Detection system and detection method of friction elevator rope groove wear loss

A friction hoist and wear detection technology, applied in elevators, transportation and packaging, etc., can solve problems such as uneven stress on wire ropes, difference in length of wire ropes, and different wear conditions of friction linings, so as to reduce labor intensity and improve use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: The friction hoist rope groove wear amount detection of the present invention includes a detection system and a detection method:

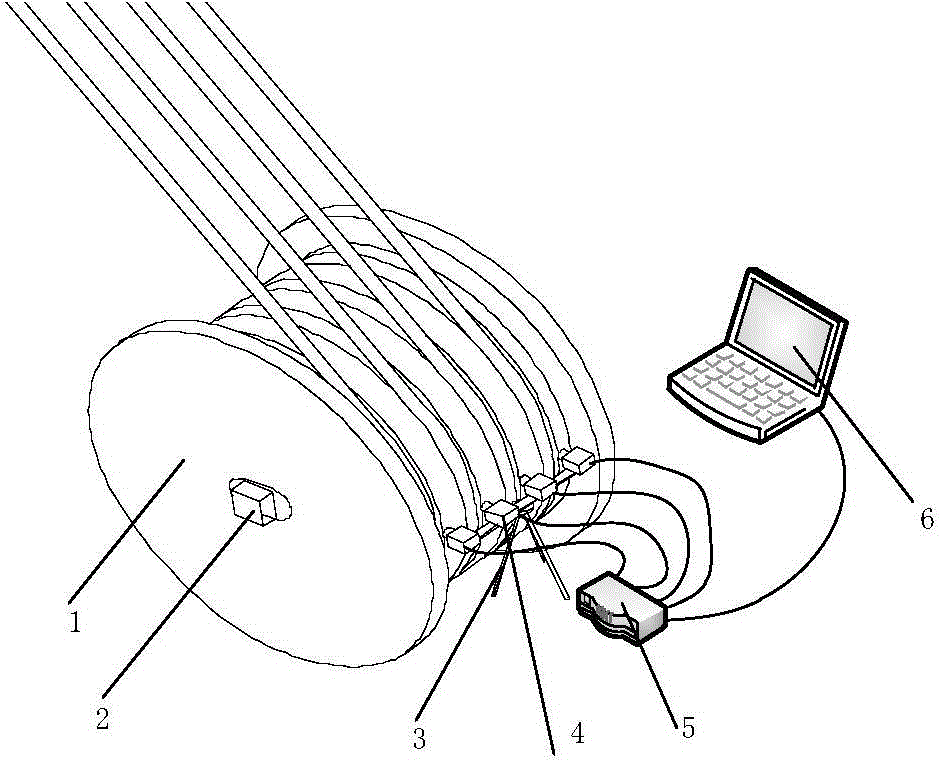

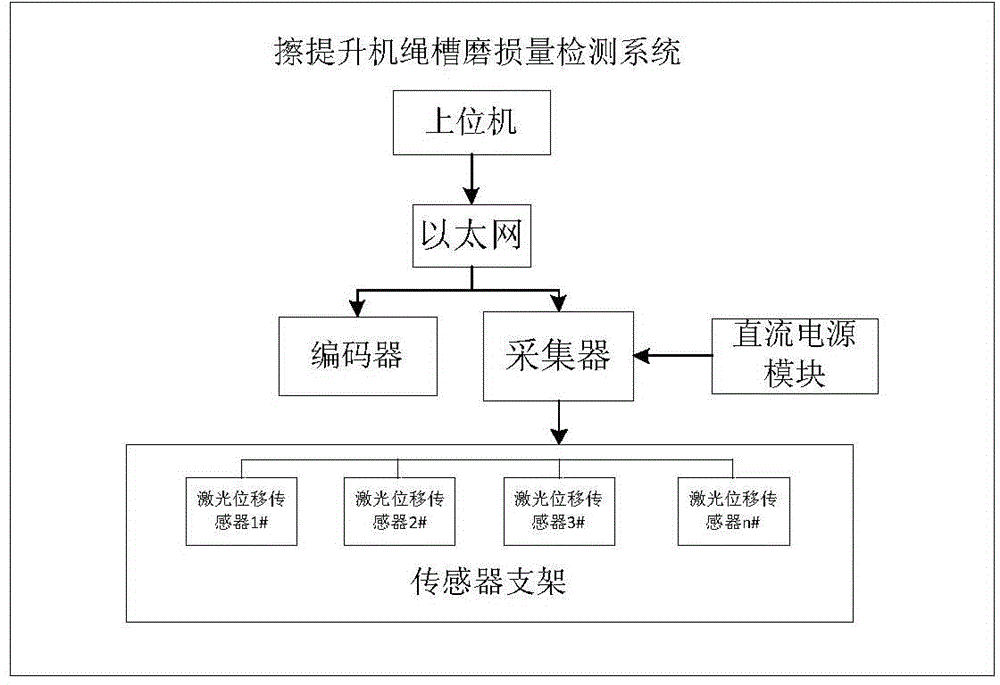

[0017] The detection system includes: a hoist 1, an encoder 2, a sensor bracket 3, a laser displacement sensor 4, a collector 5 and a host computer 6; a laser displacement sensor 4 is placed on the sensor bracket 3, and the laser displacement sensor 4 There are multiple sets, each laser displacement sensor 4 is aligned with a rope groove of the friction hoist, the output end of the laser displacement sensor 4 is connected with the input end of the collector 5, the encoder 2 is installed on the drum shaft of the hoist 1, and the encoder 2 and the collector 5 are connected to the input end of the upper computer 6 through the Ethernet.

[0018] The encoder 2 adopts E6A2-CS3E, which is convenient to convert the change of the physical quantity of mechanical angle into an electrical signal; the laser displacement sensor 4 adopts the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com