Oligomer-grafted nanofillers and advanced composite materials

A technology of nano-fillers and oligomers, which is applied in the field of composite materials and nano-materials, and can solve problems such as damage to the mechanical properties of composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

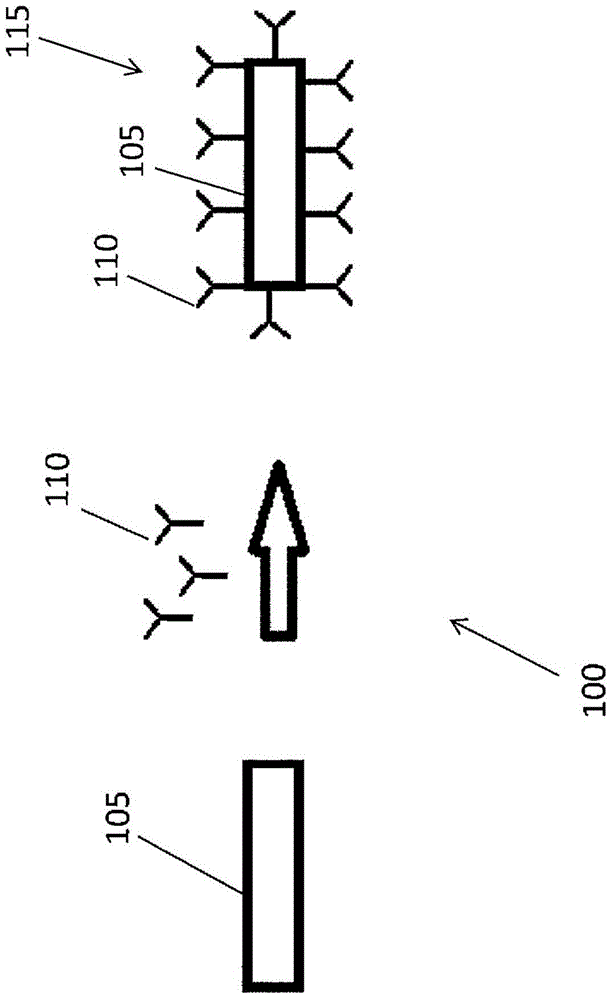

[0083] Example 1 Functionalization of Graphene Oxide Nanoparticles Using Polybutadiene-Polyacrylonitrile Rubber Oligomers

[0084] This example is the attachment of polybutadiene-polyacrylonitrile rubber oligomer to graphene oxide through a coupling agent. To functionalize graphene oxide (GO) with rubber oligomers, 0.2 g GO was dispersed into 50 mL dimethylformamide (DMF) by sonication, followed by the addition of 2 g diphenylmethane diisocyanate (MDI). The mixture was stirred at room temperature for one day and then solidified with dichloromethane. After washing at least five times with dichloromethane centrifugation, the isocyanate-functionalized GO was redispersed in 100 mL of DMF. 4 g of amine-terminated polybutadiene-polyacrylonitrile (ATBN 1300×42, molecular weight 900 g / mol, 18% polyacrylonitrile) were added and the mixture was stirred at 50° C. for 12 h. ATBN-functionalized GO was separated by centrifugation and washed with acetone at least 5 times. The product wa...

example 2

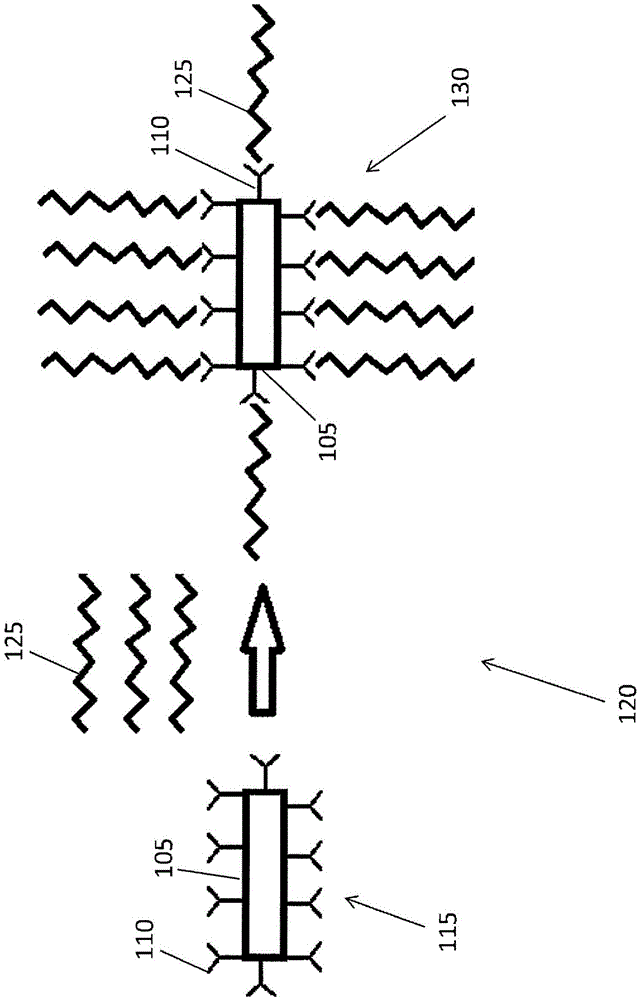

[0091] Example 2 uses the OGN of Example 1 to prepare composite materials

[0092] The desired amount of ATBN-functionalized GO was dispersed into THF by sonication, and then this dispersion was added to the THF solution of polybutadiene-polyacrylonitrile copolymer to obtain modified The final composite of graphene oxide. The complexes are obtained after solvent evaporation or precipitation in a non-solvent such as methanol.

example 3

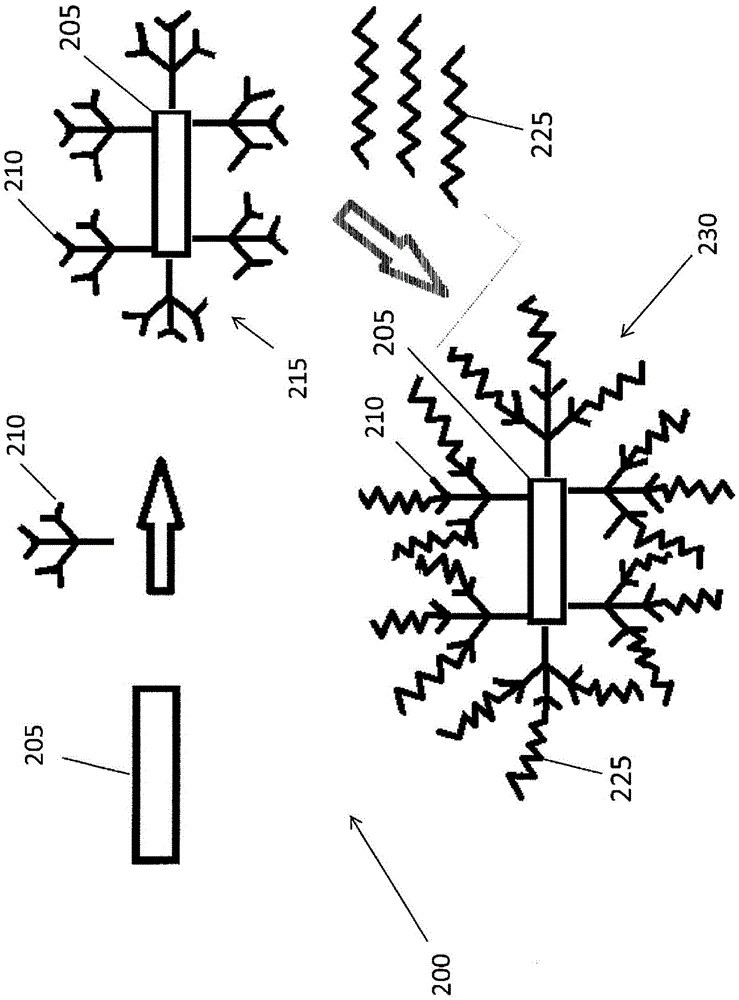

[0093] Example 3 Functionalization of Graphene Nanoparticles with Styrenic Oligomers

[0094] To grow oligostyrene on graphene, methylsilylated graphene was obtained by stirring graphene oxide and 3-chloropropyltrimethoxysilane in ethanol at 60 °C for 12 h. The chlorine-functionalized graphene was then dispersed into DMF containing CuCl and styrene for atom transfer radical polymerization (ATRP) reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com