Polyimide foam and preparation method thereof

A technology of polyimide and foamed plastics, applied in the field of polyimide foamed plastics and its preparation, can solve the problem of difficult-to-carbon fiber reinforced epoxy resin composite material support, low thermal deformation or creep capacity, and sound absorption performance. To achieve the effect of good sound absorption performance, high temperature for long-term use, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

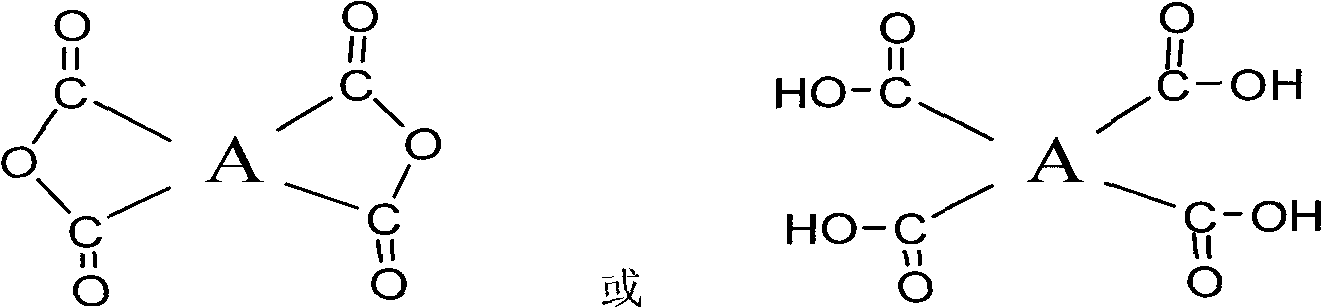

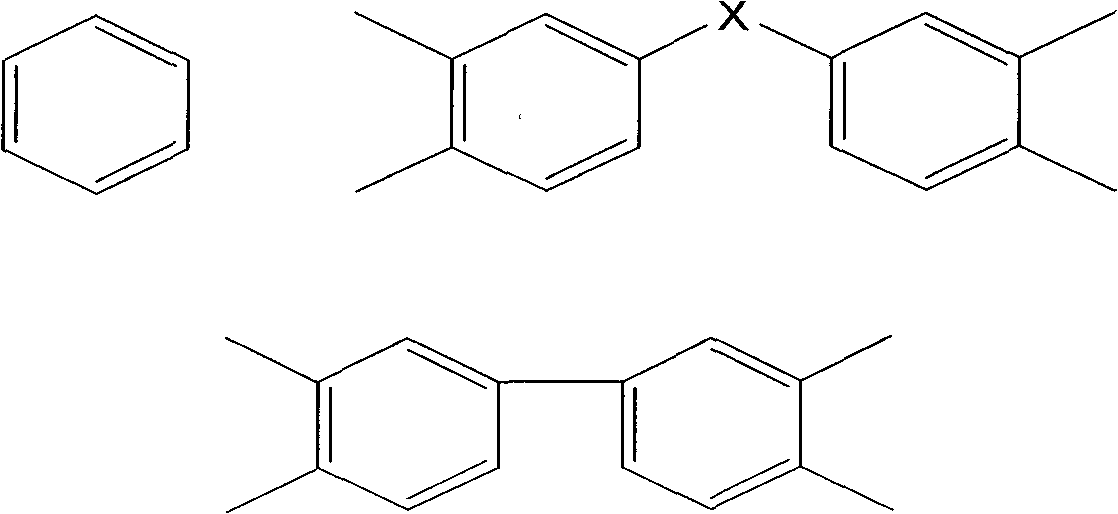

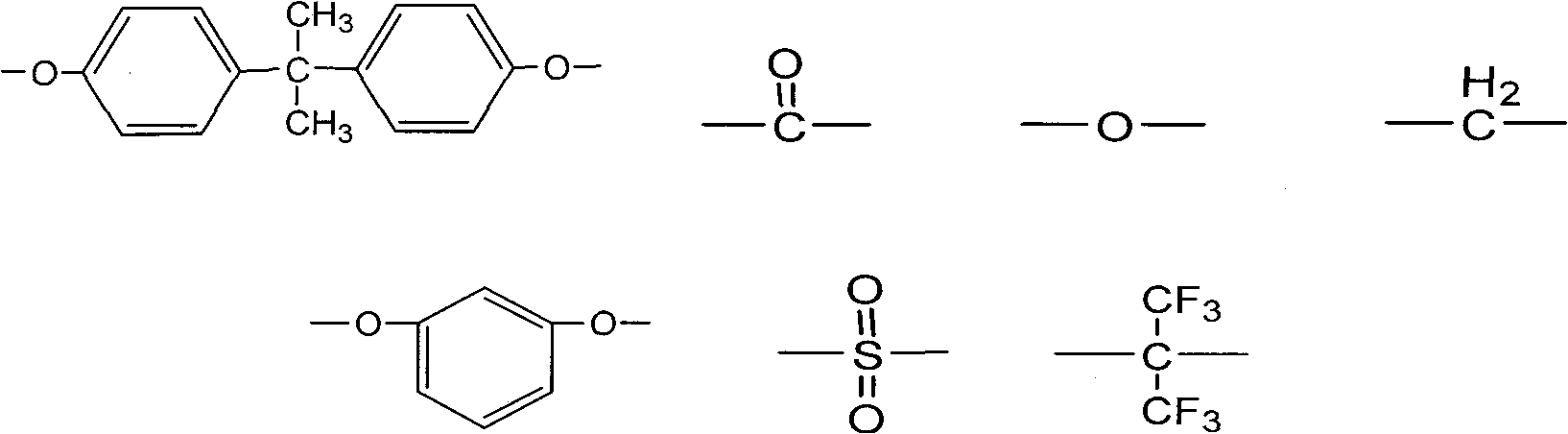

Method used

Image

Examples

Embodiment 1

[0051] 1,2,4,5-Pyromellitic anhydride 100 parts

[0052] Polymethylene polyphenyl polyisocyanate 130 parts

[0053] 150 parts of N,N-dimethylformamide

[0054] Triethanolamine 0.50 parts

[0055] Stannous octoate 0.50 parts

[0056] DC-193 2.50 parts

[0057] Foaming agent 6 parts

[0058] Add 1,2,4,5-pyromellitic anhydride and N,N-dimethylformamide solvent into the container and stir thoroughly until the 1,2,4,5-pyromellitic anhydride powder is completely dissolved , add polymethylene polyphenyl polyisocyanate, triethanolamine, stannous octoate, DC-193, and react at a temperature range of 60°C to 90°C for 0.3 hours to 2 hours, and then cool down to 30°C to obtain a higher viscosity foam precursor solution; add foaming agent, stir quickly, pour into the pre-prepared mold after the solution starts to turn white, and foam freely for 5 minutes to obtain the foam intermediate; then put the foam intermediate into a vacuum oven , solidified at 240° C. for 2 hours, and released...

Embodiment 2

[0060] 3,3',4,4'-Benzophenone tetraacid dianhydride 80 parts

[0061] Polymethylene polyphenyl polyisocyanate 109 parts

[0062] N,N-Dimethylformamide 210 parts

[0063] 0.35 parts of triethylamine

[0064] Stannous octoate 0.35 parts

[0065] AK 8805 1 copy

[0066] Foaming agent 5 parts

[0067] Add 3,3',4,4'-benzophenone tetraacid dianhydride and N,N-dimethylformamide solvent into the container and stir thoroughly until 3,3',4,4'-benzophenone After the tetraacid dianhydride powder is completely dissolved, add polymethylene polyphenyl polyisocyanate, triethylamine, stannous octoate, AK 8805, and react at 90°C for 1 hour to 2 hours, then cool down to 30°C to obtain Foam precursor solution with high viscosity; add foaming agent, stir quickly, pour the solution into the pre-prepared mold after the solution starts to turn white, and foam freely for 10 minutes to obtain the foam intermediate; then put the foam intermediate into In a vacuum oven, solidify at 250° C. for 3 ho...

Embodiment 3

[0069] 1,2,4,5-Pyromellitic anhydride 45 parts

[0070] 3,3',4,4'-Benzophenone tetraacid dianhydride 65 parts

[0071] Polymethylene polyphenyl polyisocyanate 180 parts

[0072] N,N-Dimethylacetamide 210 parts

[0073] Triethanolamine 0.40 part

[0074] Dibutyltin dilaurate 0.40 parts

[0075] AK 8805 2 copies

[0076] Foaming agent 4 parts

[0077] Add 1,2,4,5-pyromellitic anhydride, 3,3',4,4'-benzophenone tetracarboxylic dianhydride and N,N-dimethylacetamide solvent into the container and stir thoroughly, After the powders of 1,2,4,5-pyromellitic anhydride and 3,3',4,4'-benzophenone tetraacid dianhydride are completely dissolved, add polymethylene polyphenyl polyisocyanate, triethanolamine , dibutyltin dilaurate, AK 8805, and react at 90°C for 1 hour to 2 hours, then cool down to 30°C to obtain a foam precursor solution with high viscosity; add foaming agent, stir quickly, and wait until the solution starts to foam After whitening, pour it into a pre-prepared mold, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com