Calculation method for predicting wear amount of disc hob of roadheader

A disc-shaped hob, calculation method technology, applied in calculation, measurement device, special data processing application, etc., can solve the problems of little guiding significance, inability to achieve quantitative calculation, shortening construction time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The calculation method of the present invention will be further described through the following examples. It should be noted that this example is descriptive and does not limit the protection scope of the present invention.

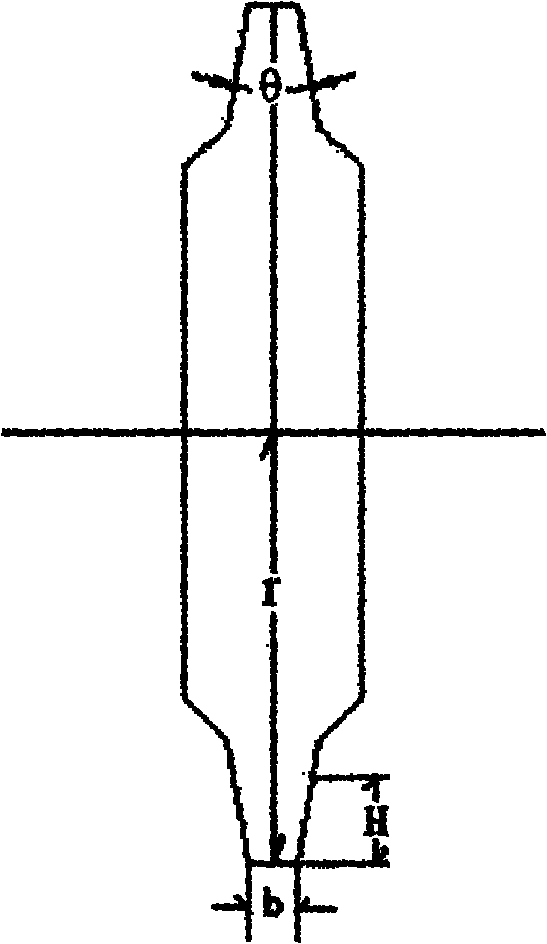

[0051] The operating parameters of the roadheader during the construction process are as follows: the total thrust of the cutter head F = 8600KN, the cutter head torque M' = 4000KNm, the cutter head rotates 4r / min, which is the rotation frequency f 1 = 1 / 15, cutterhead advancing speed V = 1m / h, roadheader structural parameters are as follows: cutterhead diameter D = 6.31m, total number of cutters on cutterhead n 4 =43, disc hob radius r=216mm, energy wear rate 1=6×10 -5 mm 3 / J, disc-shaped hob blade width b=20mm, blade angle θ=20°, the following will take the disc-shaped hob with the advancing distance of 1km and the disc-shaped hob installation radius R=1577.5mm as an example, and the calculation is given For the detailed steps of disc hob wear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com