Carbon nanotubes and graphene covalently connected synergistically reinforced polyimide composite material and preparation method thereof

A technology of carbon nanotubes and covalent connection, which is applied in the field of carbon nanotubes and graphene covalently connected synergistically reinforced polyimide composite materials and its preparation, which can solve the problem that the product performance cannot achieve the desired effect and the application process limitations, etc. problems, to achieve the effect of easy industrial implementation, increased adhesion, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] One, the preparation of graphene oxide:

[0028] Using natural flake graphite as raw material, the modified Hummers method was used to prepare graphite oxide: 1g of 325 mesh natural flake graphite was added to 60mL of concentrated sulfuric acid, and the three-neck flask was placed in an ice-water bath and mechanically stirred, slowly adding 3g of sodium nitrate, and then adding 6g Potassium permanganate; after stirring in an ice-water bath for 1 hour, raise the temperature to 35°C and continue the reaction for 3 hours; then slowly add 200mL deionized water to the reaction system, raise the temperature to 90°C for 0.5h, and then add 10mL hydrogen peroxide, stirred for 5 min and then cooled to room temperature to obtain a yellow suspension. The suspension was centrifuged and washed with 1mol L -1 HCl was washed 3 times, and then repeatedly centrifuged and washed with deionized water until the pH of the system was about 6, and graphite oxide was obtained after freeze-dryi...

Embodiment 1

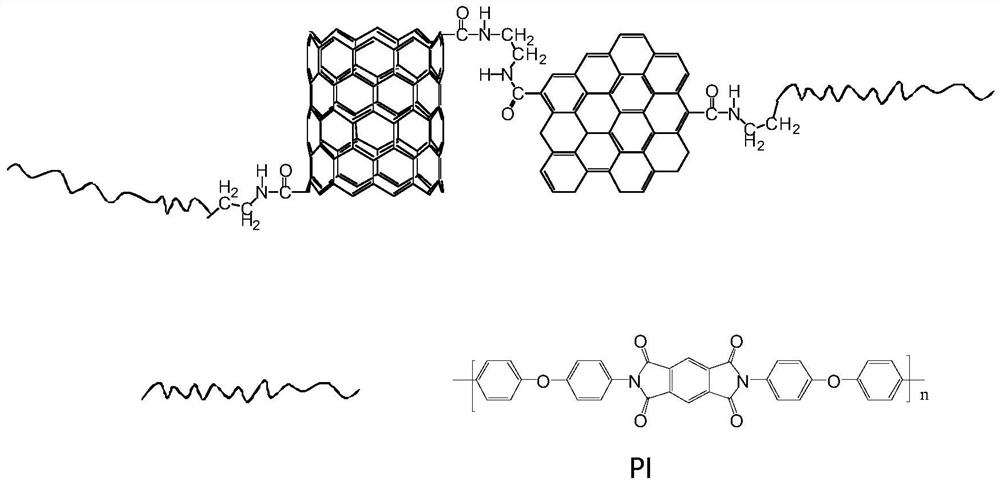

[0038] 1) Ultrasonic disperse self-prepared graphene oxide and carboxylated multi-walled carbon nanotubes of equal mass into N,N-dimethylformamide to obtain a co-dispersion with a concentration of 2mg / ml, add N,N- Dicyclohexylcarbodiimide (DCC) condensing agent, stirred for 0.5h, added ethylenediamine, reacted for 20h at 50°C, washed, and dried to obtain covalently connected carbon nanotubes and graphene; wherein ethylenediamine The mass is three times that of graphene oxide and carboxylated multi-walled carbon nanotubes, and the mass of DCC is twice that of ethylenediamine;

[0039] 2) Add 4.2 mg of covalently linked carbon nanotubes and graphene to 24 g of N,N-dimethylformamide, and sonicate for 1 hour; then add 2.0 g of 4,4'-diaminodiphenyl ether, in ice Stir mechanically in a water bath until the 4,4'-diaminodiphenyl ether is completely dissolved, then add 2.2g of pyromellitic dianhydride in batches, continue stirring for 12 hours after the addition, keep the reaction temp...

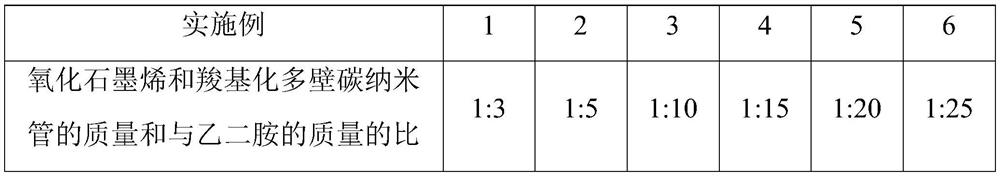

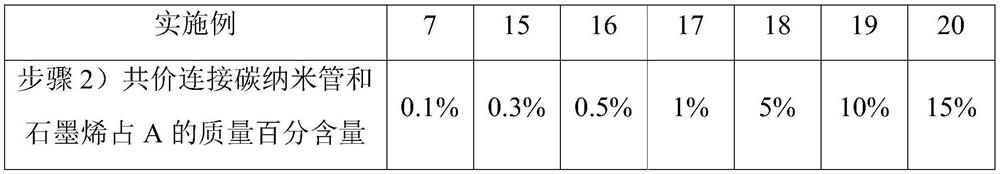

Embodiment 2~6

[0042] Only change the add-on of ethylenediamine in embodiment 1 step 1), as embodiment 2~6, list is as follows:

[0043]

[0044] Performance tests were performed on the film-like covalently linked carbon nanotubes and graphene / polyimide composite materials prepared in Examples 1-6, and Table 1 was obtained. The test method for the data in Table 1 is as follows:

[0045] X-ray photoelectron spectroscopy (XPS) (EDAX GENESIS) was used to measure the atomic content of N element, using Al Kα, hν=1486.4eV.

[0046] The tensile test was carried out by SSANS-20KN electronic universal testing machine (Shanghai, Xinsansi), the test environment temperature was 25°C, and the tensile speed was 5mm min -1 , each sample was measured 5 times and the average value was taken as the final data.

[0047] DMA242C (Germany, NETZSCH) analyzer was used for dynamic thermal analysis test, using tensile mode, temperature range: 100-500 ° C; heating rate: 5 ° C min -1 ; Static compressive stress:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com