Quick RTM manufacturing process of resin based advanced composite material

An advanced composite material and manufacturing process technology, applied in the field of rapid RTM manufacturing process, can solve the problems of high energy consumption and slow heating speed, and achieve the effect of less energy consumption, reducing residual stress and optimizing the curing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

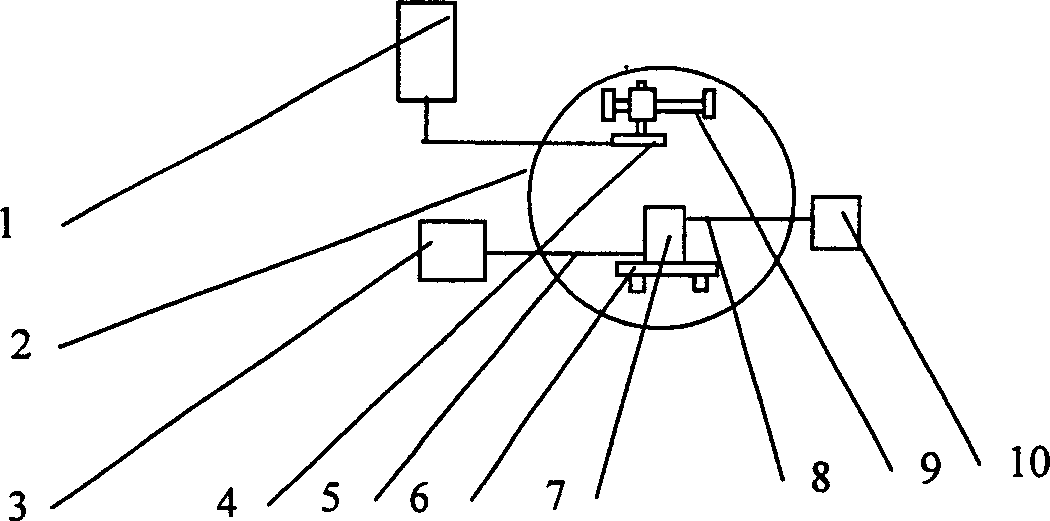

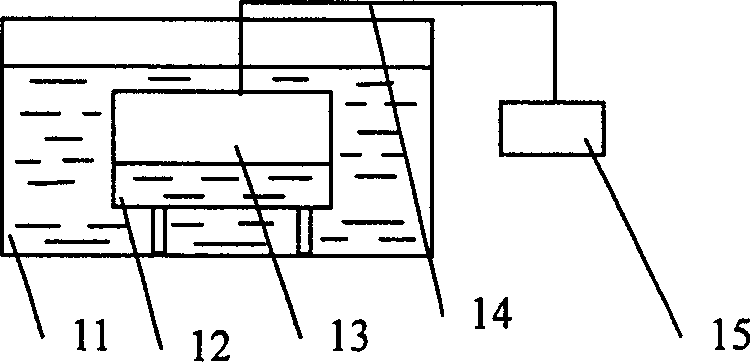

Method used

Image

Examples

Embodiment approach 1

[0040] In CAD / CAM software, carry out the three-dimensional modeling of the part prototype. And use RP (rapid prototyping) technology to make the corresponding prototype. Then remake the corresponding room temperature vulcanized silicone rubber mold. Apply silicone oil on the inner surface of the mold as a release agent. Place the carbon fiber three-dimensional prefabricated part in the mold, close the mold, and seal it. The mold is clamped on the trolley in the high-pressure water tank to fix the trolley. Connect the resin gate and riser of the mold to the resin injection pipe and the exhaust pipe of the high-pressure water tank respectively. Close the high-pressure water tank, fill it with degassed water, and adjust the water pressure to 1.5 atmospheres (assuming that the outside world is 1 atmosphere at this time).

[0041] Mix the epoxy resin with the anhydride curing agent (mass ratio: 10:7), and put it into a closed container, occupying half the volume of the contain...

Embodiment approach 2

[0045] In CAD / CAM software, carry out the three-dimensional modeling of the part prototype. And use RP (rapid prototyping) technology to make the corresponding prototype. Then remake the corresponding room temperature vulcanized silicone rubber mold. Apply silicone oil on the inner surface of the mold as a release agent. Place the carbon fiber three-dimensional prefabricated part in the mold, close the mold, and seal it. The mold is clamped on the trolley in the high-pressure water tank to fix the trolley. Connect the resin gate and riser of the mold to the resin injection pipe and the exhaust pipe of the high-pressure water tank respectively. Close the high-pressure water tank, fill it with degassed water, and adjust the water pressure to 1.5 atmospheres (assuming that the outside world is 1 atmosphere at this time).

[0046] Mix the epoxy resin with the modified amine curing agent (mass ratio is 4:1), and put it into an airtight container, occupying half the volume of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com