Tunnelling machine control system detection test platform

A control system and shield machine technology, which is applied in the field of shield machine control system detection and test devices, can solve problems such as hidden dangers in construction, unreasonable design, and delays in project progress, and achieve the effects of comprehensive functions, simple structure, and easy expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

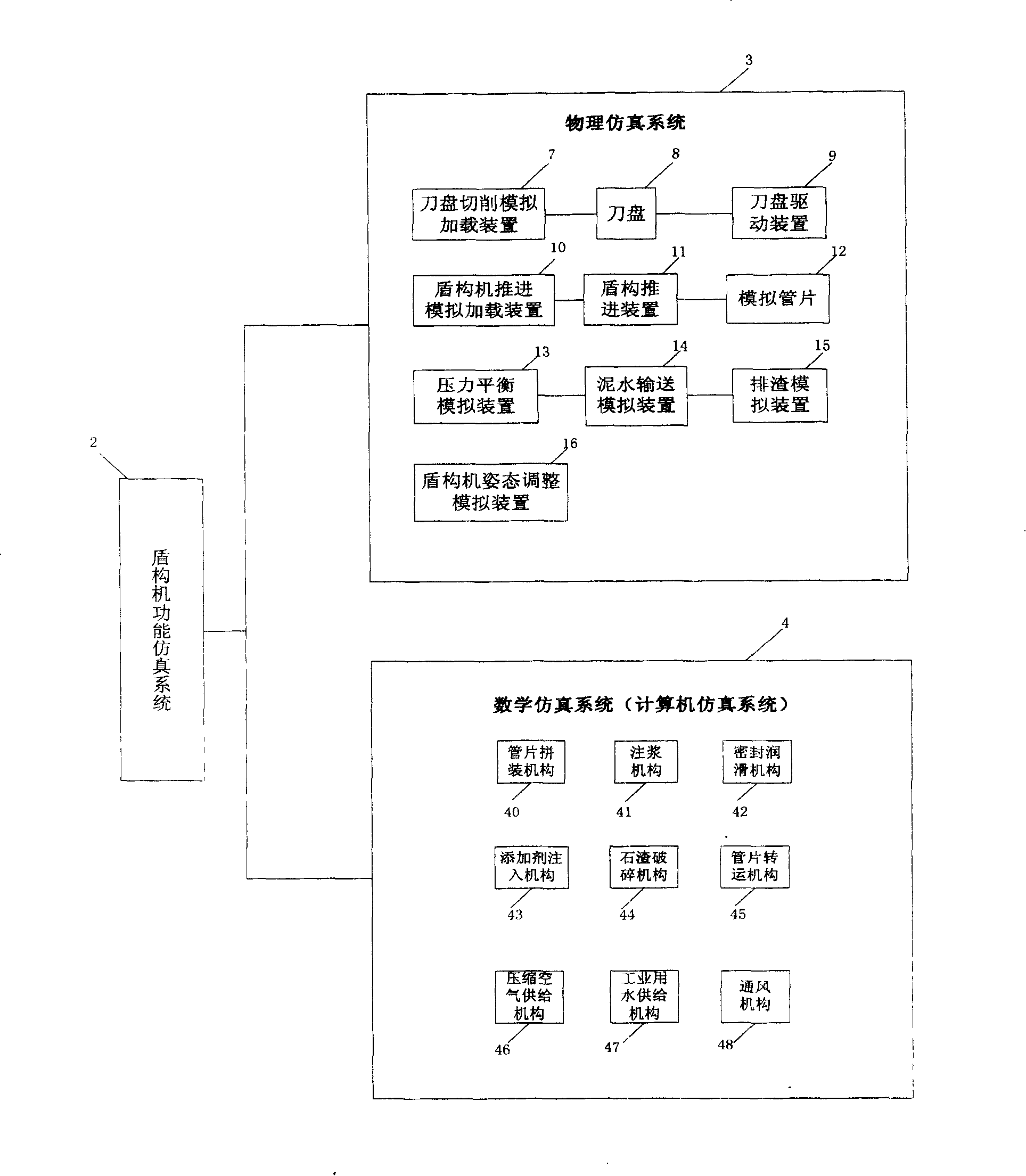

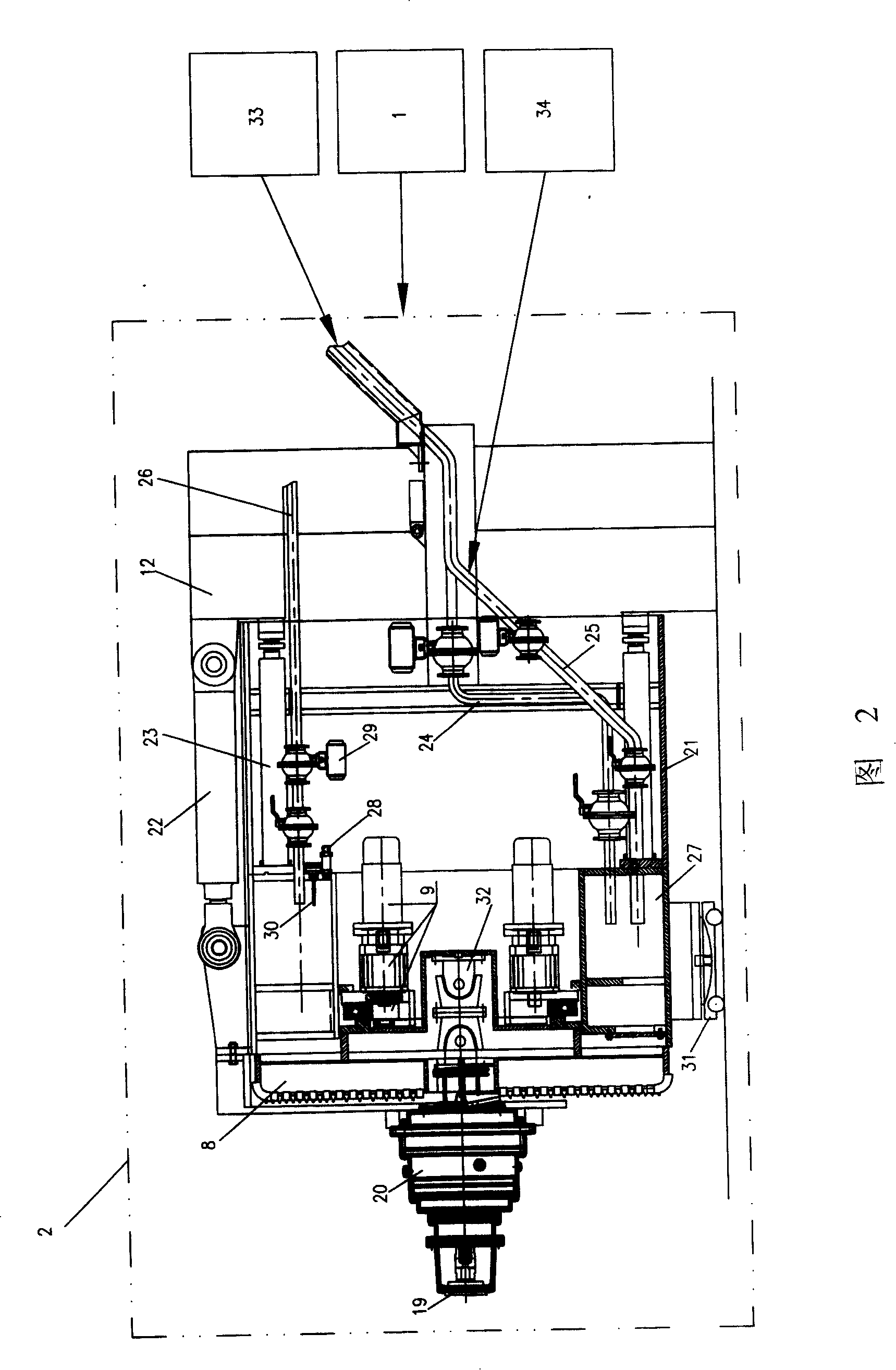

[0022] Embodiment 1: In the shield machine control system detection test bench in this embodiment, there is a shield machine function simulation system 2, which is composed of a physical simulation system 3 and a mathematical simulation system 4.

[0023] The shield machine function physical simulation system 3 is composed of a cutter head drive device 9 assembled with the shield body 21, a cutter head 8, a cutter head cutting simulation loading device 7, a simulated segment 12, a shield machine propulsion device 11, a shield machine It is composed of a machine propulsion simulation loading device 10, a slag discharge simulation device 15, a muddy water transportation simulation device 14, a pressure balance simulation device 13, and a shield machine attitude adjustment simulation device 16.

[0024] Cutter 8 is contained in the front end of shield 21, and cutter drive 9 is contained in the shield 21, and cutter drive 9 is made up of power unit together with speed reducer and l...

Embodiment 2

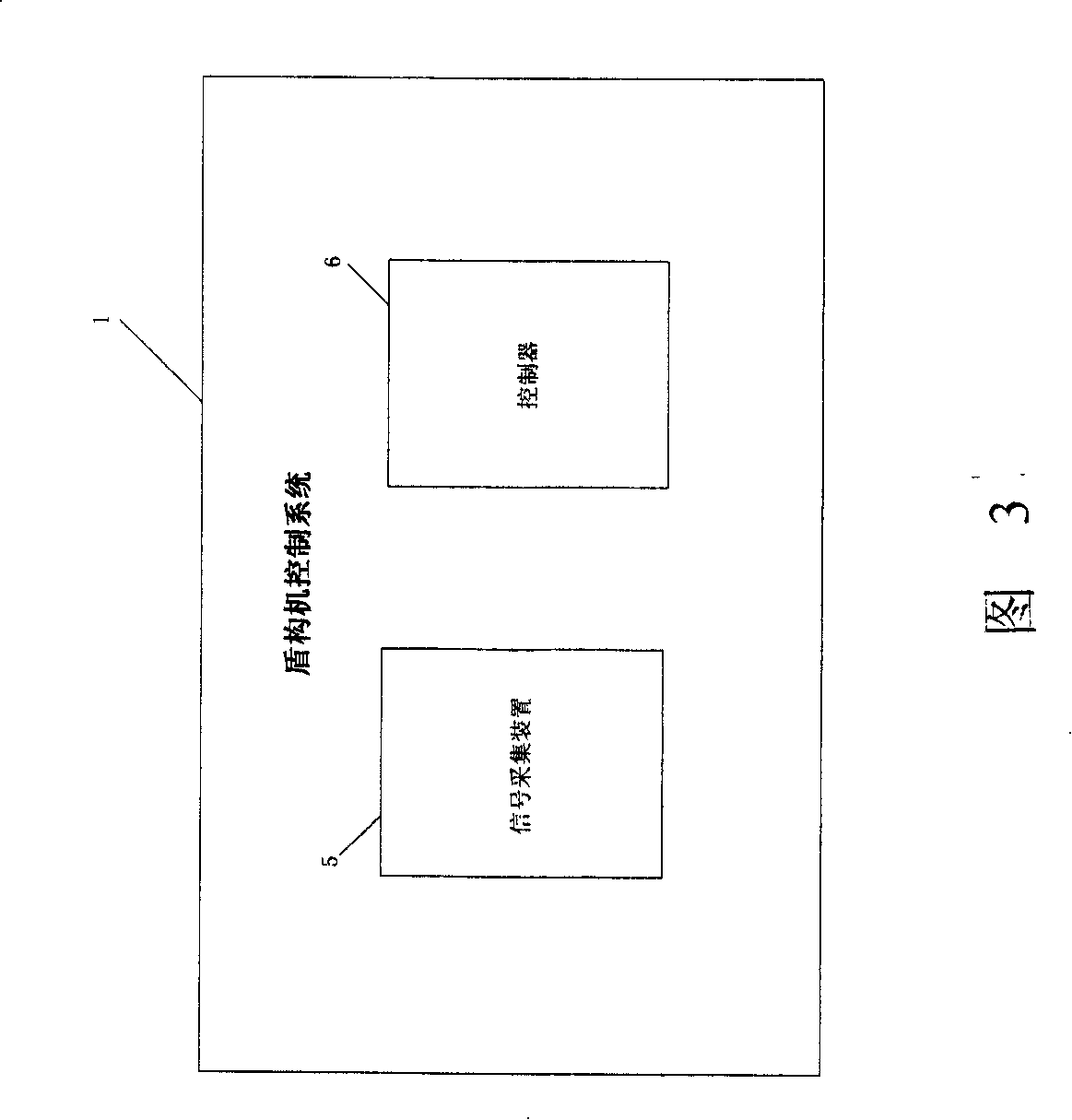

[0043] Embodiment 2: the shield machine function simulation system in the present embodiment is a physical simulation system, and its structure is identical with the physical simulation system 3 in embodiment 1, and every kind of device in this simulation system all has sensor, control button, touch screen Contact with the detected shield machine control system.

Embodiment 3

[0044] Embodiment 3: The shield machine function simulation system in this embodiment is a mathematical simulation system (also called a computer simulation system).

[0045] The shield machine function mathematical simulation system is to use the computer to simulate the cutterhead cutting simulation loading device, shield machine propulsion simulation loading device, pressure balance simulation loading device, shield machine attitude adjustment simulation device, segment assembly mechanism, The mathematical model established for the working process of the grouting mechanism, sealing lubrication mechanism, additive injection mechanism, gravel crushing mechanism, segment transfer mechanism, compressed air supply mechanism, industrial water supply mechanism, and ventilation mechanism; and through the control system of the shield machine To check the correctness of the control system.

[0046] In order to reflect the control process of the shield machine more realistically, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com