Coproduction method of potassium dihydrogen phosphate, sulfur base composite fertilizer and aluminium polychloride

A technology of polyaluminum chloride and potassium dihydrogen phosphate, which is applied in the fields of aluminum chloride, chemical instruments and methods, and aluminum halides, can solve problems such as increased energy consumption, difficulty in receiving results, and low product yield, and achieves The effect of improving production efficiency and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

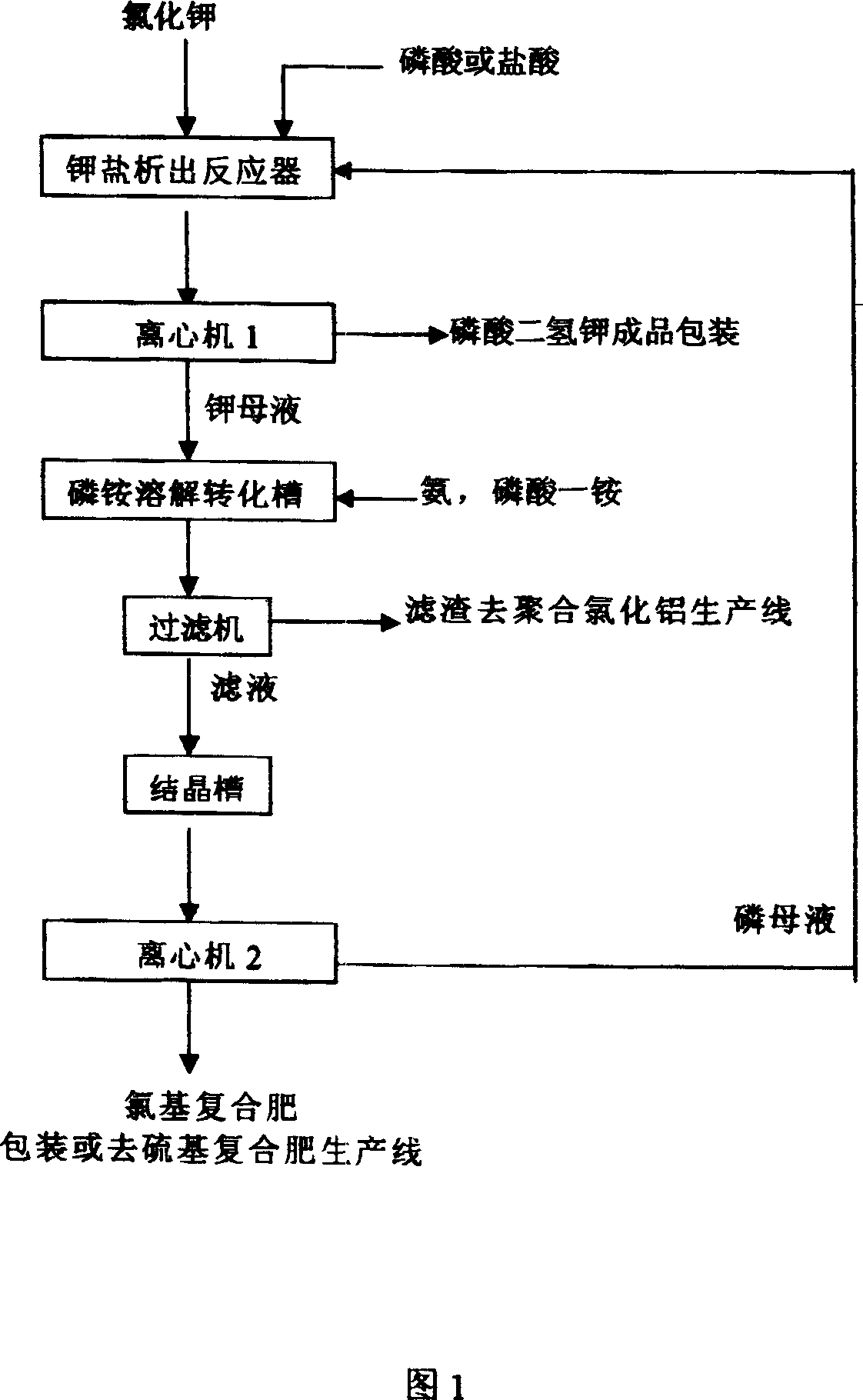

Method used

Image

Examples

Embodiment 1

[0031] A method for co-production of potassium dihydrogen phosphate, sulfur-based compound fertilizer and polyaluminum chloride is characterized in that it comprises the following steps:

[0032] (1) Monoammonium phosphate dissolution and conversion reaction: Agricultural ammonium dihydrogen phosphate is added to the mother liquor containing potassium chloride, potassium dihydrogen phosphate and ammonium chloride (called potassium mother liquor) returned from (3), stirred to dissolve and added ammonia (or ammonium bicarbonate) for the conversion reaction.

[0033] The potassium mother liquor contains K 2 O 120-140g / l, N 50-70g / l, P 2 o 5 50-70g / l, mainly contain the aqueous solution of potassium chloride, potassium dihydrogen phosphate and ammonium chloride; Potassium mother liquor can also be prepared at the time of use.

[0034] The proportion of ingredients and the reaction method are: dosing equivalent to 100% NH per cubic meter of potassium mother liquor 4 h 2 PO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com