Dual or multi-shaft vacuum pump

A vacuum pump, emergency technology, applied in the direction of pumps, pump components, pump control, etc., can solve the problem that the lubricant cannot be completely far away from the pump, complicated, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

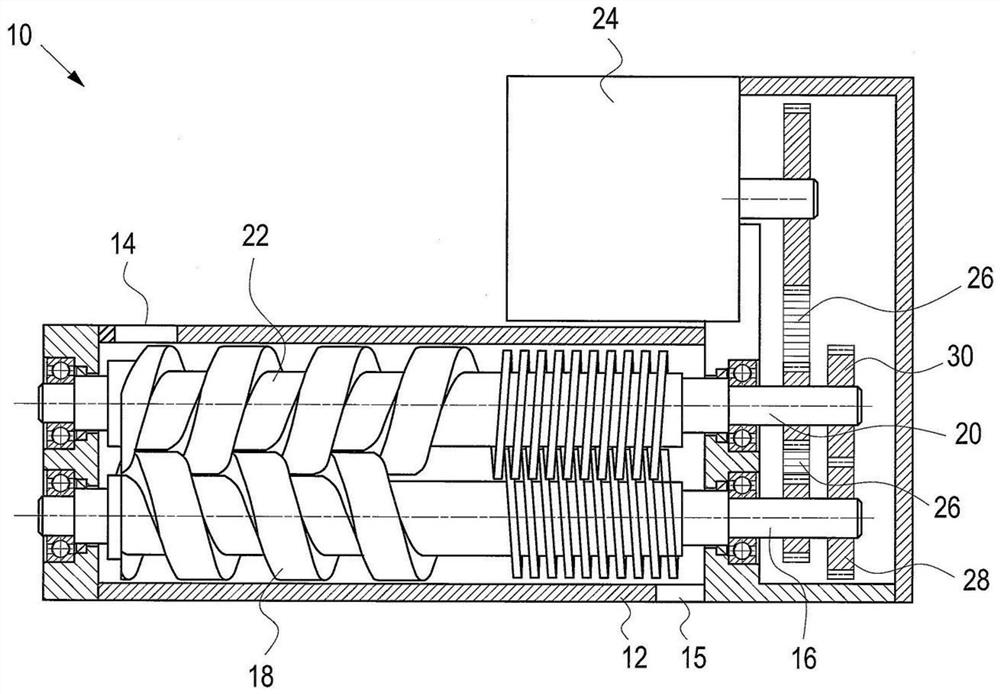

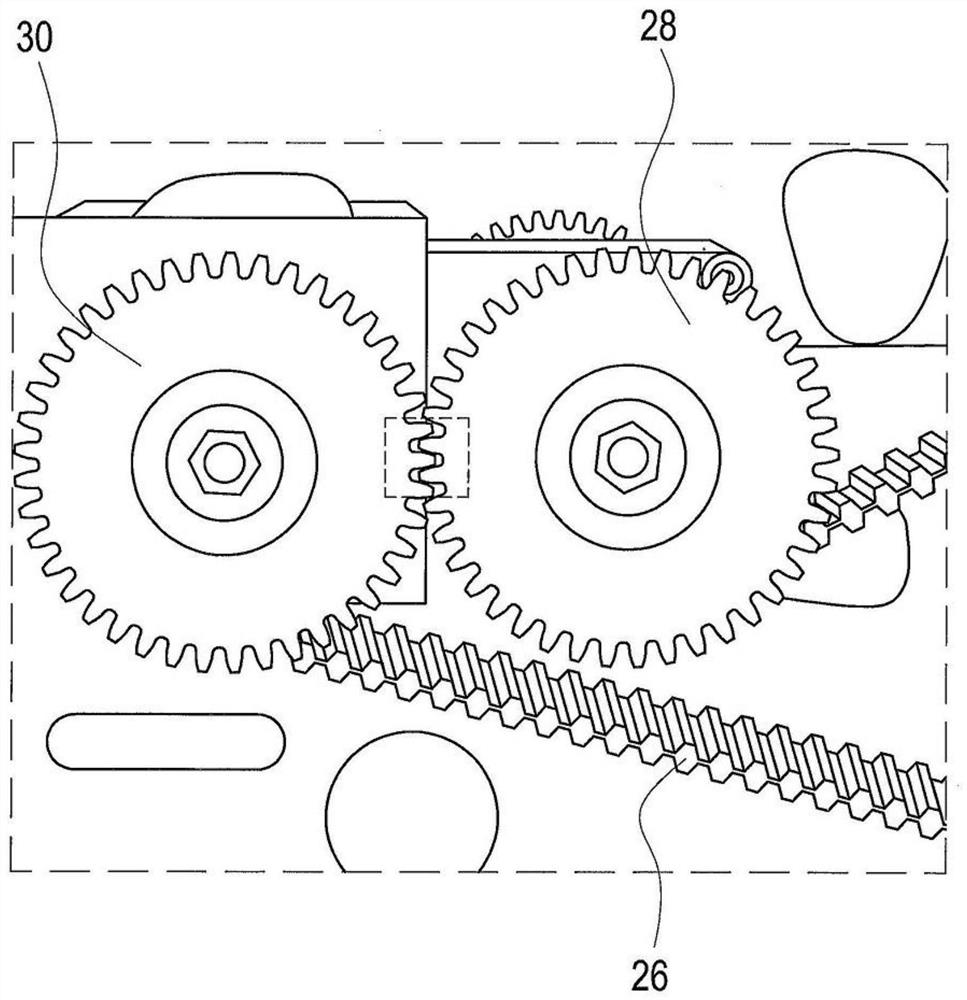

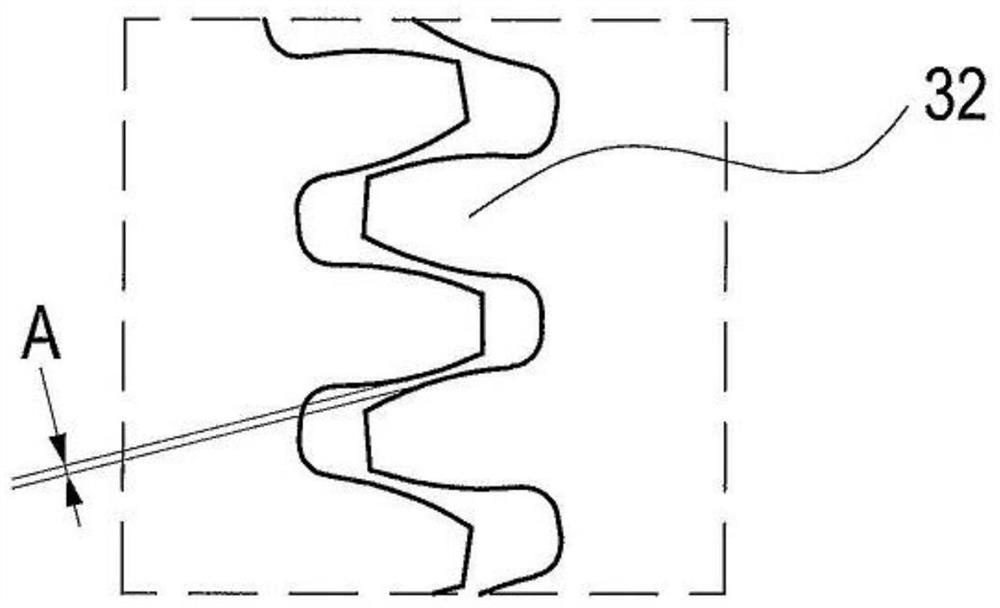

[0023] The vacuum pump 10 according to the invention is designed as a screw pump comprising a housing 12 with an inlet 14 and an outlet 15 . In the example shown, the first shaft 16 is arranged in the housing 12 and the first pump element 18 is designed as a screw body. Furthermore, a second shaft 20 is arranged in the housing 12 , the second shaft 20 having a second pump body 22 likewise designed as a screw body. The first pump member 18 and the second pump member 22 mesh with each other. Furthermore, a motor 24 is provided, which can be designed as an electric motor. The first shaft 16 and the second shaft 20 are respectively rotated or driven by a motor 24 by means of a drive belt 26 . The rotation of the shafts 16, 20 is performed in opposite directions, so that the gaseous medium is conveyed from the inlet 14 to the outlet. In order to generate an effective vacuum, the distance between the pump elements 18, 22 is required to be very small. At the same time, the pump e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com