Fe2VO4/ordered mesoporous carbon composite material and application thereof

A composite material, mesoporous carbon technology, applied in the direction of active material electrodes, electrical components, electrochemical generators, etc., can solve the problems of materials prone to rupture or collapse, low electrical conductivity, capacity decline, etc., to achieve large-scale Production, inhibition of self-agglomeration, easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

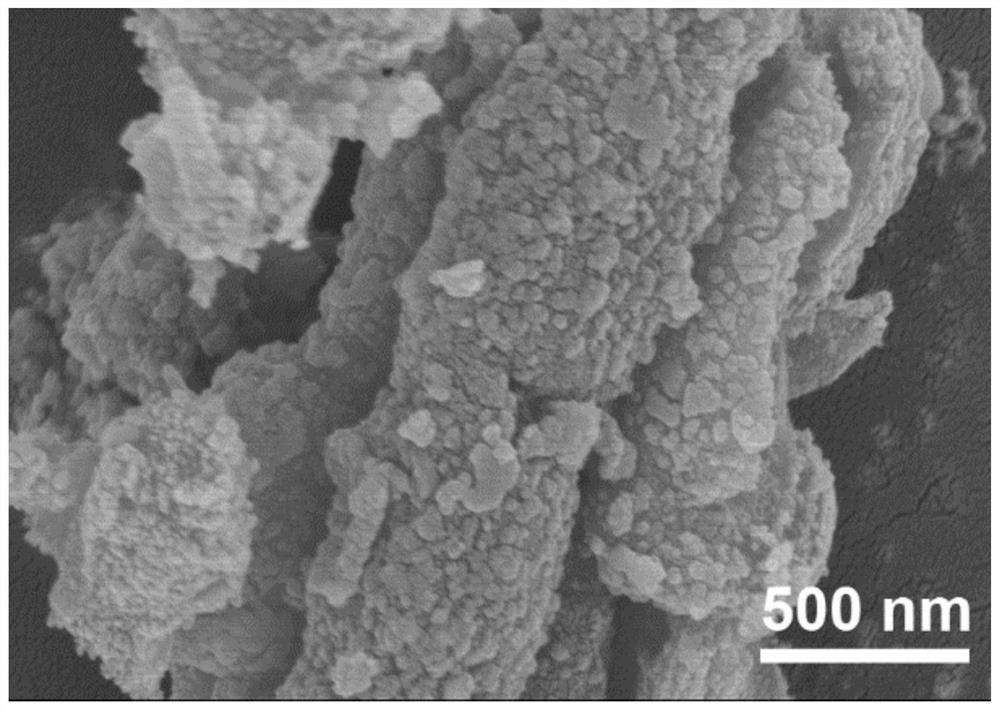

[0029] (1) Disperse 25mg CMK-3 into 40mL ethanol, ultrasonically disperse for 30min, then add 2mmol iron acetylacetonate, stir to completely dissolve iron acetylacetonate, and obtain a dispersion containing iron source; add 1mmol vanadyl acetylacetonate to 40mL ethanol and dissolved to obtain a solution containing a vanadium source; adding the solution containing a vanadium source to the dispersion containing an iron source, and stirring evenly to obtain a dispersion containing an iron source, a vanadium source and ordered mesoporous carbon;

[0030] (2) Pour the dispersion containing iron source, vanadium source and ordered mesoporous carbon into a 100mL polytetrafluoroethylene hydrothermal kettle, react at 180°C for 12h, cool to room temperature, and collect the solid product by centrifugation. Wash with ethanol several times and then dry to obtain the composite material precursor;

[0031] (4) Evenly disperse the composite material precursor in the crucible, put it into a t...

Embodiment 2

[0037] (1) Disperse 15mg CMK-3 into 40mL methanol, ultrasonically disperse for 30min, then add 1mmol ferric nitrate, stir to completely dissolve ferric nitrate, and obtain a dispersion containing iron source; add 1mmol ammonium metavanadate to 40mL methanol neutralize and dissolve to obtain a solution containing a vanadium source; add the solution containing a vanadium source to a dispersion containing an iron source, and stir evenly to obtain a dispersion containing an iron source, a vanadium source and ordered mesoporous carbon;

[0038] (2) Pour the dispersion containing iron source, vanadium source and ordered mesoporous carbon into a 100mL polytetrafluoroethylene hydrothermal kettle, react at 200°C for 10h, cool to room temperature, and collect the solid product by centrifugation. Washing with methanol several times and then drying to obtain a composite material precursor;

[0039] (4) Disperse the precursor of the composite material evenly in the crucible, put it into a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com