Battery temperature rise rate alarm method

A heating rate, battery technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problem that the battery temperature change cannot be alarmed in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

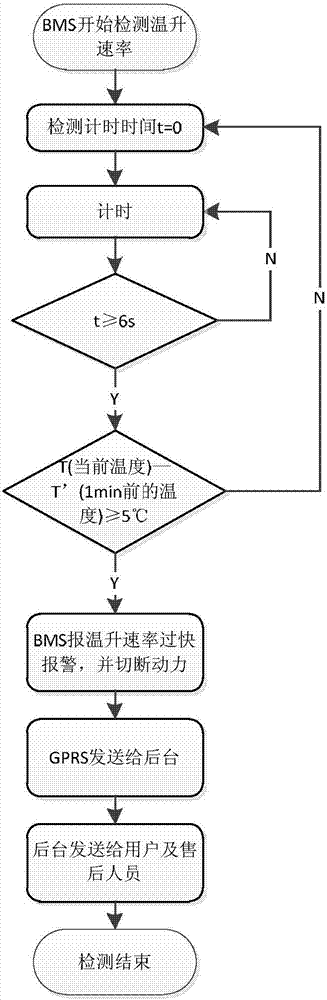

[0035] A battery temperature rise rate alarm method is applicable to the battery of an electric vehicle equipped with a BMS. The electric vehicle communicates with the background through a wireless network, comprising the following steps:

[0036] Step 1: BMS starts to detect the heating rate;

[0037] Step 2: BMS starts timing, timing time t=0, and at the same time, record the current temperature values T of all monomers;

[0038] Step 3: start timing;

[0039] Step 4: When t ≥ the set interval, record the temperature values T' of all monomers at this time; the default value of the set interval is 6 seconds.

[0040] Step five: Calculate T-T' according to the current temperature value, if T-T'≥ the calibration temperature value, then perform step six, if T-T'

[0041] Step 6: The BMS reports that the temperature rise rate is too fast and alarms, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com