Construction method for underground box culvert of existing railway line

A construction method and existing line technology, applied in earthwork drilling, mining equipment, tunnels, etc., can solve problems affecting jacking construction, affecting box culvert elevation, difficult to control displacement, etc., to speed up construction and ensure line safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

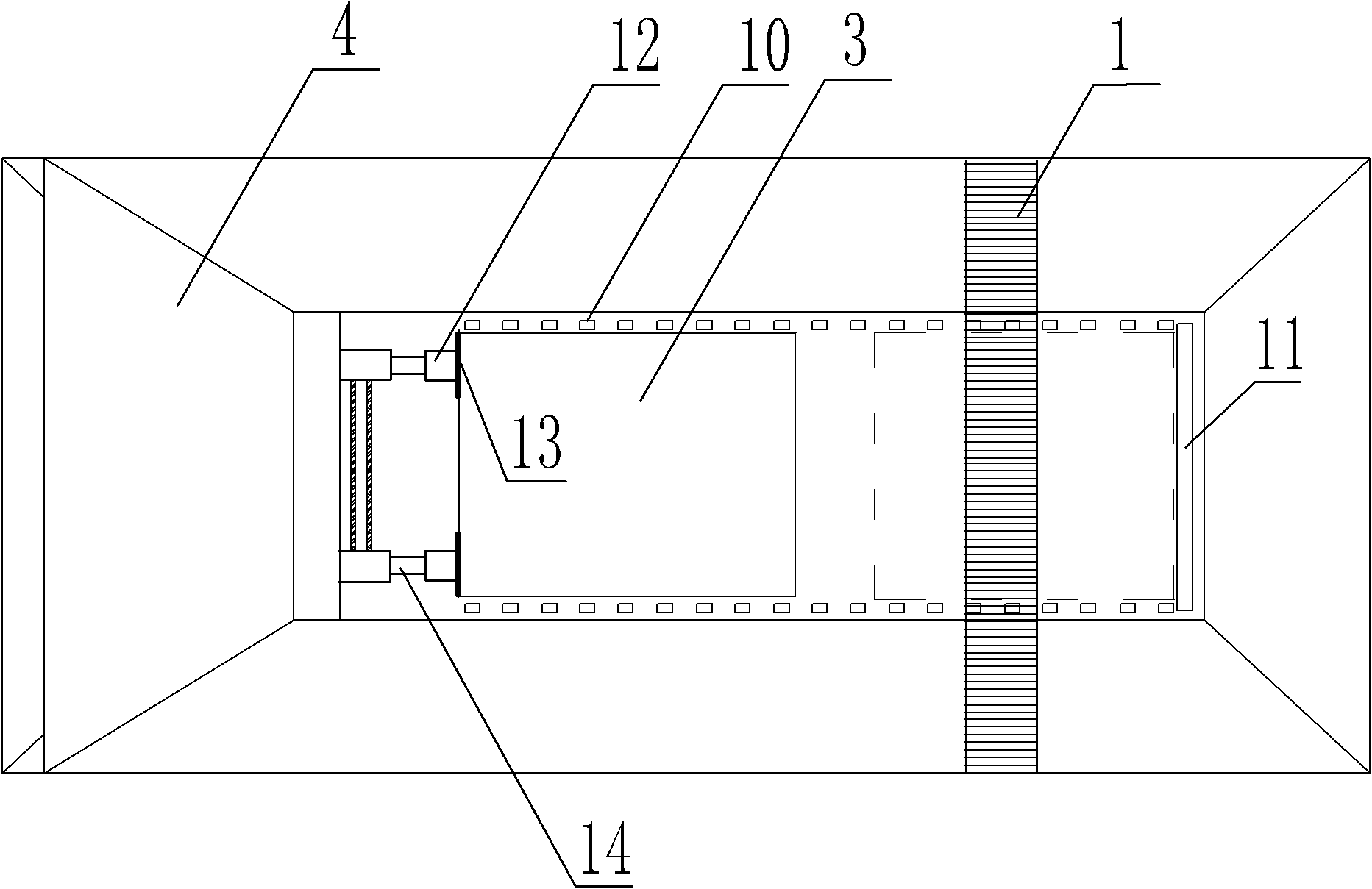

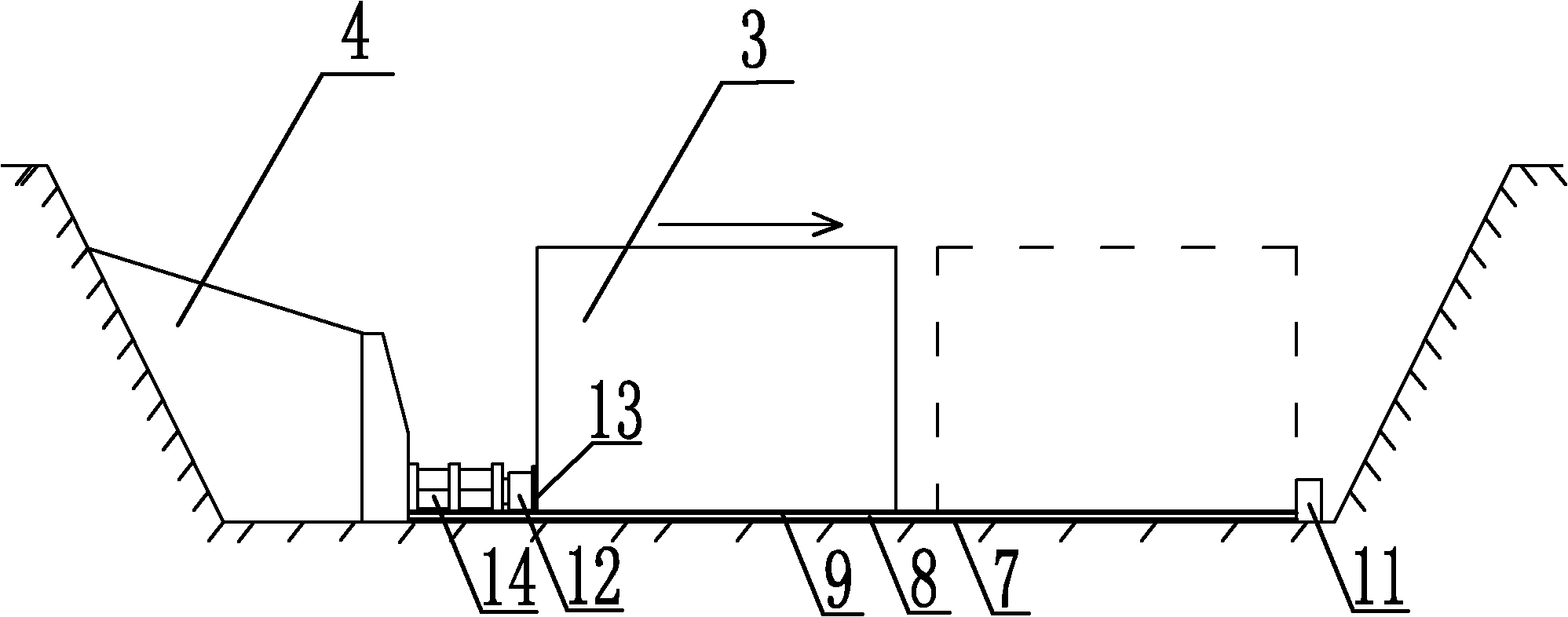

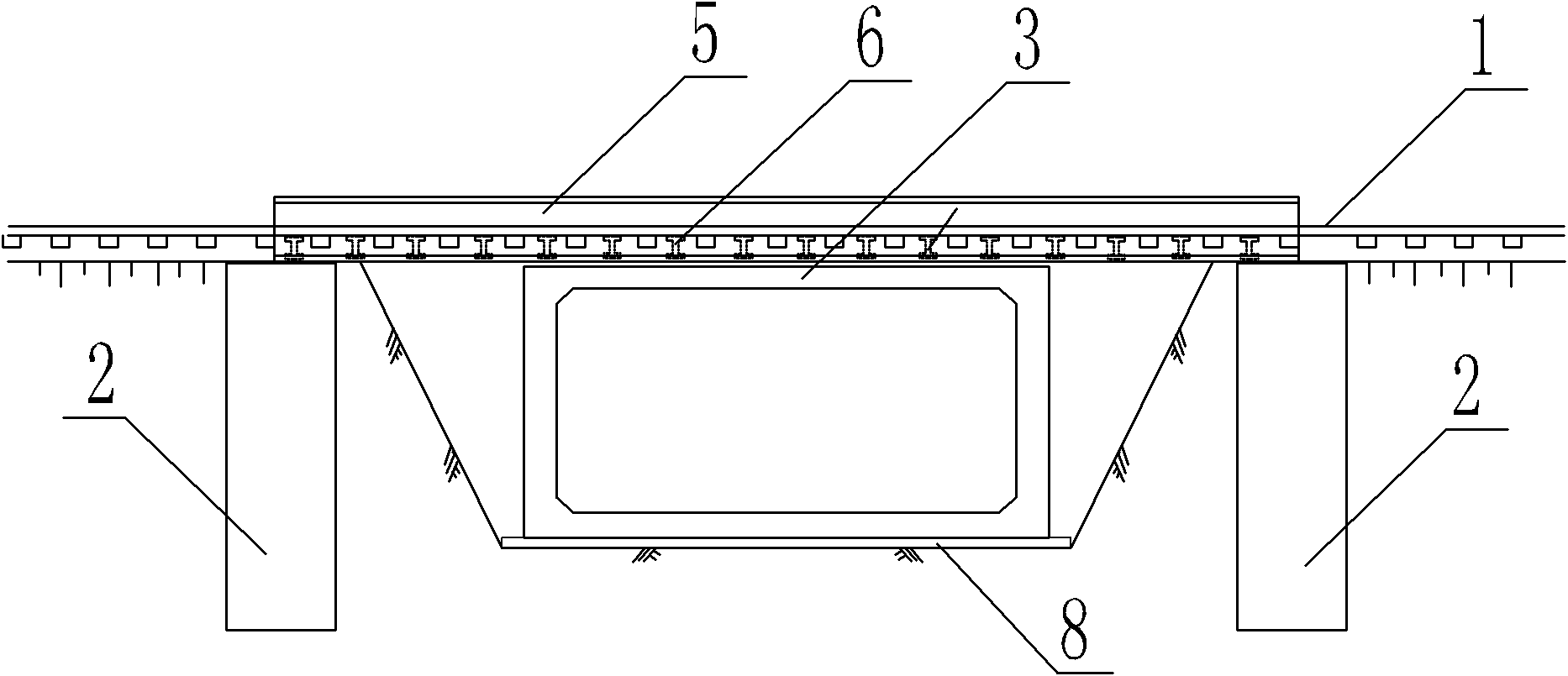

[0051] Such as Figure 1~Figure 3 As shown, the construction method of the underground box culvert of the existing railway line specifically includes the following steps:

[0052] 1. Excavate the earthwork of the beam foundation under the existing railway line 1 and set up a retaining wall, place a steel cage 2, construct a rectangular hole pile with a cross-section of 1.25×1.25m, and the concrete strength is C25, and excavate a working pit at the same time. The working pit adopts soil nailing wall or other support forms for open cut construction. The safe distance between the excavation sideline of the foundation pit near the existing line and the shoulder of the existing subgrade is more than 1.5m.

[0053] 2. Set cushion layer 7 and slide plate 8 in the working pit. Construction isolation layer 9 on the slide. The method of the isolation layer is as follows: waste engine oil and talcum powder are heated and mixed according to the volume ratio of 1:1.5, after pouring and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com