Preparation method for carbon nanotube non-woven fabric interlayer modified fiber reinforced composite materials

A carbon nanotube and composite material technology is applied in the field of preparation of carbon nanotube non-woven interlayer modified continuous fiber composite materials, which can solve the problems of carbon nanotube structure damage, reduce carbon nanotube modification effect, etc. The effect of improving strength-toughening properties, high damage tolerance, and high impact damage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

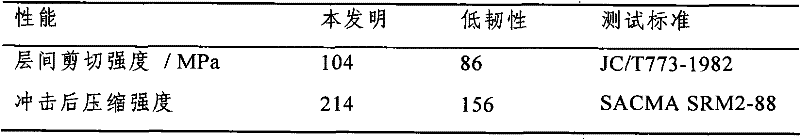

[0030] First prepare low toughness epoxy resin composite material as matrix material: prepare T300 / epoxy resin prepreg (epoxy resin composition is E-54:AG-80:DDS= 40:60:40), as per [45 / 0 / -45 / 90] 4S The method is quasi-isotropic layup. It is cured and formed in an autoclave. The forming process is: vacuuming to 0.095MPa in the whole process, heating from room temperature to 130℃, holding for 0.5h and then pressurizing to 0.55MPa~0.6MPa, then heating to 180℃ for 2 hours, and then heating to 200 ℃ for 2h, and finally cooled to below 60℃. The heating rate is 1.0°C / min to 2.0°C / min.

[0031] Prepare the same prepreg as the low toughness composite, also press [45 / 0 / -45 / 90] 4S The method is quasi-isotropic layup. In the laying process, the carbon nanotube non-woven fabric is directly attached to the surface of the epoxy prepreg, and a layer of carbon nanotube non-woven fabric is ensured between the two layers of prepreg. It is cured and formed in an autoclave according to the pr...

Embodiment 2

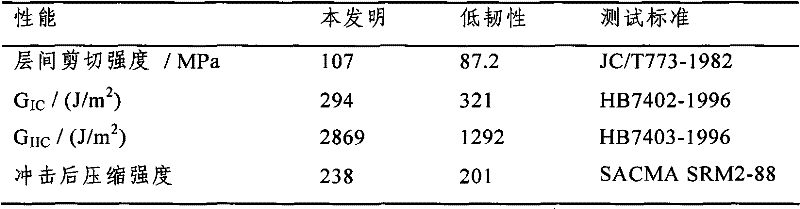

[0034] First prepare low toughness bismaleimide composite material as matrix material: prepare T700 / bismaleimide prepreg by wet method with TB-1 winding prepreg machine, according to [45 / 0 / -45 / 90] 4S The method is quasi-isotropic layup, and the autoclave is cured and formed. When it reaches 180 °C, it is kept for 3 hours, and the temperature is continued to rise to 200 °C for 5 hours. The whole process is evacuated, and finally cooled to below 60 °C to open the mold. The heating rate is 1.5 °C / min ~ 2.0 °C / min.

[0035] Prepare the same prepreg as the low toughness composite, also press [45 / 0 / -45 / 90] 4S The method is quasi-isotropic layup. In the laying process, the carbon nanotube non-woven fabric is directly attached to the surface of the Shuangma prepreg, and a layer of carbon nanotube non-woven fabric is ensured between the two layers of prepreg. It is cured and formed in an autoclave according to the process of low toughness composite materials.

[0036] Impact damag...

Embodiment 3

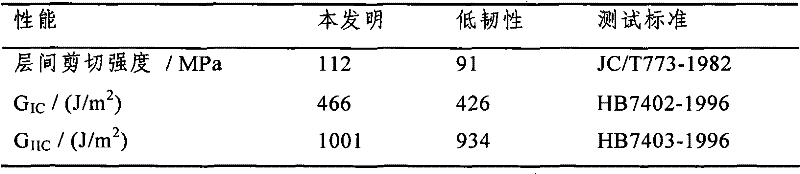

[0038] First prepare low toughness polyimide composite material as matrix material: prepare T300 / polyimide prepreg by wet method with TB-1 winding prepreg machine, according to [45 / 0 / -45 / 90] 4S The method is quasi-isotropic layering, and it is molded and cured on a hot press. The molding process: from room temperature to 205 ℃ ~ 210 ℃, after holding for 2 hours, heating to 240 ℃ ~ 250 ℃ for 1 hour, pressurizing to 1.5 MPa ~ 2 MPa , then heat up to 300 °C for 2 hours, then heat up to 325 °C for 1 hour, and finally cool to below 60 °C to open the mold. The heating rate is 1.0°C / min to 2.0°C / min.

[0039] Prepare the same prepreg as the low toughness composite, also press [45 / 0 / -45 / 90] 4S The method is quasi-isotropic layup. In the laying process, the carbon nanotube non-woven fabric is directly attached to the surface of the polyimide prepreg, and a layer of carbon nanotube non-woven fabric is ensured between the two layers of prepreg. It is cured and formed in an autoclave a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com