Method for enrichment of vanadium from stone coal mine in a manner of low consumption and high efficiency

A high-efficiency technology for stone coal mines, which is applied in the fields of flotation, comprehensive recovery and utilization of rare metals, and vanadium leaching, can solve the problems of high production cost, backward technology, simple equipment, etc., and achieves the effect of less pollution, simple process flow and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

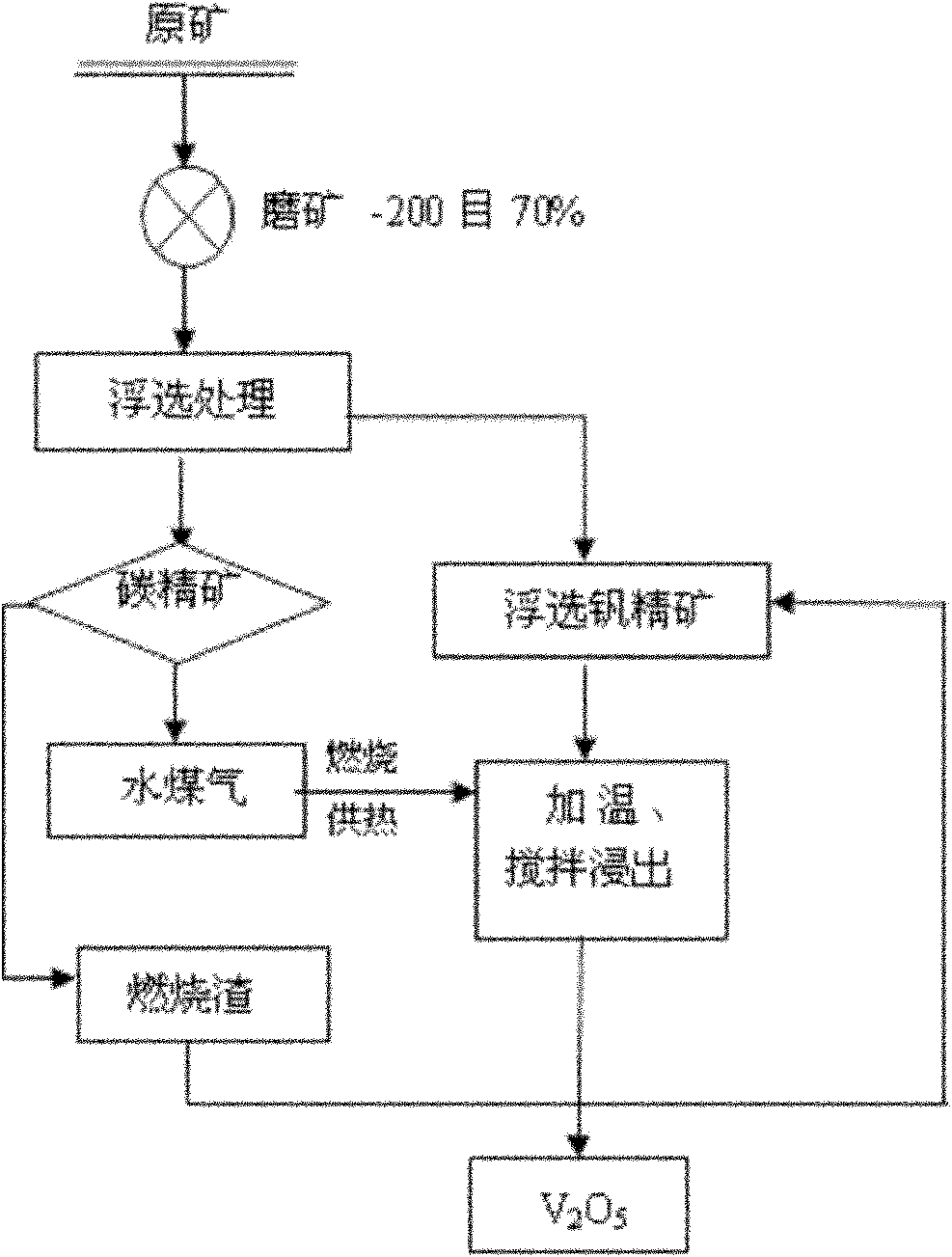

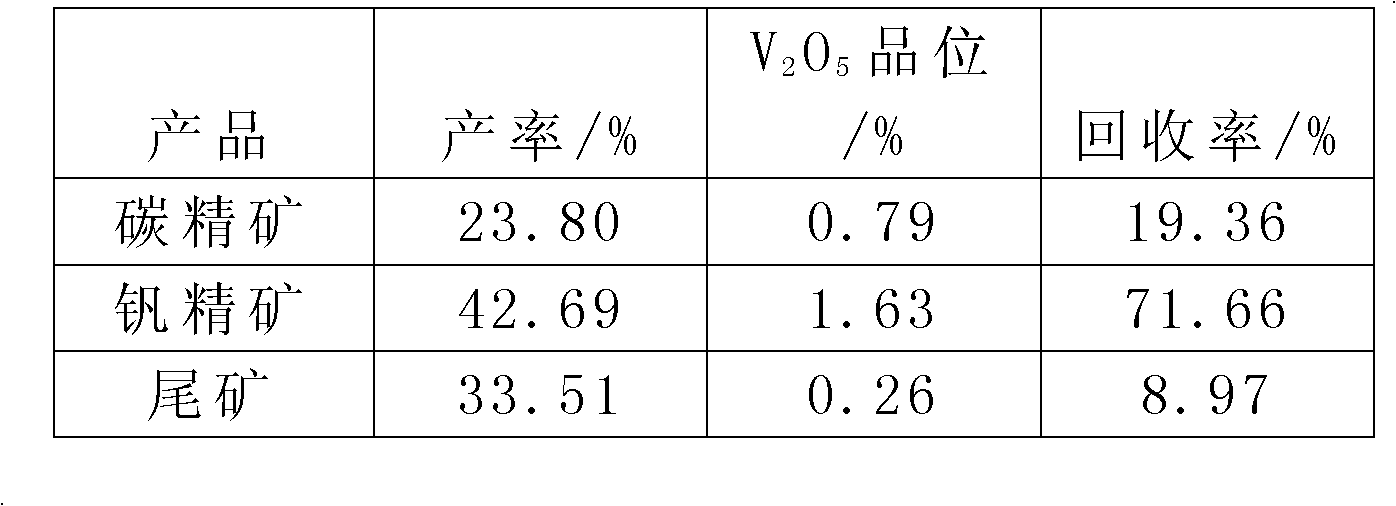

[0023] Adopt the present invention, carried out experiment to a stone coal mine in Sichuan. First, crush and grind the stone coal mine. The grinding fineness of the stone coal mine is -200 mesh, which accounts for more than 70% of the mass. The concentration of the pulp is controlled at 35%-45%. Flotation is carried out at room temperature to obtain carbon concentrate and Vanadium concentrate. The carbon concentrate obtained by flotation is made into water gas, and the carbon slag after burning vanadium concentrate and carbon concentrate is leached. The heat generated by the combustion of water gas provides the heat required for leaching, and the recovery rate of vanadium in the final flotation reaches 91.03%. , the leaching rate can reach 90.35%, and the total recovery rate of vanadium in this mine can reach 82.24%. The specific indicators are as follows:

[0024] Flotation results of a stone coal mine in Sichuan

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com