Device for testing wear resistance of disc cutter of TBM (tunnel boring machine) and application

A disc-shaped hob, testing device technology, applied in the direction of testing wear resistance, etc., can solve problems such as single applicable conditions, can not reflect the wear characteristics of the prototype cutter ring, large deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

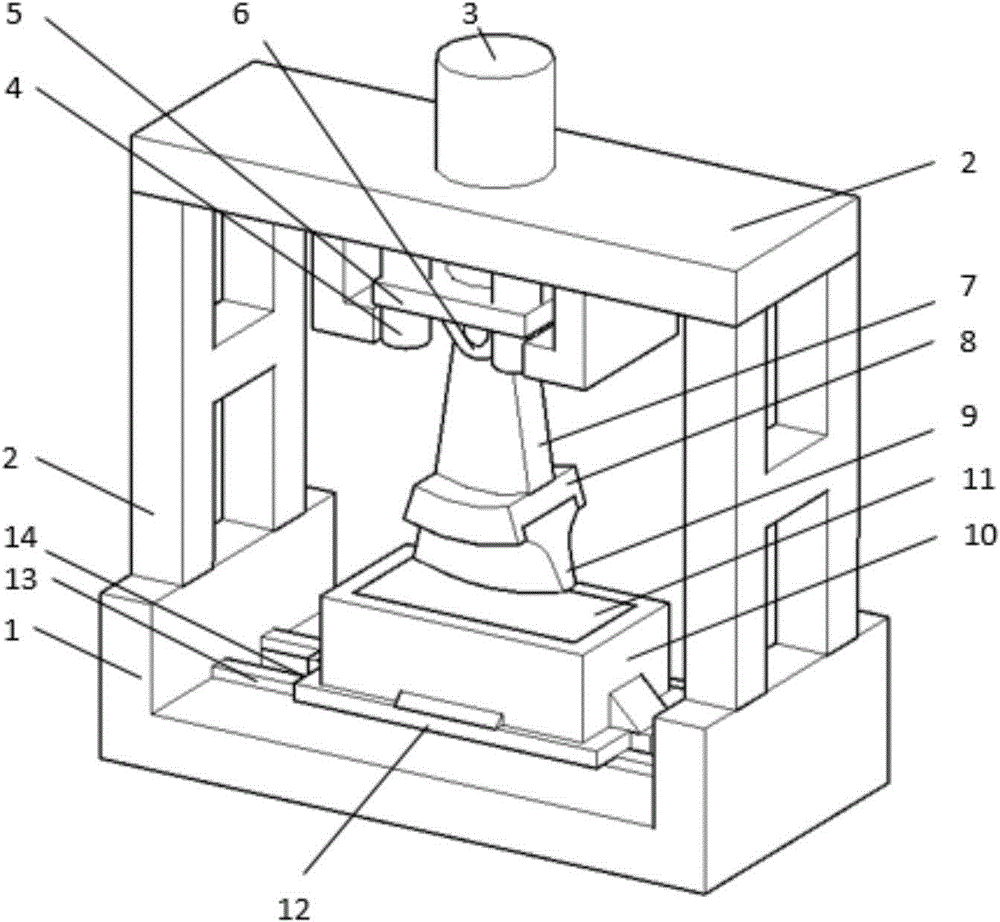

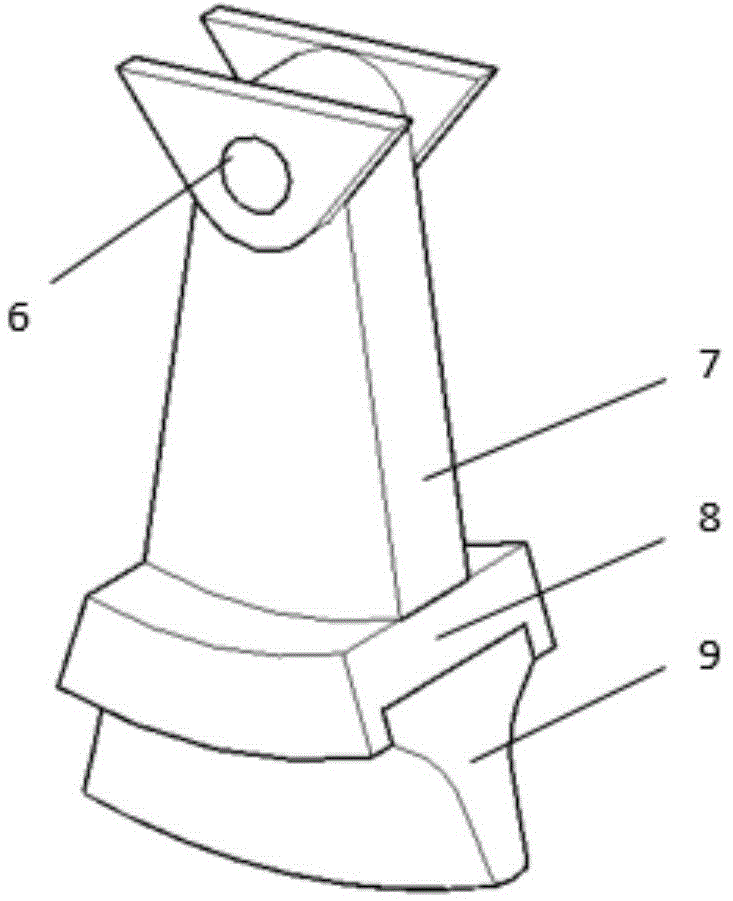

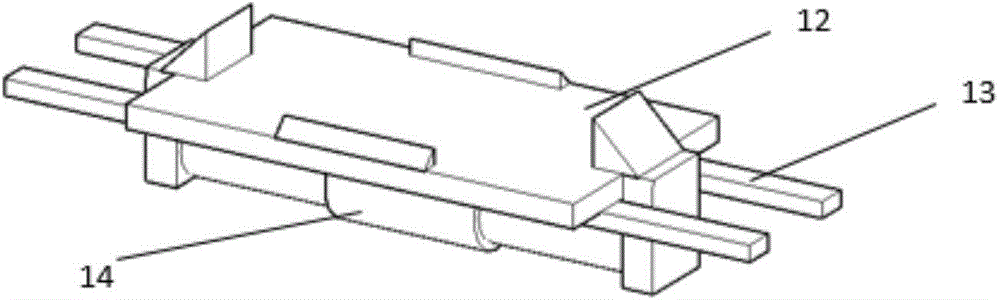

[0023] Such as Figure 1~6 As shown, a test device for the wear resistance of the disk hob of a roadheader includes a base 1, a reaction frame 2, a vertical hydraulic cylinder 3, a vertical guide rod 4, a vertical force pad 5, a bearing 6, and a knife The body 7, the knife ring fixture 8, the knife ring sample 9, the model box 10, the rock sample 11, the model box fixing block 12, the transverse slide 13, the transverse hydraulic cylinder 14 and the test system; the reaction frame 2 It includes a top beam and side longitudinal beams. The longitudinal beams are arranged on the base 1. Four vertical guide rods 4 are fixed on the lower surface of the beam. The vertical force bearing blocks 5 are sleeved on the four vertical guide rods 4 and The vertical hydraulic cylinder 3 can be moved up and down. The vertical hydraulic cylinder 3 is arranged on the top beam of the reaction frame 2 and connected to the vertical force bearing block 5 below. The knife-like body 7 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com