Semiconductor structure and forming method thereof

A semiconductor and wet etching technology, used in semiconductor devices, semiconductor/solid-state device manufacturing, transistors, etc., can solve the problems of difficult channel, poor gate-to-channel control ability, etc., and improve fin bending. , performance improvement, the effect of reducing the extrusion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The performance of current semiconductor structures needs to be improved. Combining with a method of forming a semiconductor structure, the reason why its performance needs to be improved is analyzed.

[0013] Figure 1 to Figure 4 It is a structural schematic diagram corresponding to each step in a method for forming a semiconductor structure.

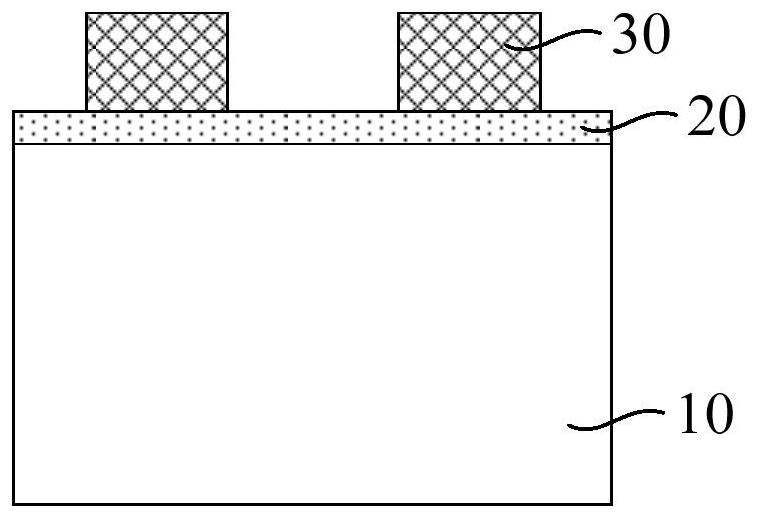

[0014] refer to figure 1 , providing a substrate 10 , forming a buffer layer 20 and a mask layer 30 on the buffer layer 20 on the substrate 10 .

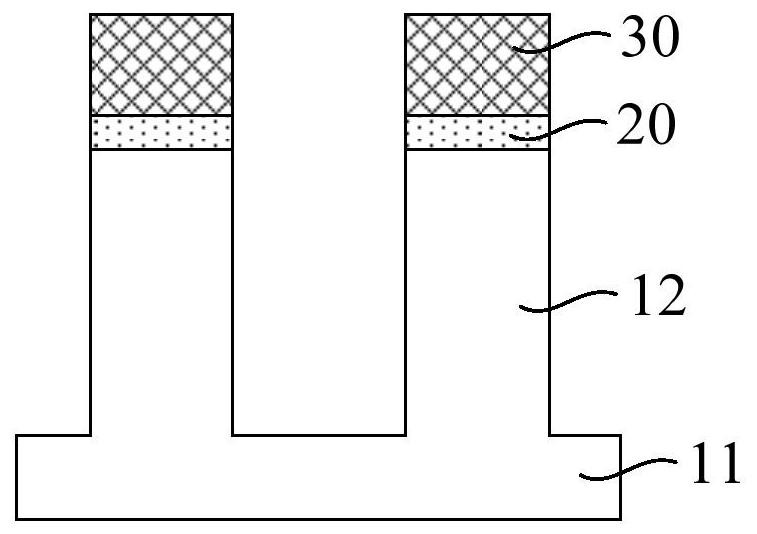

[0015] refer to figure 2 , using the mask layer 30 as a mask, sequentially etching the buffer layer 20 and the base 10 to form the substrate 11 and the fins 12 protruding from the substrate 11 .

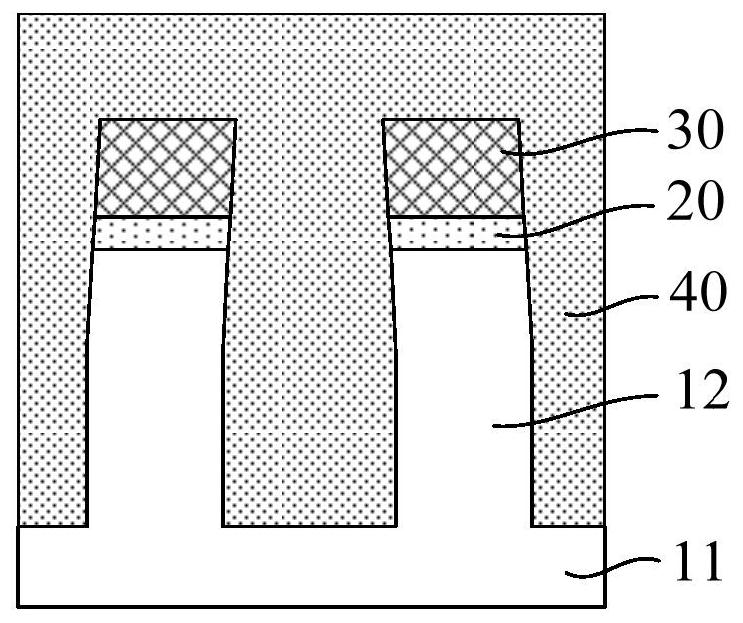

[0016] refer to image 3 , forming an isolation material layer 40 on the substrate 11 , the isolation material layer 40 fills between the fins 12 and covers the top of the mask layer 30 .

[0017] refer to Figure 4 , using the top of the mask layer 30 as a stop position, planarize ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com