A kind of preparation method of graphene/ferrite nanocomposite electrode material

A nano-composite, electrode material technology, applied in the direction of hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, separation methods, etc., can solve the problems of high cost, high energy consumption, secondary pollution, etc., and achieve low cost and high material source Wide, easy-to-manipulate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

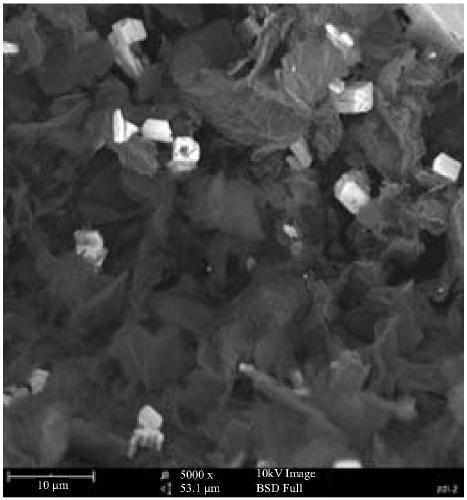

[0036] (1) Take by weighing 2.78g ferrous sulfate heptahydrate, 1.435g zinc sulfate heptahydrate, mix and be dissolved in 50ml deionized water, stir until dissolving evenly, be mixed with the mixed salt solution that Fe:Zn molar concentration ratio is 2:1;

[0037] (2) Weigh 0.5g of polyvinyl alcohol with a molecular weight of 1300 and dissolve it in 30ml of deionized water, heat and stir until uniformly mixed;

[0038] (3) Weigh 1.89g of oxalic acid (H 2 C 2 o 4 2H 2 (2) and join in the solution that step (2) prepares, mix to uniform; (4) take the graphene of 2.87g and join in the mixed solution that step (1) prepares, stir at high speed then, stirring rate is 3500r / min, the stirring time is 40min, until the graphene is evenly dispersed in the mixed solution;

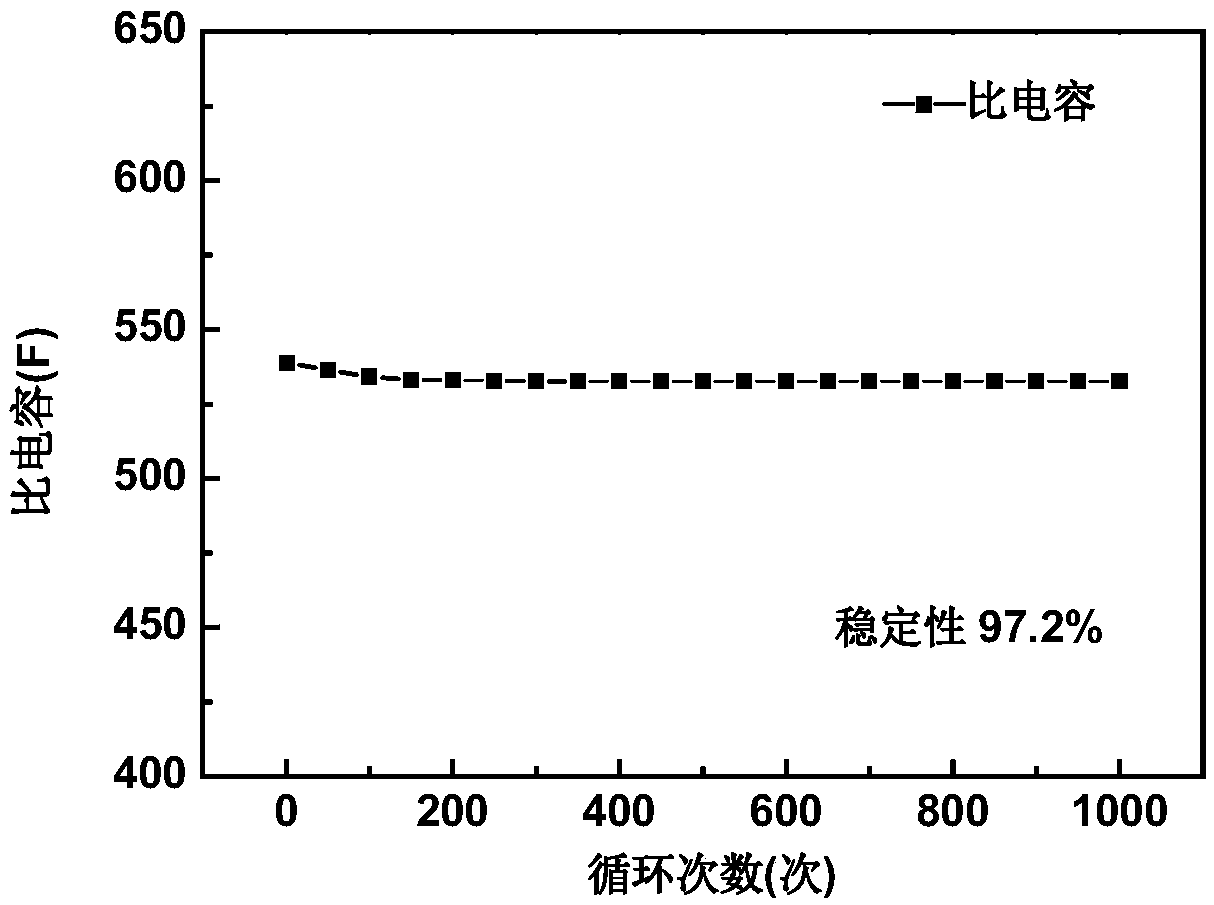

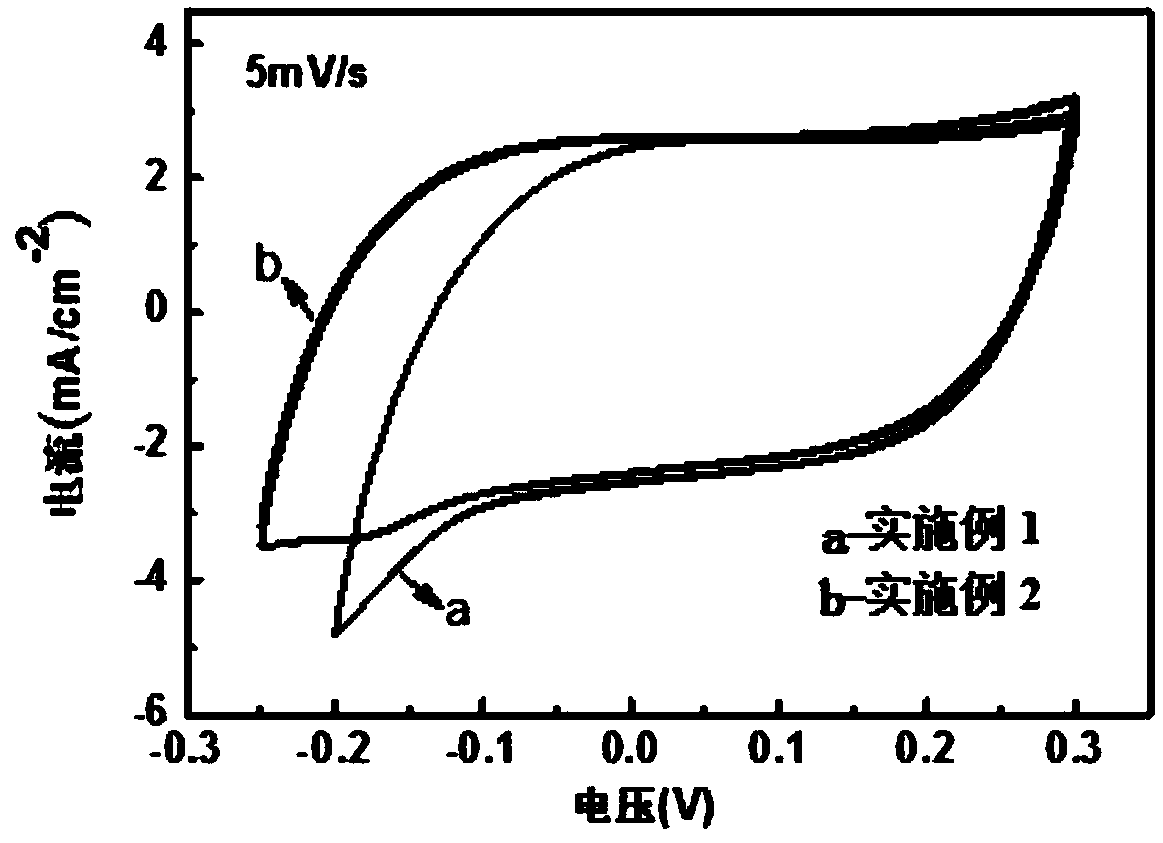

[0039](5) Slowly add the mixed liquid prepared in step (3) to the dispersion liquid prepared in step (4) under the condition of high-speed stirring, and after stirring for 60 min, the dispersion liquid is subjecte...

Embodiment 2

[0052] (1) Take by weighing 2.78g ferrous sulfate heptahydrate, 0.845g manganese sulfate monohydrate, mix and be dissolved in 50ml deionized water, stir until dissolving evenly, be mixed with the mixed salt solution that Fe:Mn molar concentration ratio is 2:1;

[0053] (2) Weigh 0.5g of polyvinyl alcohol with a molecular weight of 1300 and dissolve it in 30ml of deionized water, heat and stir until uniformly mixed;

[0054] (3) Weigh 1.89g of oxalic acid (H 2 C 2 o 4 2H 2 (2) and join in the solution that step (2) prepares, mix to uniform; (4) take the graphene of 1.69g and join in the mixed solution that step (1) prepares, then high-speed stirring, stirring speed is 3500r / min, the stirring time is 40min, until the graphene is evenly dispersed in the mixed solution;

[0055] (5) Slowly add the mixed liquid prepared in step (3) to the dispersion liquid prepared in step (4) under the condition of high-speed stirring, and after stirring for 60 min, the dispersion liquid is s...

Embodiment 3

[0068] (1) Take by weighing 2.78g ferrous sulfate heptahydrate, 1.135g cobalt sulfate hexahydrate, mix and be dissolved in 50ml deionized water, stir until dissolving evenly, be mixed with the mixed salt solution that Fe:Co molar concentration ratio is 2:1;

[0069] (2) Weigh 0.5g of polyvinyl alcohol with a molecular weight of 1300 and dissolve it in 30ml of deionized water, heat and stir until uniformly mixed;

[0070] (3) Weigh 1.89g of oxalic acid (H 2 C 2 o 4 2H 2 (2) and join in the solution that step (2) prepares, mix to uniform; (4) take the graphene of 2.63g and join in the mixed solution that step (1) prepares, then high-speed stirring, stirring rate is 3500r / min, the stirring time is 40min, until the graphene is evenly dispersed in the mixed solution;

[0071] (5) Slowly add the mixed liquid prepared in step (3) to the dispersion liquid prepared in step (4) under the condition of high-speed stirring, and after stirring for 60 min, the dispersion liquid is subje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com