Numerical control tool grinder used for grinding of disc milling cutter blade

A tool grinder, disc milling cutter technology, applied in milling cutters, manufacturing tools, milling machine equipment and other directions, can solve the problems of high cost, secondary assembly error of inserts, inability to grind and form disc milling cutters, etc. Accuracy, the effect of reasonable machine tool layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the content of the invention, features and effects of the present invention, the description is as follows according to the following embodiments and in conjunction with the accompanying drawings:

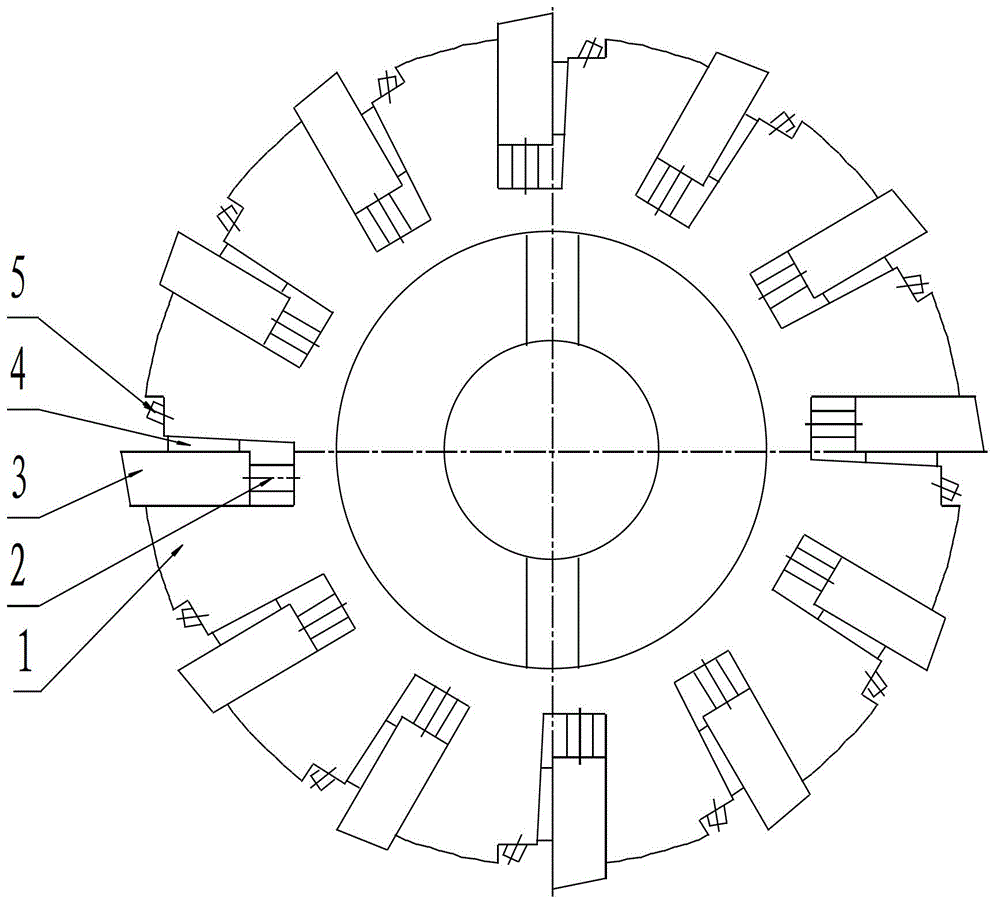

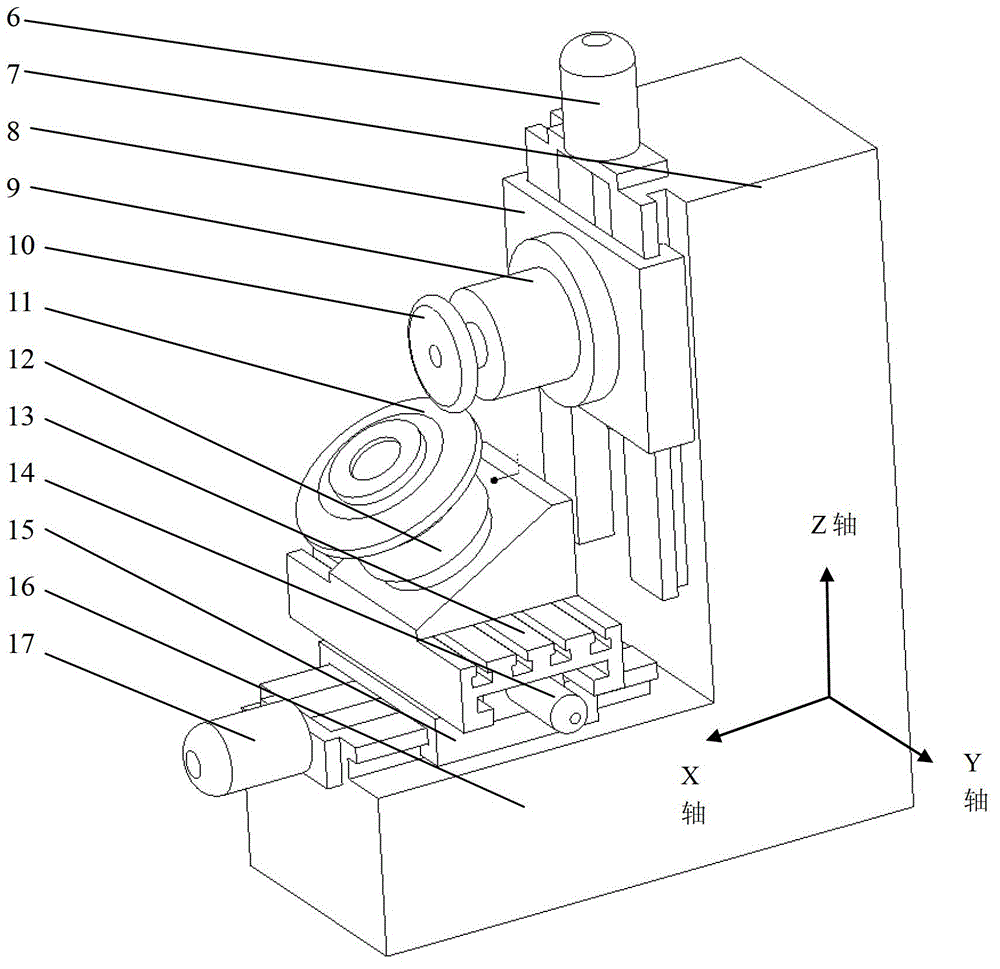

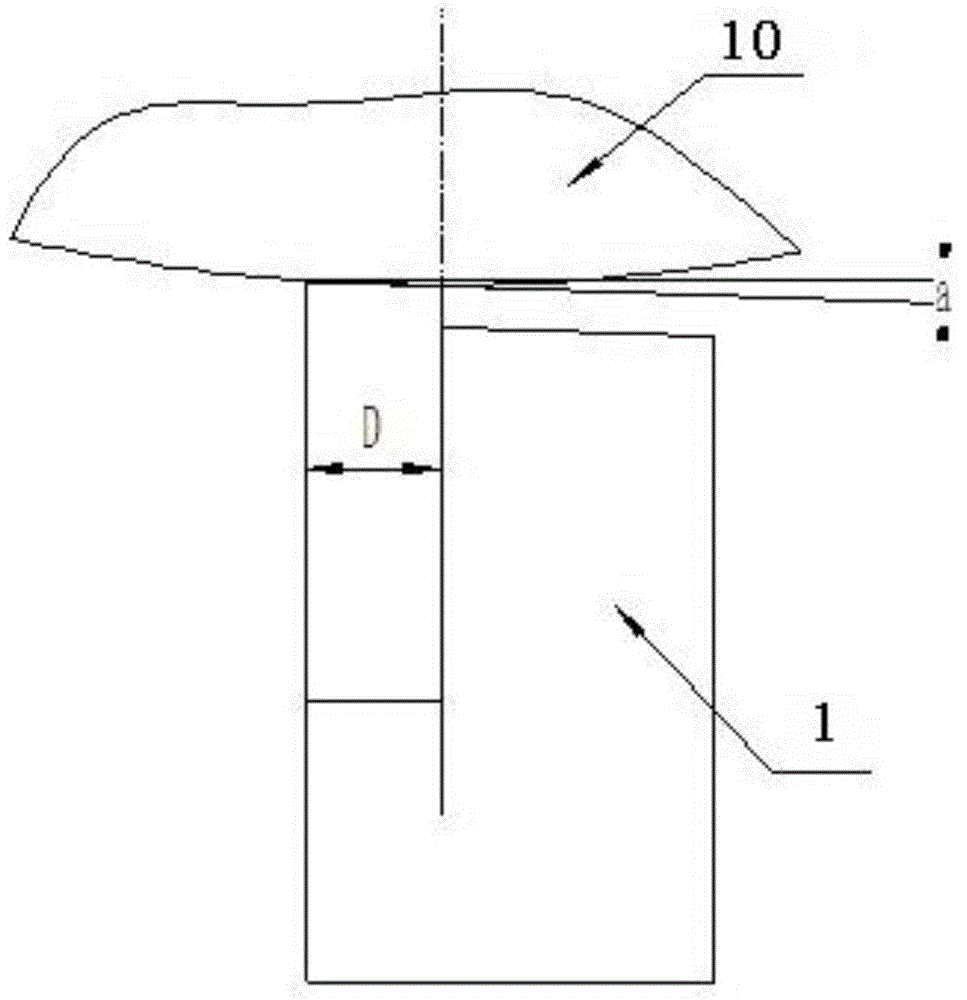

[0028] A numerically controlled tool grinding machine for sharpening disc milling cutter blades, comprising a bed 16, a column 7, a horizontal workbench, a longitudinal workbench, a numerically controlled rotary workbench 12, a vertical feed carriage 8, and a grinding electric spindle 9 , the horizontal workbench and the longitudinal workbench form a cross slide structure and are assembled on the bed 16, the CNC rotary table 12 is obliquely assembled on the horizontal workbench, and the disc-shaped milling cutter to be ground is installed on the CNC rotary table 12. on the connected positioning mandrel; the column 7 is placed on the rear side of the bed 16, and the front guide rail of the column 7 is equipped with a vertical feed carriage 8 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com