Replacing device and method for disc cutters of tool head

A tool replacement and tool head technology, which is applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of long time, longer replacement operation time, and higher cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

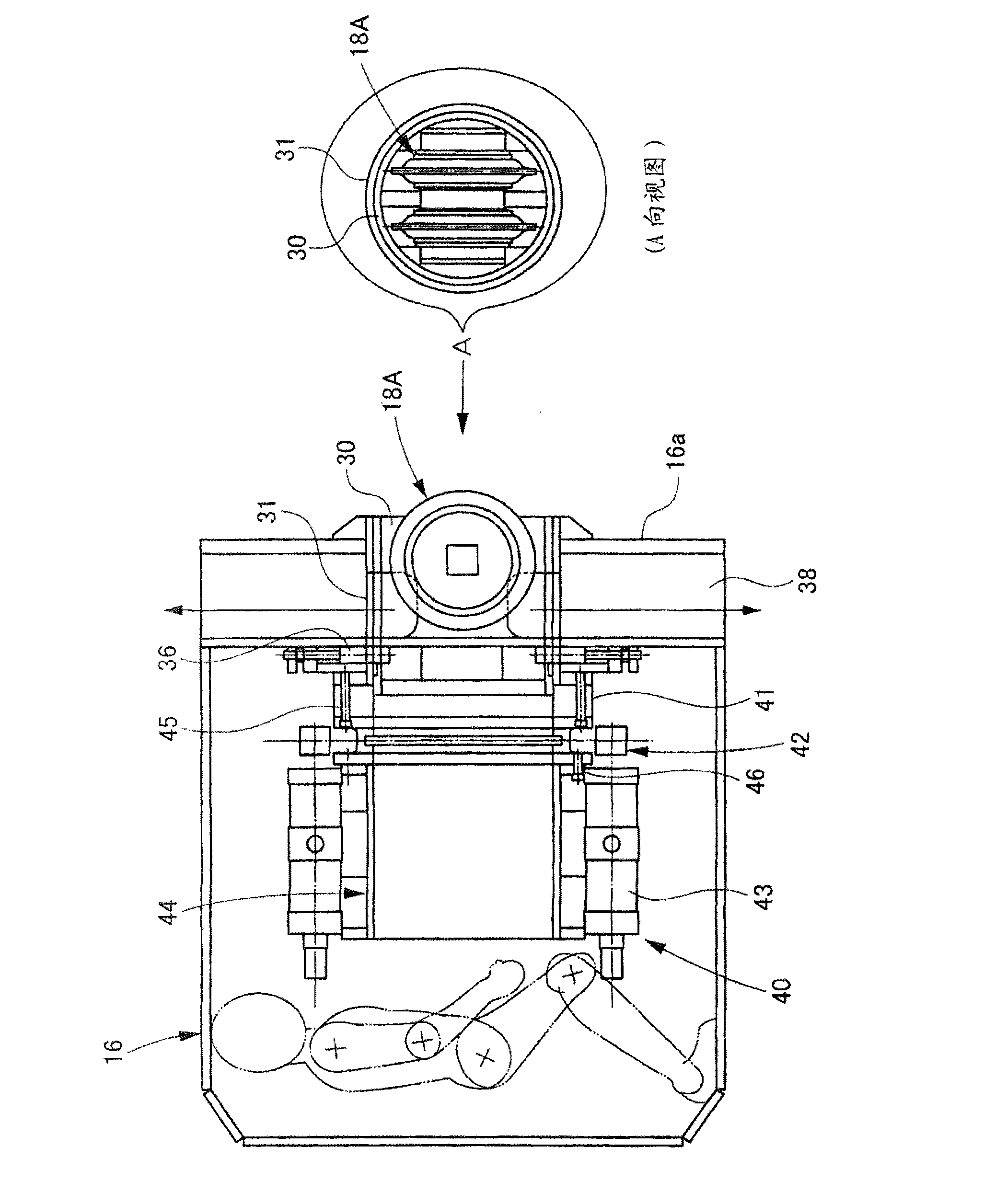

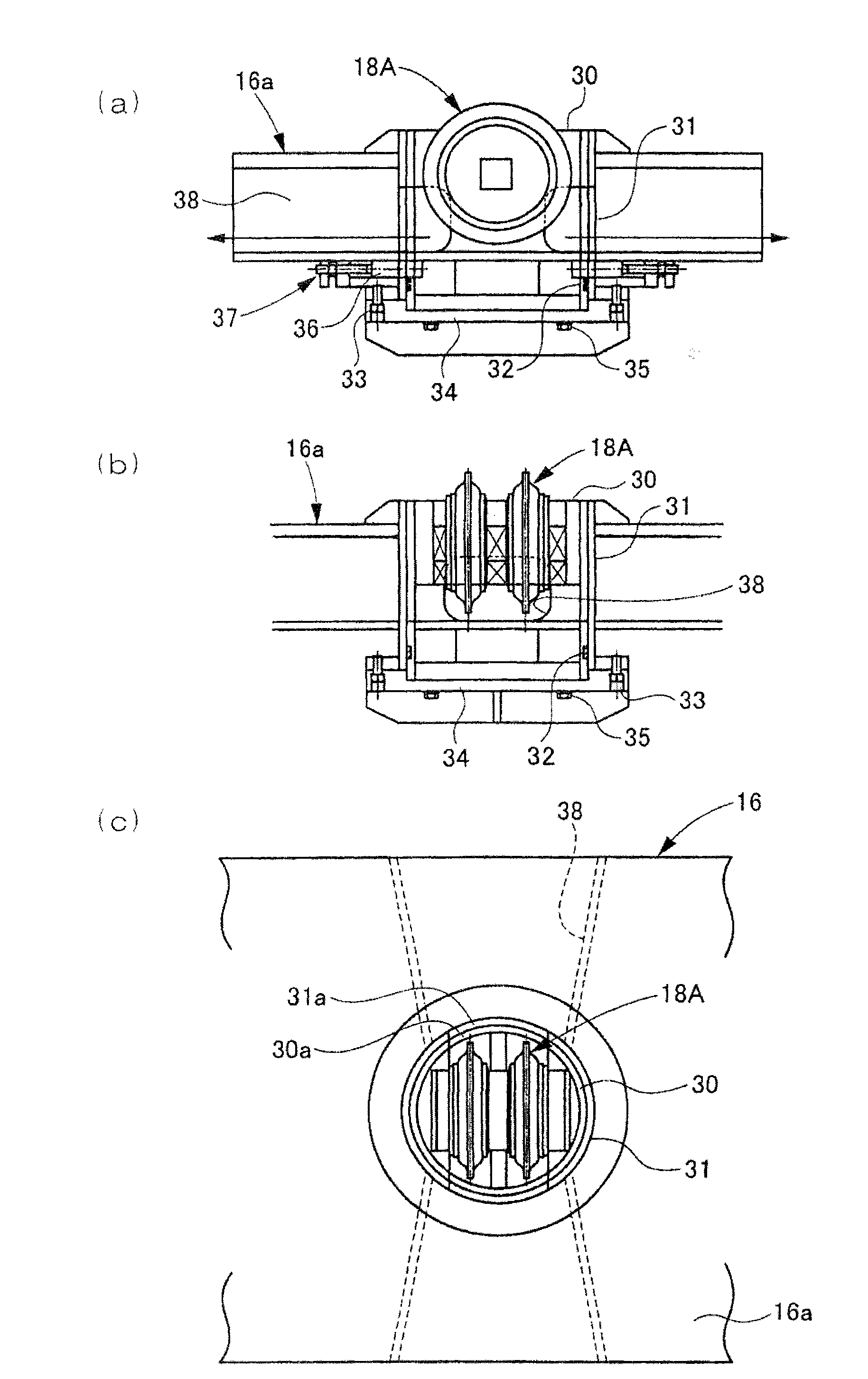

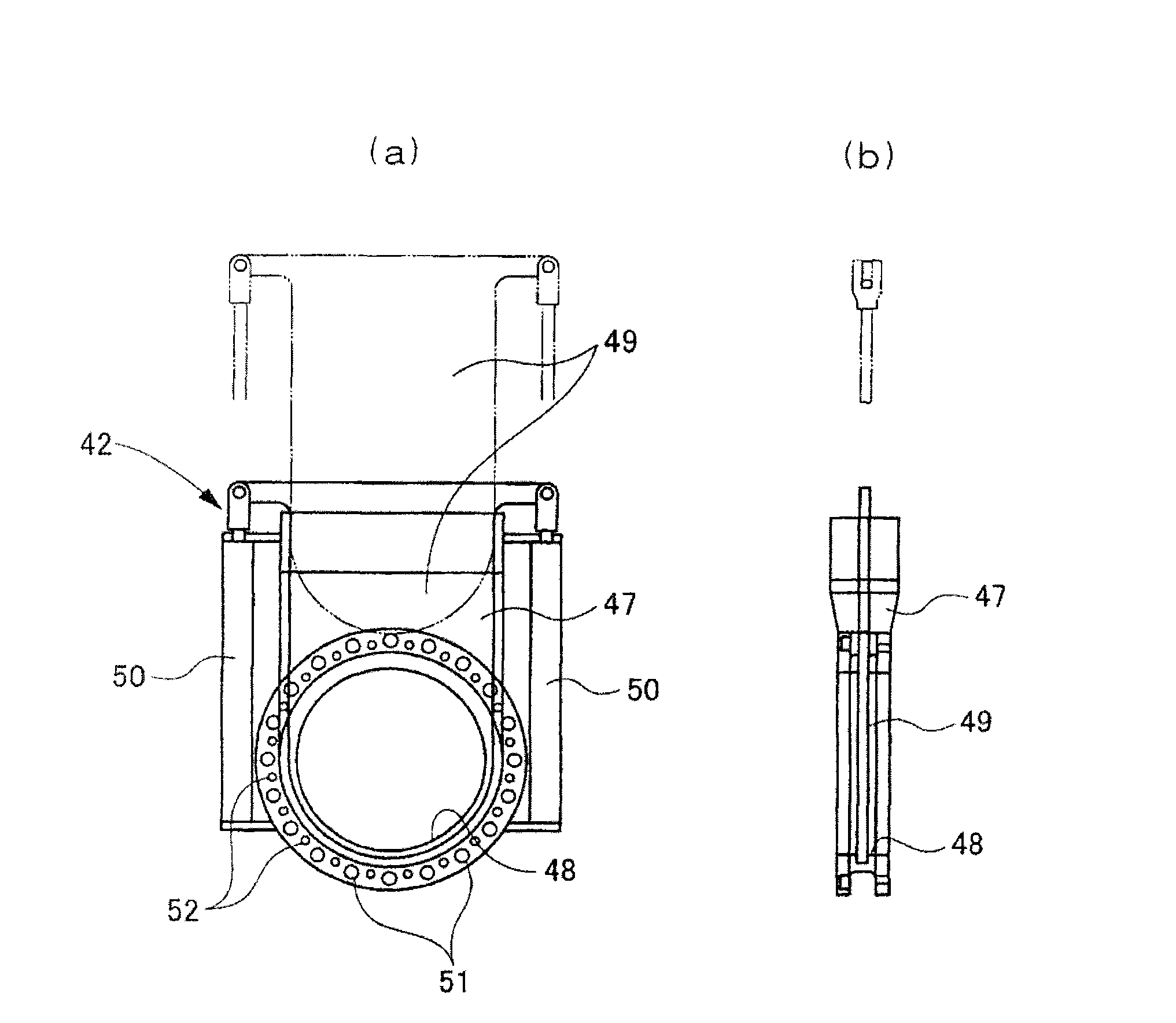

[0098] figure 1 is an overall side view showing the disc cutter changing device of Embodiment 1 of the present invention; figure 2 It is a diagram of the installation state when the disc-shaped cutter is excavated, wherein, figure (a) is a main view, figure (b) is a side view, and figure (c) is a top view; image 3 It is a structural explanatory diagram of a knife gate valve, wherein, figure (a) is a back view, and figure (b) is a side view; Figure 4 is a sectional view of the main parts of the earth pressure shield excavator; Figure 5 It is the front view of the earth pressure shield excavator (cutter head); Image 6 is an explanatory diagram of the replacement steps of the disc cutter; Figure 7 is an explanatory diagram of the replacement steps of the disc cutter; Figure 8 is an explanatory diagram of the replacement steps of the disc cutter; Figure 9 is an explanatory diagram of the replacement steps of the disc cutter; Figure 10 It is an explanatory diagram of...

Embodiment 2

[0141] Figure 12 It is a cross-sectional view showing the spokes of the cutterhead according to Embodiment 2 of the present invention, wherein, figure (a) is an installation state diagram when the disk cutter is excavated, and figure (b) is an installation state diagram when the disk cutter is replaced .

[0142] This is an example in which this disk cutter changing device is applied to a so-called front-loading double disk cutter 18A in which disk cutters are mounted from the front side of the cutter head, instead of the rear-loading double disk cutter 18A of the first embodiment.

[0143] For example, as shown, a dimple 16b is formed extending longitudinally on the front wall portion 16a of the cutter head spoke 16, within which a replaceable dual disc cutter 18A is located and mounted via a sand guide 61.

[0144] Specifically, the short cylindrical mount 30 with the top of the double disk cutter 18A is inserted into the cylindrical mounting table 31 fixedly arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com