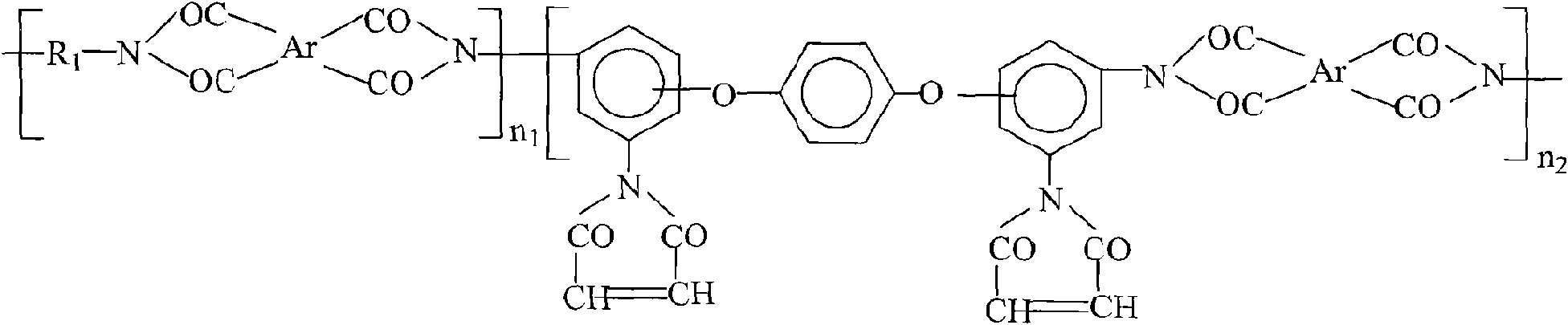

High temperature resistant composite matrix resin and preparation method thereof

A composite material and matrix resin technology, which is applied in the field of polymer resin materials and its preparation, can solve problems that have not yet been published in literature or patent reports.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

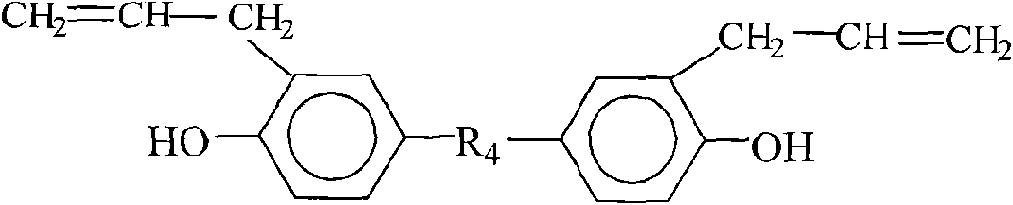

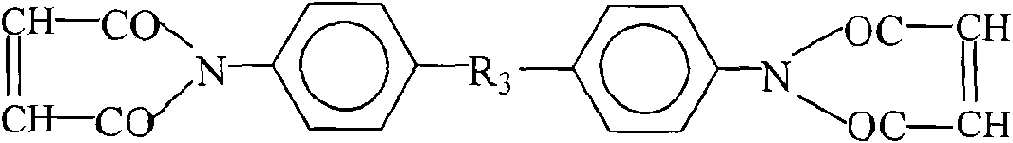

Method used

Image

Examples

Embodiment 1

[0075] Put 32.2 grams (0.1 moles) of 1,4-bis(2,4-diaminophenoxy)benzene and 2590 milliliters of N-methyl-2-pyrrolidone organic solvent into the reaction kettle, and stir and dissolve completely at room temperature , add 19.6 grams (0.2 moles) of maleic anhydride solid powder, after stirring and reacting at room temperature for 1-2 hours, add 51.8 grams (1.0 moles) of 2,2-bis[4-(4-aminophenoxy)phenyl] Hexafluoropropane aromatic dibasic primary amine, stirring at room temperature, after completely dissolving, add 156.0 grams (0.3 moles) of 2,2-bis[4-(3,4-dicarboxyphenoxy)phenyl]propanedianhydride and 257.6 g (0.8 moles) of 3,3',4,4'-tetracarboxybenzophenone dianhydride, stirred and reacted at room temperature for 5-8 hours to obtain a homogeneous transparent viscous resin solution.

[0076] Add 3.3 moles of acetic anhydride dehydrating agent and 0.33 moles of pyridine catalyst, stir and react at room temperature for 2-4 hours, heat up to 70°C-100°C, stir at high speed for 4-6 ho...

Embodiment 2

[0082] Mix maleimide-based polyimide powder MPI-1, 3,3′-diallyl bisphenol A compound and 4,4′-bismaleimide in a weight ratio of 1:2:8 Put the base diphenylmethane resin powder into the reaction kettle, heat up to 100°C-160°C, carry out the melt polymerization reaction for 3-7 hours, pour it into the cooling tank while it is hot, cool and solidify, and pulverize to obtain solid resin powder, denoted as R -11.

[0083] Add the R-11 solid resin powder into the dissolution kettle, add dichloromethane organic solvent (the organic solvent accounts for 45%-65% by mass of the whole system), stir and dissolve, and obtain a homogeneous and transparent high-temperature-resistant composite material matrix resin solution , Recorded as R-11S, the solid content is 35%-55%.

[0084] Put a small amount of R-11 solid resin powder into an aluminum foil box, put it in an oven, and carry out curing reaction. The curing process is as follows: heating from room temperature to 140°C, and holding for...

Embodiment 3

[0087] Put 32.2 grams (0.1 moles) of 1,4-bis(2,4-diaminophenoxy)benzene, 1000 milliliters of N,N-dimethylacetamide and 540 milliliters of N-methyl-2-pyrrolidone organic solvent Put it into the reaction kettle, at room temperature, after stirring and dissolving completely, add 19.6 grams (0.2 moles) of maleic anhydride solid powder, stir and react at room temperature for 1-2 hours, add 41.0 grams (0.1 moles) of 2,2-bis[4 -(4-aminophenoxy)phenyl]propane aromatic dibasic primary amine, stirring at room temperature, after completely dissolving, add 62.0 g (0.2 moles) of 3,3',4,4'-tetracarboxydiphenyl ether The dianhydride was stirred and reacted at room temperature for 5-8 hours to obtain a homogeneous transparent viscous resin solution.

[0088] Add 2.0 moles of acetic anhydride dehydrating agent and 0.1 moles of triethylamine catalyst, stir and react at room temperature for 2-4 hours, heat up to 70°C-100°C, stir at high speed for 4-6 hours, add 1540 ml of methanol precipitation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile shear strength | aaaaa | aaaaa |

| Tensile shear strength | aaaaa | aaaaa |

| Tensile shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com