Self-lubricating wear-resisting unsaturated polyester molding compound and preparation method thereof

An unsaturated, self-lubricating technology, applied in the field of thermosetting molding compounds, can solve the problems of less graphite addition, graphite is easy to conduct electricity, and the electrical properties of molding compounds are reduced, achieving good results, improving mechanical properties, and low wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

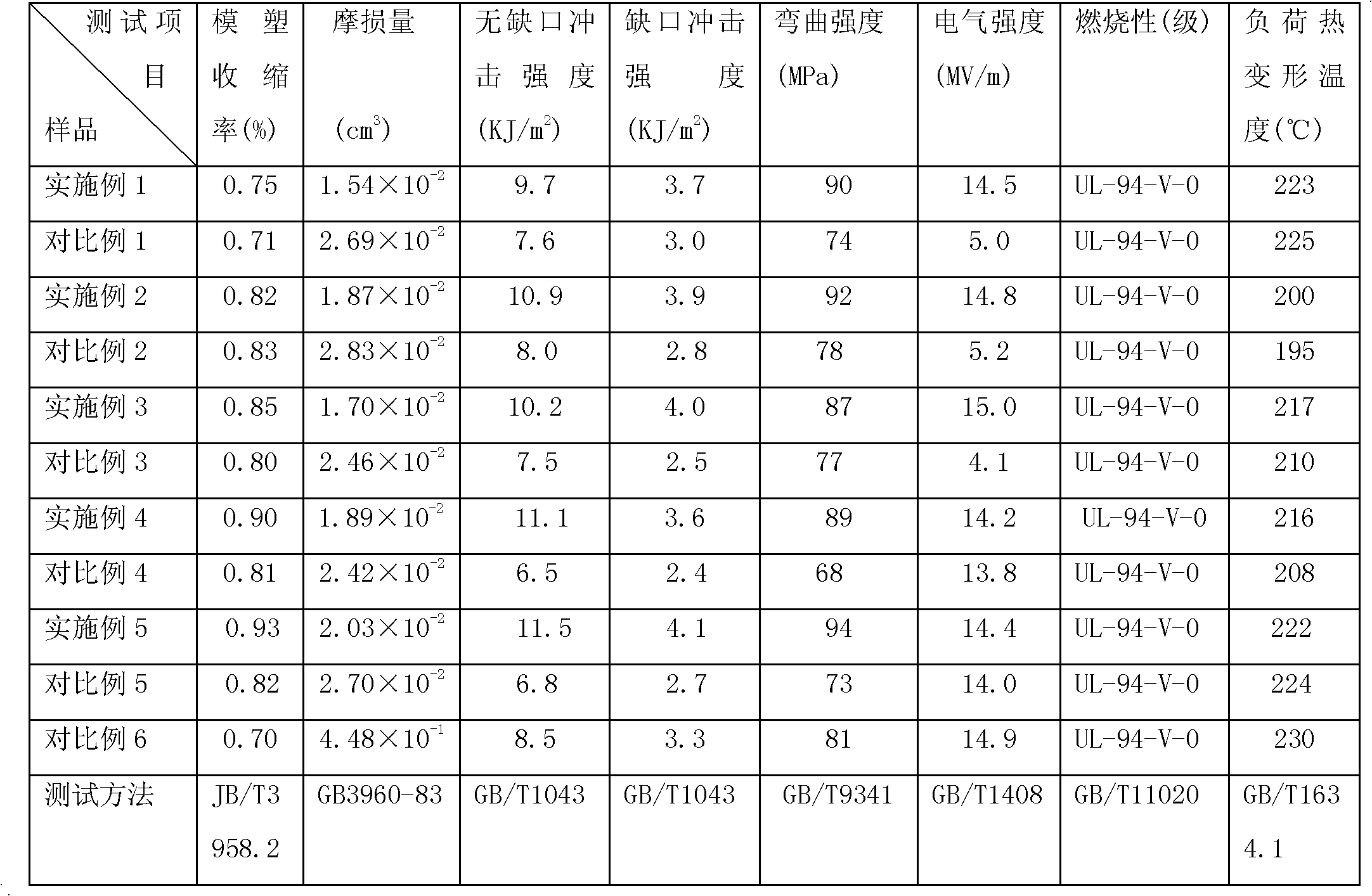

Examples

Embodiment 1

[0056] 1. Formula

[0057] 25 parts of ortho-phthalic unsaturated polyester resins with a softening point of 85°C;

[0058] 3.5 parts of triallyl cyanurate;

[0059] 0.4 parts of tert-butyl peroxybenzoate;

[0060] 0.01 parts of hydroquinone;

[0061] 2.2 parts of zinc stearate;

[0062] 10 parts of antimony trioxide;

[0063] 19 parts of triphenyl phosphate;

[0064] 18 parts of alkali-free glass fibers with a diameter of 15 μm and a length of 10 μm;

[0065] 10 parts of aramid fibers with a diameter of 15 μm and a length of 10 μm;

[0066] 10 parts of polytetrafluoroethylene powder with a particle size of 50 μm;

[0067] Iron red 1.5 parts.

[0068] 2. Preparation method:

[0069] Weigh the above-mentioned components according to the formula, put them into a dry powder high-speed mixer, mix them evenly, and refine them through a parallel twin-screw extruder. Send it into a single-screw granulator for granulation. The temperature of the barrel of the single-screw gr...

Embodiment 2

[0086] 1. Formula:

[0087] 28 parts of isophthalic unsaturated polyester resin with a softening point of 90°C;

[0088] 4.5 parts of divinylbenzene;

[0089] 1.5 parts of tert-butyl peroxy-2-ethylhexanoate;

[0090] 0.03 parts of hydroquinone;

[0091] 2.5 parts of sodium stearate;

[0092] 31 parts of zinc borate;

[0093] 10 parts of alkali-free glass fibers with a diameter of 15 μm and a length of 10 μm;

[0094] 12 parts of polyester fibers with a diameter of 20 μm and a length of 6 μm;

[0095] 10 parts of polyamide powder with a particle size of 30 μm;

[0096] 0.3 parts of titanium cyanide blue.

[0097] 2. Preparation method:

[0098] Weigh the above-mentioned components according to the formula, put them into a dry powder high-speed mixer, and after mixing evenly, they are refined by a parallel twin-screw extruder. Send it into a single-screw granulator for granulation. The temperature of the barrel of the single-screw granulator is controlled at 90-105°C to...

Embodiment 3

[0114] 1. Formula

[0115] 14 parts of o-phthalic unsaturated polyester resin with a softening point of 95°C;

[0116] 18 parts of m-xylene unsaturated polyester resin whose softening point is 88°C;

[0117] 2.5 parts of methyl methacrylate;

[0118] 2.5 parts of vinyl toluene;

[0119] 1.65 parts of 1,1-bis(tert-butylperoxy)cyclohexane;

[0120] 0.03 parts of tert-butylhydroquinone;

[0121] 2.5 parts of sodium stearate;

[0122] 12 parts of aluminum hydroxide;

[0123] 18 parts of magnesium hydroxide;

[0124] 10 parts of alkali-free glass fibers with a diameter of 25 μm and a length of 6 μm;

[0125] 6 parts of hemp fibers with a diameter of 15 μm and a length of 12 μm;

[0126] 6 parts of polyoxymethylene powder with a particle size of 100 μm;

[0127] 6 parts of polyamideimide powder with a particle size of 80 μm;

[0128] 0.5 part of permanent yellow.

[0129] 2. Preparation method

[0130] Weigh the above-mentioned components according to the formula, put th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com