Manufacturing process for middle wrapping welding type flexible joint of 66kV-500kV cable

A 66kv-500kv, production process technology, applied in the direction of connecting/terminating cable equipment, etc., can solve the problems of cable docking, large footprint, not easy to carry, etc., to achieve good performance, eliminate micro-holes, and simple processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further explained in conjunction with the accompanying drawings.

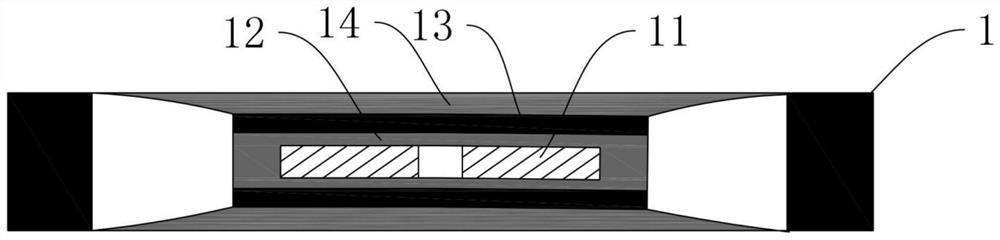

[0031] see figure 1 The manufacturing process of a 66kV-500kV cable intermediate wrapping fusion type soft joint includes the following steps:

[0032] a. Conductor 11 welding, through welding, the conductor 11 wire cores of the two sections of high-voltage cables 1 are welded together, and the conductor 11 welding point made by argon arc welding or gas welding welding technology is used to make the conductor 11 wires of the two sections of high-voltage cables 1 The cores are welded together, and the welding point is polished smooth after welding, so that the outer diameter of the welding place is equal to the outer diameter of the conductor 11 of the original cable.

[0033]b. The inner shielding layer 12 is restored, and the lining semi-conductive cloth is manually wound around the core of the conductor 11, and then the inner shielding tape is wound on the inner lining semi-co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com