Well control method for high-pressure reservoir nitrogen well drilling

A nitrogen and reservoir technology, applied in wellbore/well components, earthwork drilling, flushing wellbore, etc., can solve the problem of inability to effectively ensure the safety of nitrogen drilling well control in high-pressure reservoirs, and inability to realize remote control of multi-channel blowout gate valves , complicated operation and other problems, to achieve the effect of realizing rapid wellhead control, satisfying well control safety, and increasing the drainage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

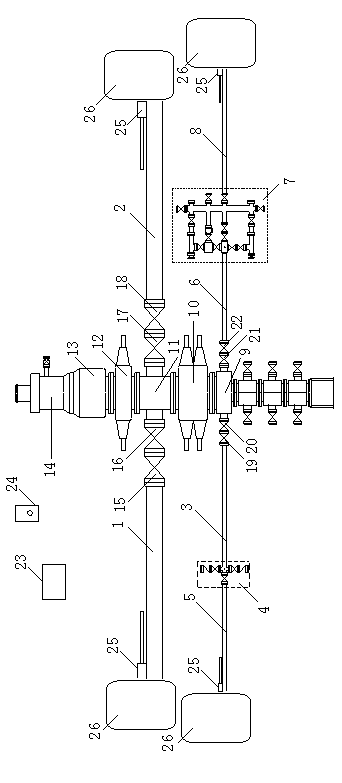

[0032] A well control method for nitrogen drilling in high-pressure reservoirs, comprising the following steps:

[0033] a. Connect the large-diameter multifunctional cross 11 in the well control equipment to the double-ram blowout preventer 10 and the single-ram blowout preventer 12 respectively;

[0034] b. During nitrogen drilling, when high-pressure and high-yield natural gas is encountered, press the shut-in button of the driller’s emergency button box 24 to issue a well shut-in command, and the PLC main control box 23 receives the well shut-in command, closes the annular blowout preventer 13, and starts Igniter 25 puts and sprays ignition;

[0035] c. Lower the pressure value of the annular blowout preventer 13 to 6MPa, adjust the height of the drilling tool, close the single ram blowout preventer 12, open the annular blowout preventer 13, and complete the well shut-in action.

[0036] This embodiment is the most basic implementation mode, "a, connect the large-diameter...

Embodiment 2

[0038] A well control method for nitrogen drilling in high-pressure reservoirs, comprising the following steps:

[0039] a. Connect the large-diameter multifunctional cross 11 in the well control equipment to the double-ram blowout preventer 10 and the single-ram blowout preventer 12 respectively;

[0040] b. During nitrogen drilling, when high-pressure and high-yield natural gas is encountered, press the shut-in button of the driller’s emergency button box 24 to issue a well shut-in command, and the PLC main control box 23 receives the well shut-in command, closes the annular blowout preventer 13, and starts Igniter 25 puts and sprays ignition;

[0041] c. Lower the pressure value of the annular blowout preventer 13 to 6MPa, adjust the height of the drilling tool, close the single ram blowout preventer 12, open the annular blowout preventer 13, and complete the well shut-in action.

[0042] In the step b, starting the igniter 25 to discharge and ignite refers to passing thro...

Embodiment 3

[0046] A well control method for nitrogen drilling in high-pressure reservoirs, comprising the following steps:

[0047] a. Connect the large-diameter multifunctional cross 11 in the well control equipment to the double-ram blowout preventer 10 and the single-ram blowout preventer 12 respectively;

[0048] b. During nitrogen drilling, when high-pressure and high-yield natural gas is encountered, press the shut-in button of the driller’s emergency button box 24 to issue a well shut-in command, and the PLC main control box 23 receives the well shut-in command, closes the annular blowout preventer 13, and starts Igniter 25 puts and sprays ignition;

[0049] c. Lower the pressure value of the annular blowout preventer 13 to 6MPa, adjust the height of the drilling tool, close the single ram blowout preventer 12, open the annular blowout preventer 13, and complete the well shut-in action.

[0050] In the step b, starting the igniter 25 to discharge and ignite refers to passing thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com