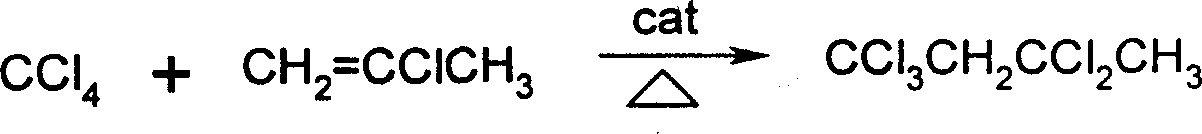

Method for preparing 1,1,1,3,3 - pentachlorobutane from materials of chloropropene and carbon tetrachloride under tempering and polymerizing catalyst

A technology of carbon tetrachloride and pentachlorobutane, applied in 1 field, can solve the problems of increased production cost, potential safety hazard, reaction temperature and reaction pressure, and achieves the effects of reduced production cost, reduced potential safety hazard, and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] With ferrous chloride as the main catalyst and triethyl phosphite as the co-catalyst, the reaction temperature is 95°C, and the molar ratio of the materials is: carbon tetrachloride / 2-chloropropene / ferrous chloride / triethyl phosphite Ester=1:0.4:0.02:0.02; the reaction time is 5 hours, and the reaction pressure is ≤0.45MPa. GC analysis was performed after the reaction, and the conversion rate of 2-chloropropene was 98%, and the selectivity of 1,1,1,3,3-pentachlorobutane based on 2-chloropropene was 95%.

Embodiment 2

[0041] With iron and ferric chloride as the main catalyst, trimethyl phosphate as the co-catalyst, the reaction temperature is 85°C, and the molar ratio of the materials is: carbon tetrachloride / 2-chloropropene / iron and ferric chloride / trimethyl phosphate Ester=1:0.4:0.03:0.02; the reaction time is 6 hours, and the reaction pressure is ≤0.40MPa. GC analysis was performed after the reaction, and the conversion rate of 2-chloropropene was 98%, and the selectivity of 1,1,1,3,3-pentachlorobutane based on 2-chloropropene was 95%.

Embodiment 3

[0043] Iron and ferric chloride are used as the main catalyst, and mixed esters of triethyl phosphate and tributyl phosphate are used as co-catalysts. The reaction temperature is 85°C, and the molar ratio of materials is: carbon tetrachloride / 2-chloropropene / iron And ferric chloride / phosphoric acid mixed ester=1:0.4:0.03:0.02; the reaction time is 6 hours, and the reaction pressure is ≤0.35MPa. GC analysis was performed after the reaction, and the conversion rate of 2-chloropropene was 99%, and the selectivity of 1,1,1,3,3-pentachlorobutane based on 2-chloropropene was 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com