Online monitoring device and online monitoring method for thrust bearing wear loss of fully-sealed pump

A technology for bearing wear and pump thrust is applied in the field of fully sealed pump monitoring devices for reactor systems, which can solve the problems of low measurement accuracy and inability to monitor the wear amount of graphite bearing bushes of thrust bearings, and achieve the effect of avoiding shutdown.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

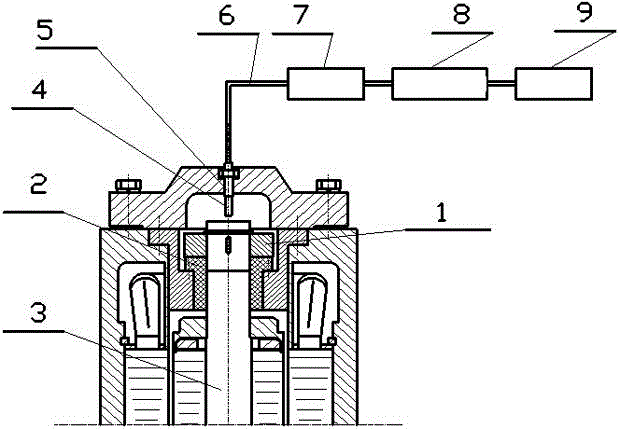

[0029] Such as figure 1 The schematic diagram shown is a schematic diagram of the structure of the water-lubricated thrust bearing inside the vertically arranged fully-sealed pump. The water-lubricated thrust bearing is mainly composed of a disc-shaped thrust plate 1 and a friction pair composed of 8 fan-shaped graphite bearing bushes 2 arranged in an axisymmetric ring. Composition, the thrust disc 1 and the rotor 3 are in the form of a rigid fixed connection structure, the friction surface of the thrust disc 1 is overlay welded with wear-resistant hard alloy with high hardness, and the hardness of the fan-shaped graphite bearing bush is lower than the friction surface of the thrust disc, and the fully sealed pump runs When the thrust disc rotates continuously around the axis, the graphite bearing pad remains stationary. Since the axial load of the thrust bearing acts on the graphite bearing pad 2 through the thrust disc 1 and keeps it downward, the long-term operation of the t...

Embodiment 2

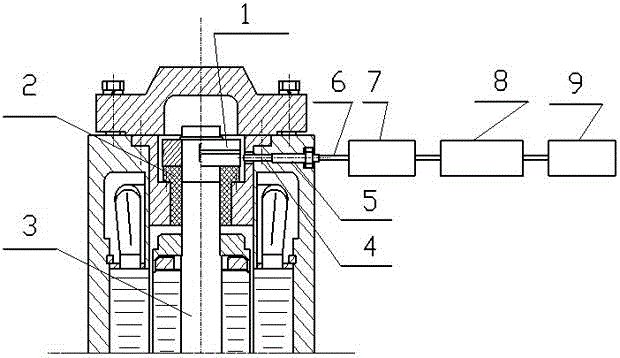

[0031] Such as figure 2 As shown in the schematic diagram, the difference between this embodiment and Embodiment 1 is that the hole for the installation position probe 4 is set on the side wall of the sealed pump, and the detection direction of the position probe 4 is in the radial direction of the rotor 3. (A) is assembled Behind the thrust plate 1, a magnetic scale line is set on the outside of the thrust plate 1; (B) During the operation of the sealed pump, the position probe 4 continuously detects the surface of the thrust plate 1. When the position probe 4 detects the magnetic scale line, a An output signal is passed to the amplifier 7 for signal amplification, and then transmitted to the analog / digital converter 8; (C) the analog / digital converter 8 receives the amplified analog signal and performs analog-to-digital conversion to form a digital signal; (D) The computer 9 receives the digital signal and judges whether the output signal is true. If it is true, the compute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com