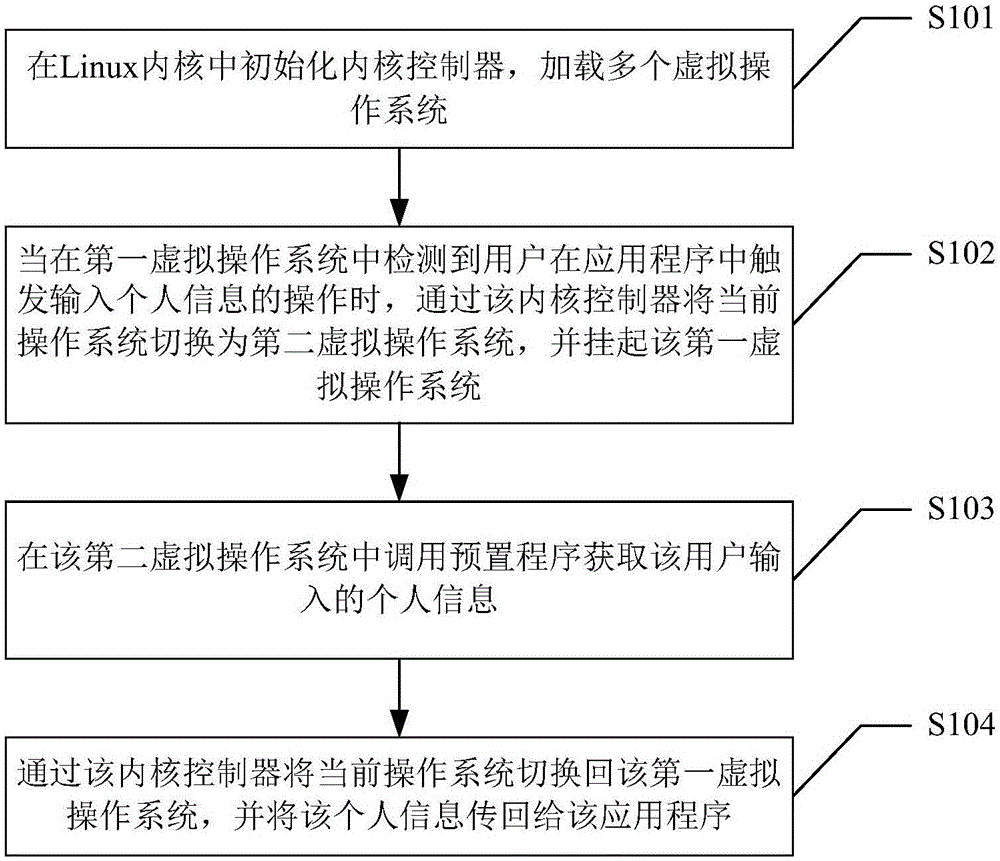

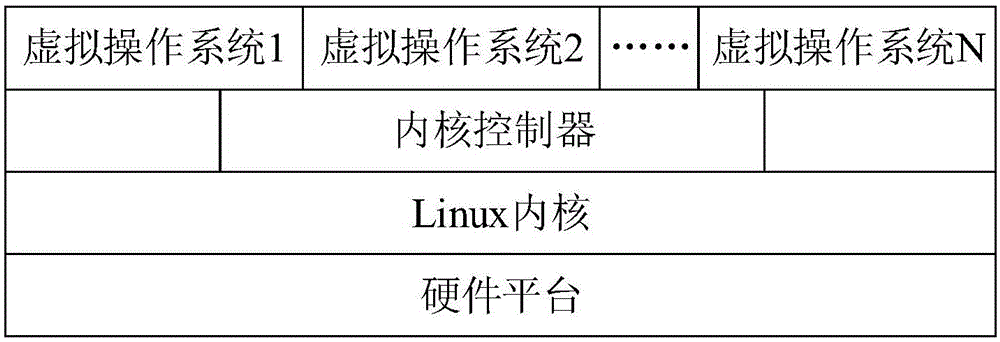

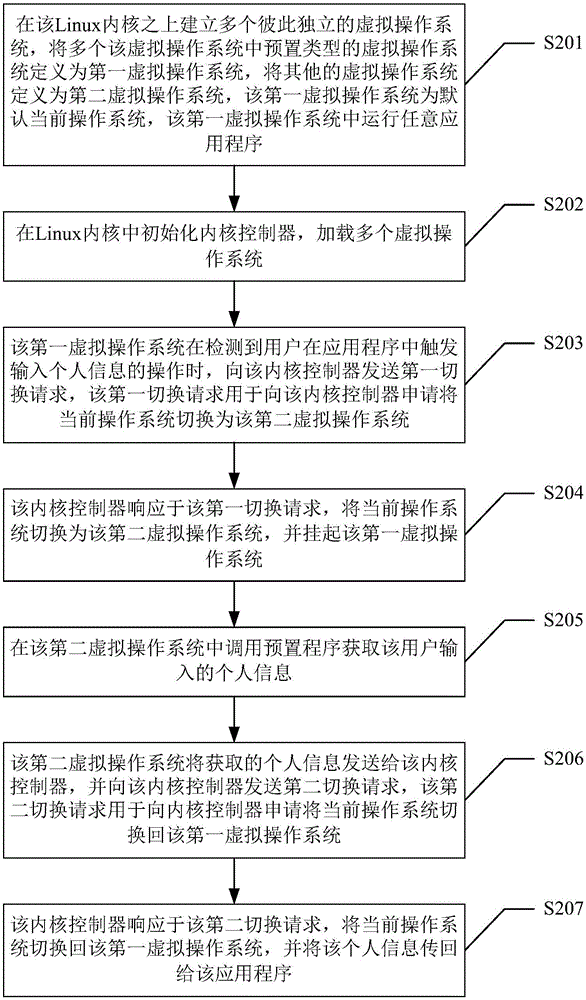

Method and device for safe operations of personal information

InactiveCN106529228AAchieving safe operationFunction increaseDigital data authenticationPlatform integrity maintainanceVirtualizationLinux kernel

The invention provides a method and device for safe operations of personal information. The method comprises the steps that a kernel controller is initialized in a Linux kernel, and multiple virtual operation systems are loaded one after another; when a user's triggering of a personal information input operation in an application program is detected in a first virtual operation system, the kernel controller can switch the current operation system to a second virtual operation system and hang up the first virtual operation system; a preset program in the second virtual operation system is called to acquire the personal information input by the user; and the kernel controller switches the current operation system back to the first virtual operation system, and the personal information is transmitted back to the application program. According to the invention, a lightweight class virtualization technology is used; the safe operations of the personal information input can be achieved conveniently; vicious programs in the first virtual operation system can be effectively prevented from sealing the personal information input by the user; and safety of the personal information input operations can be enhanced.

Owner:BEIJING ERENEBEN INFORMATION TECH

CNC (Computer Numerical Control) high-speed drilling and tapping system

InactiveCN108296876APrevent overcutAvoid tool breakageAutomatic control devicesFeeding apparatusNumerical controlMachining process

The invention discloses a CNC (Computer Numerical Control) high-speed drilling and tapping system. The CNC high-speed drilling and tapping system comprises the steps of rough machining and finish machining. The CNC high-speed drilling and tapping system is characterized in that displacement induction is performed on the machining during the rough machining, and real-time position feedback is performed on a cutter during finish machining. According to the CNC high-speed drilling and tapping system, the displacement is fed back in real time, and the rough machining is tracked in real time, so that the problem of more machining residues is avoided; additionally, the position of the cutter is monitored in real time, the track of the cutter used for the finish machining is monitored, sharp point control is performed on a complex 3D molding surface, the machining step pitch of the path of the CNC finish machining cutter is respectively calculated according to the sharp point height, and whenthe position of the machining cutter is far, the displacement of the cutter is compensated; and automatic overcut preventing treatment is set, so that the phenomena of overcut and damage to the cutter due to sudden increase of cutting load of the cutter are avoided, the cutting process of the cutter can be protected, and the safe operation of high-speed machining is realized.

Owner:KUNSHAN BOGUTE ELECTROMECHANICAL EQUIP

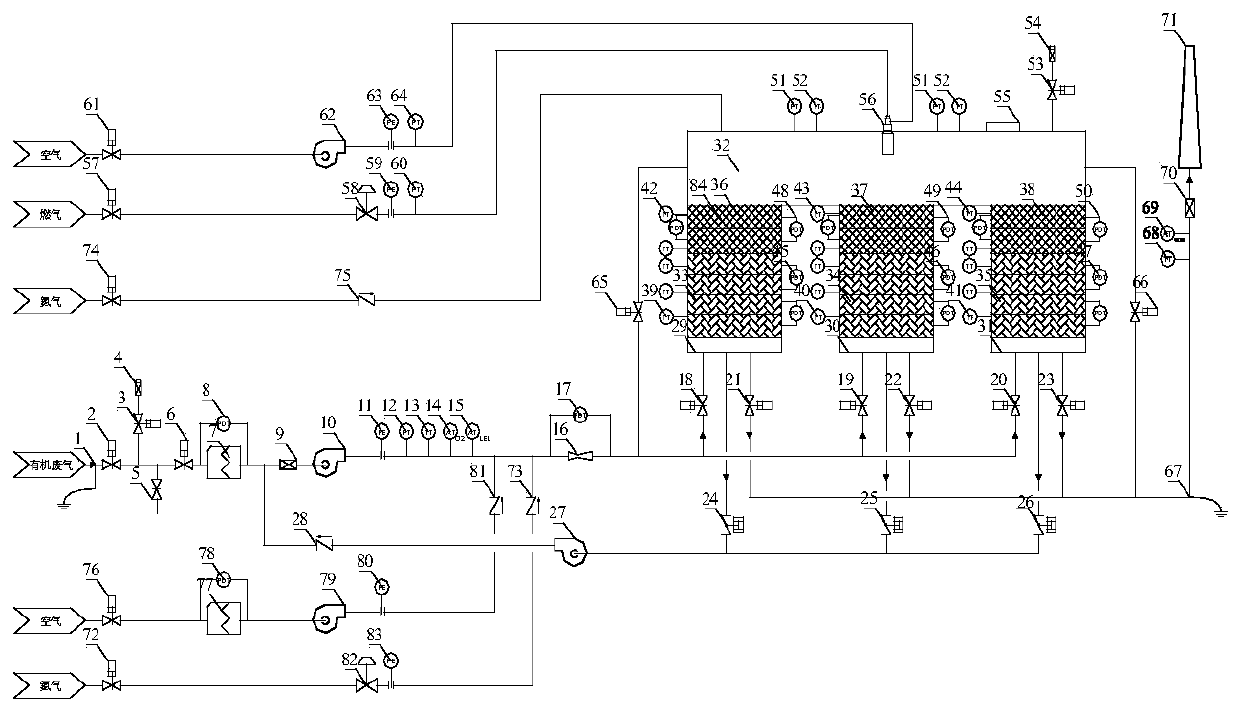

Safe organic waste gas heat storage, catalysis and oxidation device

PendingCN111457404AAvoid dangerous situationsAchieving safe operationFire rescueBlast-producing apparatusPtru catalystControl system

The invention discloses a safe organic waste gas heat storage, catalysis and oxidation device. The safe organic waste gas heat storage, catalysis and oxidation device is suitable for safely treating organic waste gas with the low concentration and the large air quantity. After organic waste gas is pretreated, the organic waste gas is supercharged by a fan to enter a heat storage and catalysis chamber and an oxidation chamber; the heat storage and catalysis chamber is filled with a heat storage body and a catalyst, organic waste gas is heated in the heat storage and catalysis chamber and is catalyzed and oxidized into water and carbon dioxide under the action of the catalyst and high temperature, and clean treatment is achieved. In order guarantee safety and stability of the organic waste gas treatment process, a series of instrument and control system is arranged for complete equipment. By means of the safe organic waste gas heat storage, catalysis and oxidation device, it can be guaranteed that the complete equipment avoids possible dangerous situations to the largest extent, or safe operation can be achieved in various expectable emergency circumstances.

Owner:JIANGSU GOLDEN GATE ENERGY & EQUIP CO LTD +1

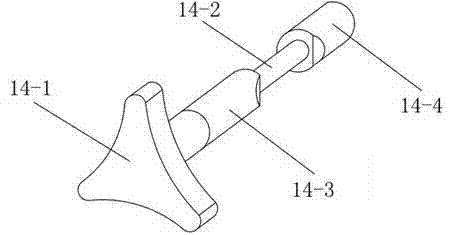

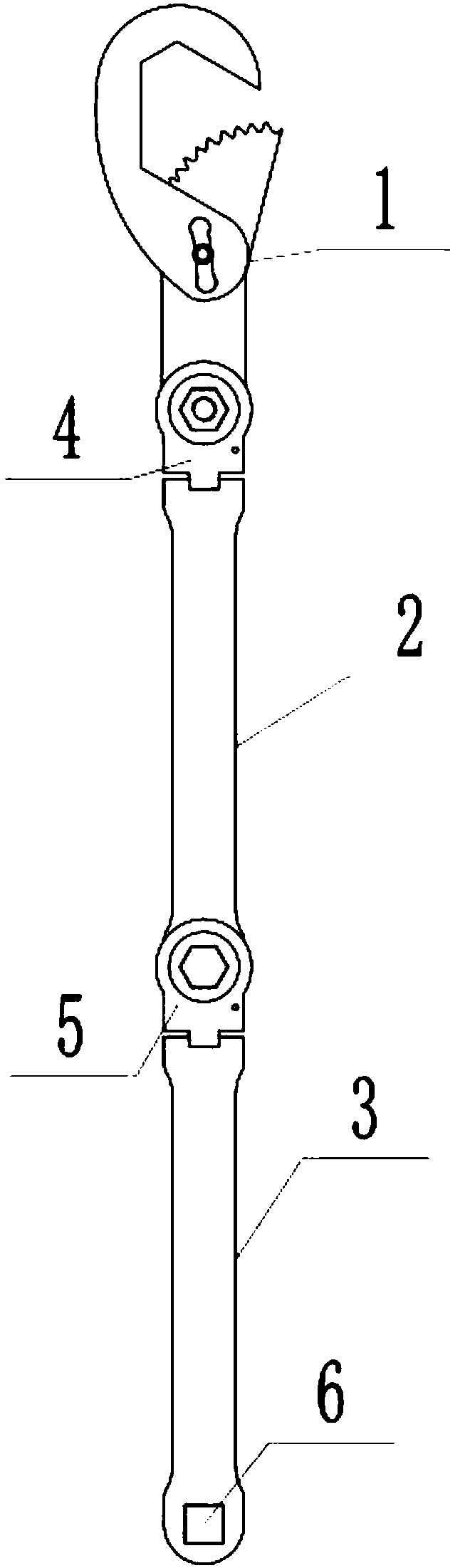

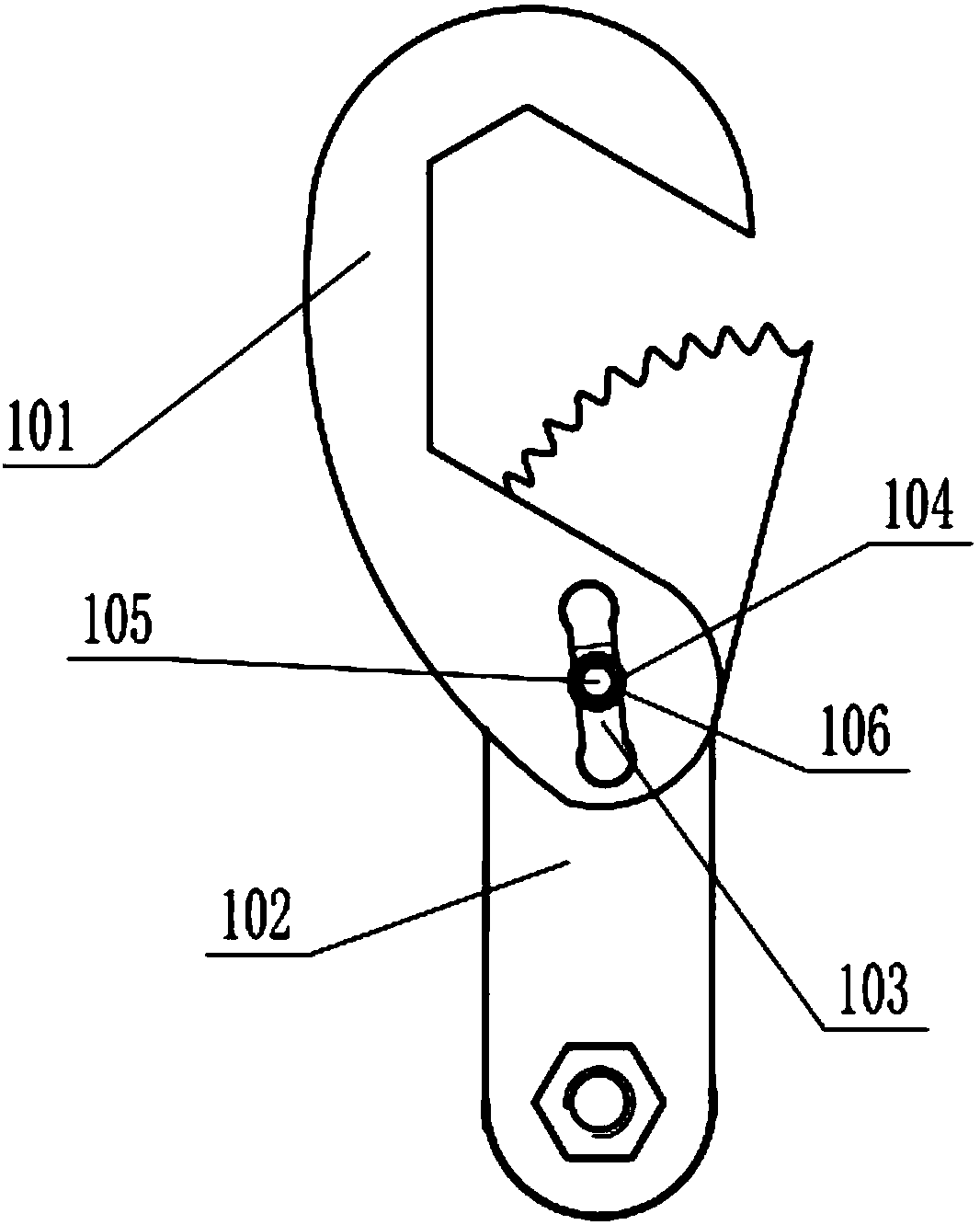

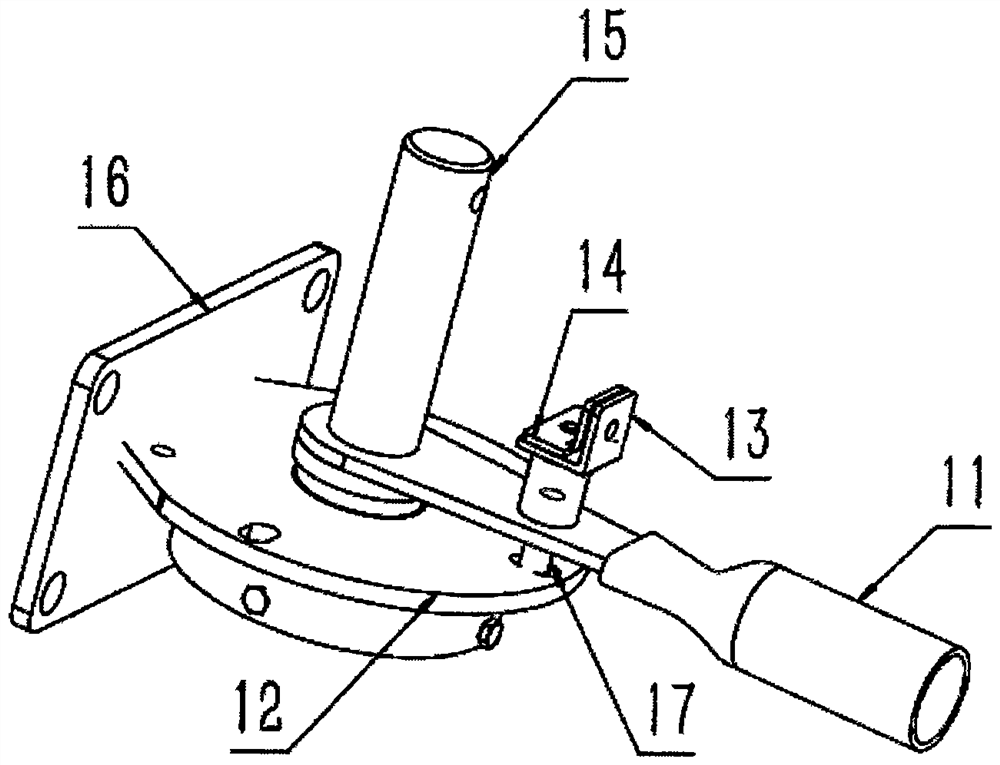

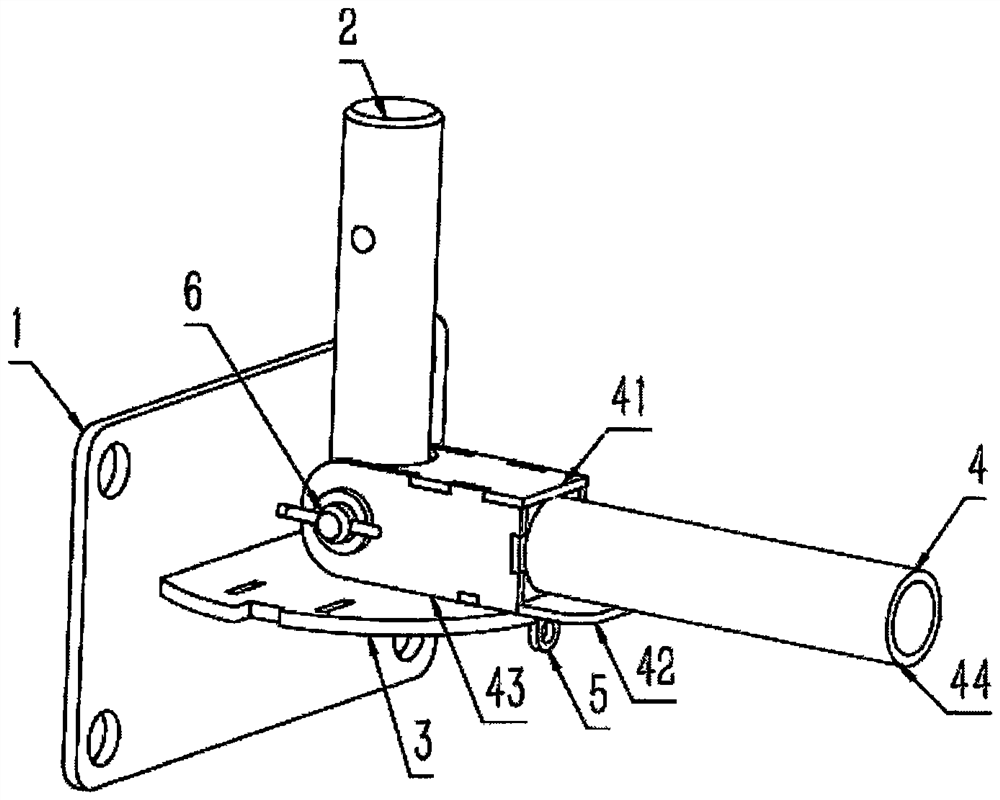

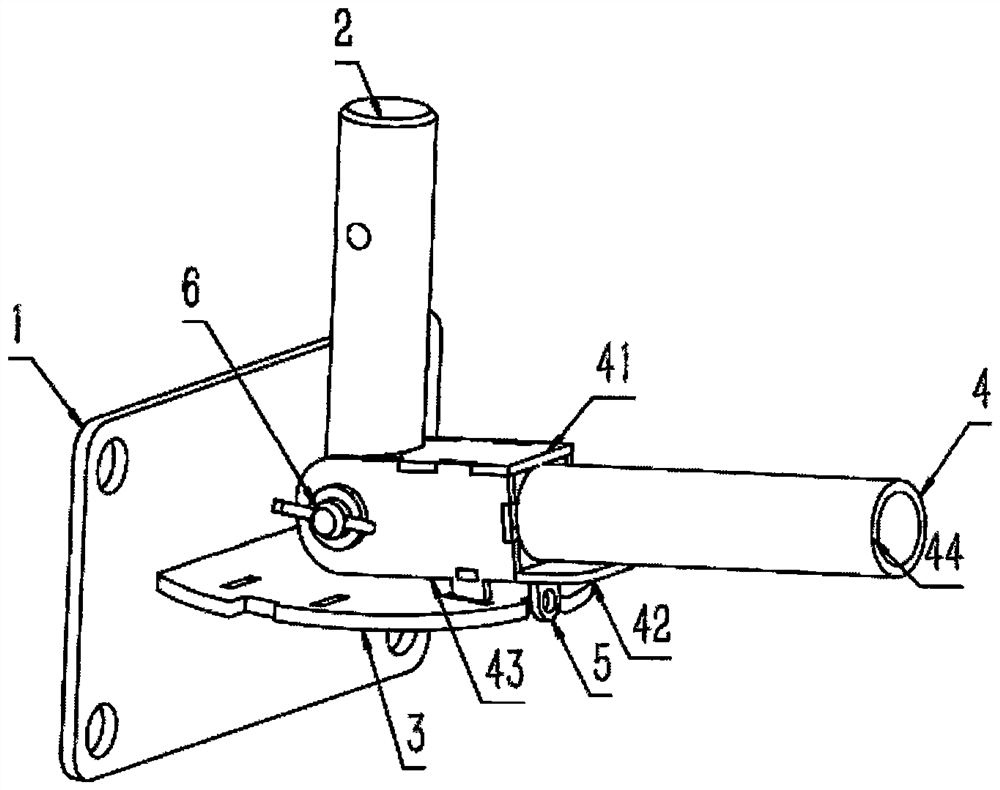

Assembling and disassembling device of oil chromatography on-line monitoring device

The invention discloses an assembling and disassembling device of an oil chromatography on-line monitoring device. The assembling and disassembling device comprises a special-shaped spanner, the special-shaped spanner is sequentially and detachably connected to a transfer ratchet wrench and a ratchet wrench, and the rotating directions of a first ratchet wheel connecting end and a second ratchet wheel connecting end are the same or opposite; a square hole is formed in the tail end of the ratchet wrench, the ratchet wrench further comprises a plurality of sleeve adapters, rotary tool heads andL-shaped adapter plates of different specifications, wherein the sleeve adapters can be inserted into the square hole; after the ratchet wrench is disassembled, one L-shaped adapter plate can be detachably connected to the second ratchet wheel connecting end through a screw and is parallel to the length direction of the ratchet wrench, the other end of the L-shaped adapter plate is provided with ahexagonal hole connecting rotary tool heads, and a plurality of inner hexagonal holes of different specifications are formed in the ratchet wrench body. According to the assembling and disassemblingdevice of the oil chromatography on-line monitoring device, disassembling and installation can be quickly completed, the maintenance efficiency is high, the operation safety is high, the weight is within the range of 0.8 kg and is greatly reduced compared with the prior art, and the carry is more convenient to brought for maintenance personnel.

Owner:GUIZHOU POWER GRID CO LTD

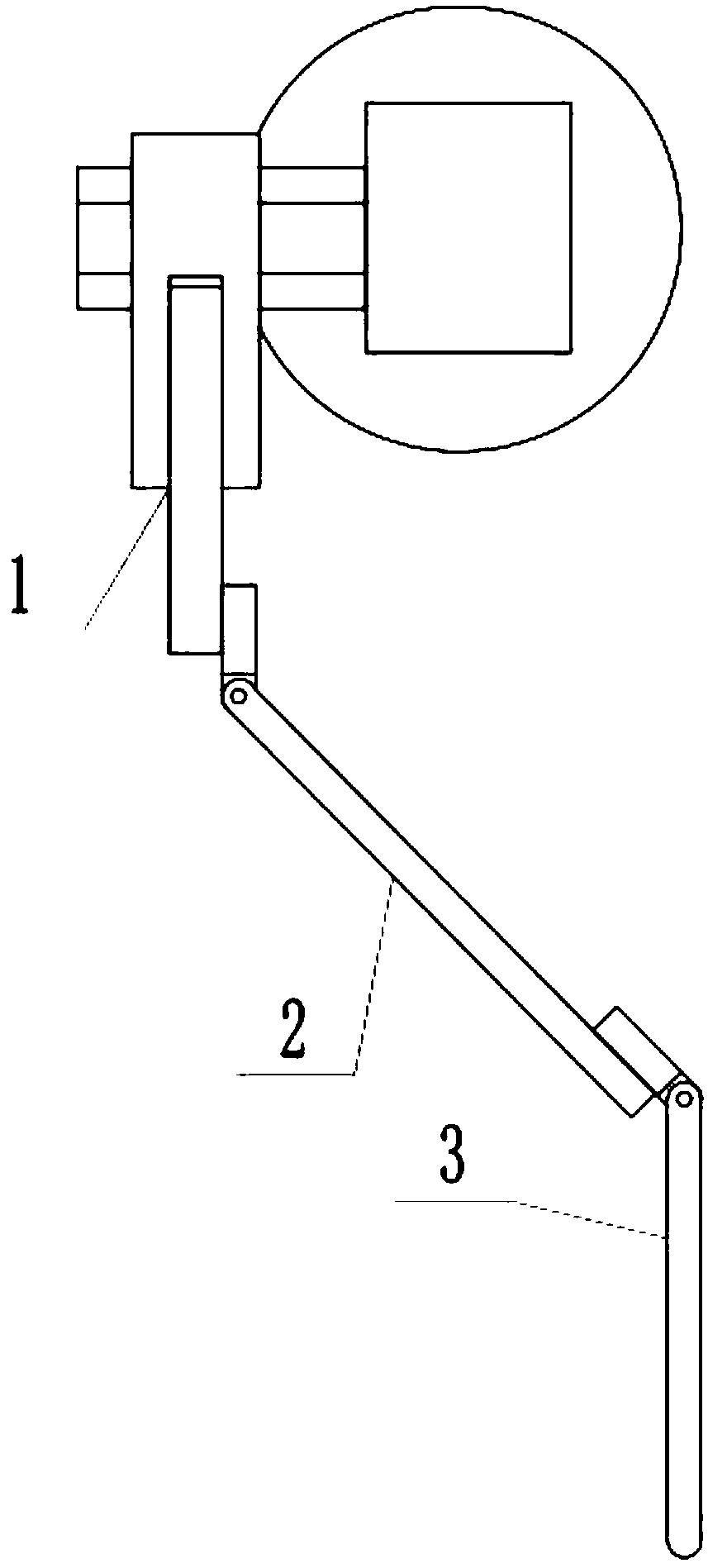

Manual operation mechanism of high-voltage isolating switch

PendingCN114530346AAvoid the risk of electric shockAchieving safe operationContact driving mechanismsAir-break switch detailsControl engineeringElectric shock

The invention provides the manual operating mechanism of the isolating switch, which is safe and standard, is simple to operate, is reliable and durable, and greatly reduces electric shock accidents generated when the manual operating mechanism is used for opening and closing.

Owner:洛阳国函铁路器材有限公司

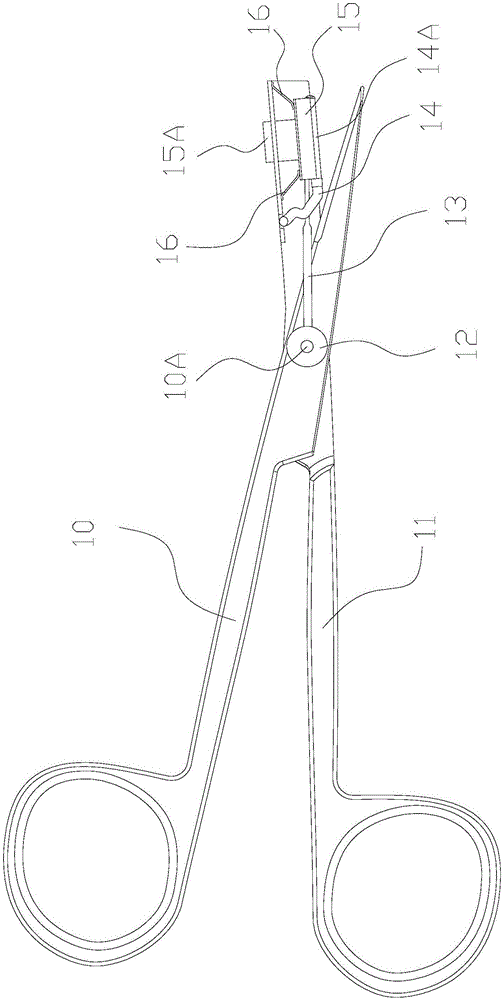

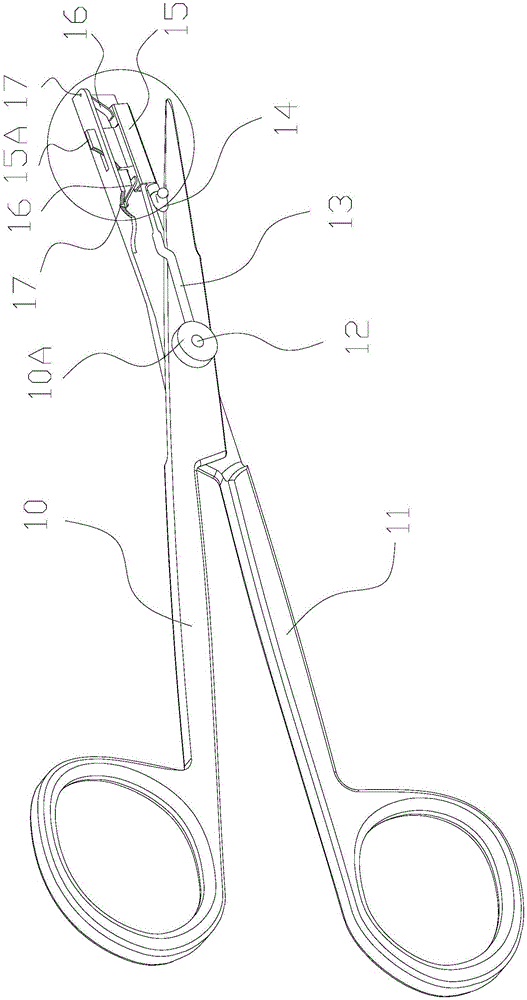

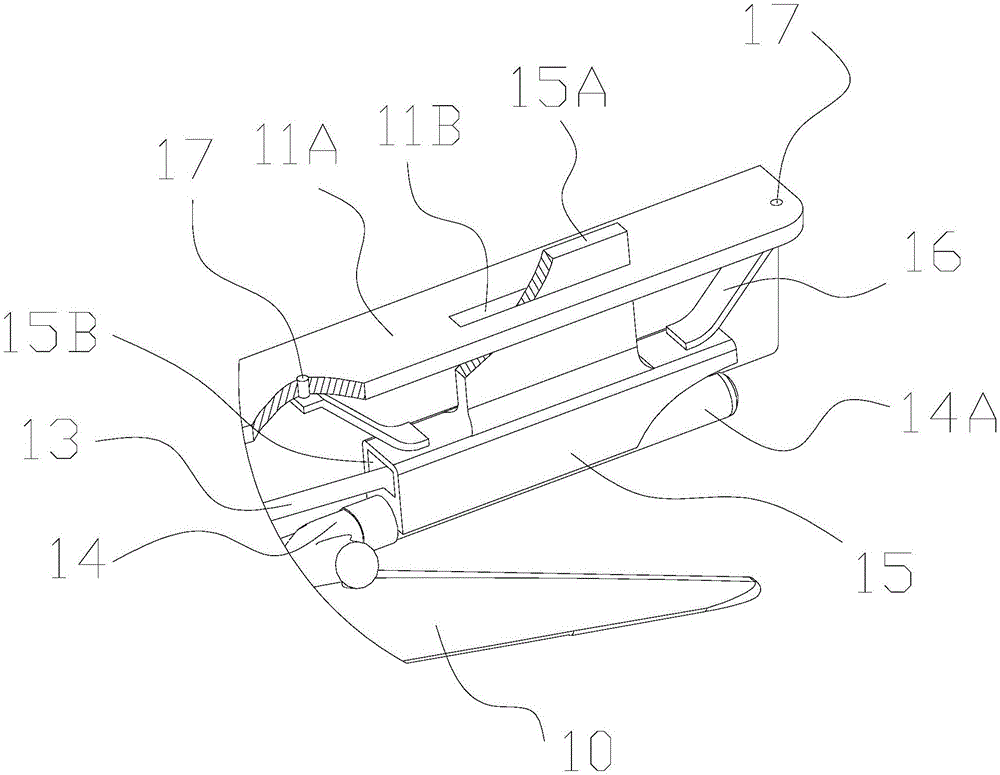

Surgical scissors with ultrasonic probe

ActiveCN105105824ASimple structureEasy to operateUltrasonic/sonic/infrasonic diagnosticsSurgical scissorsUltrasonic sensorSlide plate

The invention discloses a pair of surgical scissors with an ultrasonic probe. The surgical scissors comprise a left scissor part and a right scissor part, wherein the left scissor part is hinged to the right scissor part through a pin shaft; a convex plate is arranged at a position of the pin shaft of the left scissor part; one end of an ejector rod is fixedly connected with the convex plate, and the other end of the ejector rod is inserted into a hole in the side surface of a sliding support; the sliding support is vertically and fixedly provided with a sliding plate; a sealing plate is arranged on a cutter surface of the right scissor part in a stretching way; a sliding groove is formed in the sealing plate; the sliding plate is arranged in the sliding groove and can slide back and forth under the driving of the ejector rod; positions between the sealing plate and the sliding support at the two sides of the sliding plate are respectively provided with a spring piece; one end of each of the two spring pieces is fixedly arranged on the sealing plate, and the other end of each of the two spring pieces is arranged on the top surface of the sliding support and is matched with the top surface of the sliding support in a sliding way; one end of an ultrasonic sensor is arranged on the right scissor part in a rotating way; the ultrasonic probe of the ultrasonic sensor is clamped in a groove which is formed in the lower end of the sliding support so as to be fixed to the sliding support. According to the surgical scissors with the ultrasonic probe, disclosed by the invention, accurate surgical excision can be realized.

Owner:TIANJIN UNIV

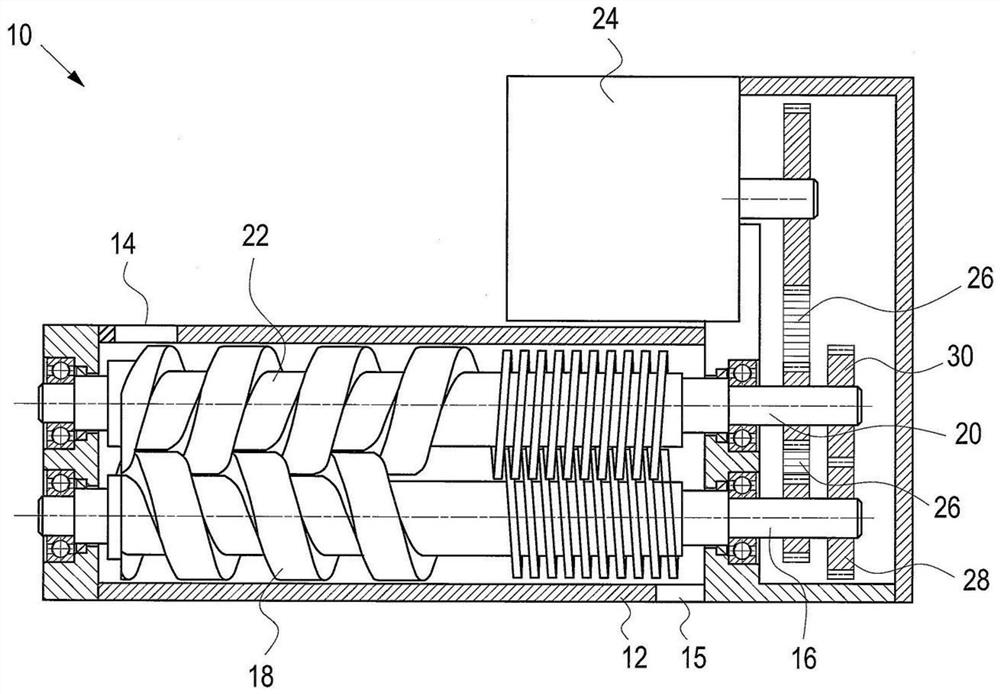

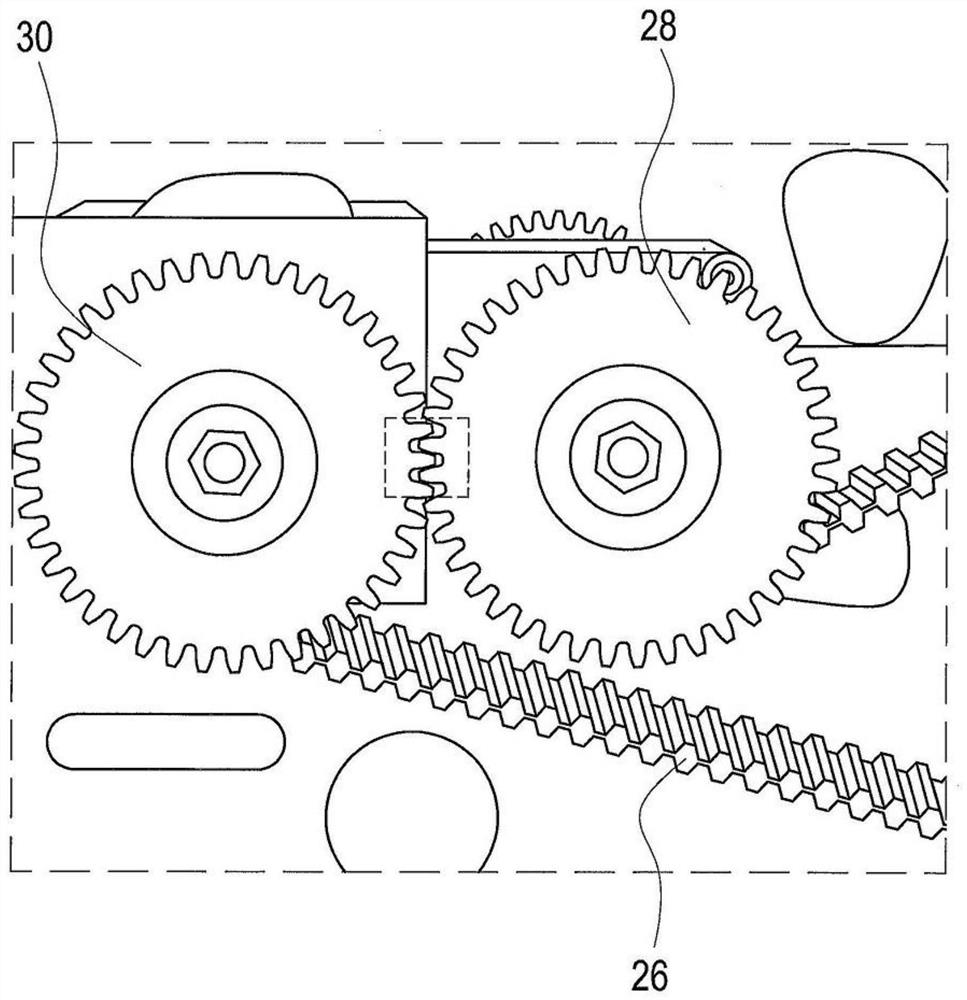

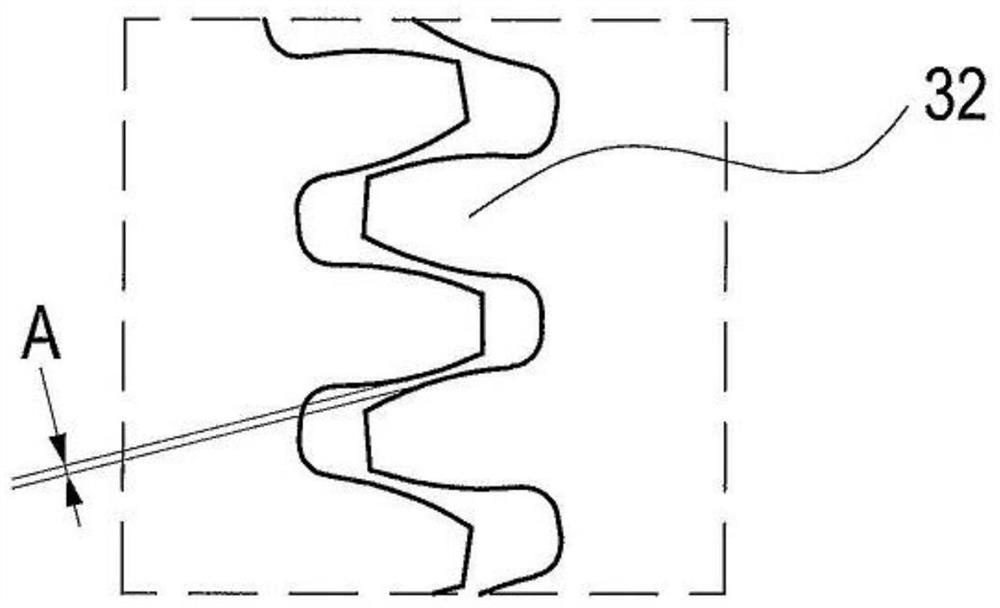

Dual or multi-shaft vacuum pump

InactiveCN112513422AAvoid contactAvoid damageRotary/oscillating piston combinations for elastic fluidsWorking fluid for enginesGear wheelControl theory

The invention relates to a dual or multi-shaft vacuum pump comprising a motor, a first shaft and at least a second shaft, wherein the first shaft and the second shaft are driven synchronously by the motor via a common drive belt. The first shaft has a pumping element, and the second shaft likewise has a pumping element, which cooperates with the pumping element of the first shaft in order to convey a gaseous medium from an inlet to an outlet. The first shaft has a first emergency running gear, and the second shaft likewise has a second emergency running gear, which meshes with the first emergency running gear.

Owner:レイボルドゲーエムベーハー

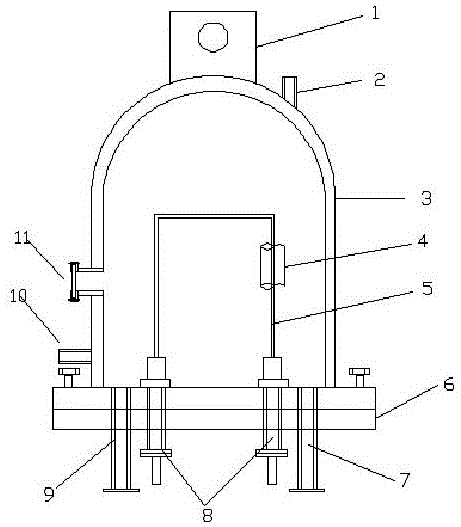

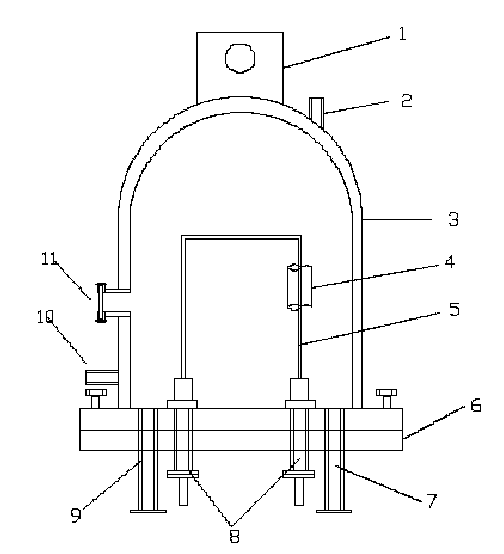

Purity evaluation device for electronic-grade trichlorosilane

ActiveCN103454377AReduce riskAchieving safe operationSilicon compoundsMaterial analysisProduct gasEngineering

The invention relates to a purity evaluation device for electronic-grade trichlorosilane. The device comprises a chassis, a bell-jar, which is arranged on the chassis and has a cooling water jacket, a tantalum filament, which is arranged in the bell-jar with the cooling water jacket, and a pair of electrodes, which go through the chassis and are connected to the power supply. The top part of the bell-jar with the cooling water jacket is provided with a hanger and a bell-jar cooling water outlet, the side wall of the bell-jar with the cooling water jacket is provided with a bell-jar cooling water inlet and a sight glass; the two electrodes are connected through the tantalum filament, the outside of the pair of electrodes is provided with a reaction gas inlet and a reaction gas outlet, and the reaction gas inlet and the reaction gas outlet go through the chassis and communicate with the cavity of the bell-jar with the cooling water jacket. The purity evaluation device for electronic-grade trichlorosilane has the advantages of simple structure and low cost, achieves the goals of rapid and precise purity measurement, and realizes safety operation.

Owner:青海黄河上游水电开发有限责任公司新能源分公司 +1

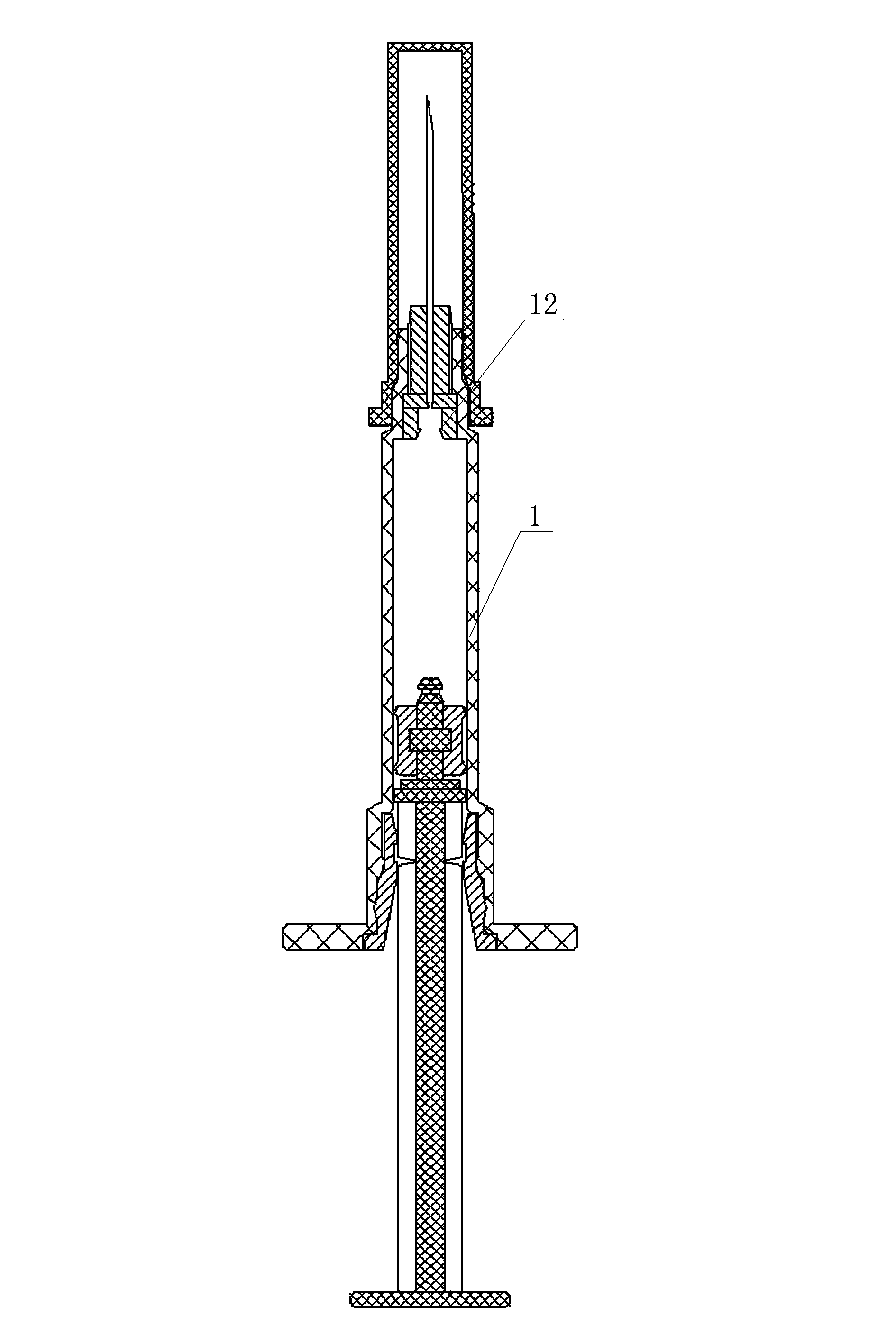

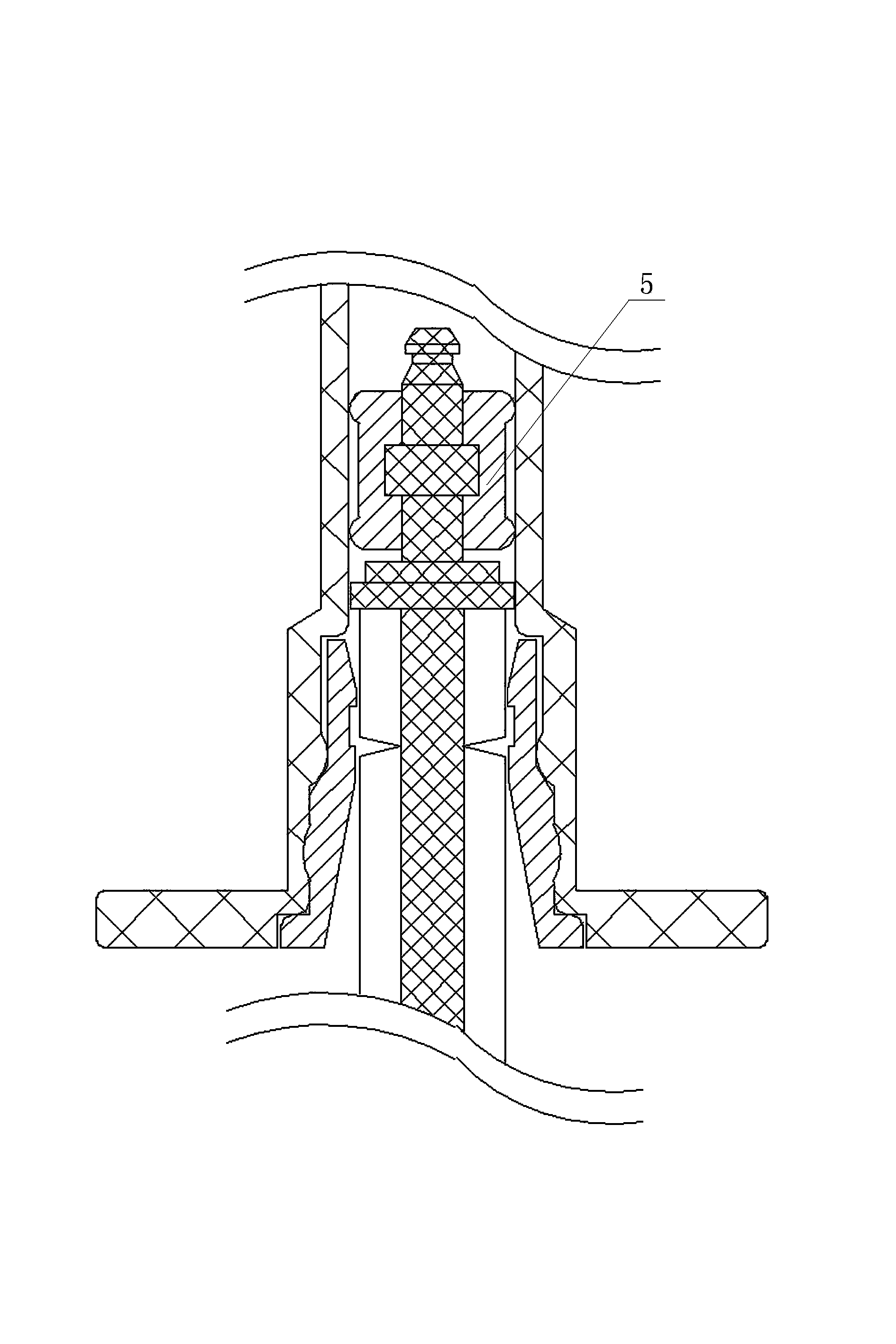

Core rod locking-type safety syringe

InactiveCN103446643APrevent push forwardPrevent back pullInfusion syringesIntravenous devicesSelf lockingEngineering

The invention discloses a core rod locking-type safety syringe. A needle seat is arranged in a barrel neck on the upper end portion of a barrel, a core rod is arranged in the barrel, a rubber plug is connected at a position, close to the upper end portion, of the core rod in a sleeved manner, and a needle tube is arranged on the upper end portion of the needle seat. The core rod locking-type safety syringe is characterized in that a clamping-matching portion is arranged at a lower-end inner cavity of the needle seat, a locking and pulling-back portion matched with the clamping-matching portion is formed on the end portion of the core rod, a core rod locking member is arranged at a position, close to the inner cavity of the lower end portion, of the barrel, and a self-locking piece matched with the core rod locking member is arranged at the core rod. The core rod locking-type safety syringe has the advantages that the core rod locking member is internally arranged at at a lower-end opening of the syringe barrel, can realize firm meshing with the core rod, can simultaneously realize firm meshing with the inner wall of the barrel and can effectively prevent the core rod from being pushed forwards or pulled backwards in a safe state, so that a needle head portion of the end portion of the core rod is avoided from causing accidental damage to personnel; the core rod locking member is reasonable in product design structure and ingenious in concept, the improved core rod locking member can realize full-automatic assembly of the rear portion, requirements of automatized and large-scale production can be met, and the core rod locking member is easy to popularize and apply in safety syringes and safety self-destroying syringes in various specifications.

Owner:常州市康福莱医疗用品有限公司

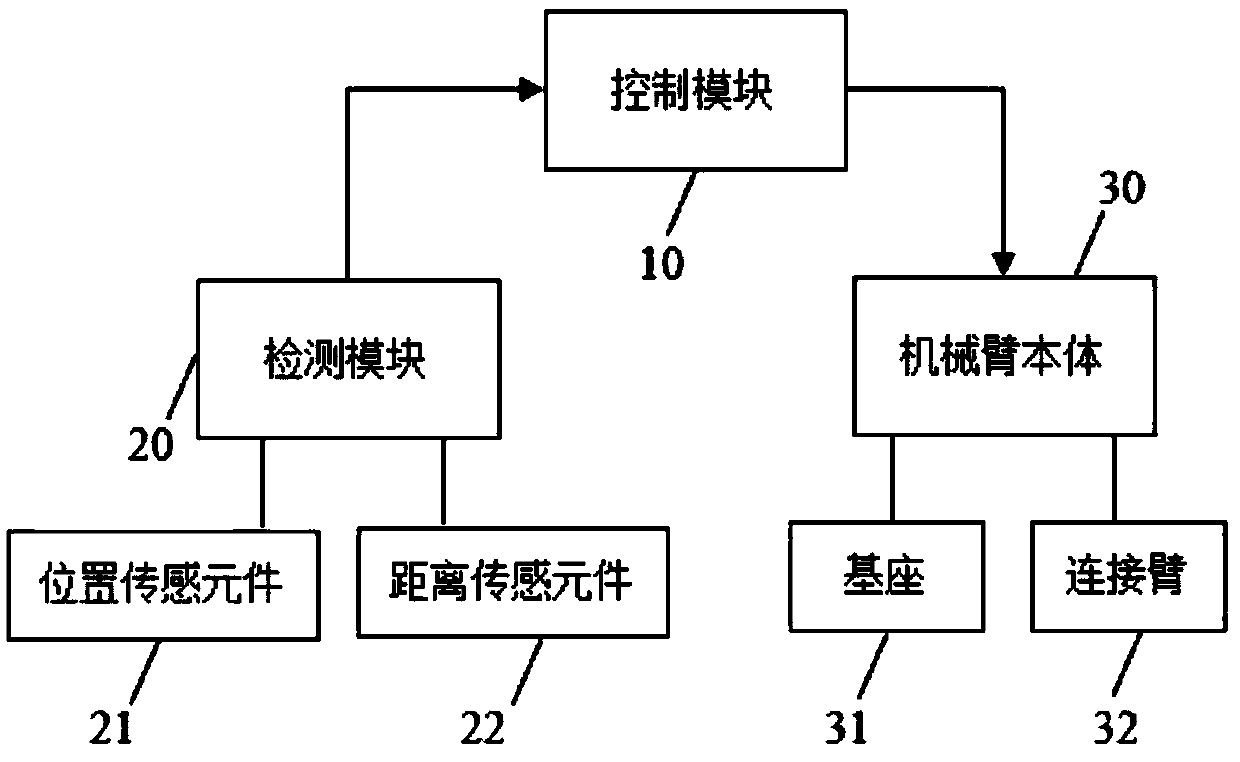

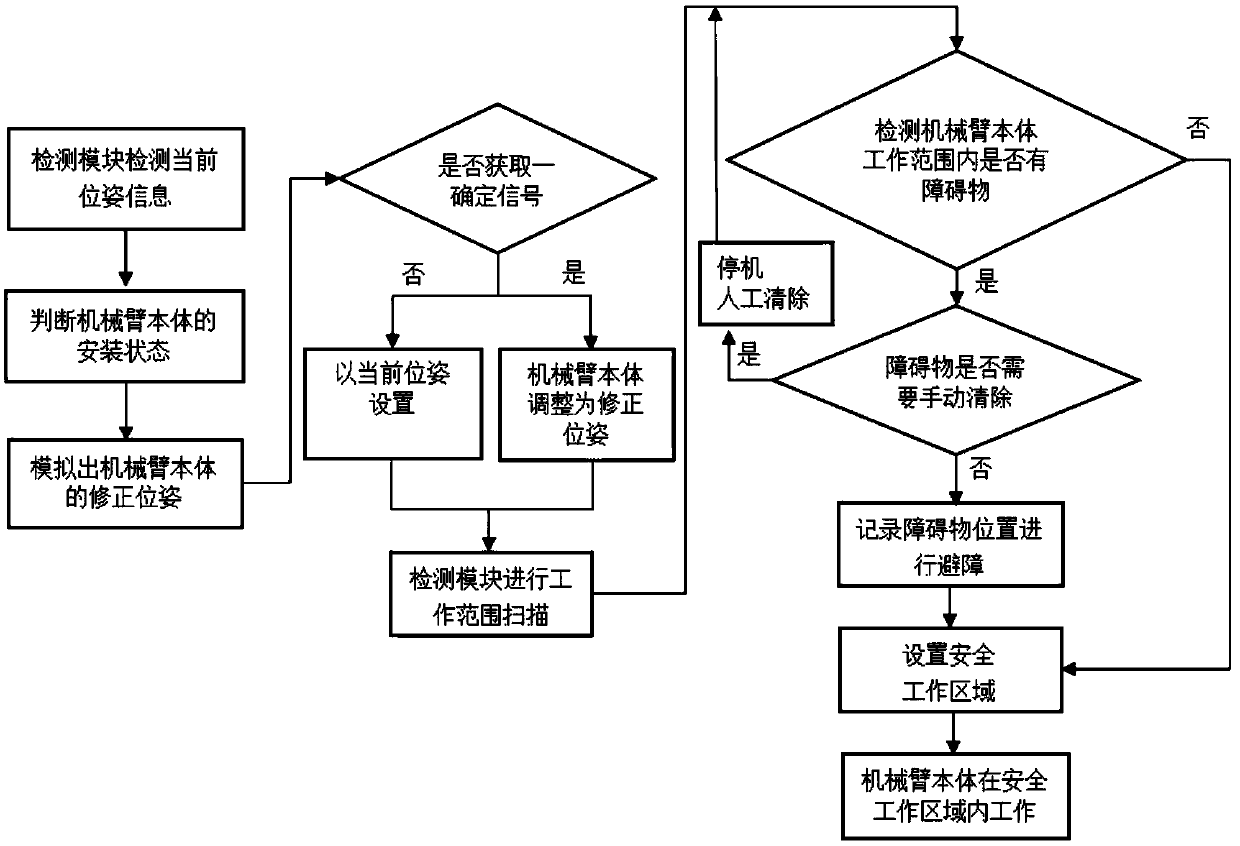

Mechanical arm control method and mechanical arm

ActiveCN109531559AAchieving safe operationProgramme-controlled manipulatorControl engineeringSafe operating area

The invention relates to a mechanical arm control method and a mechanical arm. The mechanical arm control method comprises steps that a detection module automatically detects the position-pose information of a mechanical arm body, and a control module adjusts the position-pose of the mechanical arm body according to the position-pose information so as to adapt to the installation state of the mechanical arm body. In addition, through a safe working area arranged for the mechanical arm body, safety operation of the mechanical arm body can be ensured.

Owner:INVENTECSHANGHAI TECH +2

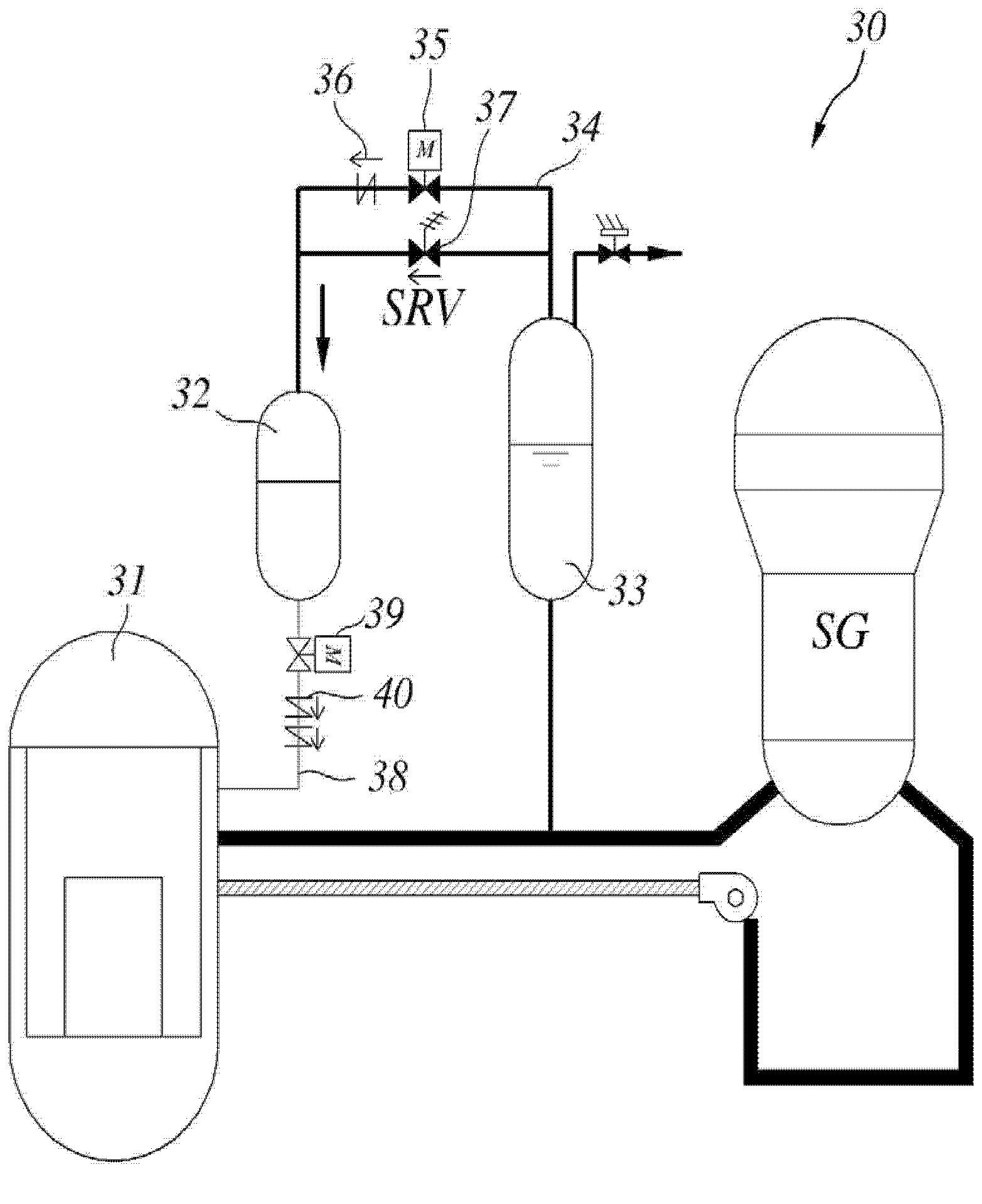

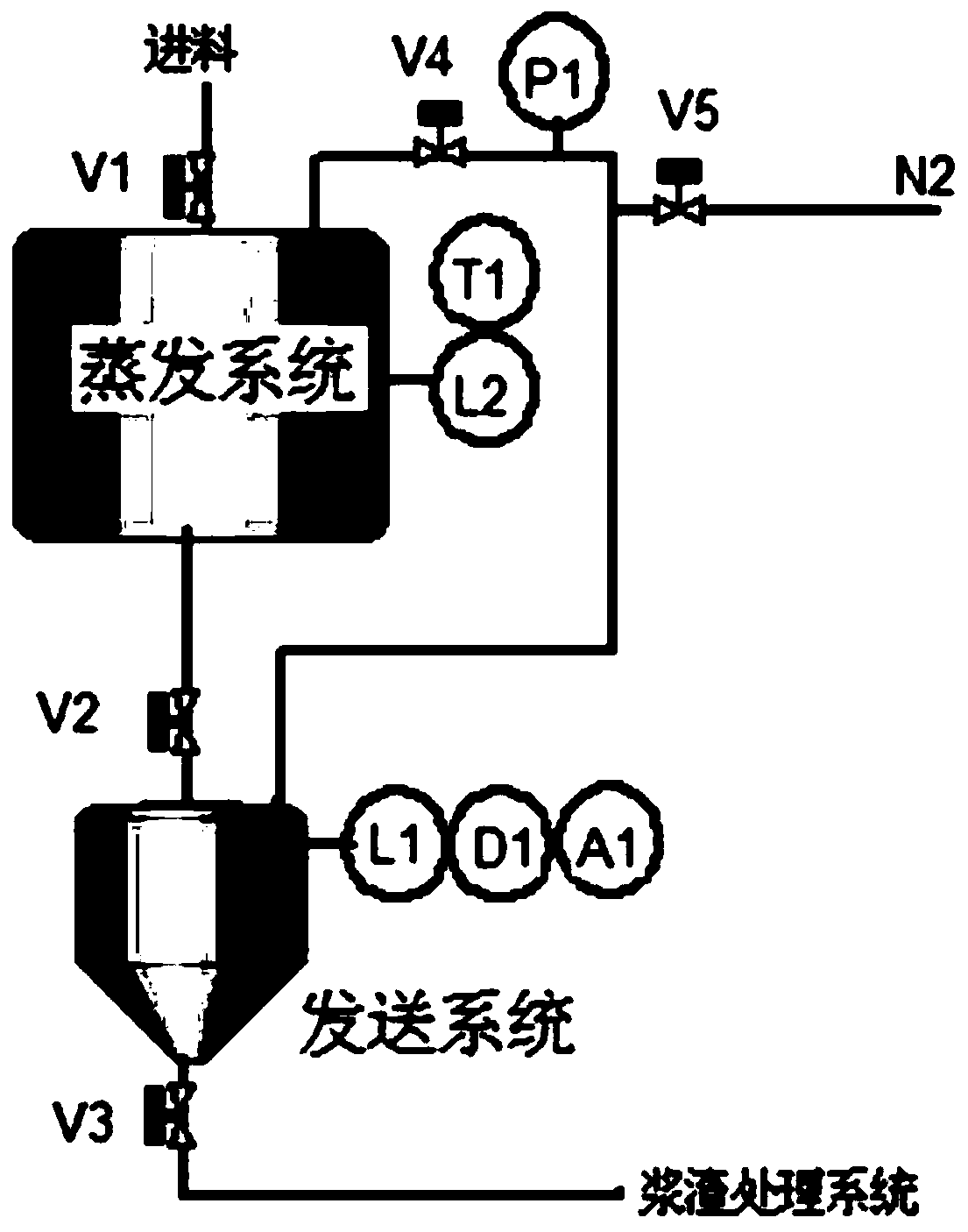

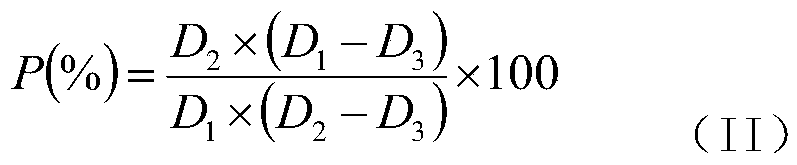

Method for automatically discharging silane slurry residue according to solid-containing content

ActiveCN110433507AEmission reductionReduce processingEvaporator regulation/controlSilanesEvaporation

The invention provides a method for automatically discharging silane slurry residue according to the solid-containing content. The method comprises the following steps that heavy component materials after the washing tower separation enters an evaporation system, the evaporation system is heated to evaporate light components, after concentration by the evaporation system, the slurry residue is discharged to a slurry residue sending system, and then the slurry residue is discharged; the discharge time interval of the slurry residue in the sending system is calculated according to the formula presented as the formula (I): T<n>=T<n-1>+T<n-1>*(P<0>-P<n-1>) / P<0> (I). The treatment of the silane slurry residue according to the method for automatically discharging the silane slurry residue according to the solid-containing content can effectively reduce the emission, the number of clogging is reduced, the production cost of organic silicon is saved, and at the same time, the requirements of energy saving and emission reduction is met; the method is a treatment method suitable for large-scale industrial popularization of the silane slurry residue.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

A low-voltage switch operating device

InactiveCN107578931AAvoid electric arc injury accidentsImprove reliabilityContact operating partsLow voltageManipulator

The invention belongs to the field of mechanical structures, and more specifically relates to a low-voltage switch operating device which includes a first joint, a pin, a second joint, a positioning bolt, a rotating rod and an operating rod. The first join and the second joint are rotatably connected by the pin; the second joint is screwed with the operating rod; the rotating rod goes through theoperating rod to be connected to the positioning bolt; the positioning bolt goes through the second joint to make contact with and abut closely against the first joint; and the rotating rod is a rotating rod member. According to the invention, through connecting the low-voltage switch operating device to an operating handle of the switch, pulling the low-voltage switch operating lever is equivalent to adding an extended manipulator to overcome the problems of the original operating handle being short, the operating distance being close and the operating requirements being great, thereby keeping a certain safety distance between operation and maintenance staff and the low-voltage switch, avoiding the accident of people being injured by the electric arc during arc burning, improving the reliability and safety of the operation of the low-voltage switch and effectively preventing the occurrence of electric arc injury accident.

Owner:QINGYUAN POWER SUPPLY BUREAU OF GUANGDONG POWER GRID CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com