Preparation method of large-area and continuous graphen/zinc oxide composite structure

A composite structure, graphene technology, applied in zinc oxide/zinc hydroxide and other directions, can solve the problem of not forming three-dimensional space composite, and achieve the effects of low equipment requirements, strong process repeatability, and good process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of graphene oxide: Using the improved Hummer method, take 98% concentrated sulfuric acid, cool at low temperature, add a certain amount of natural flake graphite, NaNO 3 and KMnO 4 , control the temperature of the reaction solution at 0-10°C, stir the reaction for 5 hours, then carry out the high-temperature reaction, control the temperature of the reaction solution within 100°C, and continue stirring for 30 minutes. Dilute the reaction solution with deionized water and add appropriate amount of H 2 o 2 , filtered while hot, fully washed with deionized water until there was no SO in the filtrate 4 2- . Weigh 0.0030 g of graphite oxide into a beaker, add deionized water to make a 100 ml solution, and then ultrasonically disperse the solution for 60 minutes to obtain a graphene oxide solution.

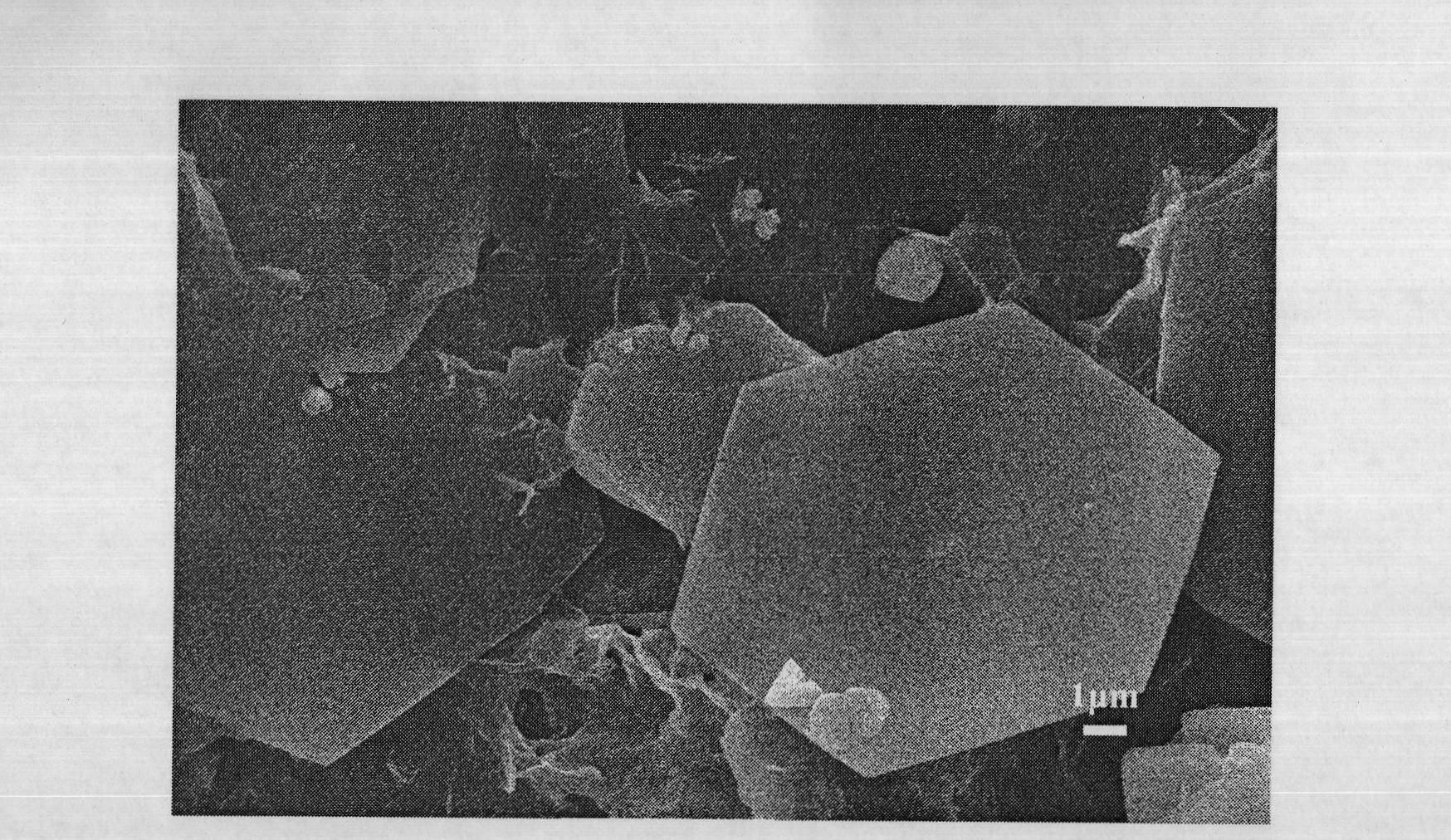

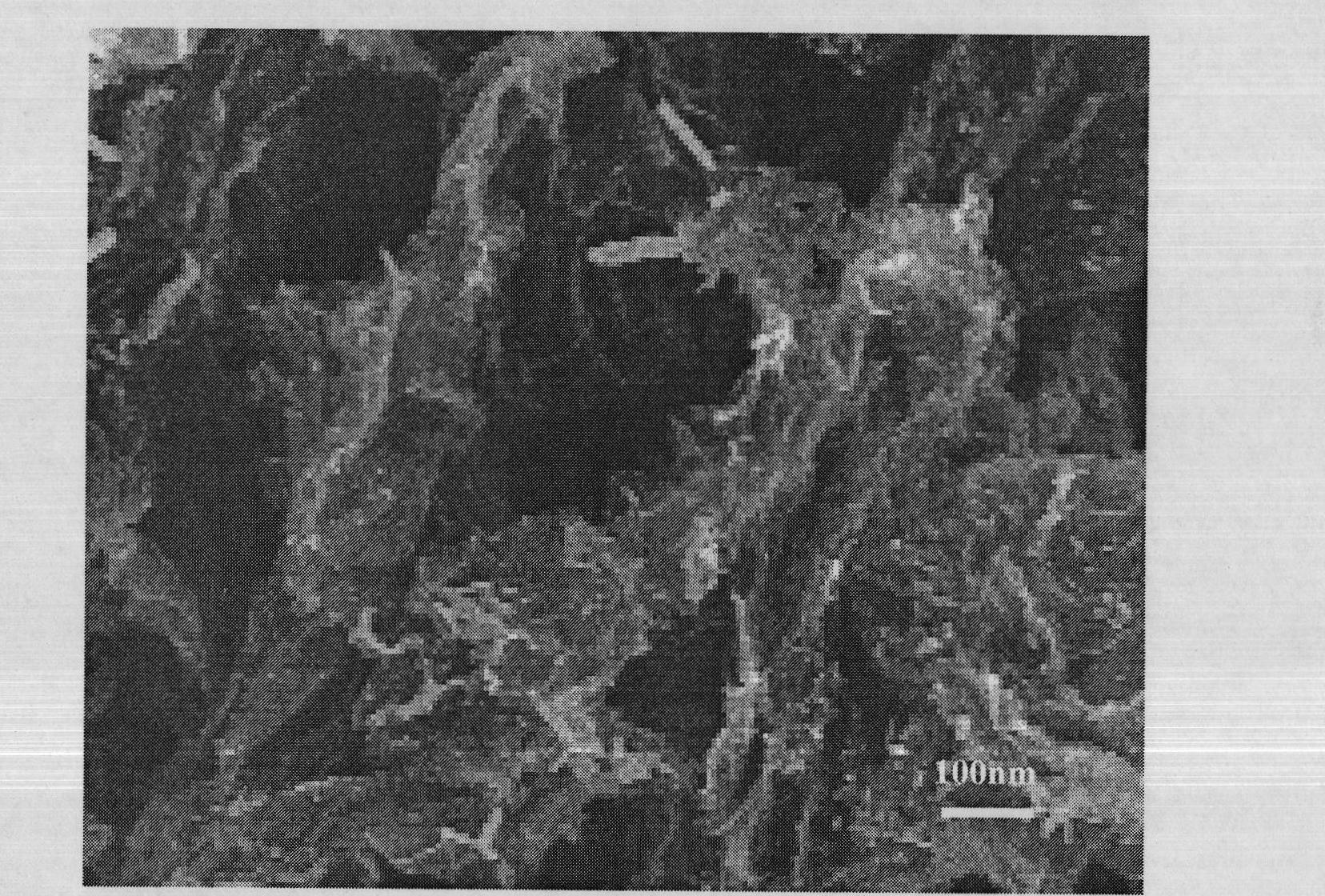

[0026] Weigh 0.1910g of zinc nitrate and 0.1518g of hexamethylenetetramine into the solution, continue ultrasonication for 10 minutes, and then put the solution i...

Embodiment 2

[0028] Embodiment two: the preparation of graphene: Utilize the improved Staudenmaier method to add natural flake graphite in the mixed solution of 98% concentrated sulfuric acid and nitric acid, stir and add potassium nitrate, control the reaction liquid temperature 0-10 ℃, stir reactant 24 hours Obtain graphite oxide. Dilute the reactant, filter, and wash thoroughly with deionized water until there is no SO in the filtrate 4 2- , and then dried, ground and sieved, and rapidly heat-treated at 1100°C to obtain single-layer or several-layer graphene flakes.

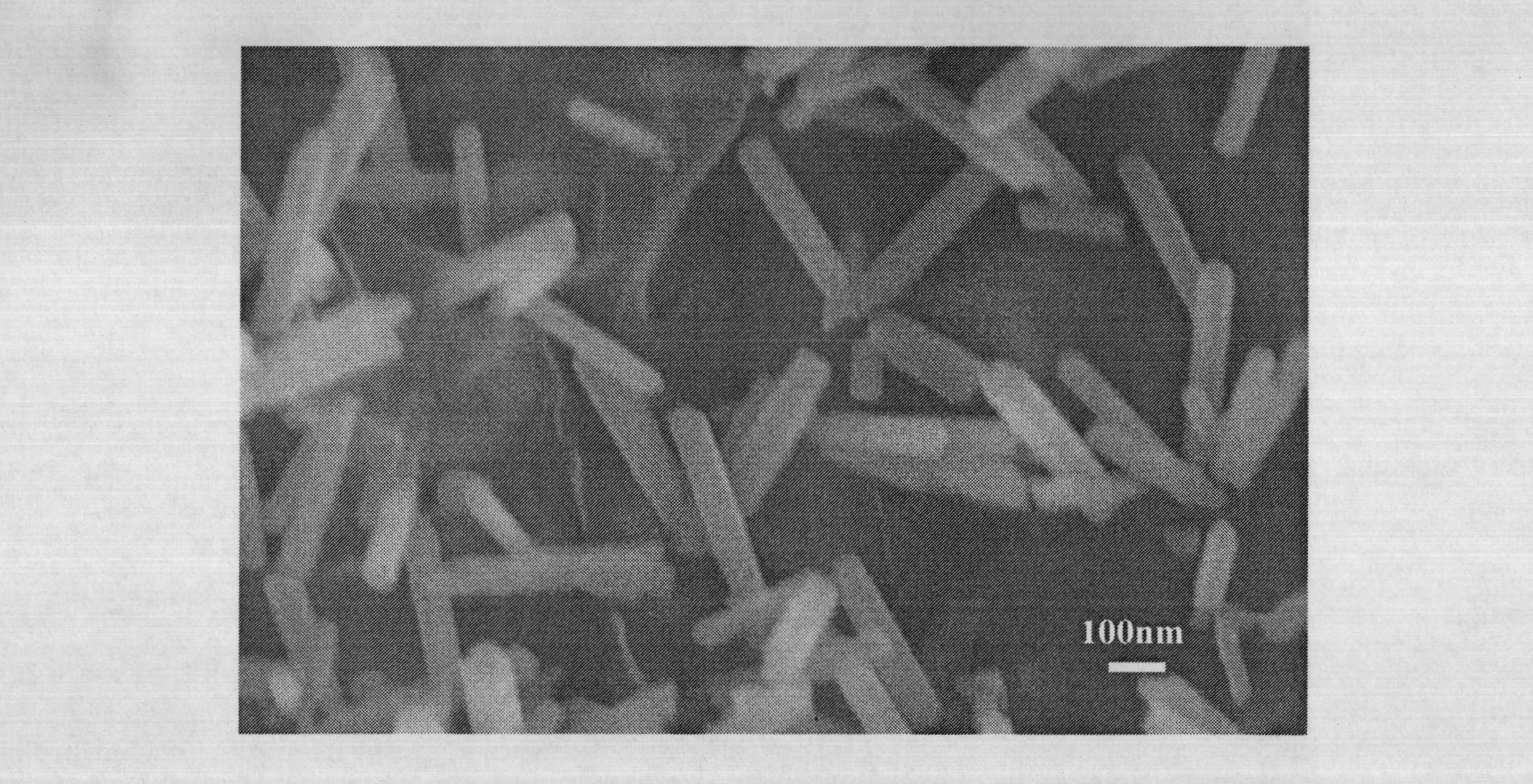

[0029] Weigh 0.012g of graphene into a beaker, add deionized water to make a 100ml solution, and then ultrasonically disperse the solution at 20°C for 30 minutes. Weigh 0.1910g of zinc acetate, pour 0.1518g of hexamethylenetetramine into the solution, and continue ultrasonication for 30 minutes, wherein the molar ratio of graphene to zinc ions is about 1:1. Then put the solution in an oven at 70°C and react for 1 hour t...

Embodiment 3

[0030] Embodiment three: the preparation of graphene: Utilize the improved Staudenmaier method to add natural flake graphite in the mixed solution of 98% concentrated sulfuric acid and nitric acid, stir and add potassium nitrate, control the reaction liquid temperature 0-10 ℃, stir reactant 24 hours Obtain graphite oxide. Dilute the reactant, filter, and wash thoroughly with deionized water until there is no SO in the filtrate 4 2- , and then dried, ground and sieved, and rapidly heat-treated at 1100°C to obtain single-layer or several-layer graphene flakes.

[0031] Weigh 0.012g of graphene into a beaker, add deionized water to make a 1000ml solution, add 0.5ml of ammonia water dispersant, and then ultrasonically disperse the solution for 1 hour. Weigh 2.989g of zinc nitrate and 1.407g of hexamethylenetetramine into the solution, and continue ultrasonication for 1 hour. The molar ratio of graphene to zinc ions is about 1:15. Then the solution was put into an oven at 90° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com