Preparation method of nitrogen and phosphorus doubly-doping porous carbon nanofiber material for air electrode

An air electrode, nanofiber technology, applied in nanotechnology for materials and surface science, battery electrodes, nanotechnology, etc., can solve problems such as limited application and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

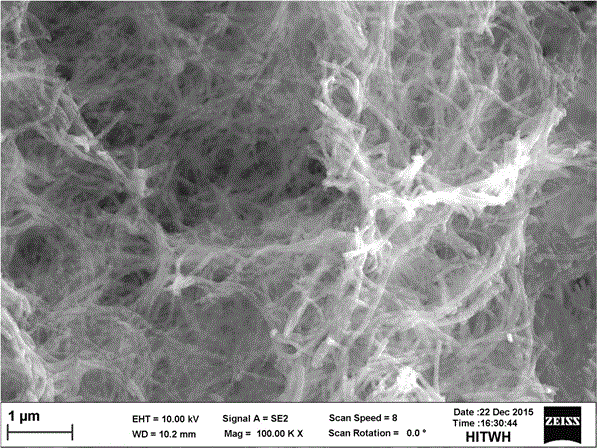

Embodiment 1

[0024] 2.8ml of aniline solution was added to 50ml of 7.7% phytic acid aqueous solution, heated and stirred at 90°C for 10min to generate aniline-phytic acid salt solution, and then cooled to 4°C. 1.716 g of ammonium persulfate was weighed and dissolved in 6 ml of deionized water and cooled to 6°C. The two solutions were quickly mixed, the mixed solution was placed in an ice-water bath for 2 hours, the synthesized hydrogel was soaked for 36 hours, and then lyophilized for 72 hours to form aerogels. The aerogel was carbonized at 1000 °C under the protection of Ar gas for 3 h to obtain the porous carbon nanofiber material.

Embodiment 2

[0026] 2.8ml of aniline solution was added to 50ml of 7.7% phytic acid aqueous solution, heated and stirred at 90°C for 10min to generate aniline-phytic acid salt solution, and then cooled to 8°C. 1.716 g of ammonium persulfate was weighed and dissolved in 6 ml of deionized water and cooled to 8°C. The two solutions were quickly mixed, and the mixed solution was placed in an ice-water bath for 8 h, the synthesized hydrogel was soaked for 24 h, and then lyophilized for 72 h to form aerogel. The aerogel was carbonized for 1 h at 1100 °C under the protection of Ar gas, and the porous carbon nanofiber material was obtained.

Embodiment 3

[0028] 2.8ml of aniline solution was added to 50ml of 7.7% phytic acid aqueous solution, heated and stirred at 90°C for 10min to generate aniline-phytic acid salt solution, and then cooled to 2°C. 1.716 g of ammonium persulfate was weighed and dissolved in 6 ml of deionized water and cooled to 4°C. The two solutions were quickly mixed, the mixed solution was placed in an ice-water bath for 10 hours, the synthesized hydrogel was soaked for 18 hours, and then lyophilized for 72 hours to form aerogels. The aerogel was carbonized at 800°C under the protection of Ar gas for 2 h to obtain the porous carbon nanofiber material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com