Method for treating heavy metal industrial sewage

A technology for industrial wastewater and treatment methods, which is applied in metallurgical wastewater treatment, water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problems of large area occupied by the sedimentation system, limited separation effect, long sedimentation time, etc., to achieve The effect of low operating cost, reduced equipment footprint and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

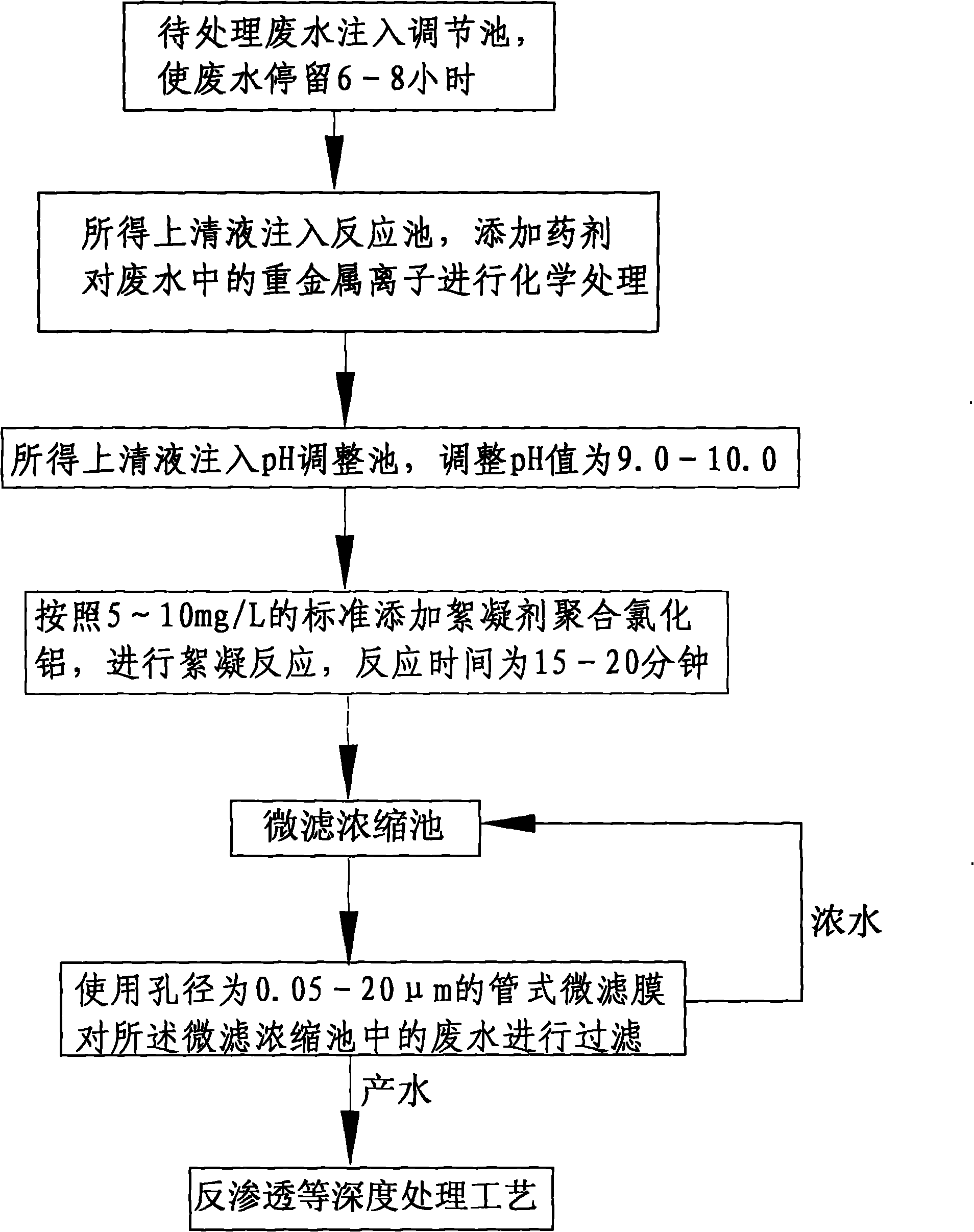

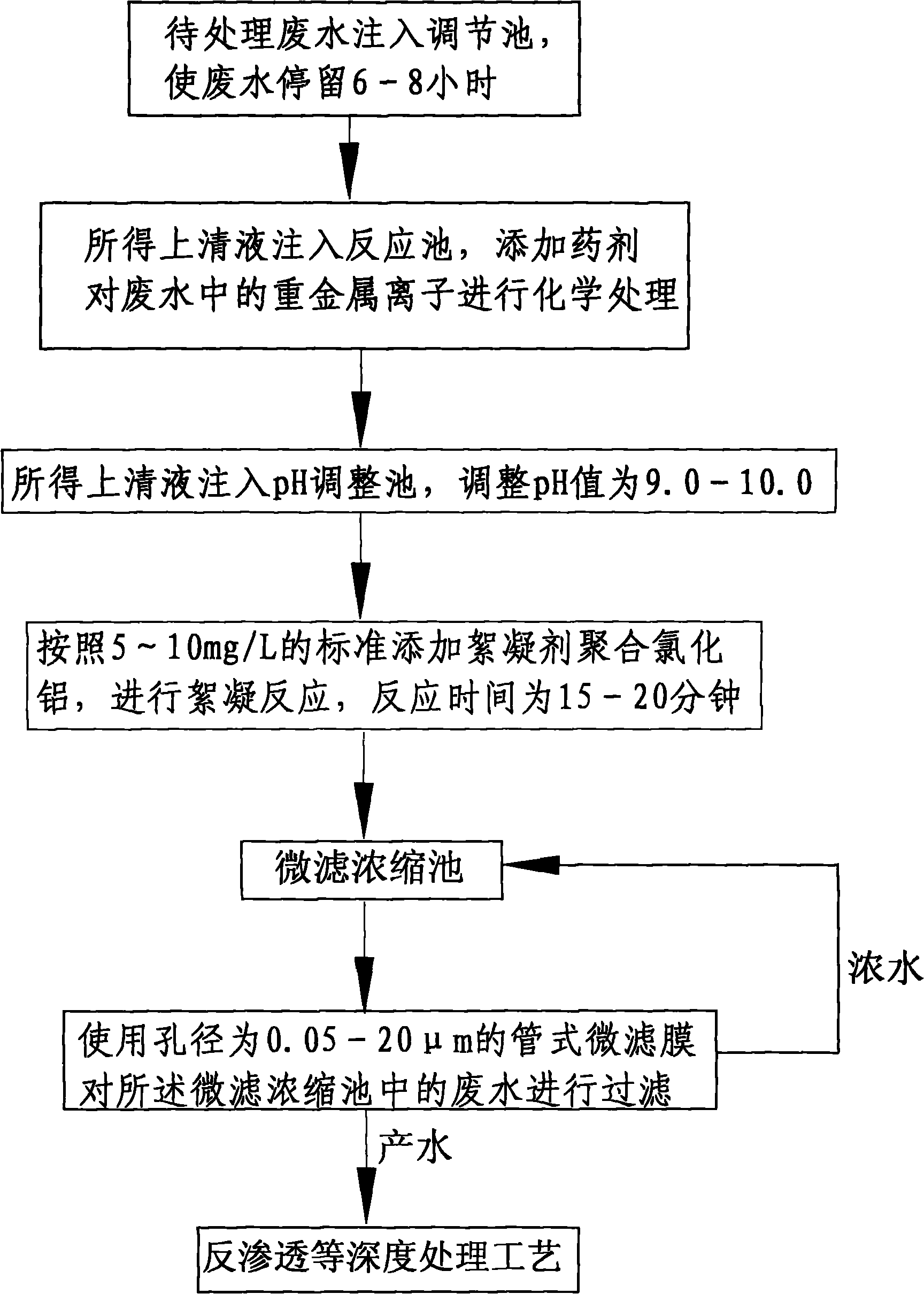

[0018] Refer to attached figure 1 , in the treatment method of a kind of heavy metal industrial waste water of the present invention, after the waste water enters the adjustment tank, balance water quality and water quantity; The aeration pipe of the aeration pipe is used to aerate the wastewater to be treated intermittently or regularly at a frequency of 1 to 3 times a day, 1 to 4 hours each time, to prevent anaerobic odor of the wastewater, and to uniform the water quality and quantity of the wastewater to be treated, ensuring The water quality stability of the system feed water, the adjustment time of the adjustment tank is determined according to the production characteristics, and the general design residence time is 6 to 8 hours;

[0019] The supernatant obtained in step a is injected into the reaction tank, and the heavy metal ions in the waste water are chemically reacted by adding medicaments. The medicaments can be ferrous sulfate, sodium bisulfite, sodium hypochlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com