Vacuum air-pressure infiltration forming method of fiber reinforced aluminum base composite material

An aluminum-based composite material and fiber-reinforced technology, applied in vacuum evaporation plating, metal material coating process, ion implantation plating, etc., can solve problems such as infiltration micropores and loose fiber damage, and achieve wide application prospects. The effect of microporosity and porosity defect elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

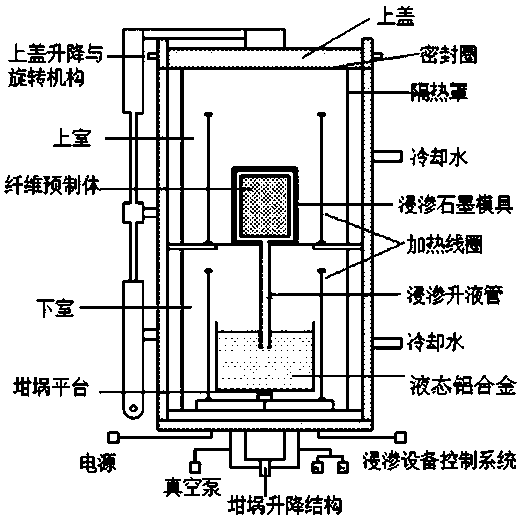

Image

Examples

Embodiment 1

[0027] A vacuum pressure infiltration forming method of M40J fiber reinforced aluminum matrix composite material, the preparation steps are as follows:

[0028] A. First weave the M40J fiber prefabricated body with three-dimensional orthogonal structure;

[0029] B. Carry out vacuum evaporation coating of magnesium element on the woven three-dimensional orthogonal structure M40J fiber prefabricated body, and the thickness of the coating film is 3 μm;

[0030] C. The impregnated graphite mold is made of high-purity graphite material. After machining and forming, it is baked at 500 ° C for 30 minutes, and cleaned with acetone after cooling to room temperature;

[0031] D. Embed and fix the fiber preform in the impregnated graphite mold, and weld and package the impregnated graphite mold embedded with the three-dimensional orthogonal M40J fiber preform with stainless steel plates and stainless steel pipes. There is an opening at the top of the tube, and the impregnated graphite ...

Embodiment 2

[0038] A vacuum pressure infiltration forming method of 2.5D braided C fiber reinforced aluminum matrix composite material, the preparation steps are as follows:

[0039] A. First weave the C fiber prefabricated body with 2.5D structure;

[0040] B. Plasma coating of titanium element is performed on the woven 2.5D structure C fiber prefabricated body, and the coating thickness is 0.5 μm;

[0041] C. The impregnated graphite mold is made of high-purity graphite material. After machining and forming, it is baked at 400°C for 30 minutes, and cleaned with ethanol after cooling to room temperature;

[0042]D. Embed and fix the fiber prefabricated body in the impregnated graphite mold, and use stainless steel plates and stainless steel pipes to weld and package the impregnated graphite mold embedded with the C fiber prefabricated body with a 2.5D structure. There is an opening at the top of the tube, and the impregnated graphite mold is welded and packaged for air tightness testing...

Embodiment 3

[0049] A vacuum pressure infiltration forming method of a three-dimensional five-directional SiC fiber reinforced aluminum matrix composite material, the preparation steps are as follows:

[0050] A. First weave the SiC fiber prefabricated body with three-dimensional five-directional structure;

[0051] B. Carry out vacuum evaporation coating of magnesium element on the woven SiC fiber prefabricated body with three-dimensional five-directional structure, and the thickness of the coating film is 1.5 μm;

[0052] C. The impregnated graphite mold is made of high-purity graphite material. After machining and forming, it is baked at 500°C for 50 minutes, and cleaned with acetone after cooling to room temperature;

[0053] D. Embed and fix the fiber prefabricated body in the impregnated graphite mold, and use stainless steel plates and stainless steel pipes to weld and package the impregnated graphite mold embedded with the three-dimensional five-directional SiC fiber prefabricated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com