Solvent-free process method for continuously producing methyl hydrogen silicone oil

A technology of methyl hydrogen-containing silicone oil and a process method, which is applied in the field of solvent-free continuous production of methyl hydrogen-containing silicone oil, can solve the problems of low product production efficiency, unstable product quality, large production consumption, etc., and achieves good product quality, Change the effect of low product efficiency and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

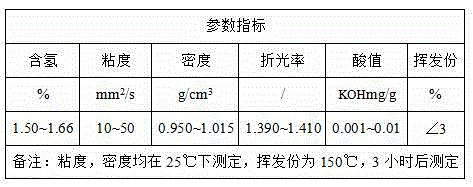

[0054] The invention relates to a solvent-free continuous production process of methyl hydrogen-containing silicone oil, especially a preparation method for producing finished methyl hydrogen-containing silicone oil by using organic silicon monomer production by-products as raw materials. The preparation method is similar to the existing patent documents The difference between CN102516545B, CN103554502A, CN102030905B, CN102643428A, and CN103788377A is that this preparation method not only changes the defects of low product efficiency, unstable quality and the introduction of organic solvents in traditional production in the traditional batch method, but also can achieve the purpose of saving energy and reducing consumption , Reduce environmental pollution and other characteristics, but also has many advantages such as reducing production costs, shortening production cycles, improving product quality, increasing finished product yield, strong industrial operation safety, and has ...

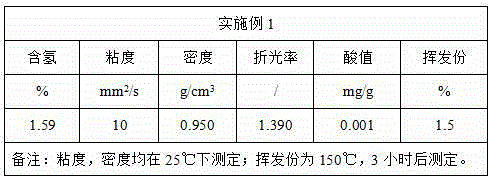

Embodiment 1

[0073] In this embodiment, methyldichlorosilane and trimethylmonochlorosilane with a weight ratio of 10:1 are selected as raw materials. In the initial stage of the reaction, a hydrochloric acid solution with a concentration of 10% is added to the tubular reactor. The specific steps are as follows:

[0074] (a) Hydrolysis: Send methyldichlorosilane and trimethylmonochlorosilane into a mixing tank in proportion to mix to form a monomer mixture, and then continue to add the monomer mixture and water in a ratio of 1:1 by weight Carry out the reaction of the hydrolysis loop in the tubular reactor, and obtain the acidic hydrolyzate, wherein, the weight ratio of the hydrochloric acid solution and the monomer mixture is 1:1, as the reaction continues, the added monomer mixture and low molecular weight silicone oil The weight ratio is 1:0.1, the average residence time of the control hydrolysis loop is 30min, and the reaction temperature is 5°C.

[0075] (b) Stratification: The acidic ...

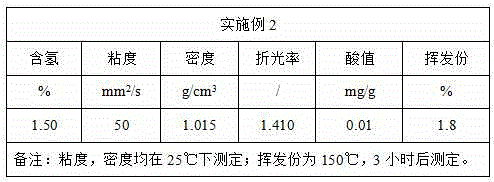

Embodiment 2

[0087] In this embodiment, methyldichlorosilane and trimethylmonochlorosilane with a weight ratio of 60:1 are selected as raw materials. In the initial stage of the reaction, a hydrochloric acid solution with a concentration of 30% is added to the tubular reactor. The specific steps are as follows:

[0088] (a) Hydrolysis: Send methyldichlorosilane and trimethylmonochlorosilane into a mixing tank in proportion to mix to form a monomer mixture, and then continuously add the monomer mixture and water in a ratio of 1:5 by weight Carry out the reaction of the hydrolysis loop in the tubular reactor, and obtain the acidic hydrolyzate, wherein, the weight ratio of the hydrochloric acid solution and the monomer mixture is 1:5, as the reaction continues, the added monomer mixture and low molecular weight silicone oil The weight ratio is 1:0.5, the average residence time of the controlled hydrolysis loop is 90min, and the reaction temperature is 30°C.

[0089] (b) Stratification: The ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity value | aaaaa | aaaaa |

| Acidity value | aaaaa | aaaaa |

| Acidity value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com