Ion exchange system for producing functional oligosaccharide and using method thereof

A functional oligosaccharide and ion exchange technology, applied in amphoteric ion exchange, ion exchange, ion exchange treatment devices, etc., can solve the problems of uneven quality of water consumption products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Galacto-oligosaccharides (GOS for short) are saccharified into feed liquid (component GOS≥55%), decolorized and filtered to obtain galacto-oligosaccharides, and the light transmittance of galacto-oligosaccharides (440nm, 30%)≥ 95%, conductivity 400μs / cm, PH4.68;

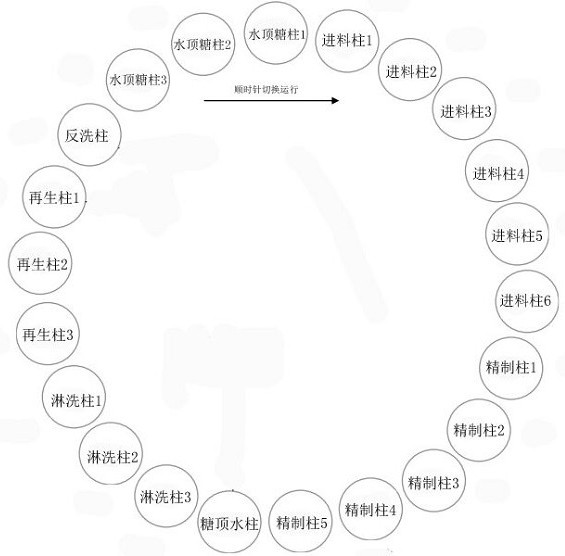

[0045] (2) Refining: The galacto-oligosaccharide feed liquid is fed from the upper end of the feed column 1-6 of the cation exchange resin system respectively, and after treatment, enters the anion exchange resin system respectively through the lower end of the feed column 1-6 of the cation exchange resin system. The upper end of the material column 1-6, after treatment, the lower end of the anion exchange resin system feed column 1-6 enters the upper end of the refining column 1-5 of the cation exchange resin system and the upper end of the sugar top water column, and is refined by the cation exchange resin system after treatment The lower end of the column 1-5 and the lower end of the sugar top water col...

Embodiment 2

[0056] (1) Isomaltooligosaccharide (IMO for short) is saccharified and the feed liquid (component IMO≥50%) is decolorized and filtered to obtain isomaltooligosaccharide, and the light transmittance of isomaltooligosaccharide (440nm, 30%)≥ 95%, conductivity 450μs / cm, PH4.95;

[0057] (2) Refining: Isomaltose oligomeric feed liquid is fed from the upper end of the feed column 1-6 of the cation exchange resin system respectively, and after treatment, enters the anion exchange resin system respectively through the lower end of the feed column 1-6 of the cation exchange resin system. The upper end of the material column 1-6, after treatment, the lower end of the anion exchange resin system feed column 1-6 enters the upper end of the refining column 1-5 of the cation exchange resin system and the upper end of the sugar top water column, and is refined by the cation exchange resin system after treatment The lower end of the column 1-5 and the lower end of the sugar top water column e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com