Track and posture composite control method in shield tunneling process

A composite control and composite controller technology, applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems affecting the accuracy of the tunnel axis, difficulty in trajectory adjustment, and optimal design of the rectification path, so as to reduce the frequency of trajectory rectification and improve the Tunnel rectification efficiency and the effect of improving tunnel forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

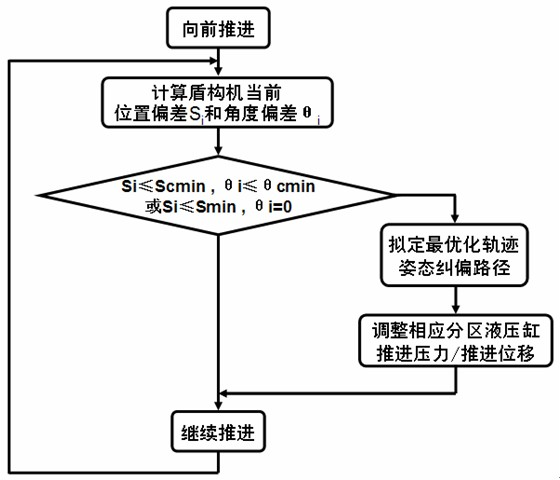

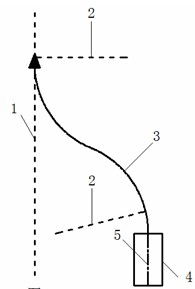

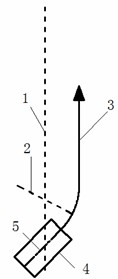

[0028] The trajectory and attitude compound control flow chart in the process of shield tunneling is attached figure 1 As shown, the present invention adopts both attitude and trajectory setting thresholds for control. Even if the trajectory has not yet reached the deviation correction threshold, as long as the attitude deviates beyond the limit, the posture adjustment will be performed in time to avoid aggravating the trajectory deviation; when the shield is moving forward , obtain the current position deviation S of the shield machine through measurement and calculation i , angle deviation θ i , if S i ≤ Position deviation threshold S of trajectory attitude composite controller cmin and θ i ≤Trajectory Attitude Composite Controller Angle Deviation Threshold θ cmin when, or S i ≤Permissible deviation S of the actual tunnel construction position min and θ i =0, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com