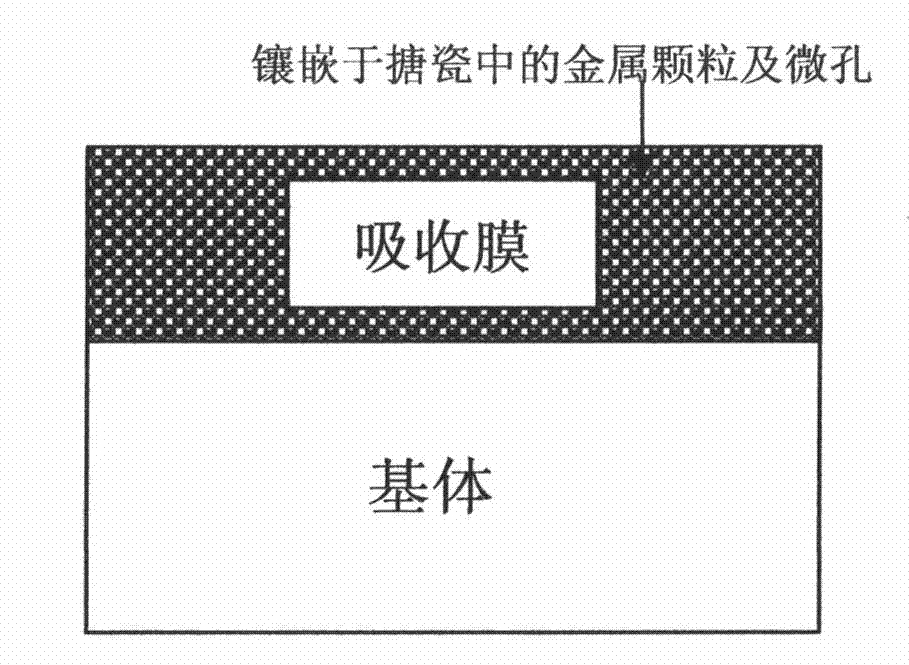

High-temperature-resistant selective solar energy-absorbing film and preparation method thereof

A solar energy absorption and selective technology, used in solar thermal power generation, solar thermal devices, heating devices, etc., can solve problems such as functional degradation, achieve great economic value and social value, good atmospheric corrosion resistance, good anti-oxidation protection effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

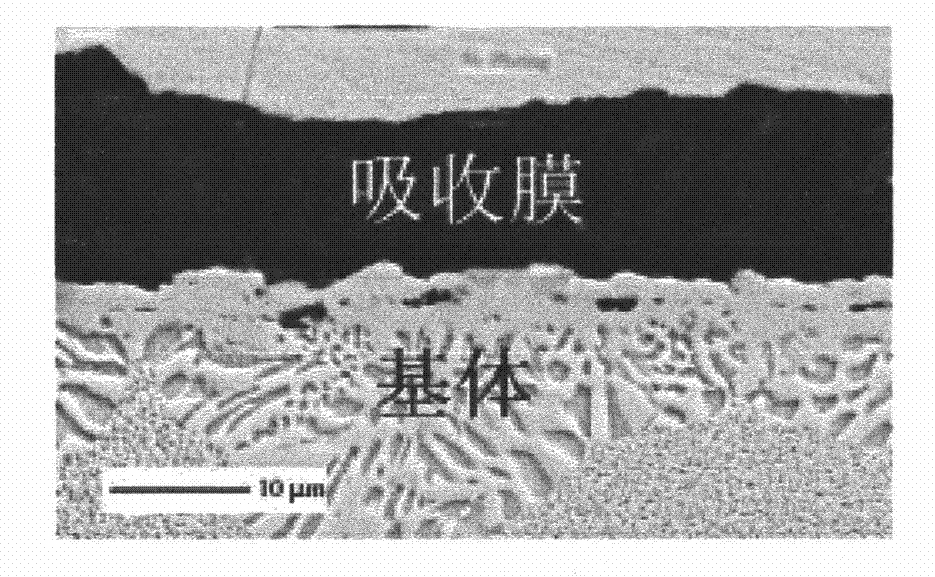

[0026] Weigh 95g of enamel powder, 5g of NiCrAlY powder, and 50g of alcohol, add it to the agate ball mill tank, ball mill for 100h, spray it on the surface of the stainless steel plate by air spraying, and then heat it for 10 minutes in a muffle furnace heated to 950℃. The profile microstructure appearance is like figure 2 As shown, the macro photo is image 3 Shown. Measure its weight gain by oxidation at 600℃ to be 0.0001mg / cm 2 .h, the solar energy absorption rate reaches 98%, and the infrared radiation rate is 1%.

Embodiment 2

[0028] Weigh 90g of enamel powder, 10g of 304 stainless steel powder, and 50g of alcohol, add it to the agate ball milling tank, ball mill for 100h, spray it on the surface of the stainless steel plate by electrostatic spraying, and then heat it in a muffle furnace heated to 800°C for 30 minutes, and measure it Oxidation weight gain at 600℃ is 0.0001mg / cm 2 .h, the solar energy absorption rate reaches 95%, and the infrared radiation rate is 4%.

Embodiment 3

[0030] Weigh 85g of enamel powder, 15g of chromium powder, and 80g of alcohol, add it to the agate ball mill tank, ball mill for 200h, spray it on the outer surface of the stainless steel pipe by airless spraying method, and then heat it in a muffle furnace heated to 850℃ for 20 minutes, and measure Its 600℃ oxidation weight gain is 0.0001mg / cm 2 .h, the solar energy absorption rate reaches 96%, and the infrared radiation rate is 4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com