Core rod locking-type safety syringe

A safety syringe and locking technology, applied in the field of medical devices, can solve problems such as accidental injury, waste of manpower and funds, unreasonable design structure, etc., to achieve the effect of ensuring automated mass production, avoiding accidental injury, and reasonable design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the accompanying drawings.

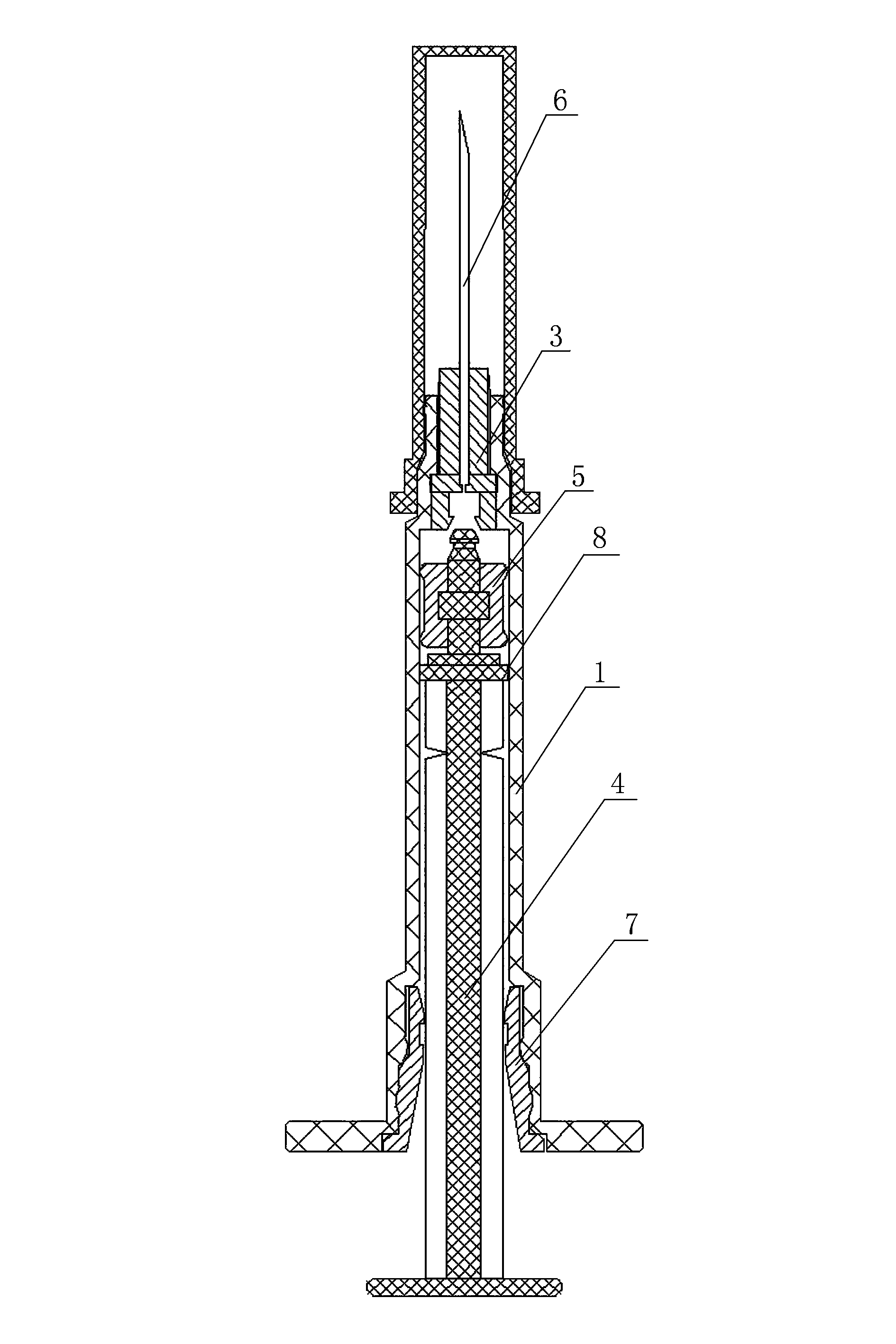

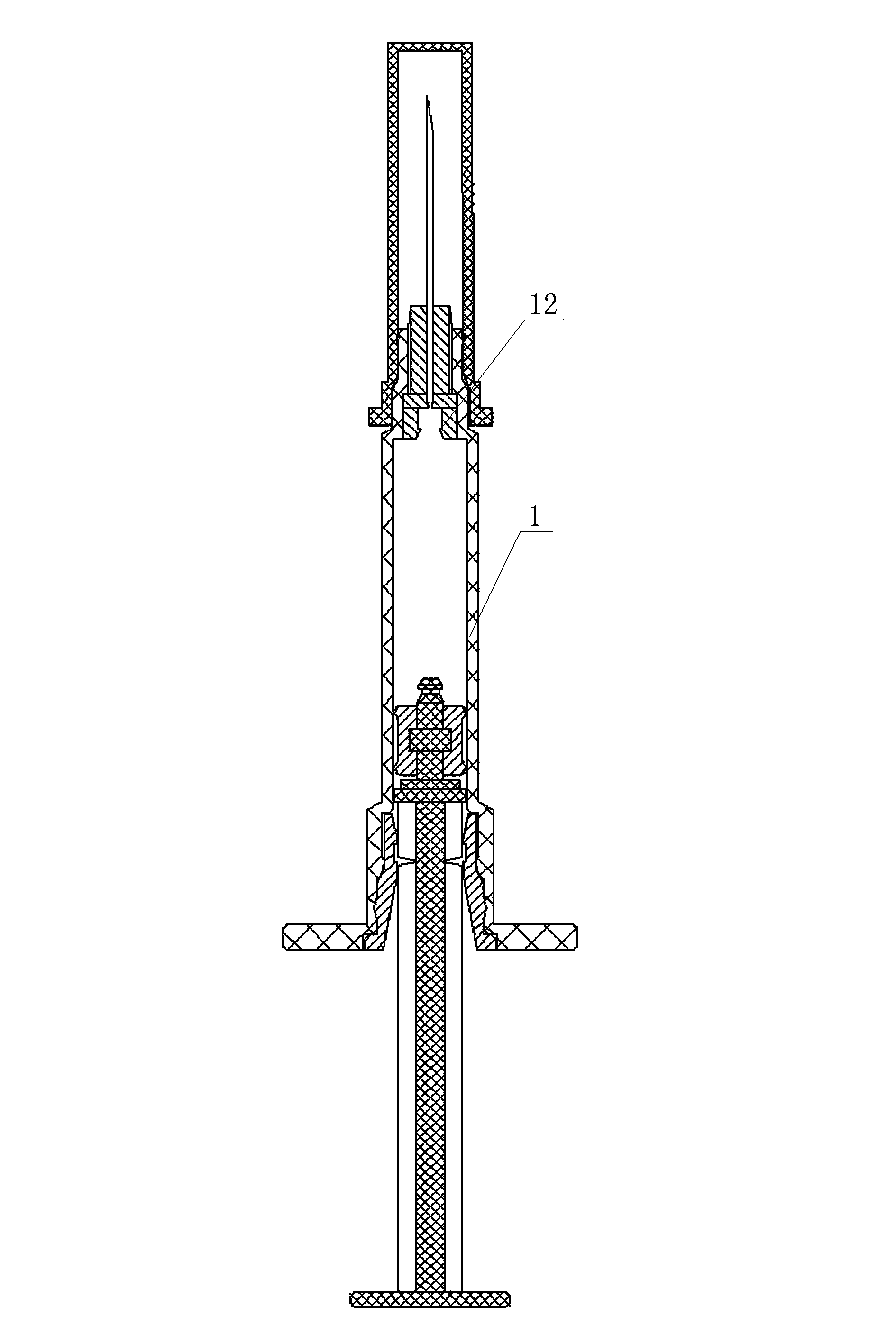

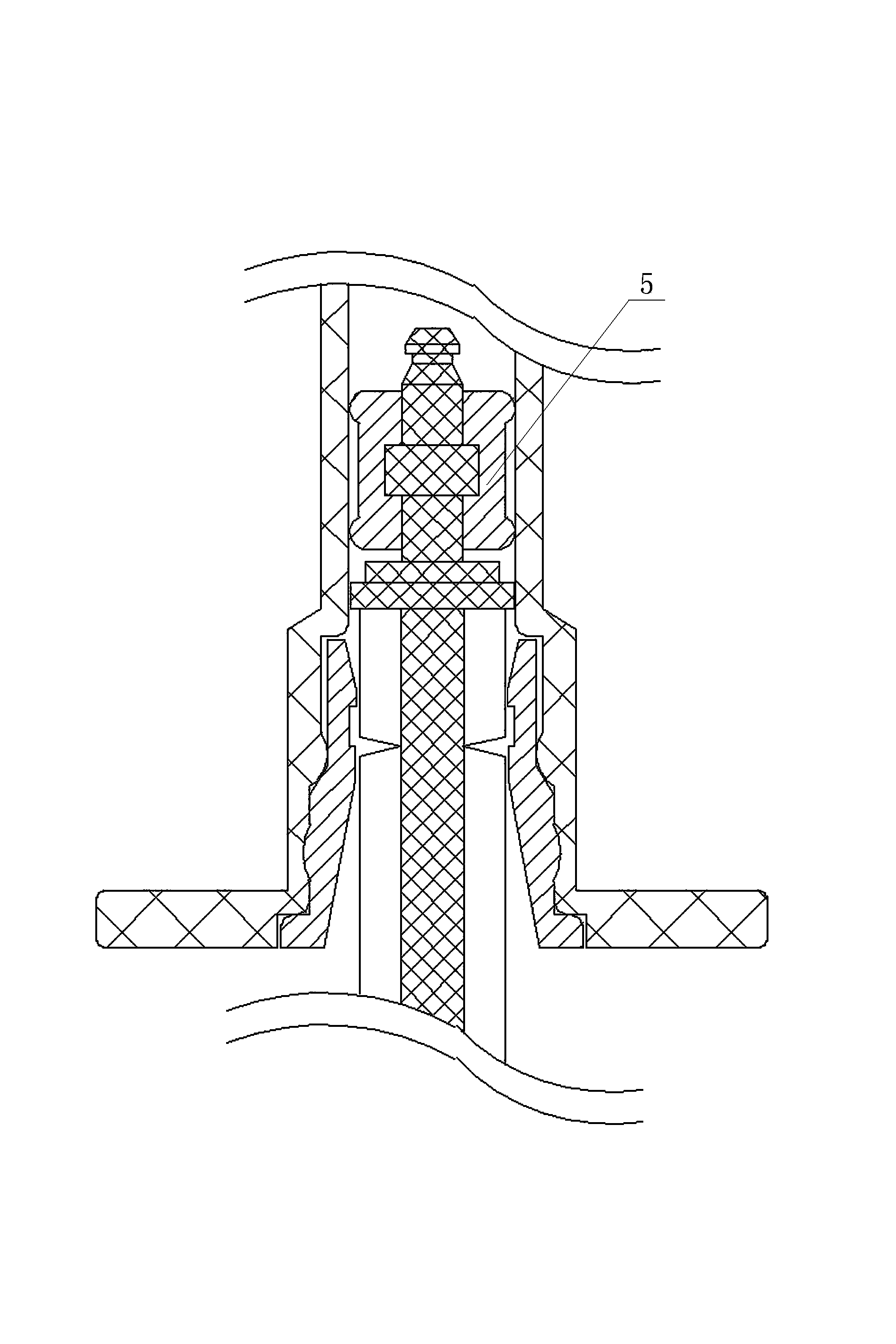

[0029] The present invention is a kind of plunger locking safety syringe, such as figure 1 As shown in , it includes a cylinder body 1, a needle seat 3 is provided in the cylinder neck 2 at the upper end of the cylinder body 1, a core rod 4 is provided inside the cylinder body 1, and a rubber plug 5 is sleeved near the upper end of the core rod 4, The upper end of the needle base 3 is provided with a needle tube 6, which is different from the prior art in that: the inner cavity at the lower end of the needle base 3 is provided with a locking part 9, and the end of the core rod 4 forms a locking pull-back that matches the locking part. Part 10, the inner cavity of the cylinder body 1 near the lower end is provided with a core rod locking piece 7, and the core rod 4 is provided with a self-locking piece 8 that cooperates with the core rod locking piece 7.

[0030] In spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com