Safe organic waste gas heat storage, catalysis and oxidation device

An organic waste gas, catalytic oxidation technology, applied in incinerators, combustion types, lighting and heating equipment, etc., can solve the problems of long heating time, high investment cost, and heavy equipment weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

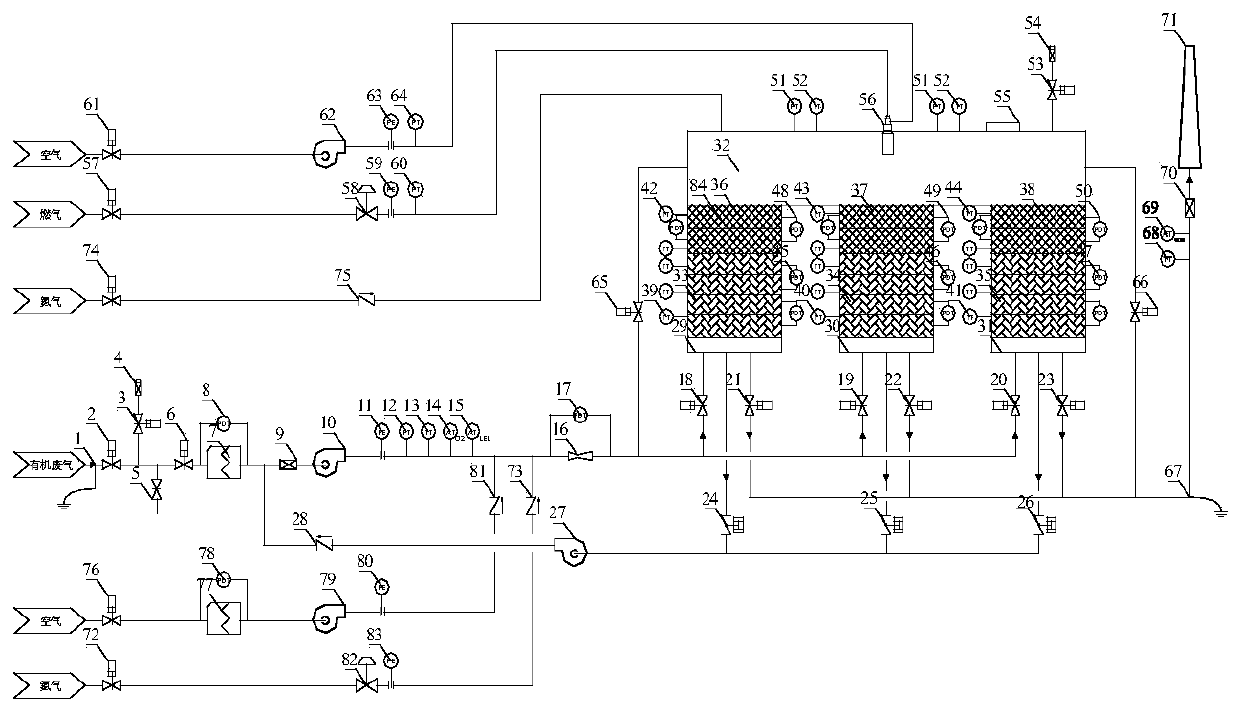

[0040] Attached below in conjunction with the instructions figure 1 The technical scheme, operation mode and control program of a safety type organic waste gas thermal storage catalytic oxidation device of the present invention are further described in detail with specific embodiments.

[0041] The present invention is a safe type organic waste gas heat storage catalytic oxidation device, including: grounding and anti-static system, emergency emptying system, pretreatment system, fire prevention system, pressurized fan, anti-backfire system, heat storage catalytic oxidation reactor And supporting heat storage body, catalyst, heating system, purge system, air supply system, emergency fire extinguishing system, oxidation temperature adjustment system, explosion venting system, bypass system, supporting instrument and control program, and discharge cylinder.

[0042] The grounding and anti-static system is used to protect the grounding and anti-static of the device to avoid the accumu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com