Graphene oxide/cyanate ester composite material and preparation method thereof

A technology of cyanate resin and composite materials, which is applied in the field of advanced composite materials science, can solve the problems of brittle cured products, achieve the effects of enhancing interface bonding strength, improving mechanical properties, and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

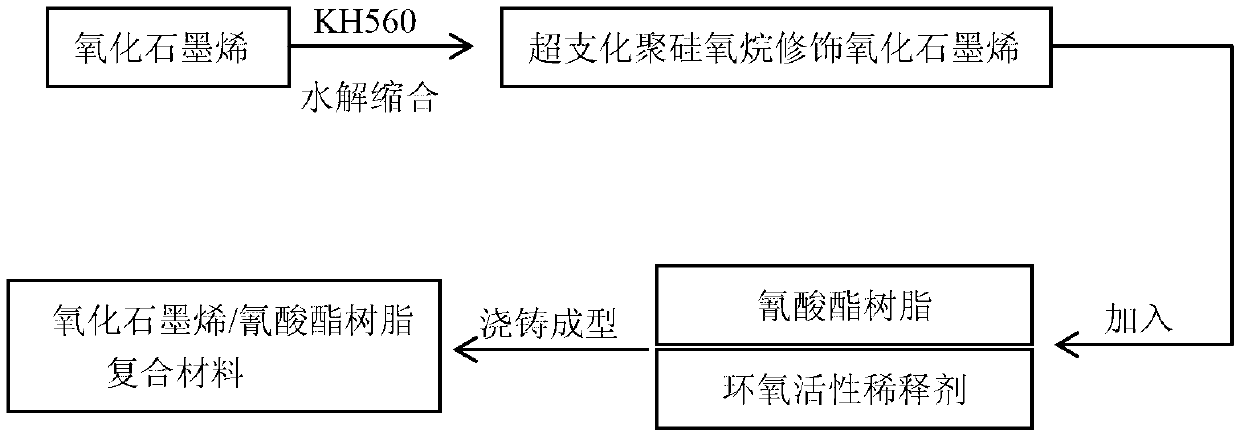

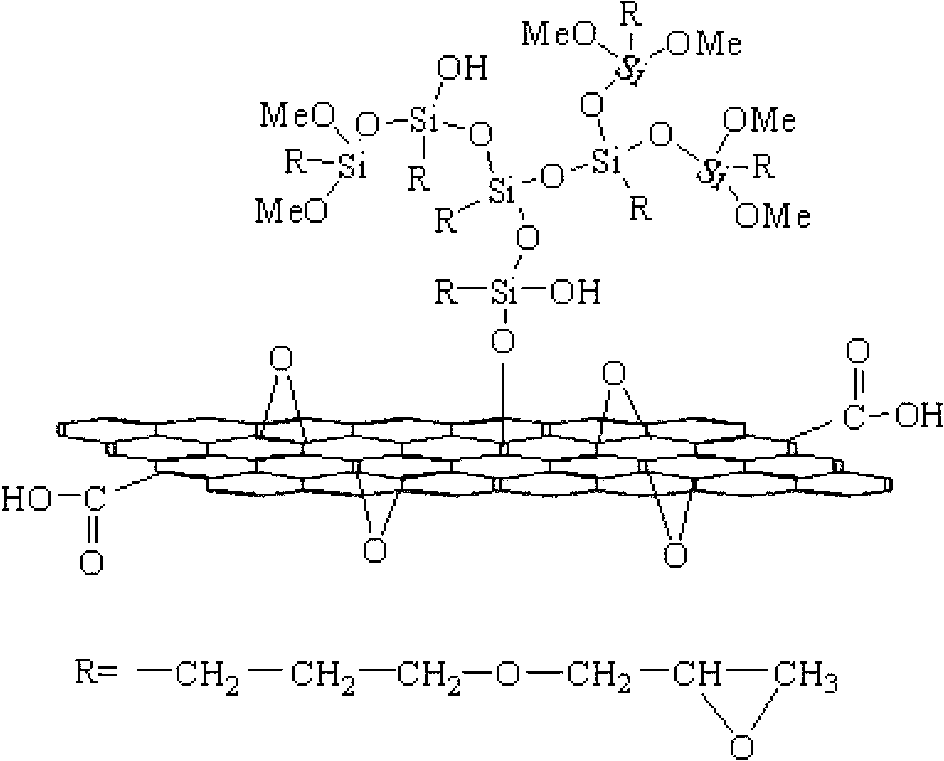

[0028] (1) Add 0.1~10 parts of graphite oxide to 1~100 parts of KH-560 tetrahydrofuran solution, and ultrasonically disperse for 0.5h. Then add 1~50mL of HCl aqueous solution with a concentration of 1mol / L dropwise, after the dropwise addition, stir at 50~80°C for 4~7h, remove the small molecular substances generated in the reaction, and obtain hyperbranched polysiloxane modified graphite oxide alkene.

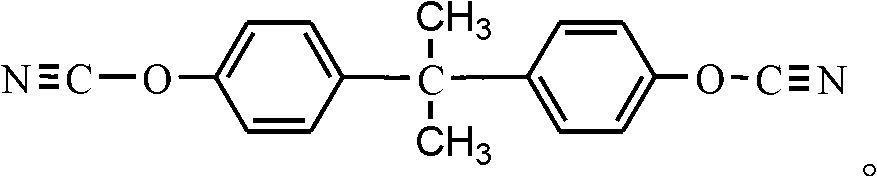

[0029] (2) Add 0.1 part of hyperbranched polysiloxane-modified graphene oxide to 10 parts of epoxy reactive diluent E-44, ultrasonically disperse at 40~70W for 0.5~3 hours, then add to 100 One part of the bisphenol A cyanate resin monomer that has been melted at 80°C is pre-polymerized at 80-120°C for 15-60 minutes, then poured into a preheated mold, and pumped in a vacuum box at 120°C Remove air bubbles in a vacuum until no bubbles emerge, take out the mold, put it into a blast drying oven for staged temperature rise curing, the curing process is 140°C / 2h+160°C / 2h+180°C / 2h, ...

Embodiment 2

[0031] (1) The preparation method of hyperbranched polysiloxane-modified graphene oxide is the same as that of Example 1.

[0032] (2) Add 1 part of hyperbranched polysiloxane-modified graphene oxide to 15 parts of epoxy reactive diluent E-51, ultrasonically disperse at 40~70W for 0.5~3 hours, then add to 100 One part of the bisphenol A cyanate resin monomer that has been melted at 80°C is pre-polymerized at 80-120°C for 15-60 minutes, then poured into a preheated mold, and pumped in a vacuum box at 120°C Remove air bubbles in a vacuum until no bubbles emerge, take out the mold, put it into a blast drying oven for staged temperature rise curing, the curing process is 140°C / 2h+160°C / 2h+180°C / 2h, then cool naturally, after demoulding, After post-treatment at 200°C for 2 hours, the graphene oxide / cyanate resin composite material was obtained.

Embodiment 3

[0034] (1) The preparation method of hyperbranched polysiloxane-modified graphene oxide is the same as that of Example 1.

[0035] (2) Add 3 parts of hyperbranched polysiloxane-modified graphene oxide to 20 parts of epoxy reactive diluent E-44, ultrasonically disperse at 40~70W for 0.5~3 hours, then add to 100 One part of the bisphenol A cyanate resin monomer that has been melted at 80°C is pre-polymerized at 80-120°C for 15-60 minutes, then poured into a preheated mold, and pumped in a vacuum box at 120°C Remove air bubbles in a vacuum until no bubbles emerge, take out the mold, put it into a blast drying oven for staged temperature rise curing, the curing process is 140°C / 2h+160°C / 2h+180°C / 2h, then cool naturally, after demoulding, After post-treatment at 200°C for 2 hours, the graphene oxide / cyanate resin composite material was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com