Friction and wear testing machine with controllable humidity

A friction and wear test, humidity technology, applied in the direction of testing wear resistance, etc., can solve the problems of long time consumption of humidity, poor stability, lack of friction and wear testing machine, etc., to achieve the effect of reducing loss and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

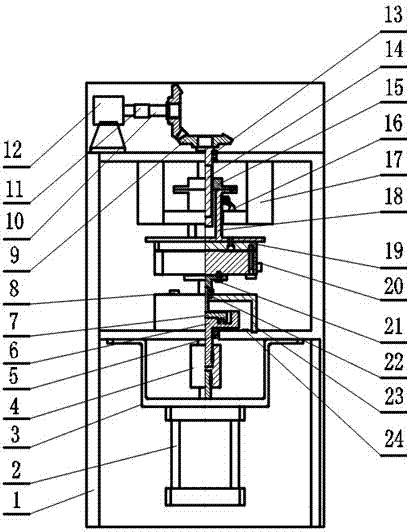

[0019] In the figure, the friction and wear testing machine with controllable humidity includes workbench chamber 1, spindle motor 2, motor mounting beam 3, spindle motor coupling 4, thrust ball bearing 5, lower fixture 6, lower sample 7, ventilation Spring button switch 8, bevel gear pair 9, bevel gear shaft 10, servo motor coupling 11, servo motor 12, screw bearing 13, screw shaft 14, screw nut 15, anti-rotation roller 16, column beam 17, Loading sleeve 18, cushion block 19, triaxial force sensor 20, upper fixture 21, upper sample 22, environmental chamber 23 and STH11 digital temperature and humidity sensor 24.

[0020] exist figure 1Among them, the humidity-controllable friction and wear testing machine has a closed workbench chamber 1, which is divided into upper, middle and lower layers, and the spindle motor 2 is fixed on the lower layer of the workbench chamber 1 through the motor installation beam 3 Inside, the spindle motor 2 is connected to the lower fixture 6 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com