Method for automatically discharging silane slurry residue according to solid-containing content

A technology of automatic discharge and solid content, applied in separation methods, chemical instruments and methods, evaporator adjustment/control, etc., can solve the problems of increased processing costs, less slurry discharge, increased raw material unit consumption, etc., to achieve reduction The effect of reducing the discharge of pulp and rejects, reducing the discharge of pulp and improving the utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) In the initial step, after the normal production of the monomer synthesis unit, the pulp residue is manually discharged twice, and the automatic program automatically records the discharge time interval and the solid content of the pulp residue discharged from the sending tank;

[0037] (2) Waiting step, after the slurry conveying is completed, the solid content automatic discharge slurry program is put into use, and the target value of the solid content of the slurry discharge is 50%, and the initial discharge interval is 5 hours. Calculate the time interval for discharging pulp and slag this time, and when the timing interval is reached, start the pulp and slag filling step;

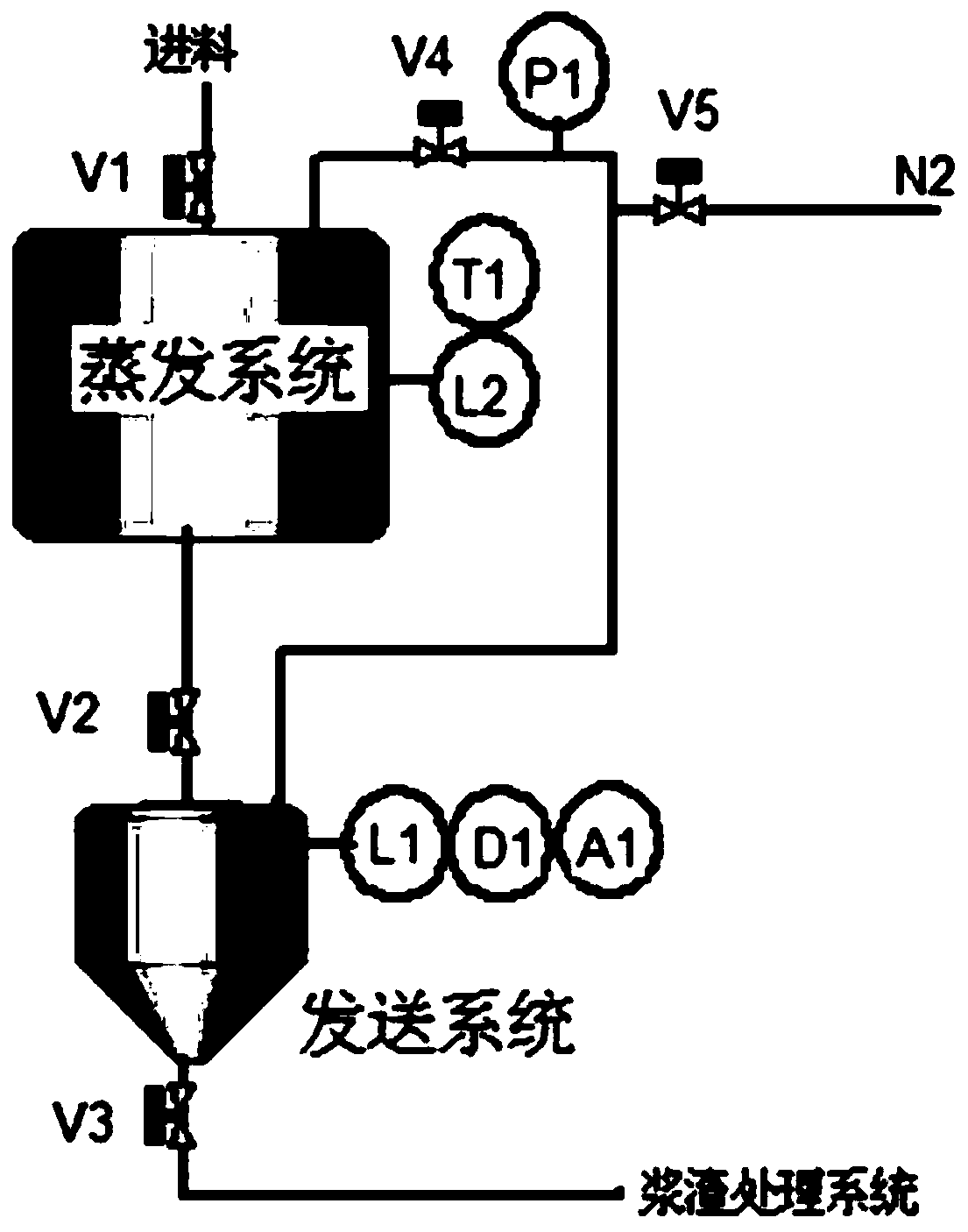

[0038] (3) Filling steps: detect that V2, V3, V4, and V5 are in the closed state; open V4, wait for 60s, and start the time interval timing for the next discharge of pulp and slag at the same time; open V2, and the material in the evaporation system is transported to the delivery system. Whe...

Embodiment 2

[0046] Other steps are consistent with embodiment 1, the difference is that the solid content target setting value is 45%. Table 2 is the 45% automatic discharge slurry slag statistics table of embodiment 2 solid content target setting value:

[0047] Table 2

[0048] serial number project unit Statistics 1 Emission times times / class 12.1 2 Average discharge solid content % 45.2 3 emissions kg / t monomer 17.6 4 Blocking times times / production cycle 0

Embodiment 3

[0050] The other steps are the same as in Example 1, except that the solid content target setting value is 55%, and the sending pressure value set in the automatic program sending step is optimized to 4.2 bar. Table 3 is the 55% automatic discharge slurry slag statistics table for embodiment 3 solid content target setting value:

[0051] table 3

[0052] serial number project unit Statistics 1 Emission times times / class 6.7 2 Average discharge solid content % 55.1 3 emissions kg / t monomer 11.8 4 Blocking times times / production cycle 0

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com