Paint immersion device for motor stator

A motor stator and varnish impregnation technology, which is applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of affecting production efficiency, incomplete impregnation of varnish, and low work efficiency, so as to improve the efficiency of varnish immersion and improve the efficiency of immersion varnish. Paint effect, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

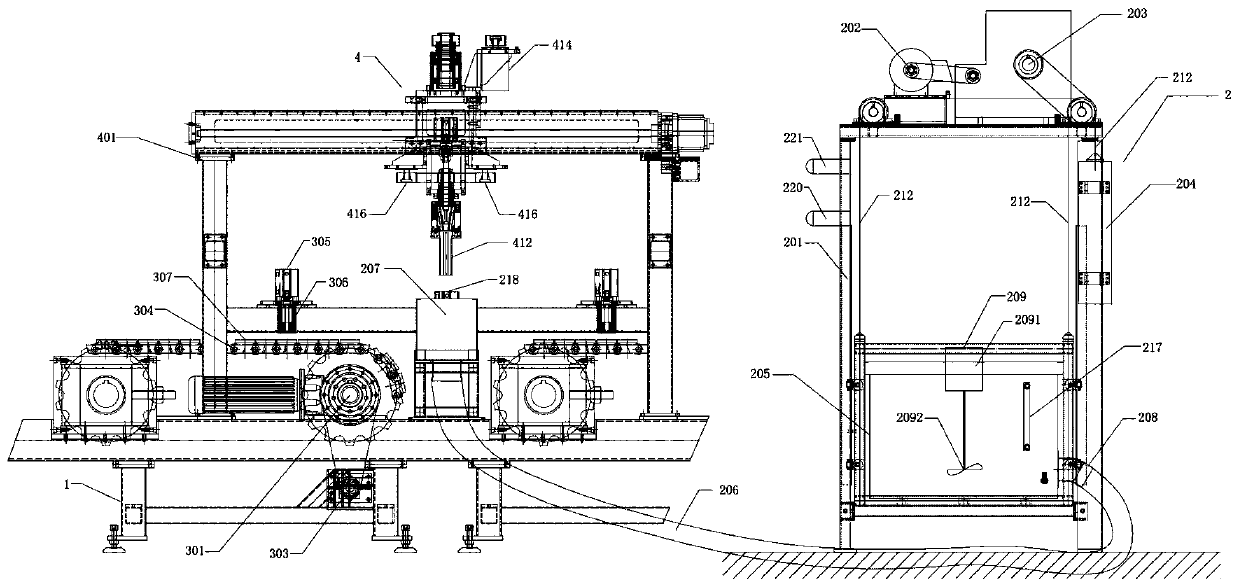

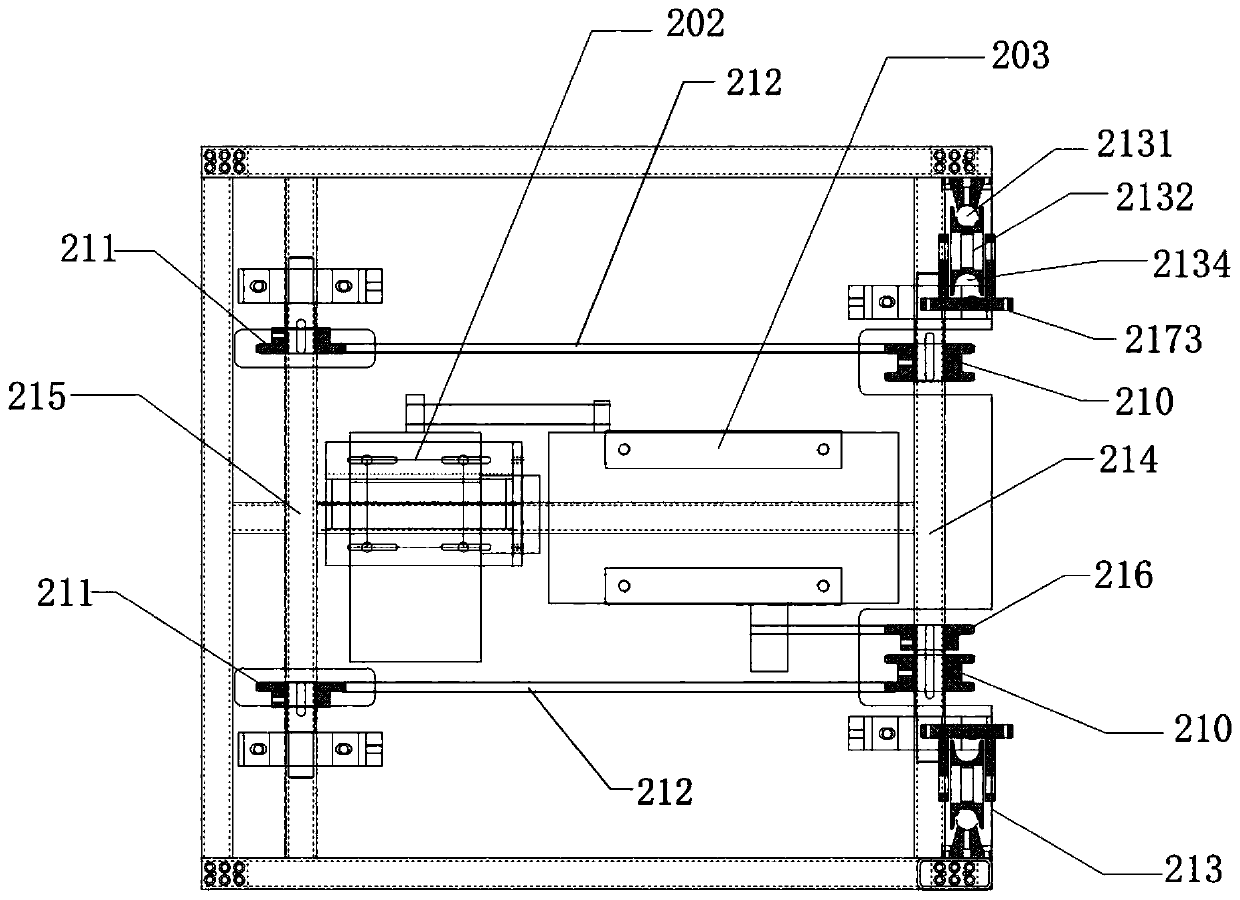

[0040] see Figure 1-7 as shown,

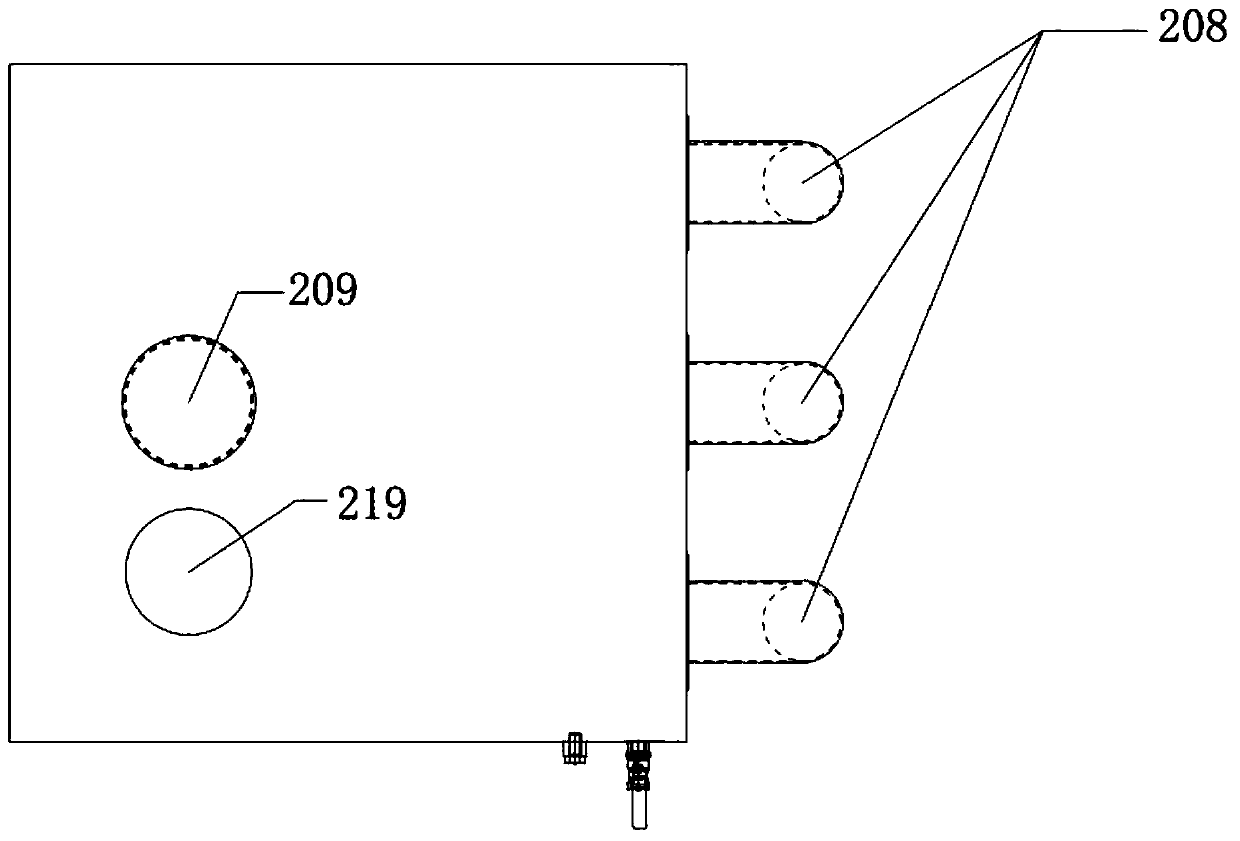

[0041] When the present invention is in use, the staff connects the paint inlet pipe for adding paint liquid through the paint inlet 219 of the gantry elevator 2, so that the inside of the paint bucket 205 is full of paint liquid, and connects the paint pipe 206 through the paint outlet 208, and the paint pipe 206 The other end of the other end is connected to the paint dipping box 207, so that the paint liquid is filled in the paint dipping box 207, and the second inductor 218 on the paint dipping box 207 can accurately sense the paint liquid level height in the paint dipping box 207, and the first servo electric device 202 Operation makes the paint bucket 305 move up and down, because the paint liquid in the paint dipping box 207 and the paint bucket 205 maintains the same level state, the paint liquid amount in the paint dipping box 207 is maintained at a suitable height;

[0042] The second servo motor 302 of the stator transport mechani...

Embodiment 2

[0045] The difference between this embodiment and Embodiment 1 is that when the stator stretches into the paint dipping box 307, the stator will occupy the position of the paint liquid, so that the paint liquid rises, and the first servo electric device 202 runs, so that the paint bucket 305 moves downward, The paint liquid in the paint dipping box 207 flows into the paint bucket 305, and the paint liquid in the paint dipping box 207 is reduced; when the paint dipping is completed, the stator can take away a part of the paint liquid, so that the paint liquid drops, and the first servo motor 202 Reverse operation makes the paint bucket 305 move upward, and the paint liquid in the paint bucket 305 flows into the paint dipping box 207, so that the paint liquid in the paint dipping box 207 rises, so that the interior paint liquid of the paint dipping box 207 is maintained at a suitable height ;

[0046] Moreover, after the paint is dipped, the paint liquid in the paint bucket 305 ...

Embodiment 3

[0048] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that when the device is used for a long period of time, the paint liquid in the dipping tank 207 is consumed, causing the paint bucket 205 to continuously Elevate, when paint bucket 205 rises to lower stopper 220 places, the alarm that lower stopper 220 is connected sends out the alarm sound, reminds the staff that the paint liquid amount inside paint bucket 205 is insufficient, when the staff does not take measures in time, The paint bucket 205 continues to rise, and when the paint bucket 205 rises to the upper stop 221, the power switch connected to the upper stop 221 closes the power supply of the device, thereby ensuring that the device is not damaged and improving the service life of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com