Method for screening and enrichment culture of nitrifying bacterium floras with alternation of intermittent ammonia nitrogen flow and intermittent operation

A nitrifying bacteria, enrichment culture technology, applied in the direction of chemical instruments and methods, biochemical equipment and methods, microbial-based methods, etc., can solve the problems of reduced reaction rate, difficulty in maintaining short-term nitrification, slow nitrification reaction rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] 1. Daytime intermittent operation cycle (A) to cultivate the nitrifying bacteria flora

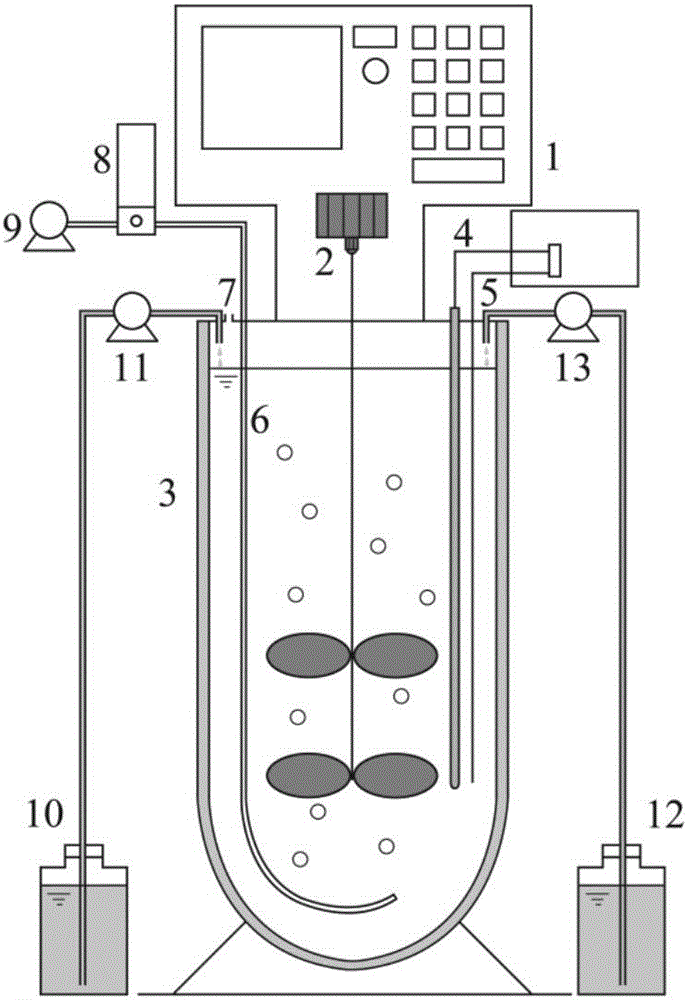

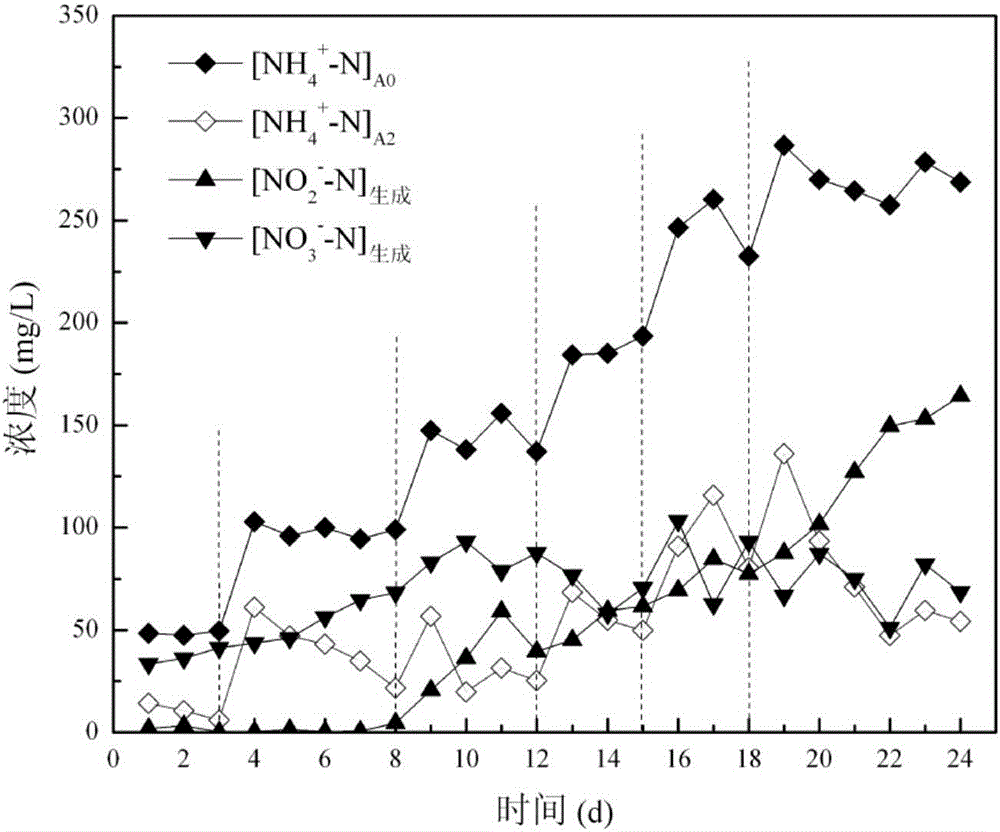

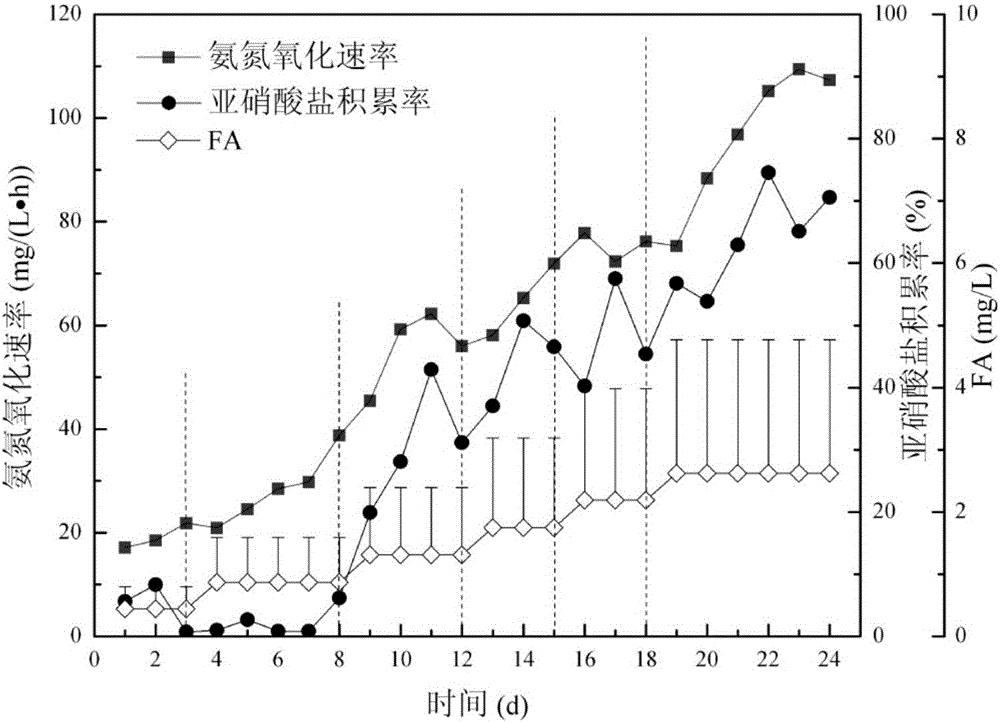

[0083] Take sewage treatment plant A 2 / O process reflux sludge is inoculated sludge, and the automatic bacterial fermentation tank is used as the test device, with an effective volume of 6L, such as figure 1 shown. The sludge concentration (MLSS) of the inoculum sludge was 4573mg / L. Temperature 23±1°C, pH7.2~7.4, reaction initial DO1.0~1.5mg / L, stirring speed 100rpm, Na 2 CO 3 The stock solution concentration is 200g / L. The nitrifying bacterial flora was cultivated by intermittent, ammonia nitrogen feeding-intermittent operation alternately. The reactor was operated for 25 days, and the first 24 days were intermittent and ammonia nitrogen feeding-intermittent each cycle. The composition and concentration of the basal culture medium are shown in Table 1:

[0084] Table 1 basal culture solution components (the following components are not mixtures, but multiple separate solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com