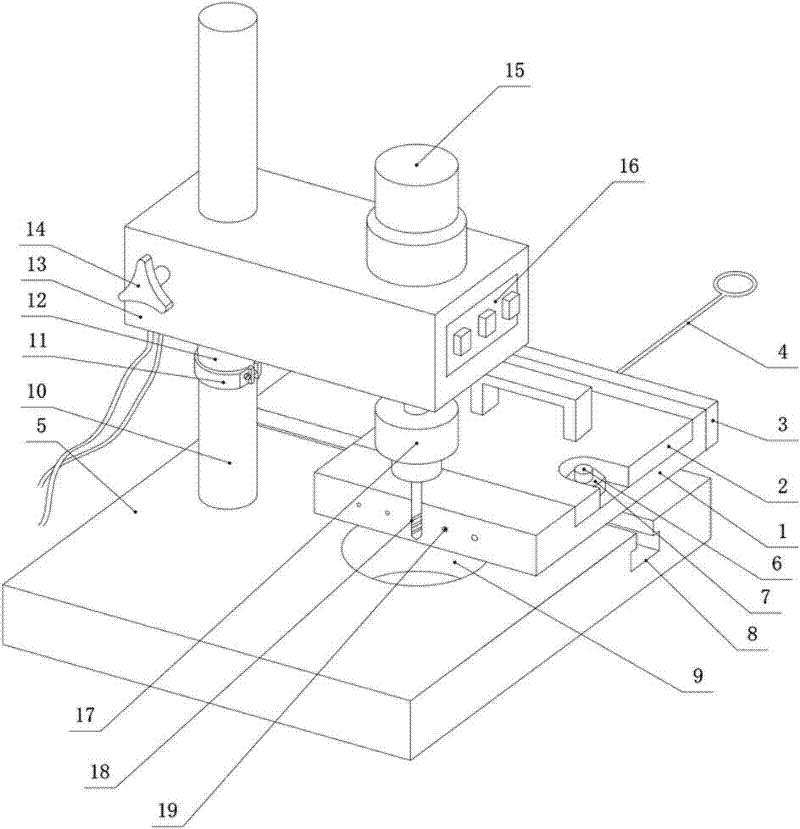

Rapid preparation device for small particle size gunpowder stabilizer content analysis sample

A technology for analyzing samples and preparing devices, which is applied in the field of rapid preparation devices for analyzing samples of small particle size gunpowder stabilizers, can solve the problems of poor uniformity of test pieces, polluted environment by waste liquid, difficulty in manual cutting, etc., so as to improve the quality , the effect of avoiding accumulation and shortening solvent extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

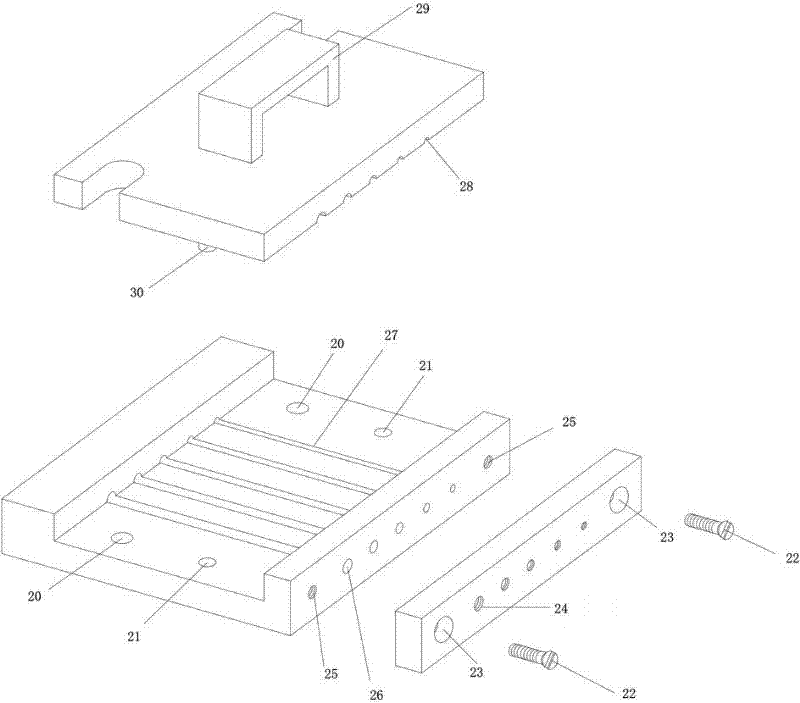

Embodiment 1

[0039] The base of the feeder (1) is made of stainless steel, and its front end is the discharge hole section, which is 20mm long. There are five discharge holes (19) with different diameters, and the inner diameters are Φ2.4mm, Φ2.2mm, Φ2.0mm, Φ1.8mm, Φ1.6mm, the distance between adjacent shaft centers is 12mm, suitable for processing medicine particles with different diameters, the discharge hole section is quenched, and the front end of the discharge hole section is close to the cutter; the feeder base ( 1) The bottom is 80mm long, and there are 5 troughs (27) on it. The troughs (27) are semicircular troughs that are concentric with the discharge hole (19) and have the same hole diameter. Connected horizontally with the screw channel (26), the inner diameters are Φ2.4mm, Φ2.2mm, Φ2.0mm, Φ1.8mm, Φ1.6mm, and the distance between adjacent shaft centers is 12mm; the bottom two sides of the feeder base (1) There are positioning holes (21) on the sides respectively, with an inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com