Patents

Literature

50results about How to "Achieve meshing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

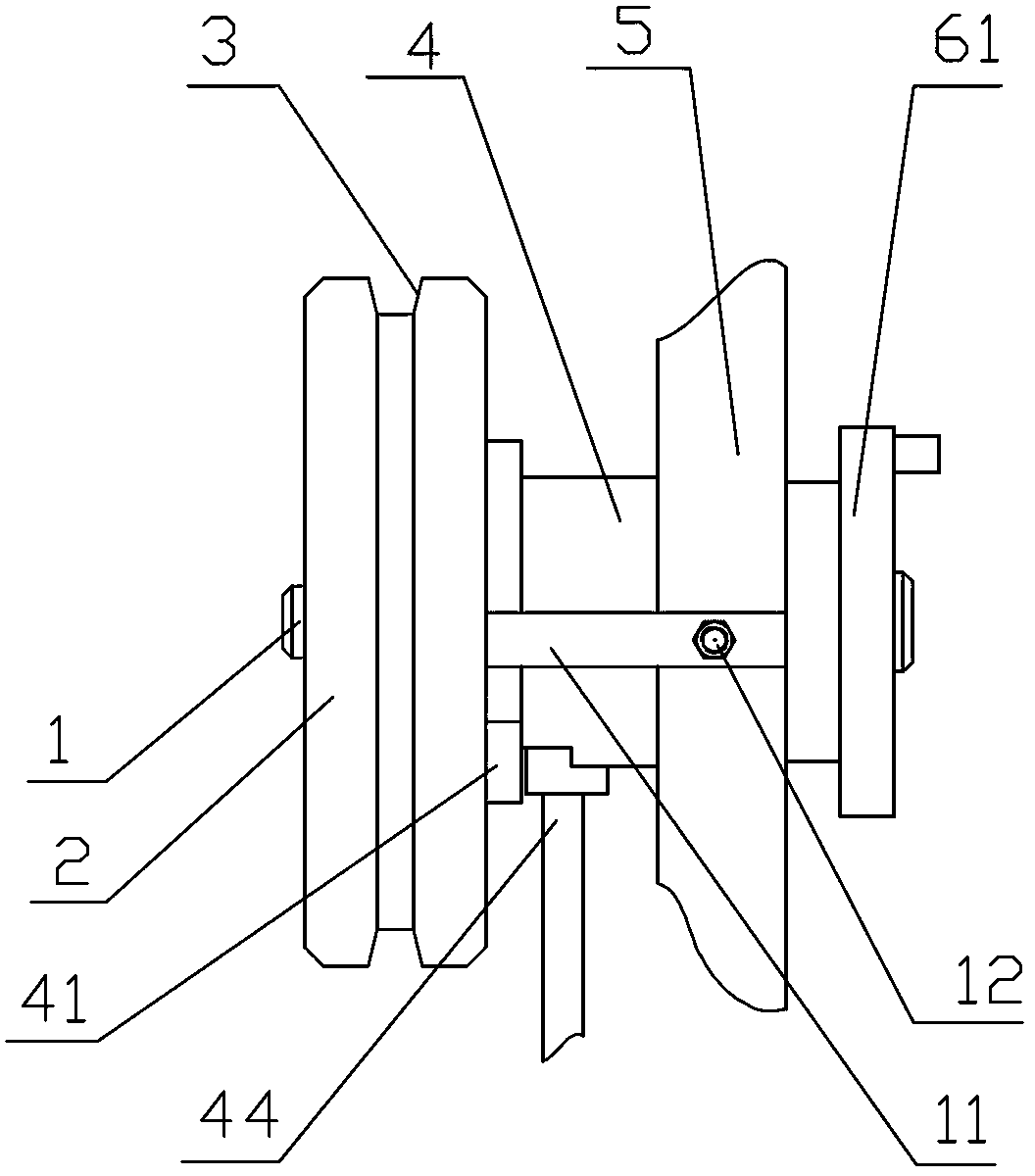

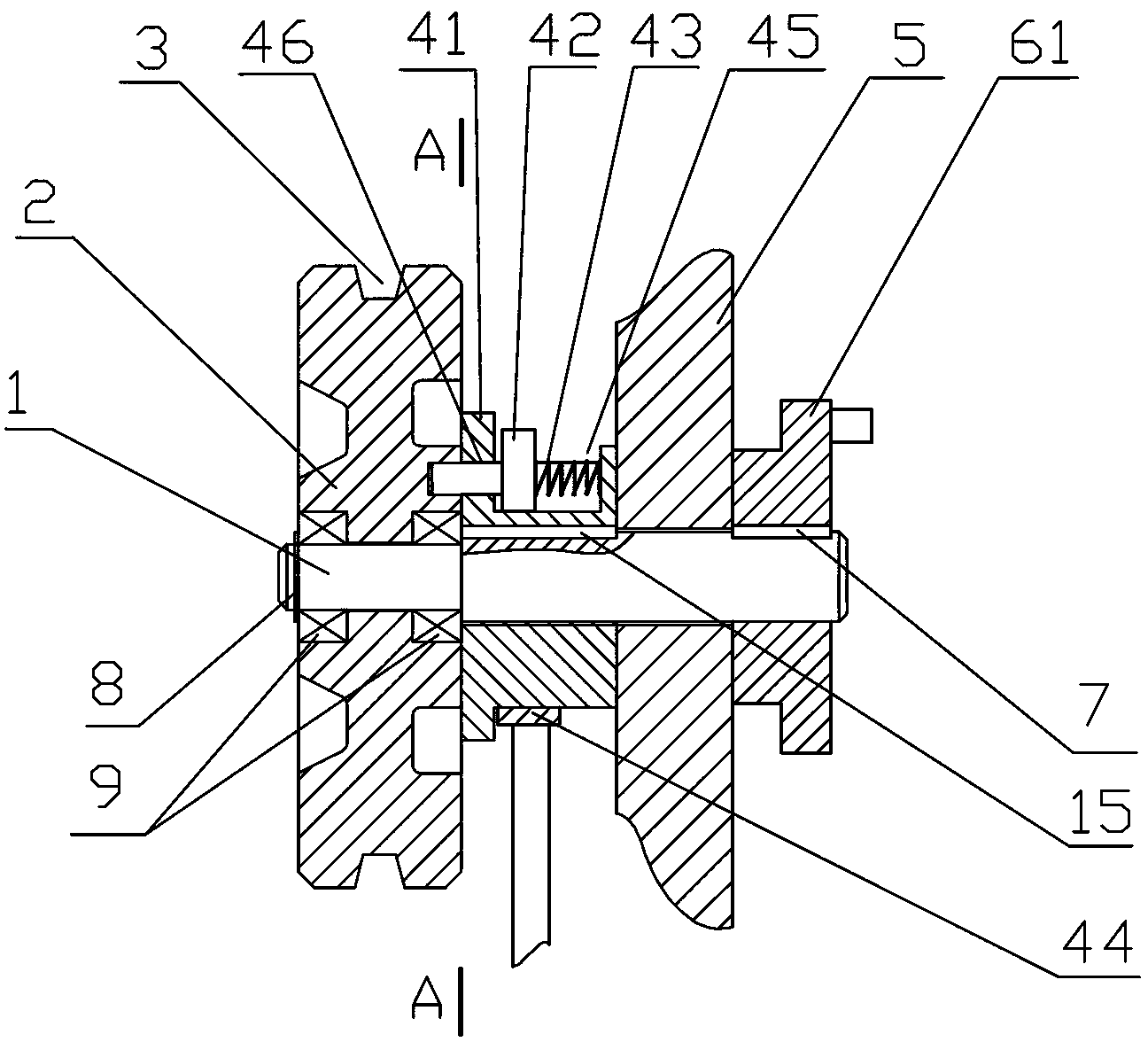

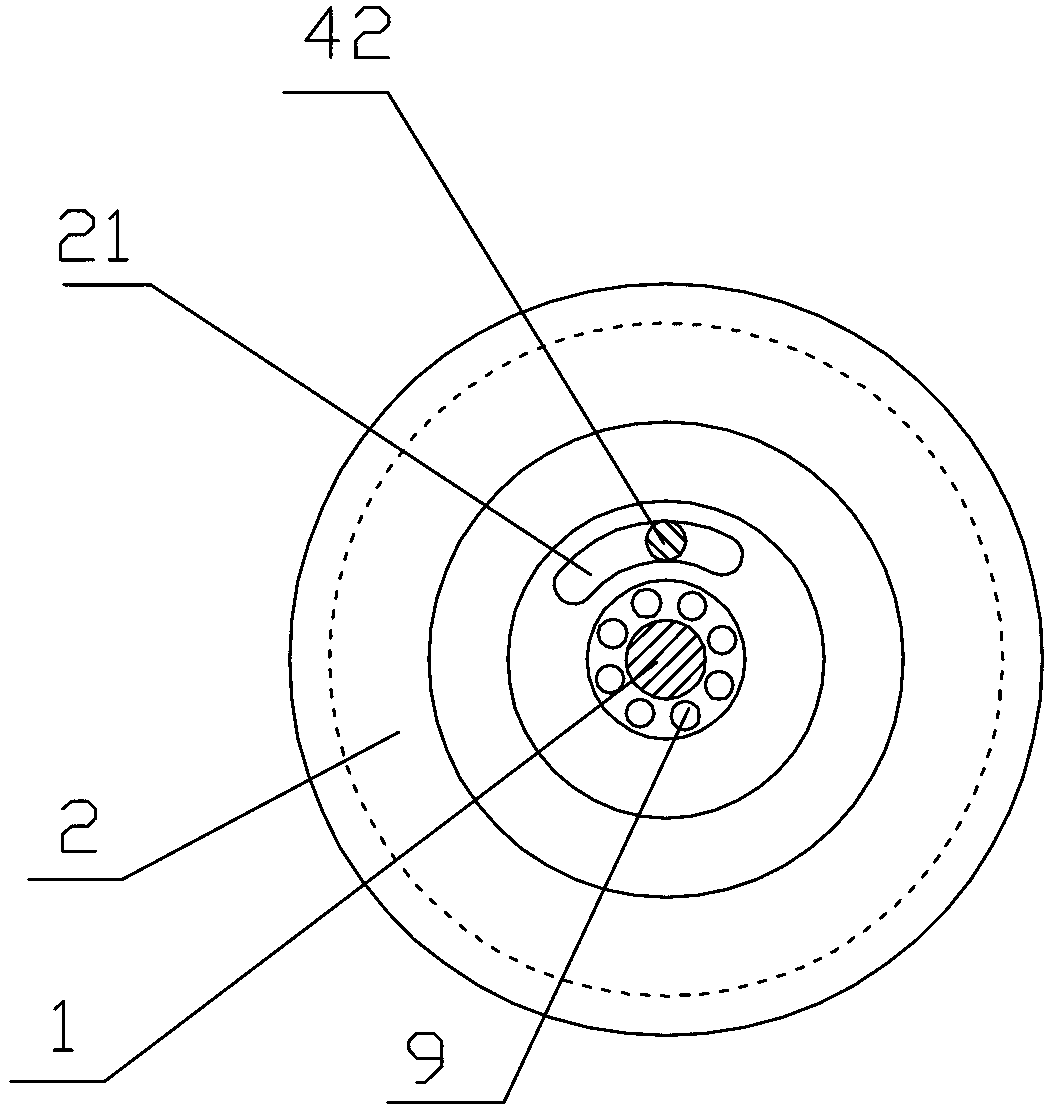

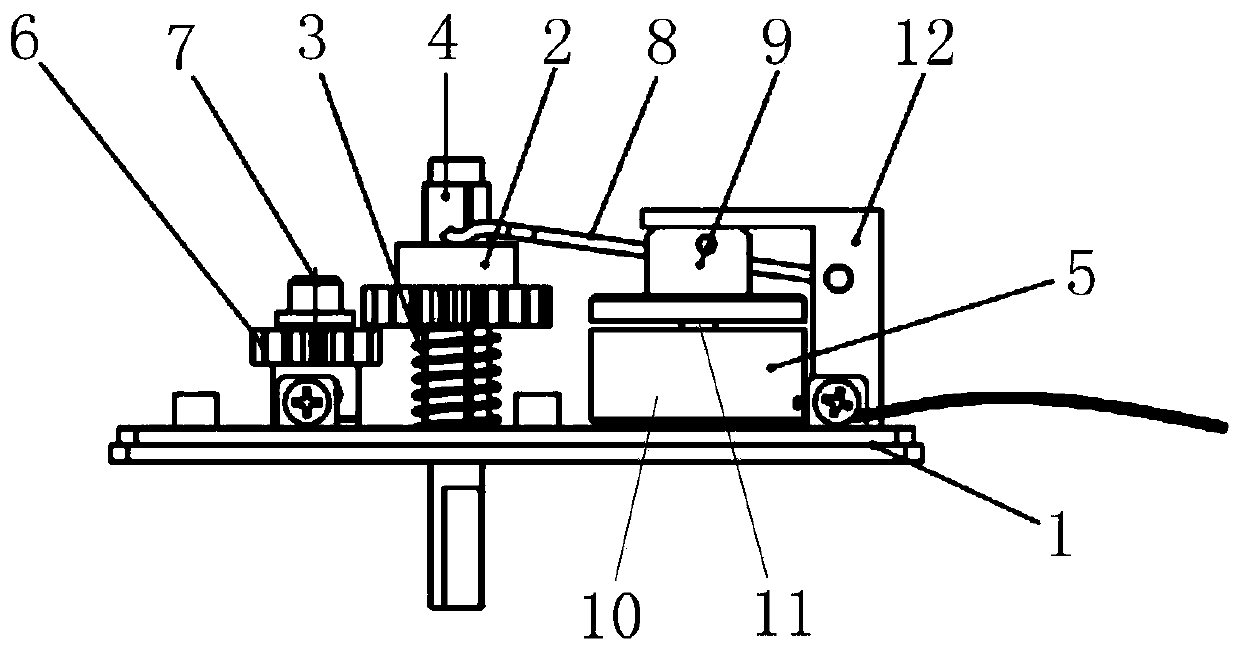

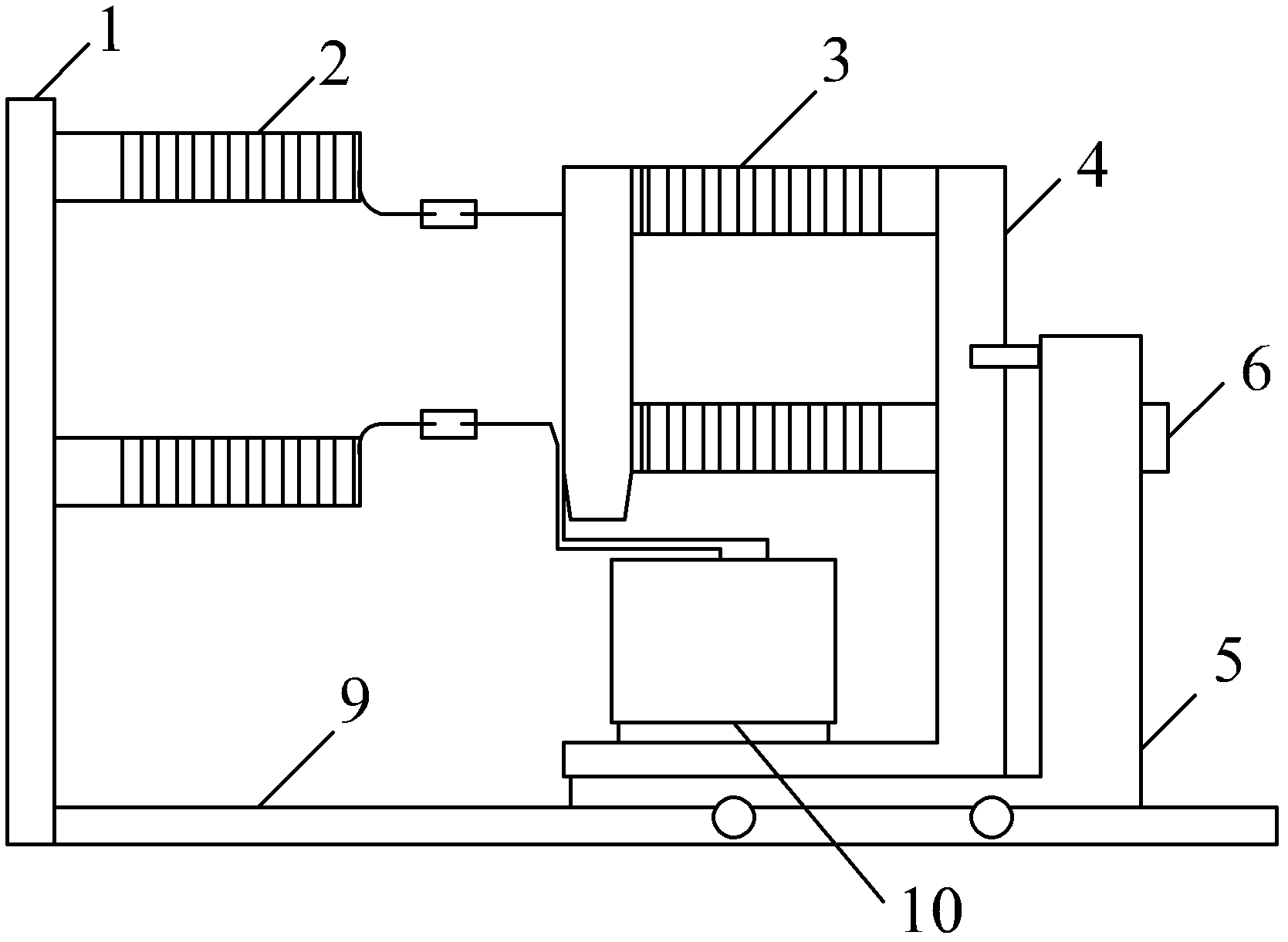

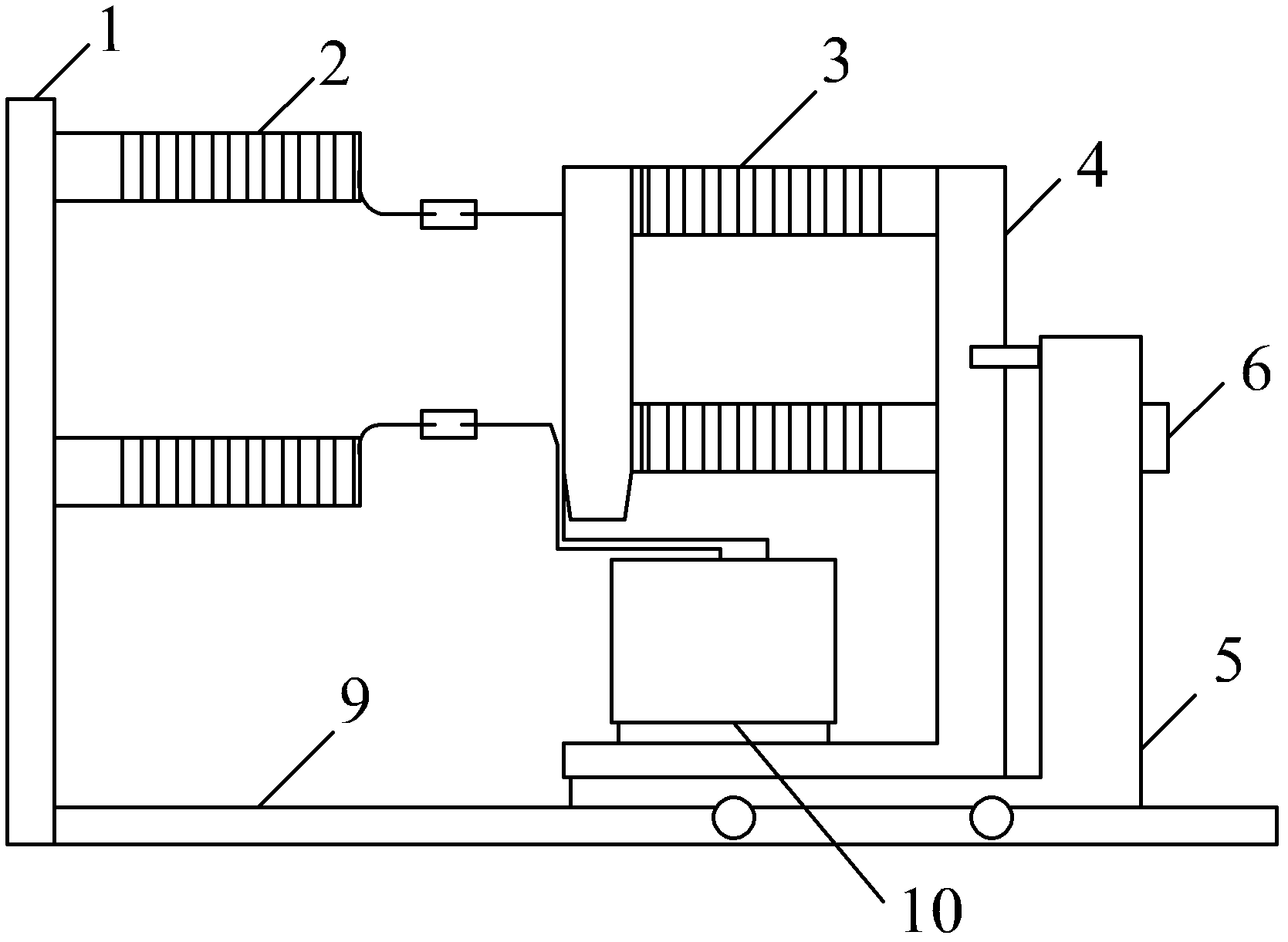

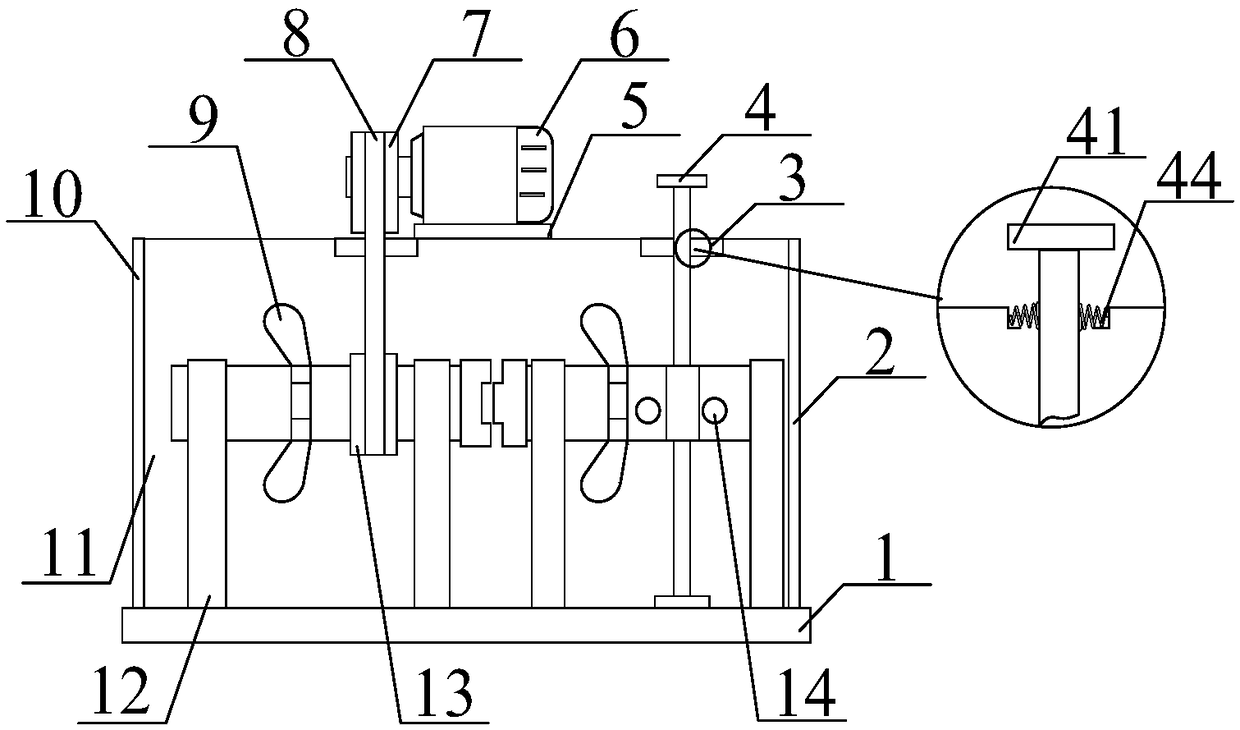

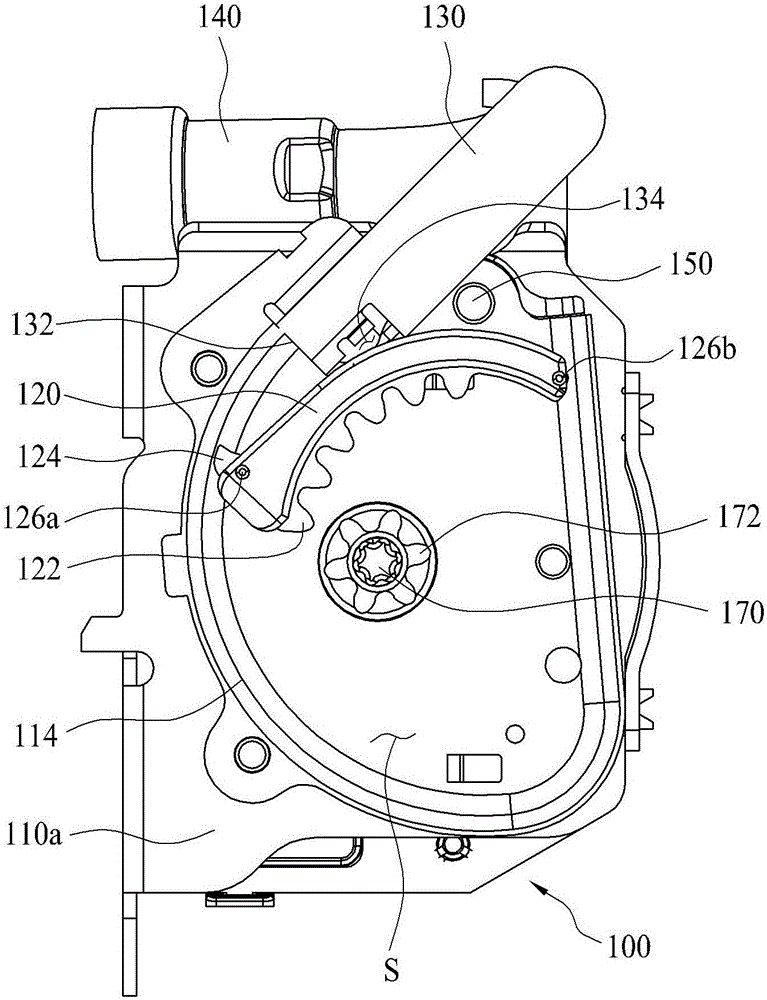

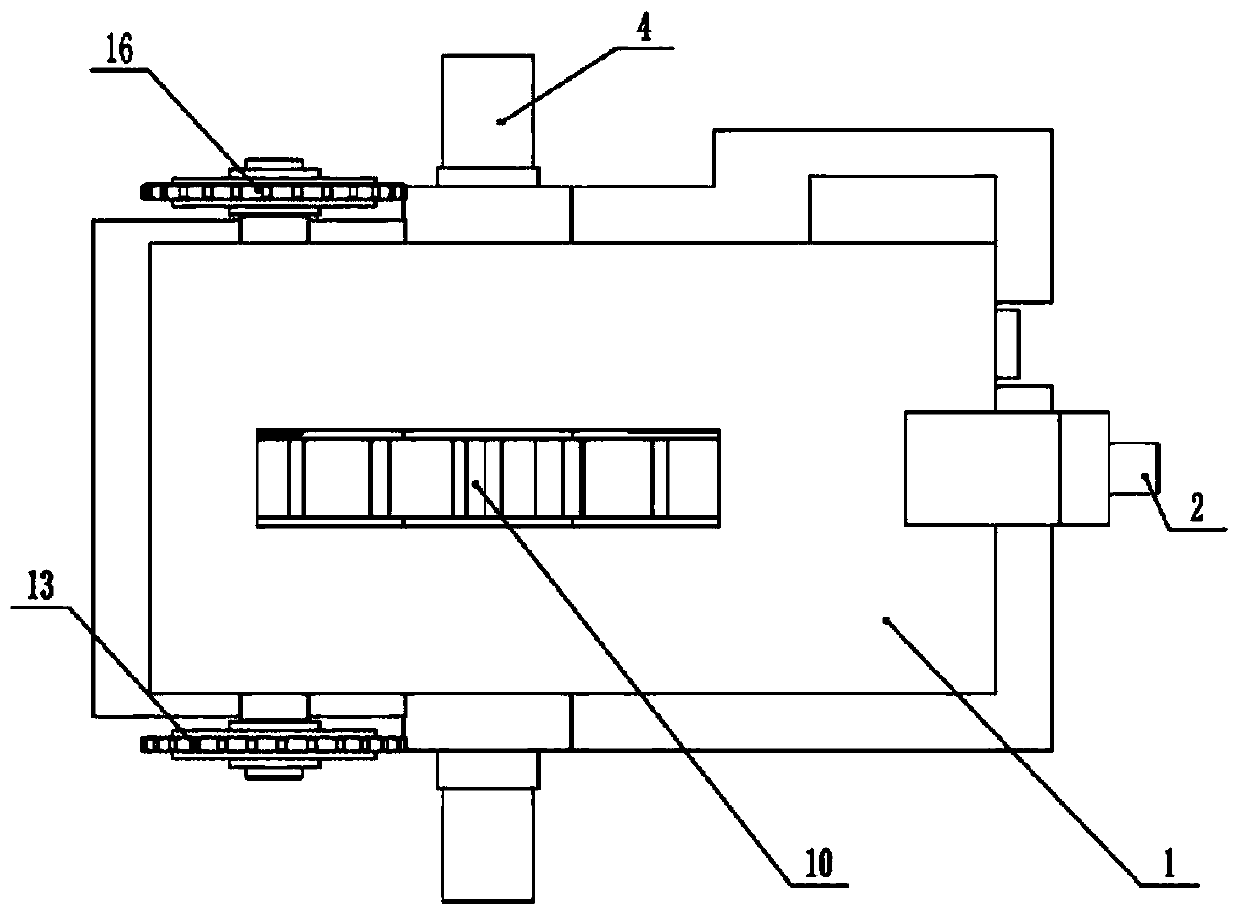

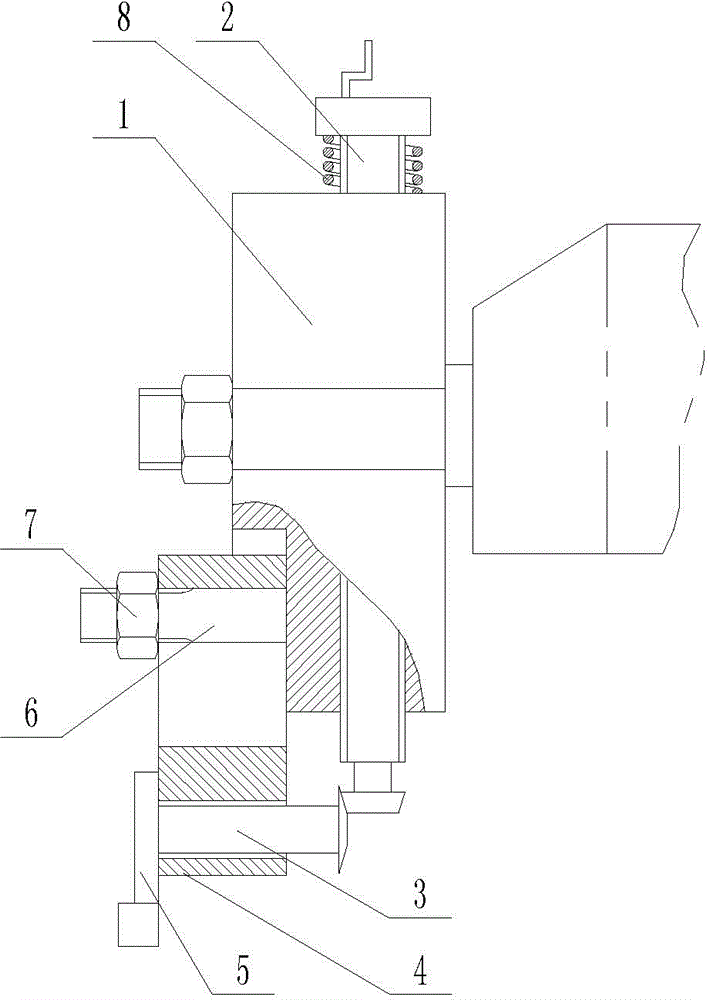

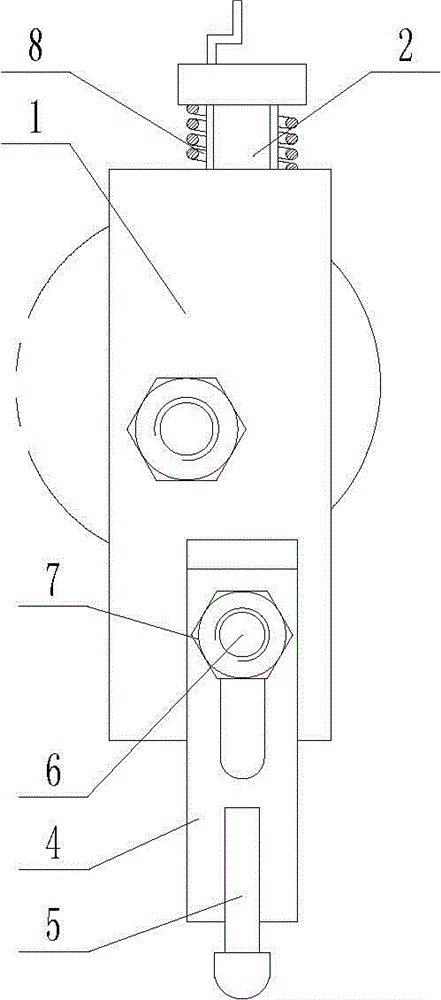

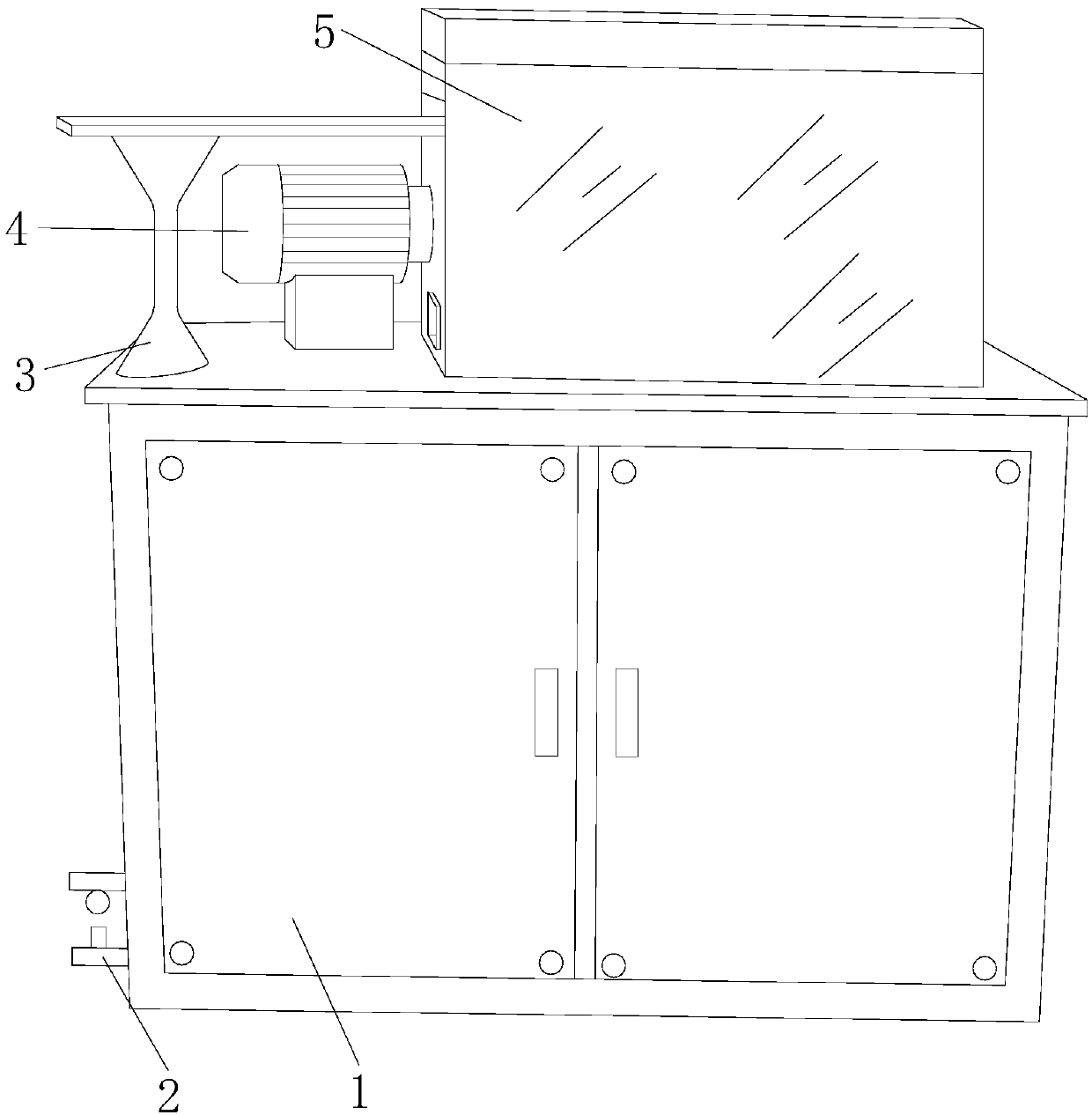

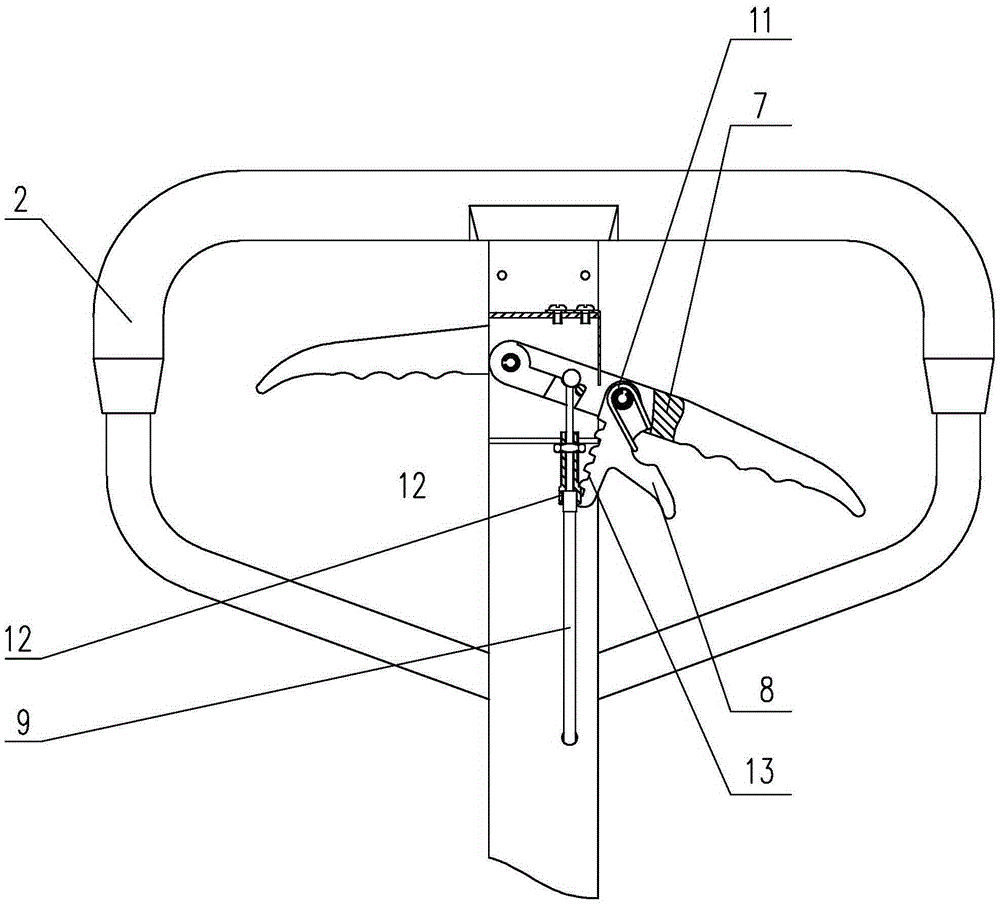

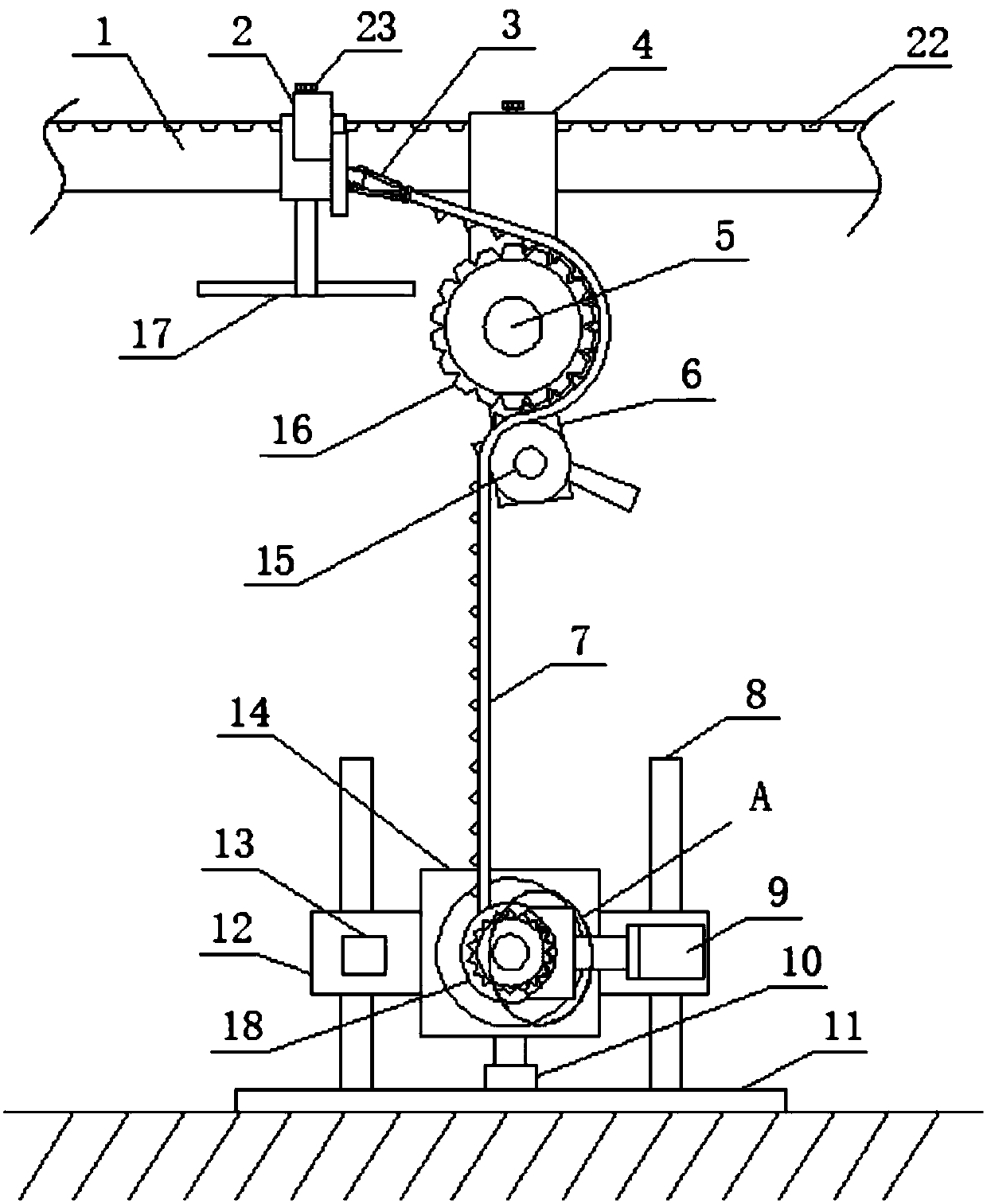

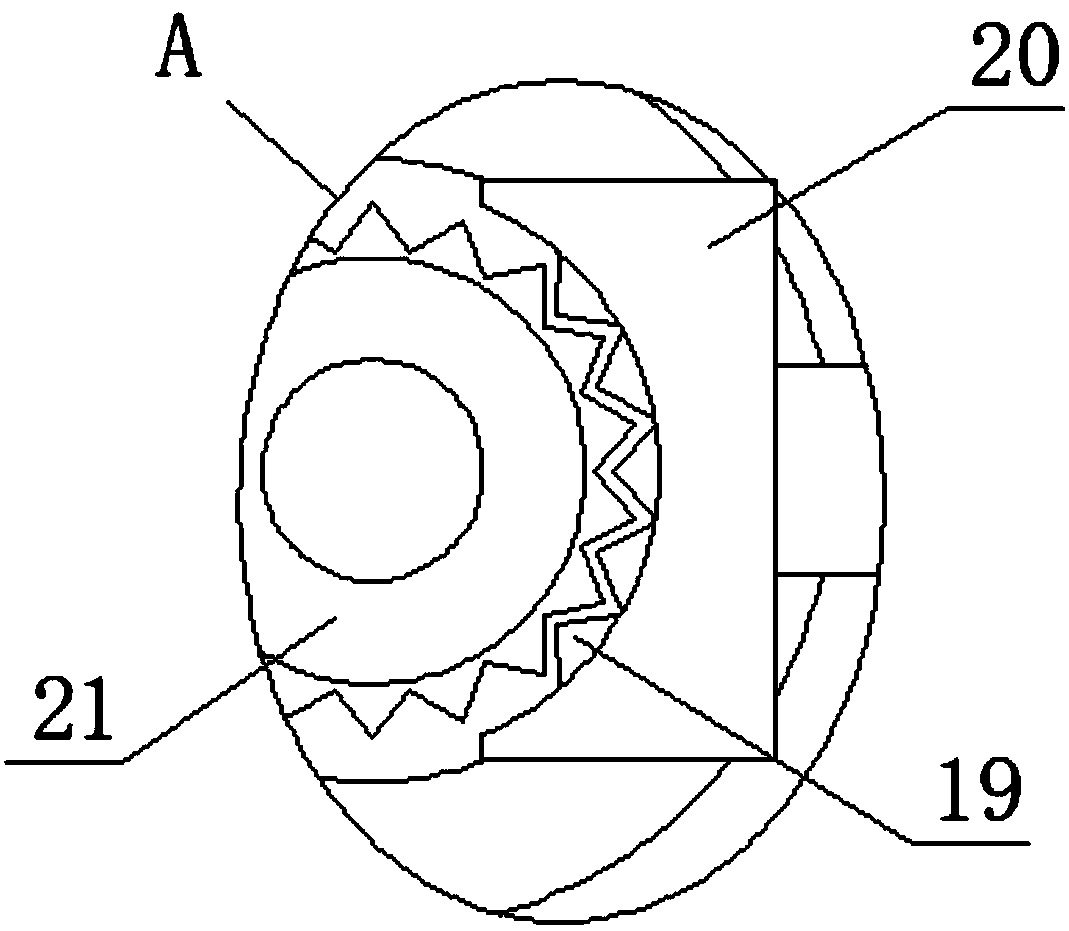

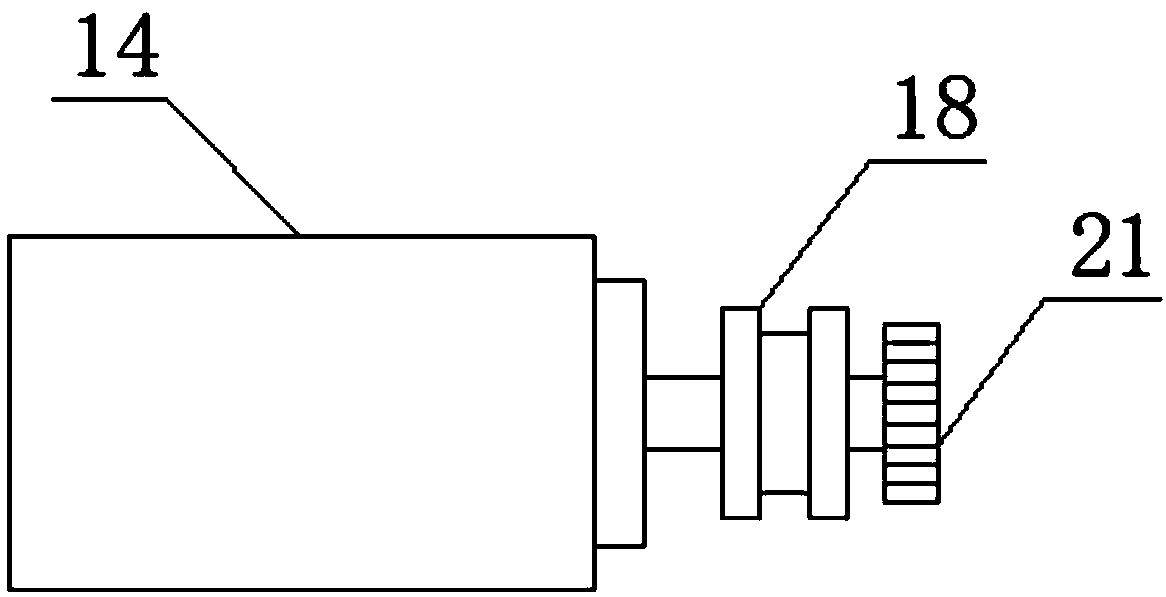

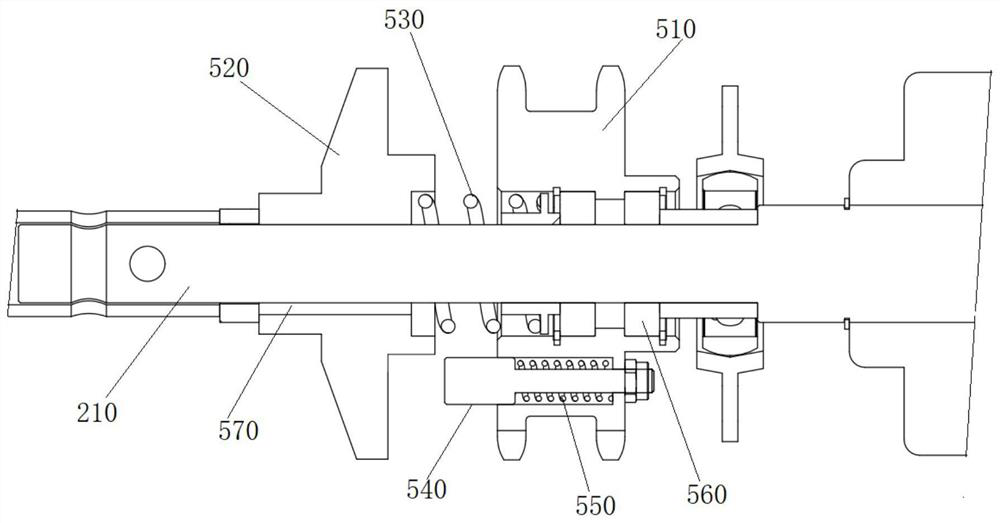

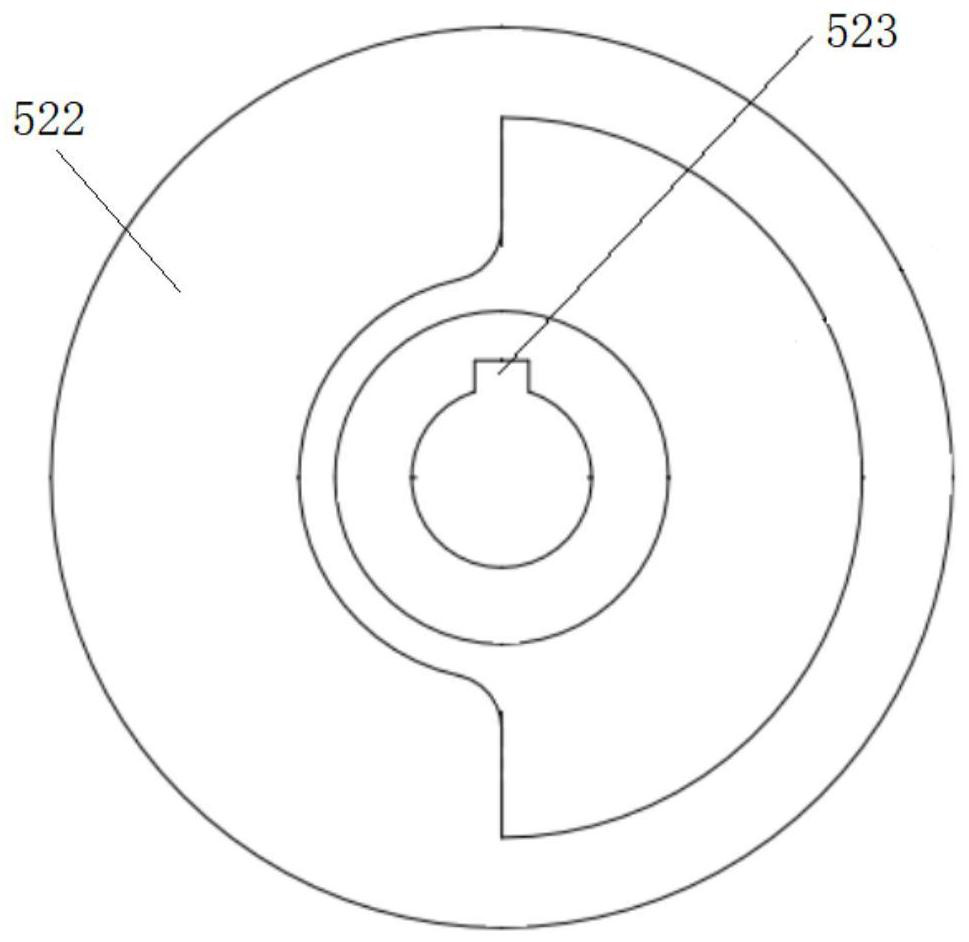

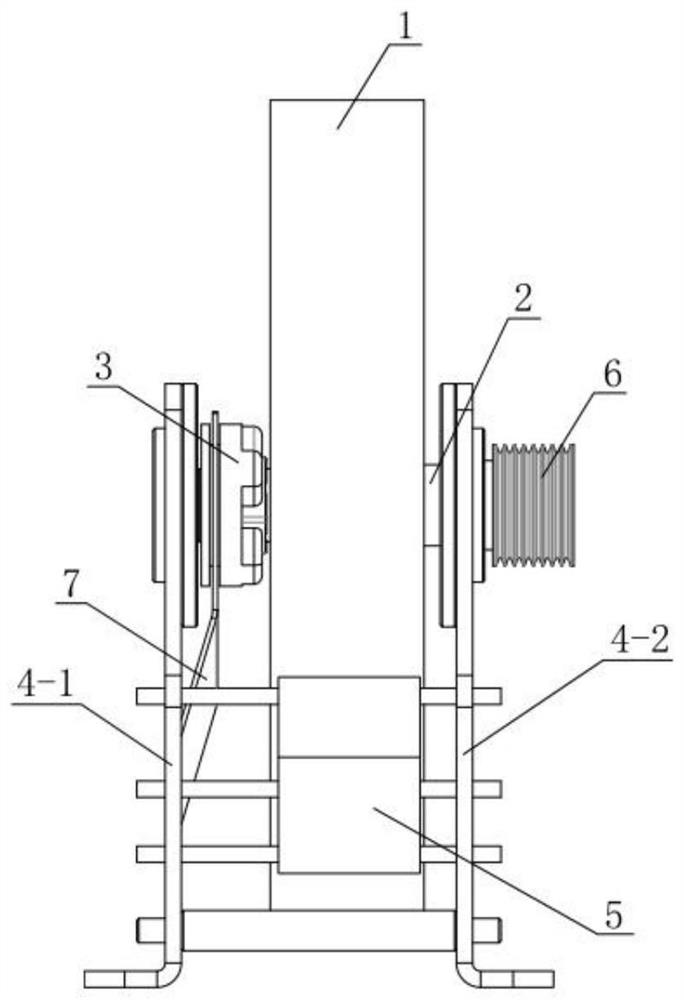

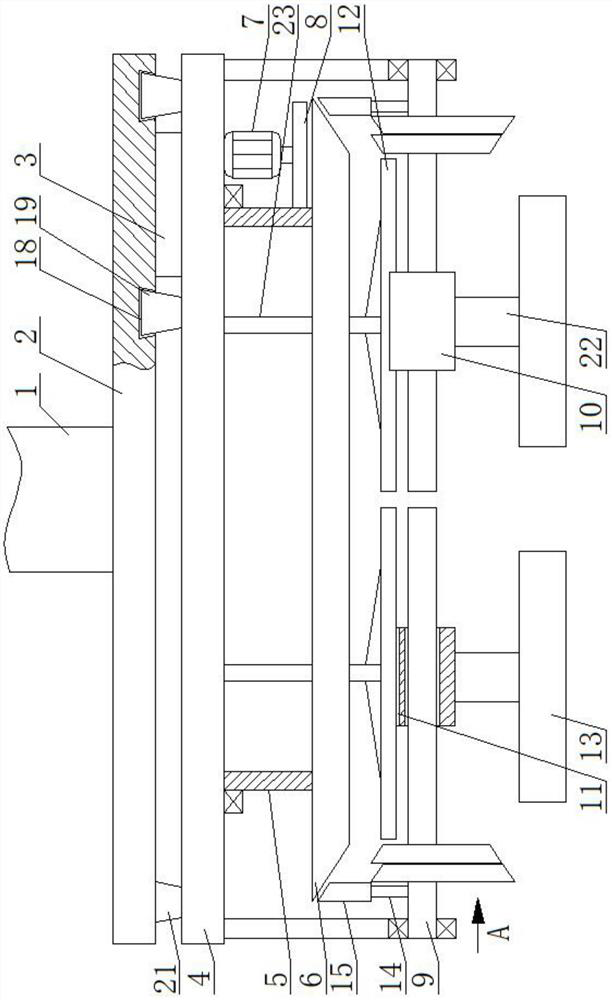

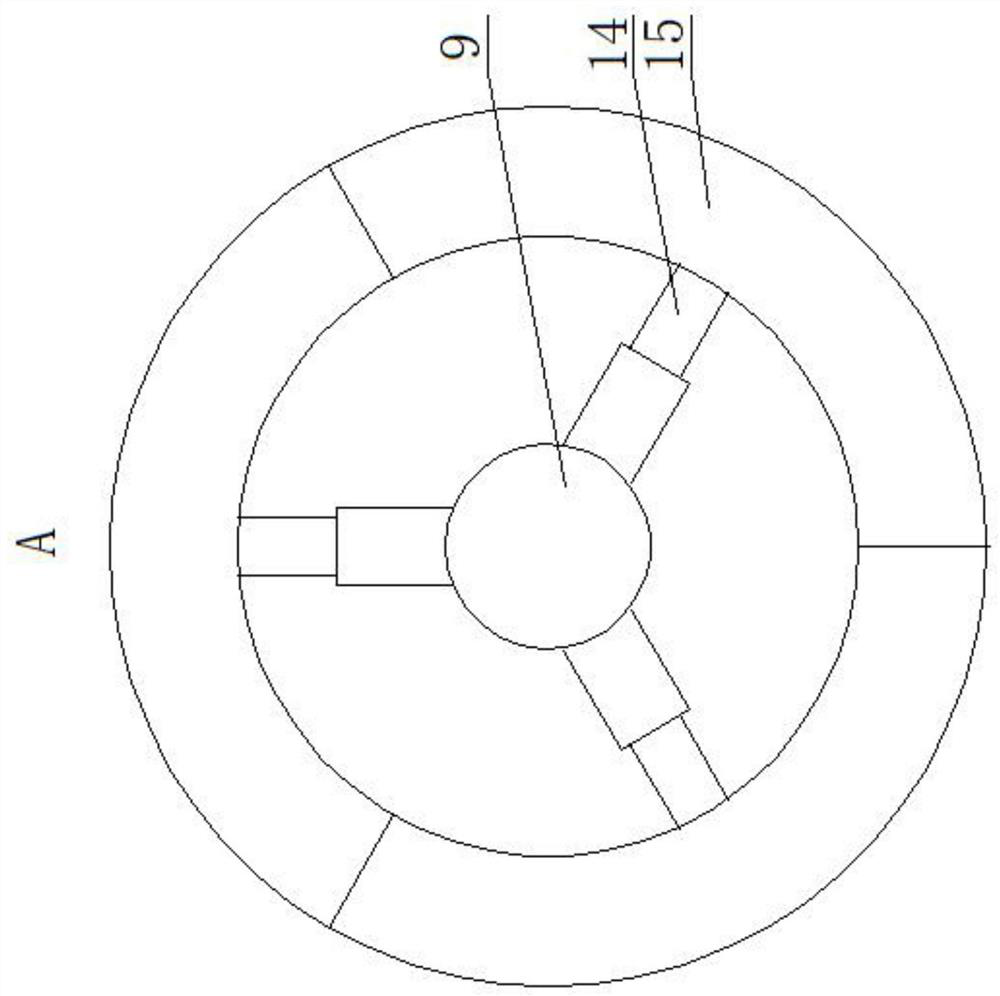

Thin-walled profile punching machine

The invention relates to a punching machine, and provides a thin-walled profile punching machine which comprises a machine body, a motor, a transmission mechanism, a punching device, a main shaft, and a rotating energy storage component and a clutch braking device which are mounted on the main shaft, wherein the clutch braking device comprises a clutch braking pin shaft and a clutch braking rod; after the clutch braking rod is bounced off, the clutch braking pin shaft is meshed with the rotating energy storage component so as to drive the punching device to complete a punching procedure, and at this moment, the reset clutch braking rod enables the clutch braking device rotating for a circle to be automatically separated from meshing with the rotating energy storage component, and brakes the clutch braking device, so that the punching procedure is completed, and the punching device waits for starting of another punching procedure. The thin-walled profile punching machine has the benefits that through the unique clutch structure, power of the rotating energy storage component is fully utilized for punching, and compared with the traditional hydraulic punching machine, the thin-walled profile punching machine is high in punching speed, higher in efficiency, lower in cost, and more suitable for punching of thin-walled profiles.

Owner:柳州市中基机械有限公司

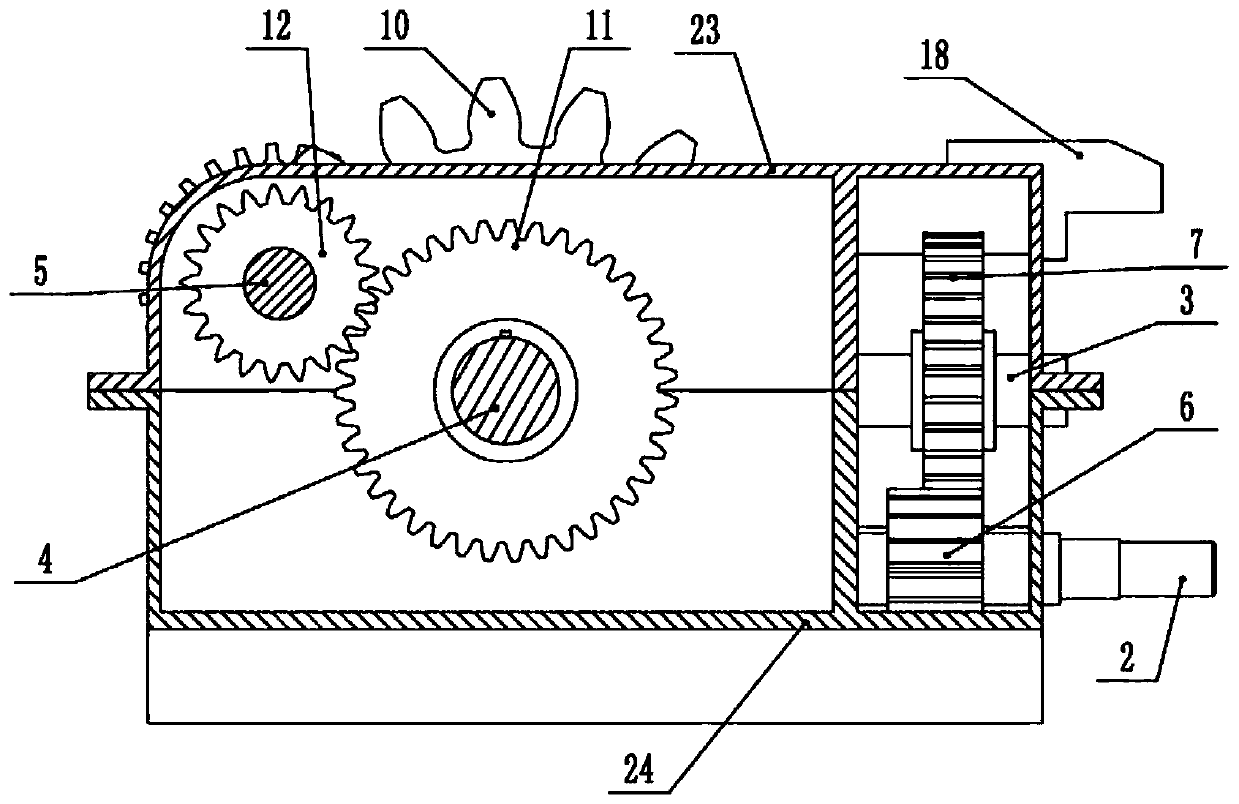

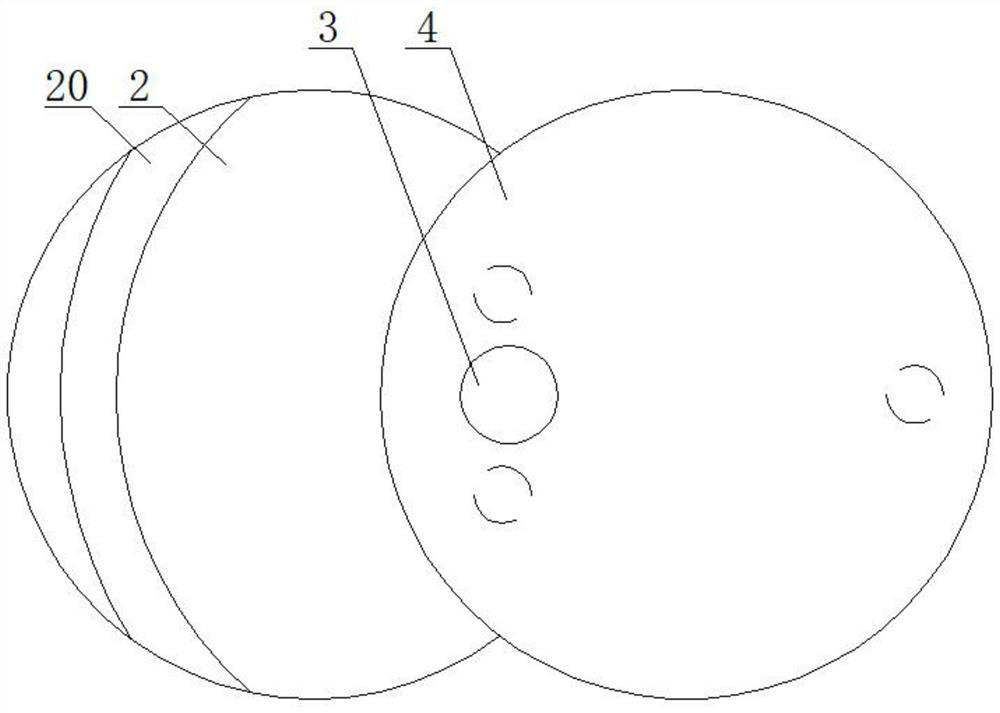

Electromagnetic clutch

InactiveCN110953264ALow torque consumptionRealize automatic adjustmentMagnetically actuated clutchesPower-operated mechanismPhysicsElectromagnetic clutch

The invention provides an electromagnetic clutch. The electromagnetic clutch comprises an upper cover plate, a clutch gear, a return spring, an output spindle and an electromagnetic control mechanismfor controlling the clutch gear to move up and down; the output spindle is rotationally arranged on the upper cover plate; the output spindle is sleeved with the clutch gear which can move up and down; the output spindle is sleeved with the return spring; the return spring is arranged between the upper cover plate and the clutch gear; and the output end of the electromagnetic control mechanism isin drive connection with the top end of the clutch gear. By controlling the clutch gear to move up and down through the electromagnetic control mechanism, the clutch gear can be disengaged or engagedwith other transmission gears according to actual needs, and switching between a manual mode and an automatic mode of the clutch gear is achieved, and torque consumption is low.

Owner:方得(北京)物联科技有限公司

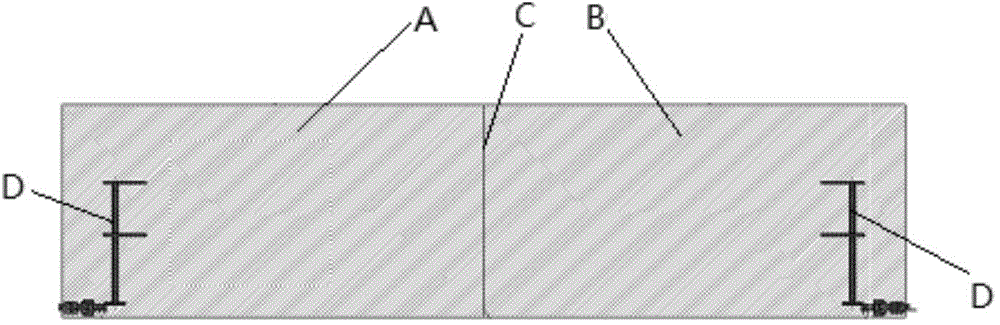

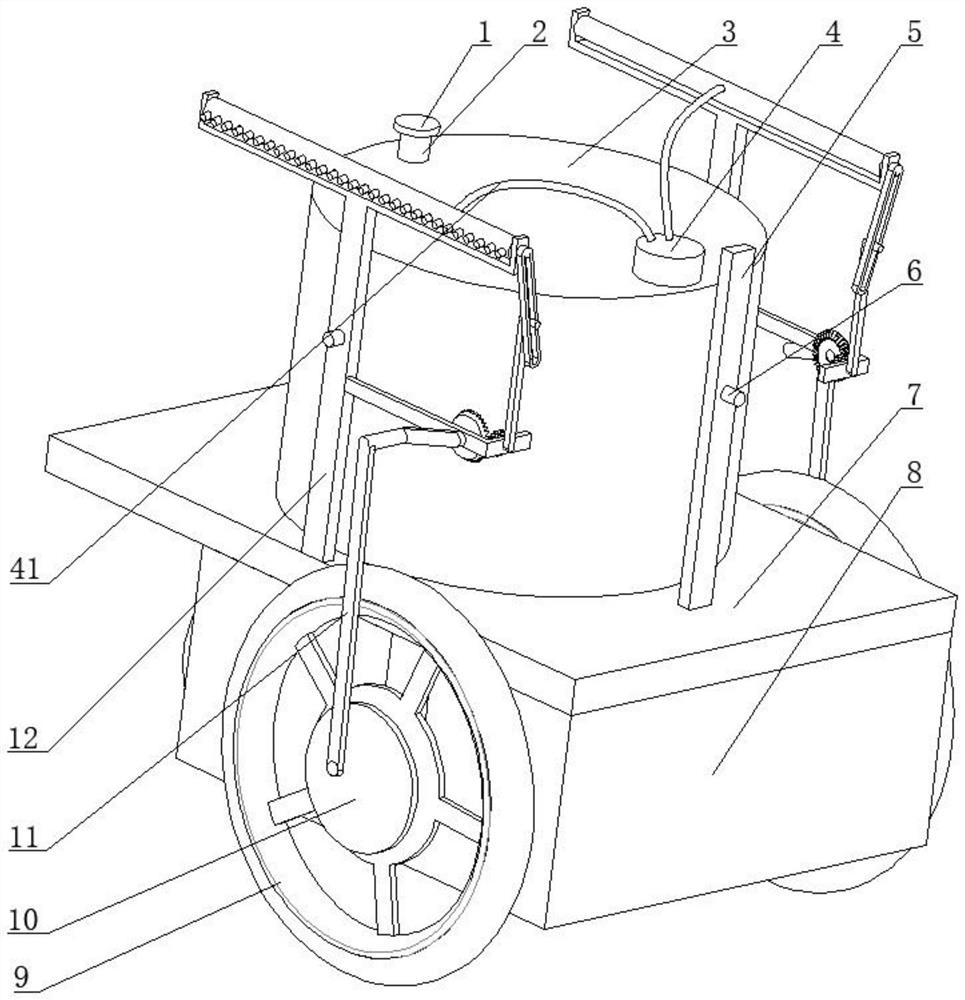

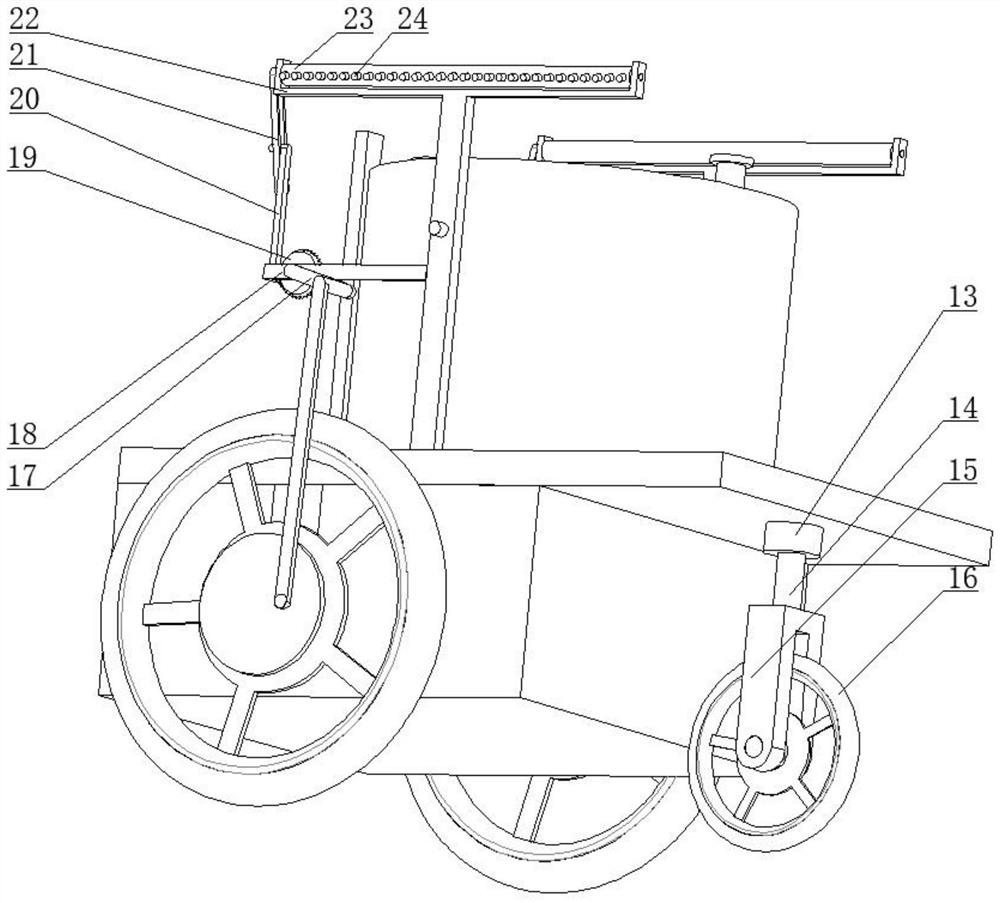

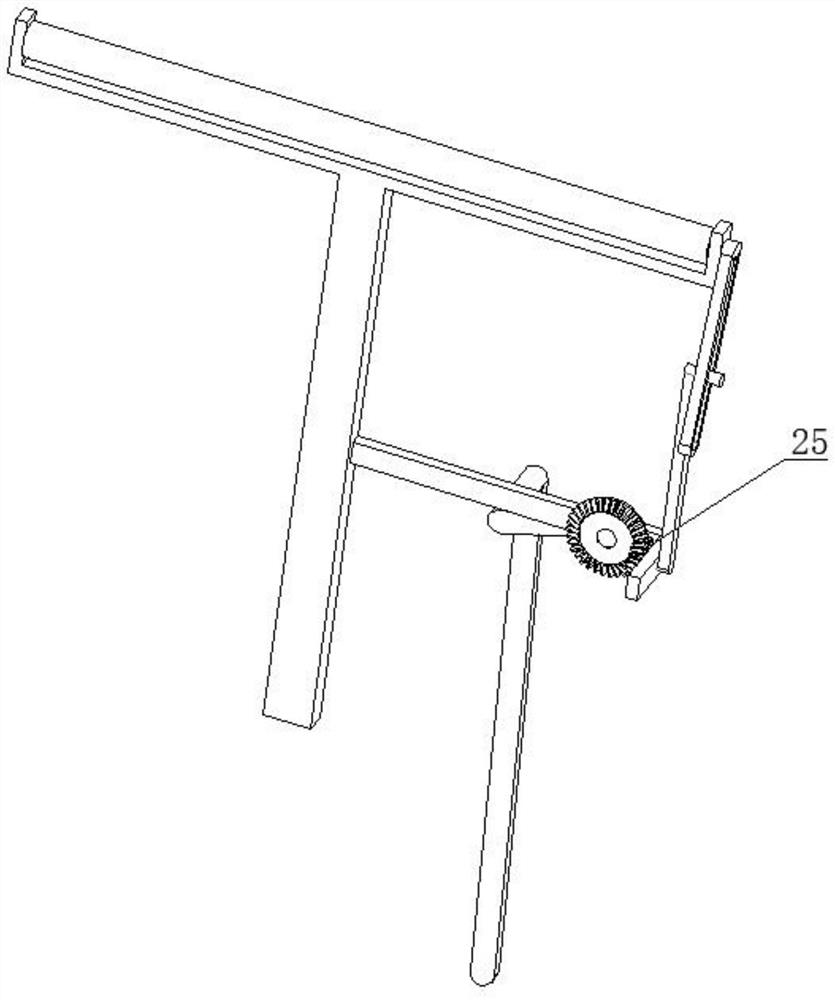

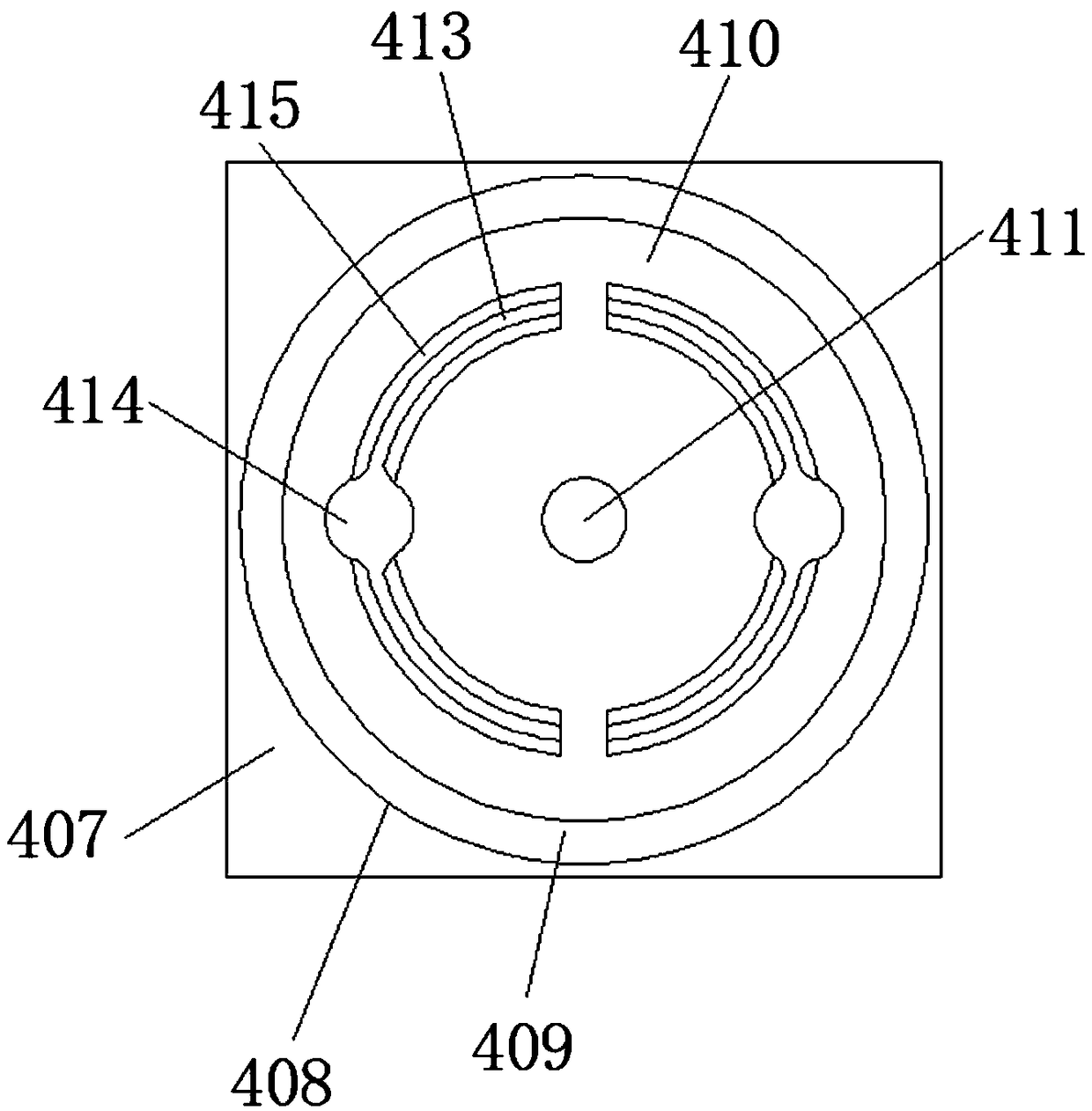

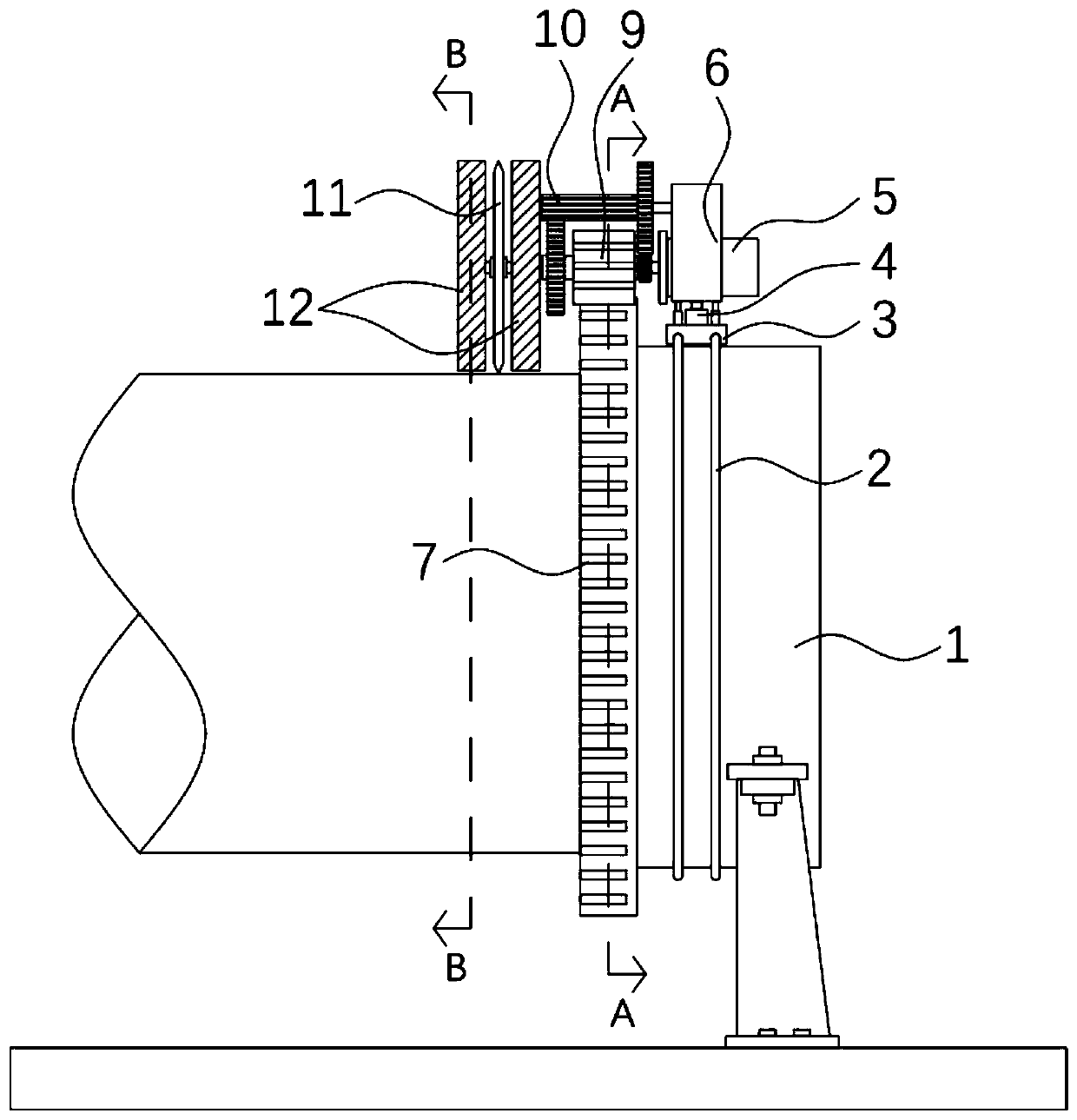

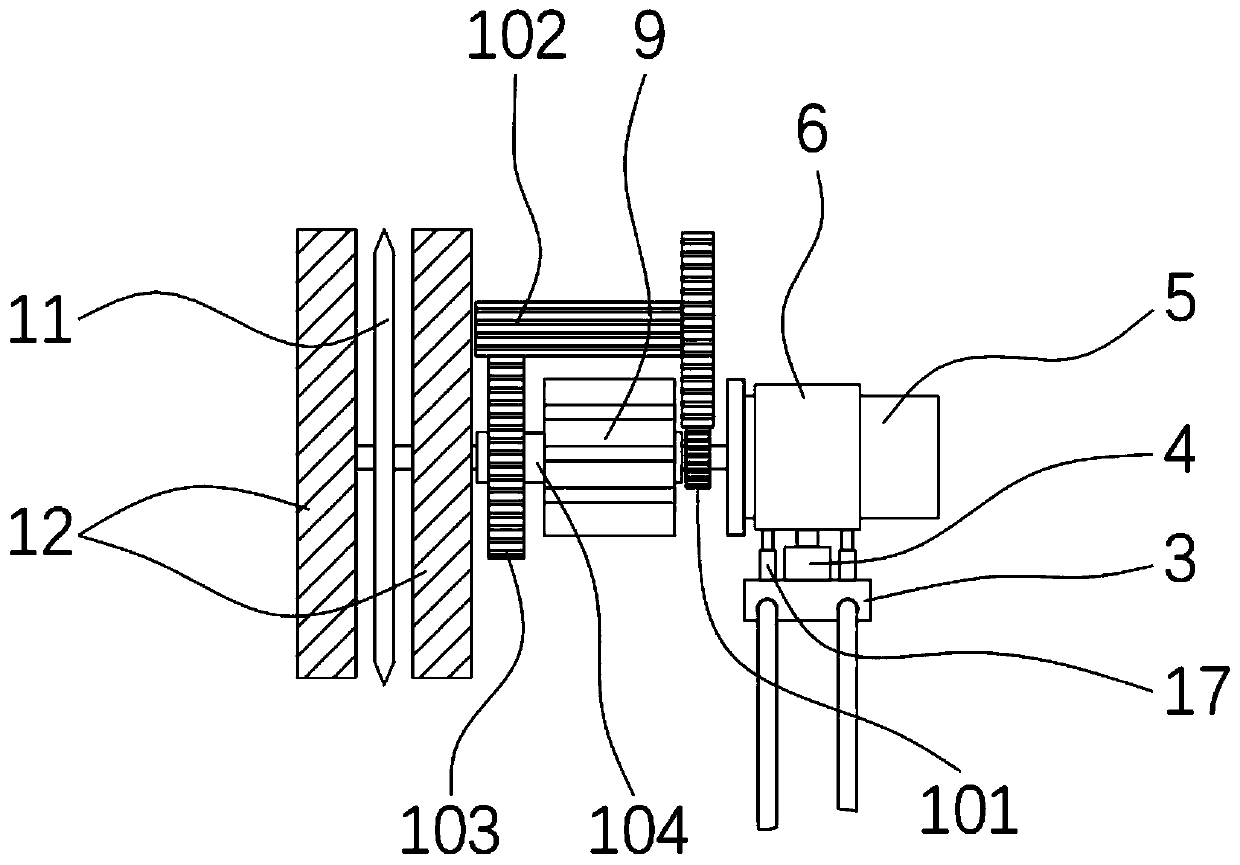

Finely-adjustable anti-reflective blackboard

InactiveCN104476953AImprove classroom teaching effectAchieve regulationWriting boardsTurn angleLight reflection

The invention relates to a finely-adjustable anti-reflective blackboard. The finely-adjustable anti-reflective blackboard comprises two blackboards which are connected together through a hinge and are movably arranged in a blackboard frame, wherein fine adjustment mechanisms are arranged at the outer edges of back face plates of the blackboards; cranking hand wheels of the fine adjustment mechanisms drive sleeves to turn, meanwhile, spring devices are contracted, the sleeves drive bevel gear groups, the bevel gear groups drive cams to move, the blackboards are jacked up by the cams, and fine adjustment or the change of positions of reflective areas of the blackboards is realized, so that the avoidance of light reflection is realized; after a proper angle is obtained through adjusting, the cranking hand wheels are released and return under the action of springs, self-locking mechanisms are enabled to be in a locked state, and the reverse self-locking of the blackboards is realized. According to the finely-adjustable anti-reflective blackboard, when visual sense is affected due to lighting changes of a classroom, a turning angle of the blackboard can be appropriately adjusted to remove light reflection, the utilization ratio of the blackboard is greatly increased, and the manufacturing cost is low.

Owner:XI'AN PETROLEUM UNIVERSITY

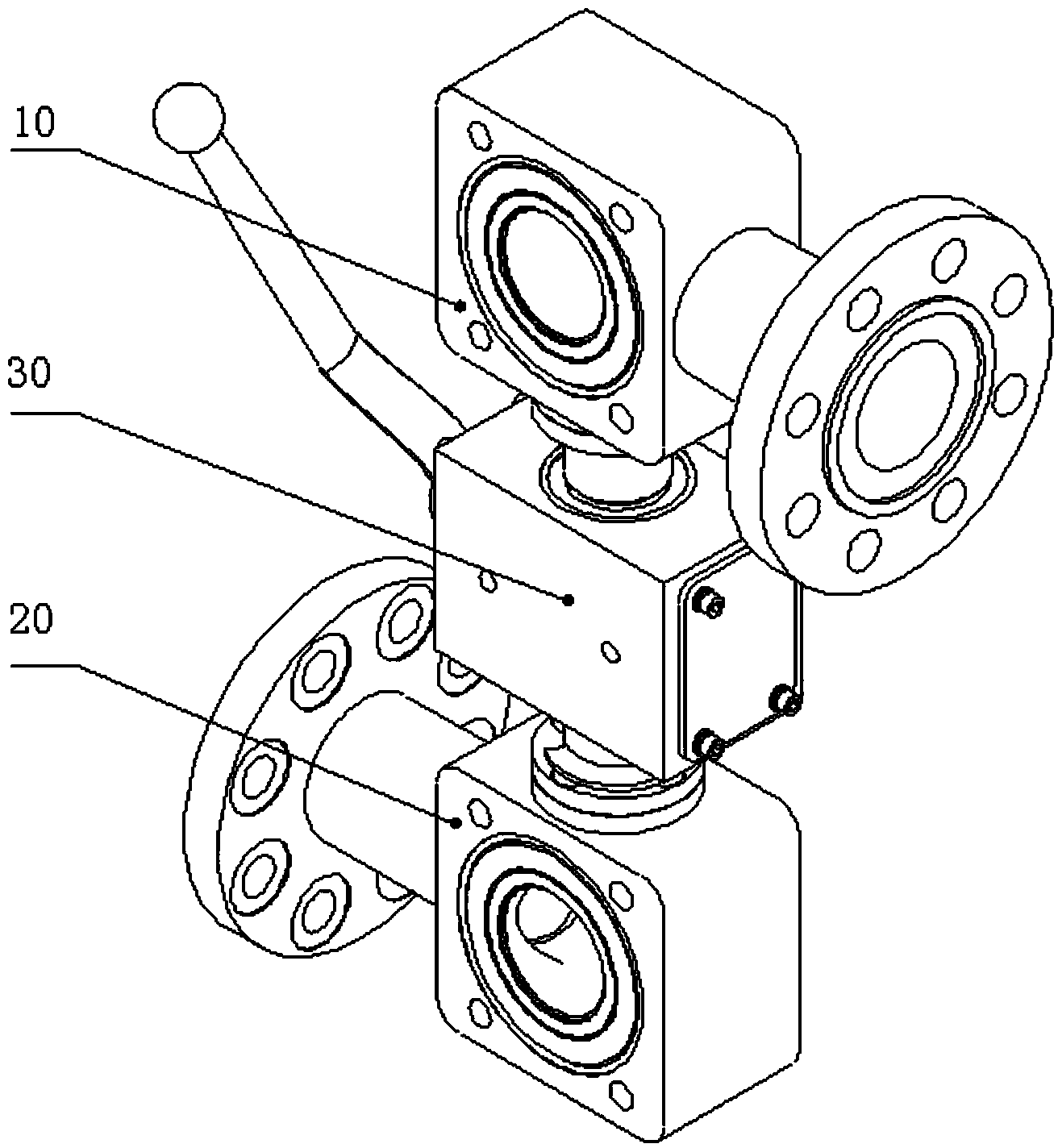

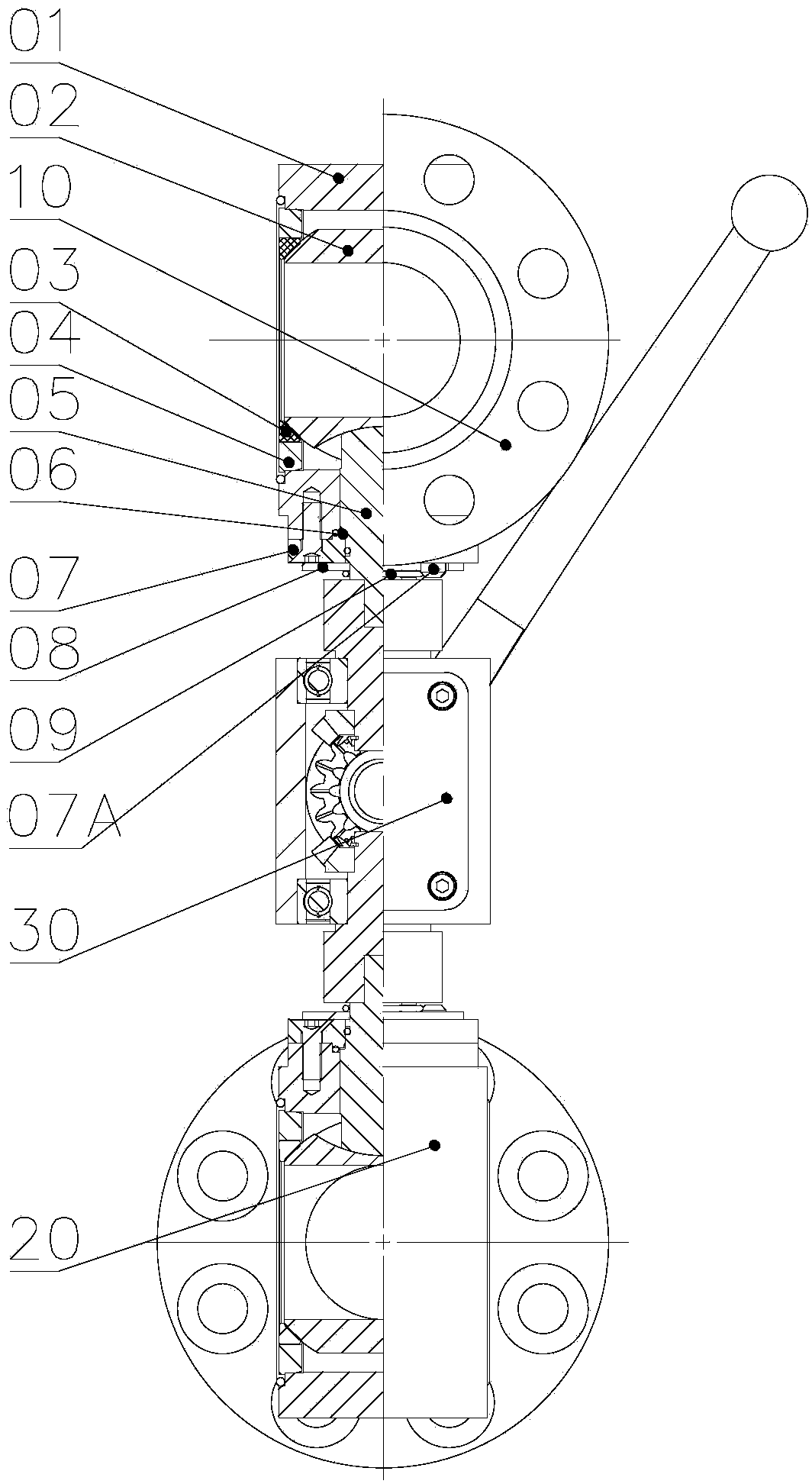

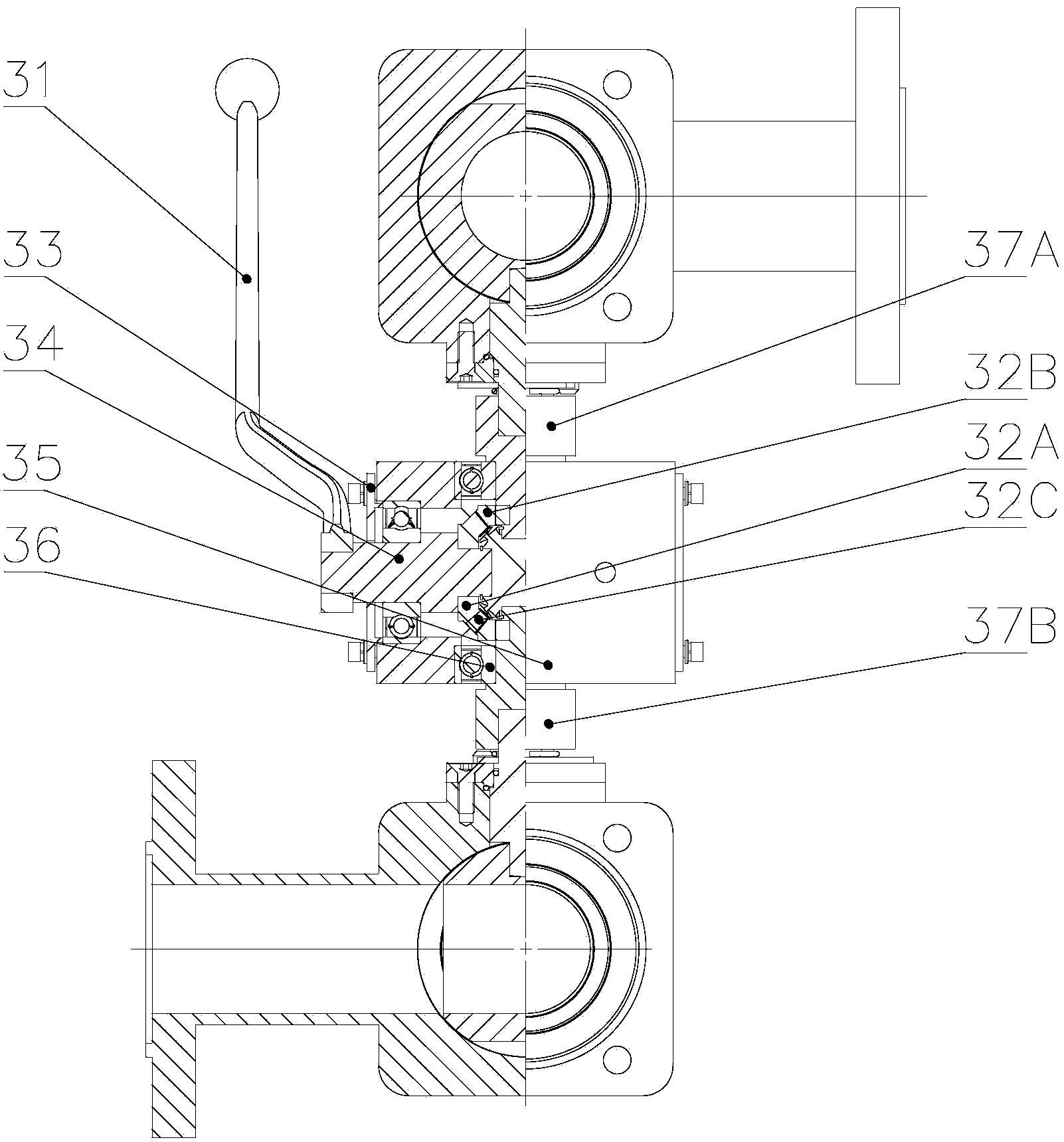

Six-way switching ball valve

ActiveCN104390035AAchieve closureAvoid sliding frictionOperating means/releasing devices for valvesMultiple way valvesBall bearingEngineering

The invention discloses a six-way switching ball valve, and belongs to switching valves. The ball valve solves the problem that an inlet and an outlet of an existing six-way switching valve are located on the same side, and consequently an application occasion is limited. The six-way switching ball valve is composed of an upper three-way ball valve, a lower three-way ball valve and a driving conversion mechanism; the structure and component parts of the upper three-way ball valve and the structure and component parts of the lower three-way ball valve are completely the same; each of the upper three-way ball valve and the lower three-way ball valve is composed of a valve body, a ball body, a sealing gasket ring, a sealing check ring, a rotating shaft, a thrust ring, a flange gland, a rotating check block and a steel wire check ring; the driving conversion mechanism comprises a handle, a conical gear, a gearbox, an input shaft, a ball bearing, an upper output shaft and a lower output shaft; the upper output shaft and the lower output shaft of the driving conversion mechanism are connected with the rotating shaft of the upper three-way ball valve and the rotating shaft of the lower three-way ball valve respectively in a matched mode. The six-way switching ball valve is simple in structure and small in switching torque; an inlet and an outlet of the six-way switching ball valve are arranged on the different sides; the problem that the inlet and the outlet are arranged on the same side, and the application occasion is limited is solved; and when the driving conversion mechanism is replaced by a sleeve, the valve can adapt to the occasion in which the oil inlet and the oil outlet are arranged on the same side, the interchangeability is high, and field pipelines are more flexibly arranged.

Owner:中国船舶重工集团公司第七〇七研究所九江分部

Electrified railway switching equipment

ActiveCN102324339AWith reliable interlock functionAchieve meshingHigh-tension/heavy-dress switchesAir-break switchesPush and pullEngineering

The invention relates to electrified railway switching equipment. The electrified railway switching equipment comprises a guide rail framework and a circuit breaker handcart, wherein the guide rail framework comprises a guide rail base and a facade mounting bracket; the circuit breaker handcart comprises a propulsion cart and a carrying cart; and an electrified railway vacuum circuit breaker, a current transformer and a primary moving contact are arranged on the propulsion cart. With the adoption of a landing handcart in the electrified railway switching equipment, the handcart runs on a special rail and has a reliable interlocking function; in the moving process of the handcart, the circuit breaker cannot be switched on, and the handcart cannot be pushed and pulled when the circuit breaker is switched on; and when the handcart moves from a testing position to a working position, the meshing of moving and fixed contacts is realized through a propulsion mechanism on an operation panel.

Owner:北京美基机电设备有限公司

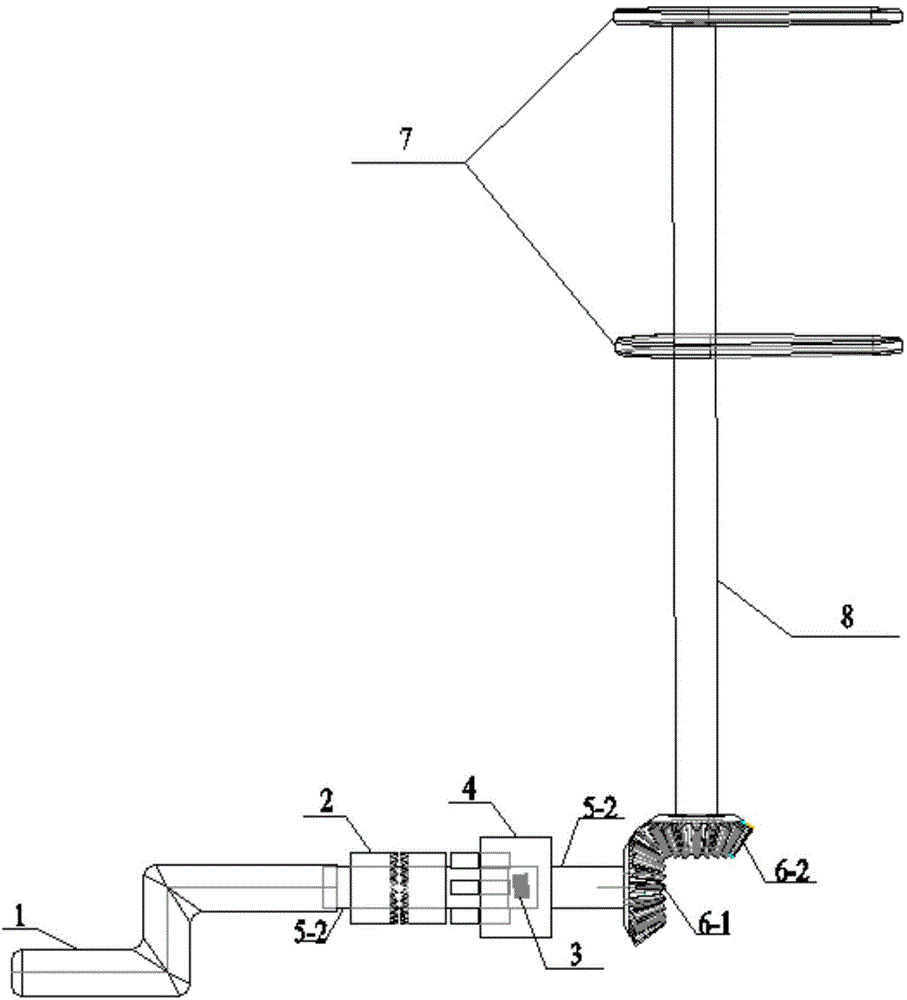

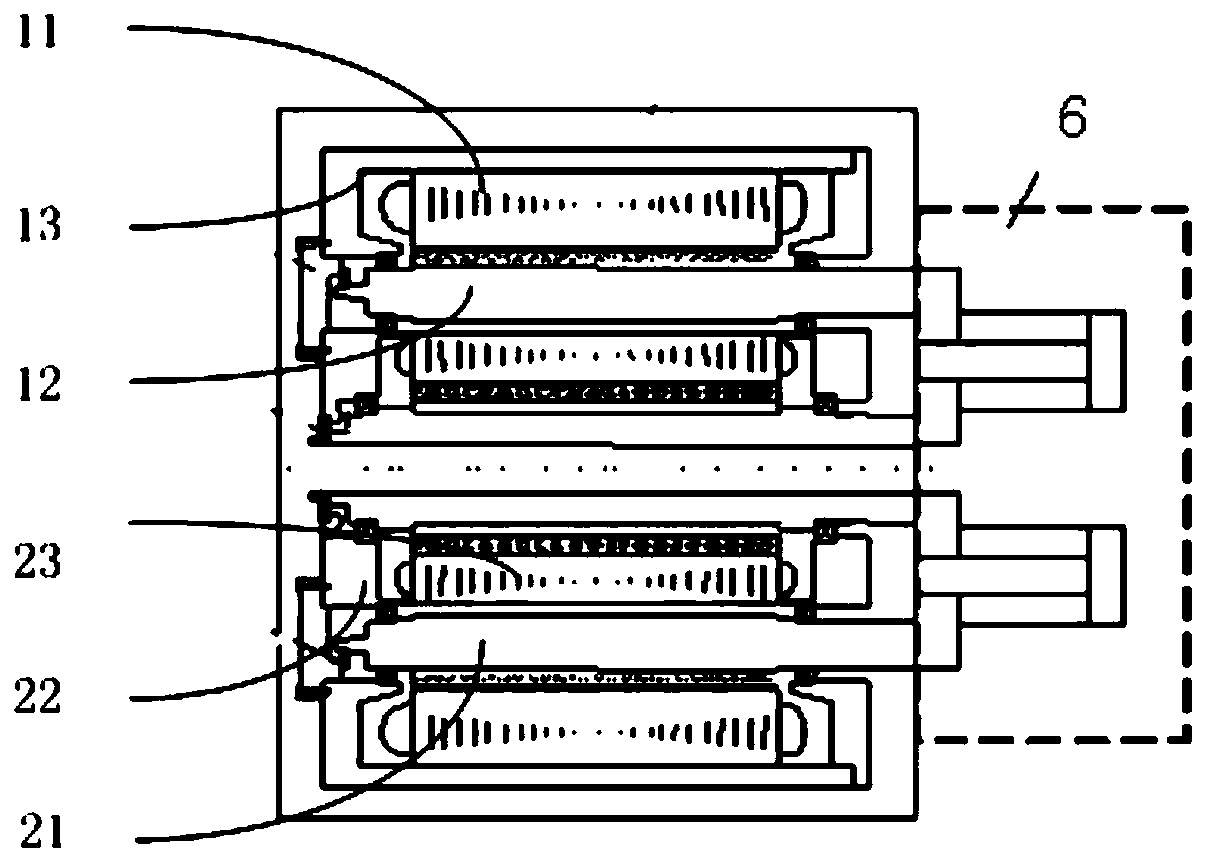

Forward and backward rotation power box for deep-layer cement mixing pile

The invention discloses a forward and backward rotation power box for a deep-layer cement mixing pile. A hollow pipeline is arranged at the middle portion of a drive gear, the middle portion of a forward rotation planetary gear box and the middle portion of a backward rotation planetary gear box. A rotating shaft is located in the hollow pipeline. The end, away from a support, of the hollow pipeline is connected with a grout sprayer. A clutch is fixed to the position, with the height the same as a power device, on the hollow pipeline. The forward rotation planetary gear box and the backward rotation planetary gear box are installed on the hollow pipeline. The drive gear is fixed to the rotating shaft. A forward rotation sun gear is located in the forward rotation planetary gear box. Forward rotation planetary gears surround the outer side of the forward rotation sun gear and are connected with the forward rotation sun gear in an engaged manner. A backward rotation sun gear is located in the backward rotation planetary gear box, and backward rotation planetary gears surround the outer side of the backward rotation sun gear and are connected with the backward rotation sun gear in an engaged manner. The forward and backward rotation power box for the deep-layer cement mixing pile can rotate forward and backward and is simple in structure and long in service life.

Owner:TIANJIN LIYOU BUILDING ENG CO LTD

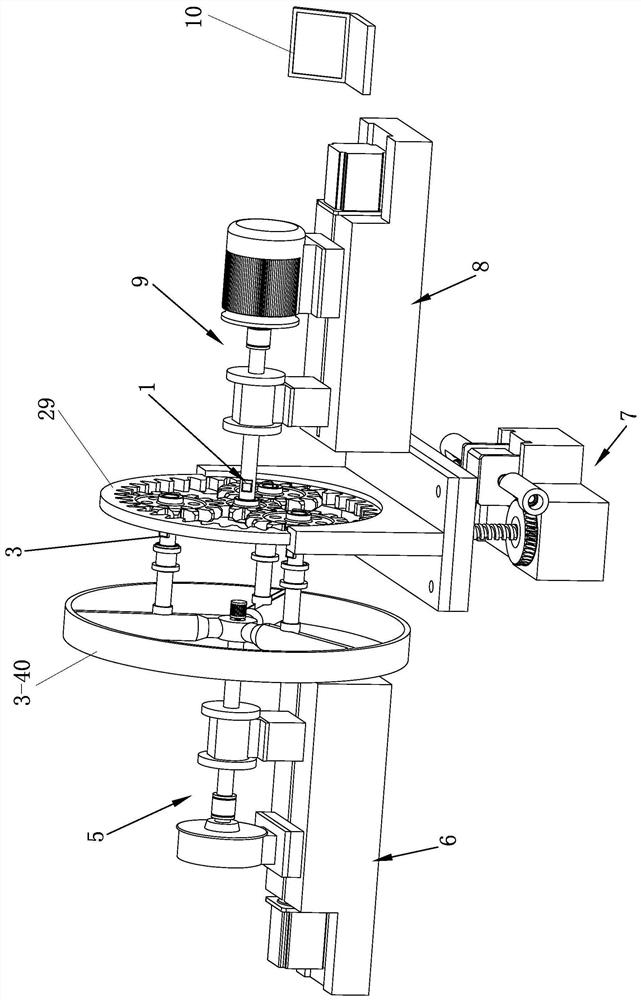

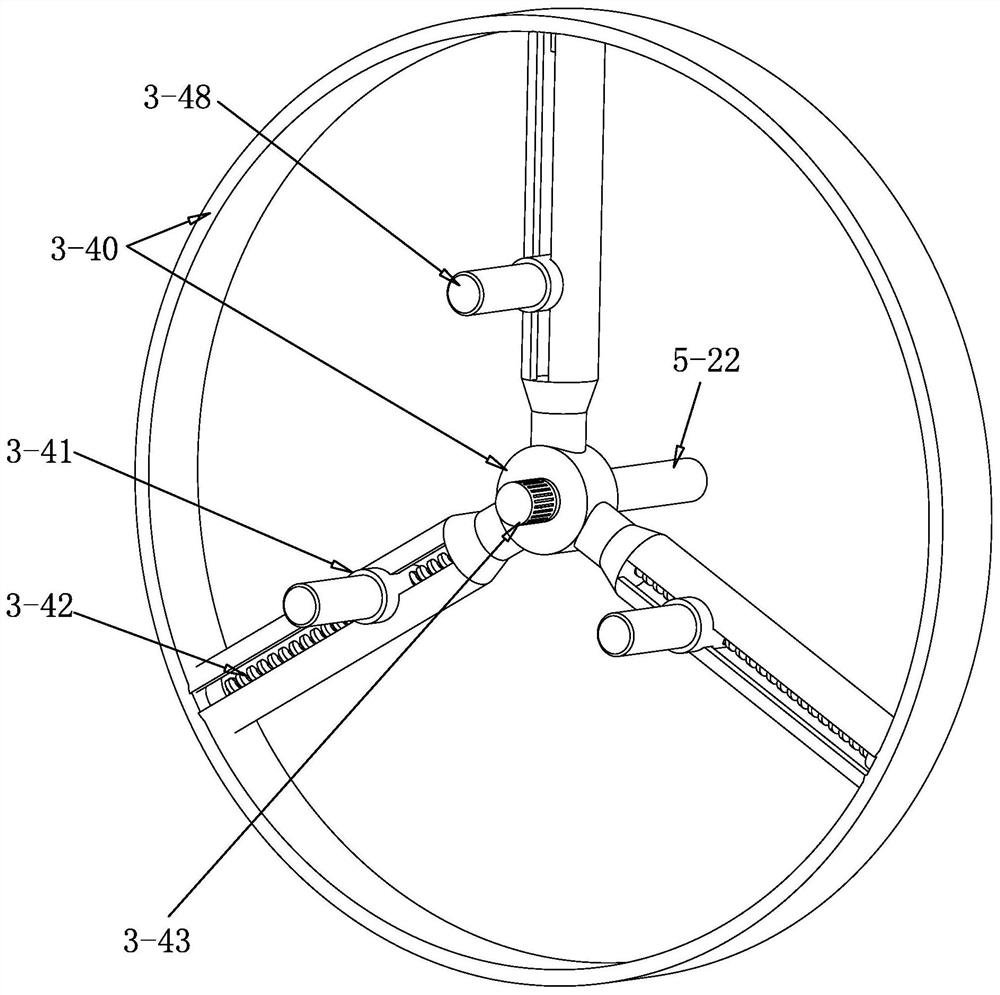

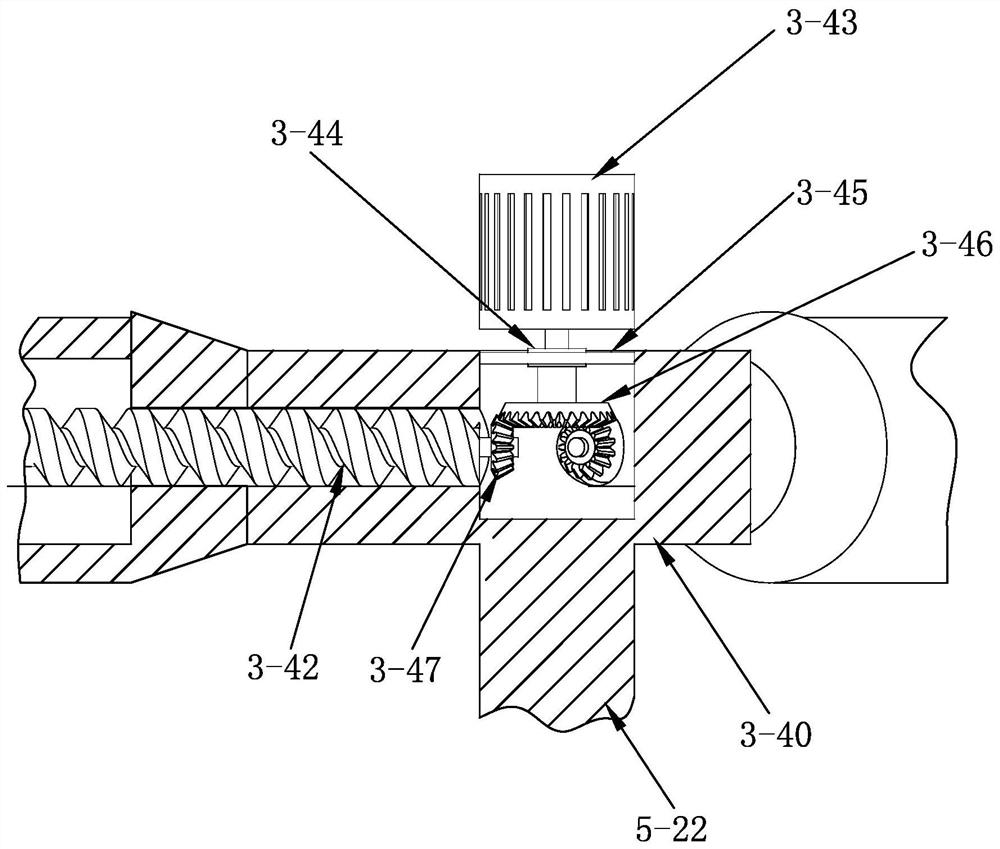

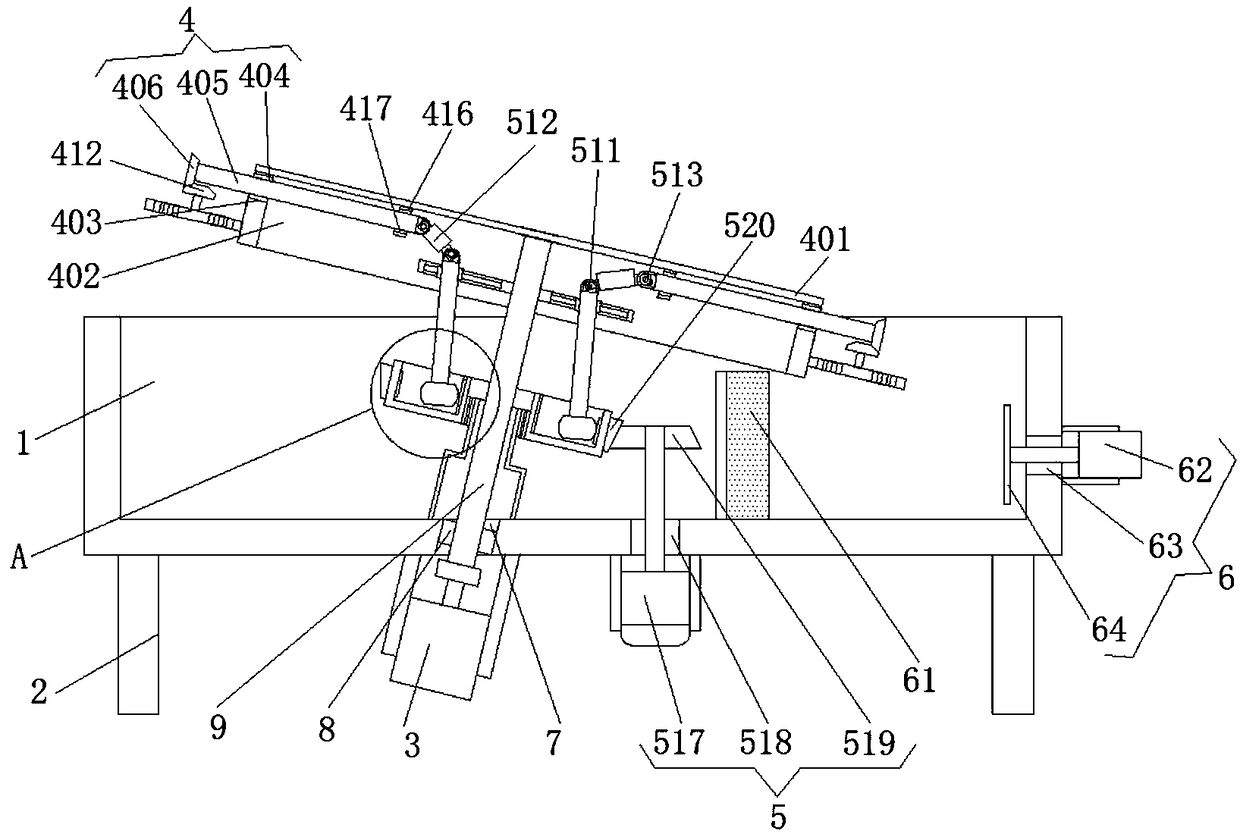

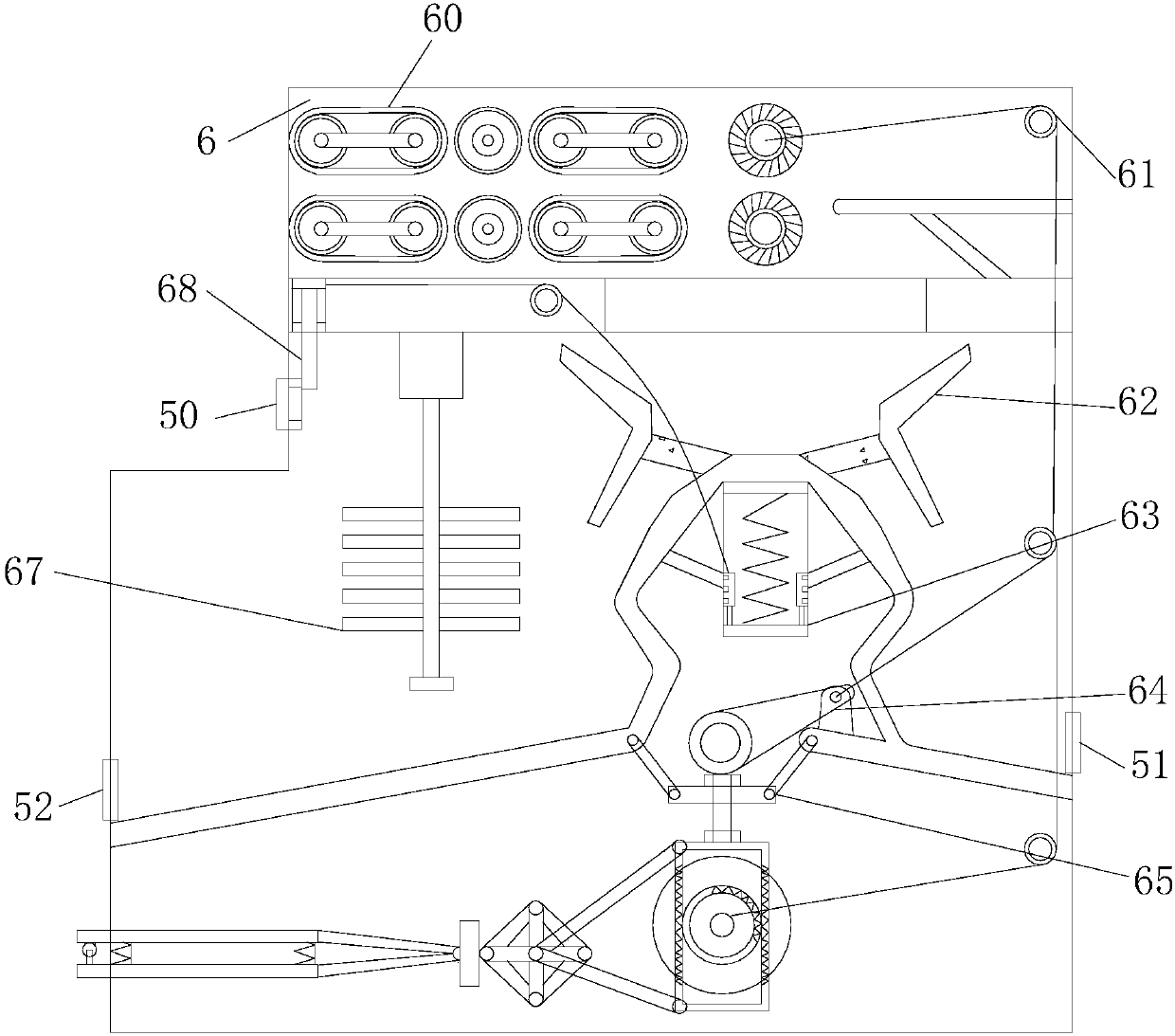

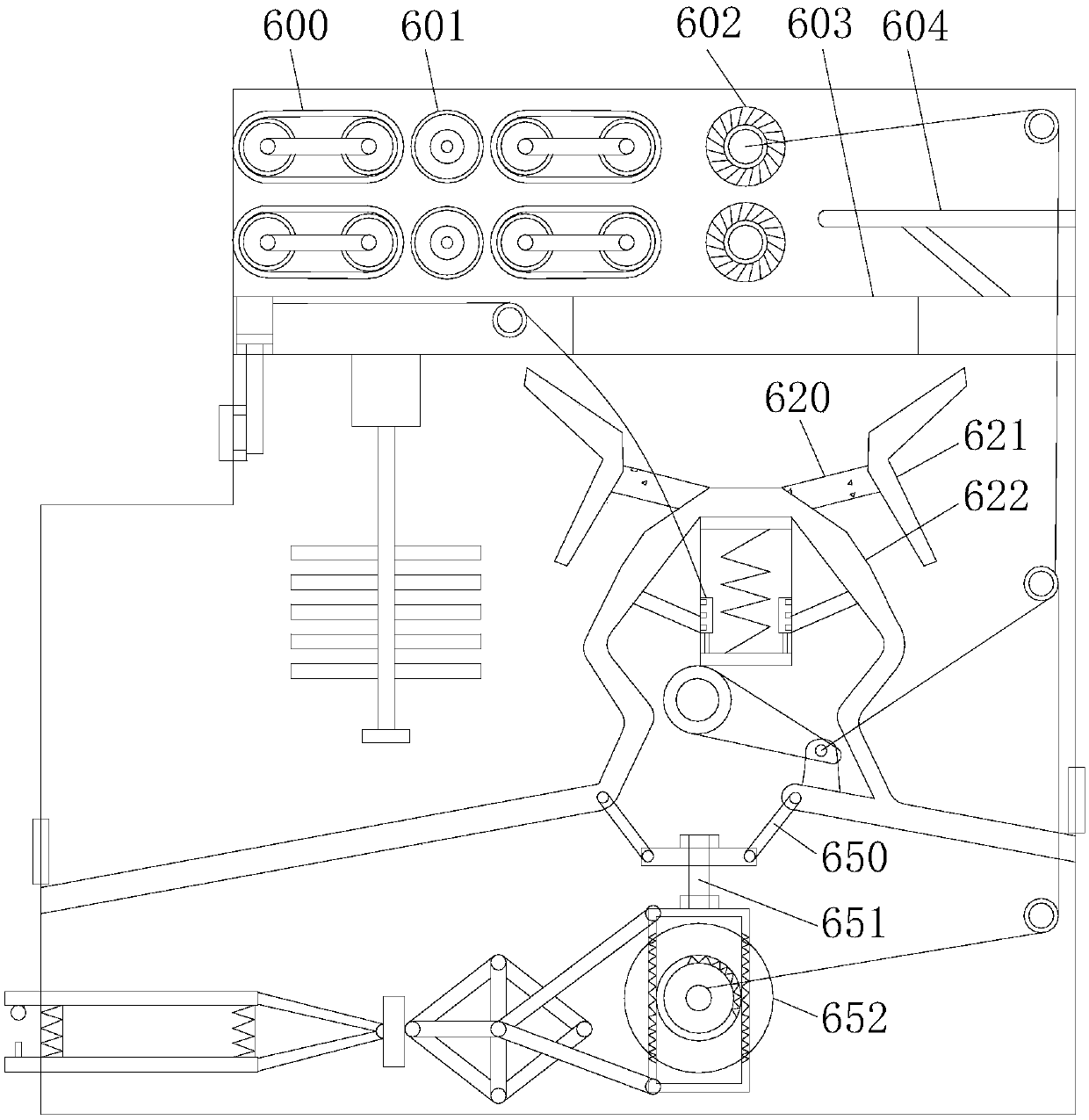

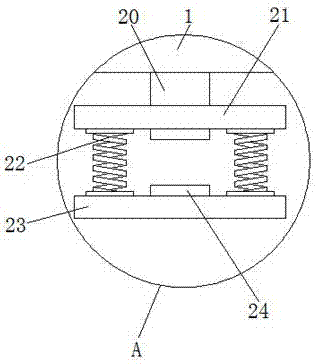

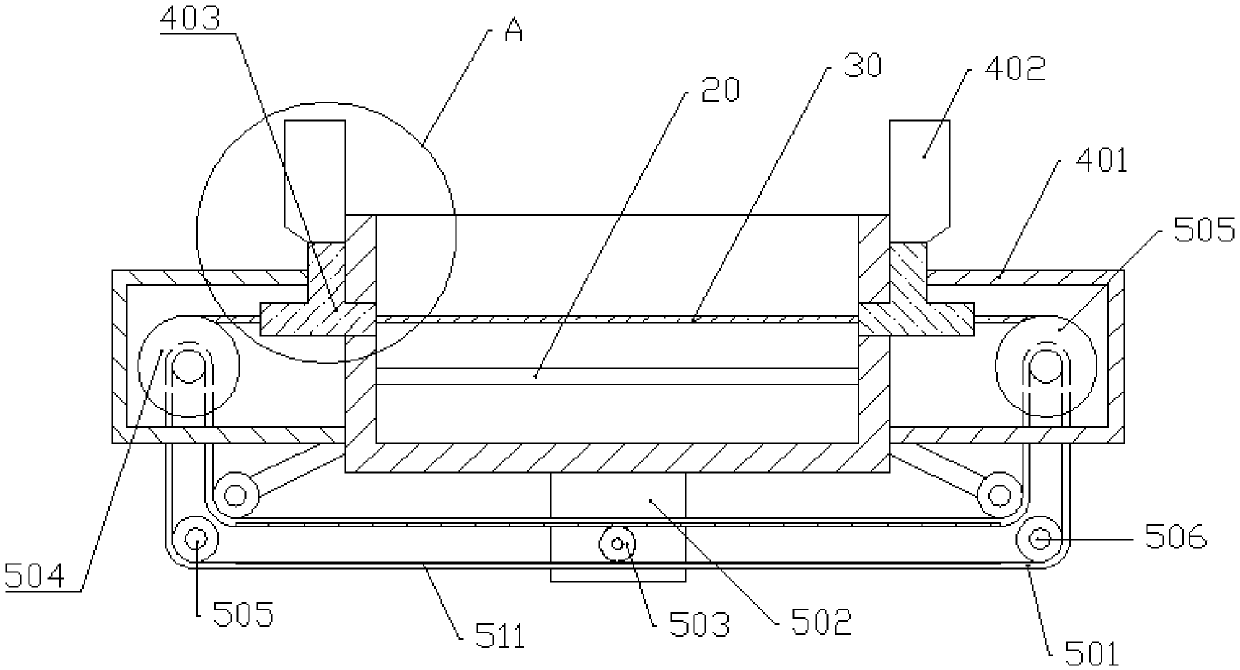

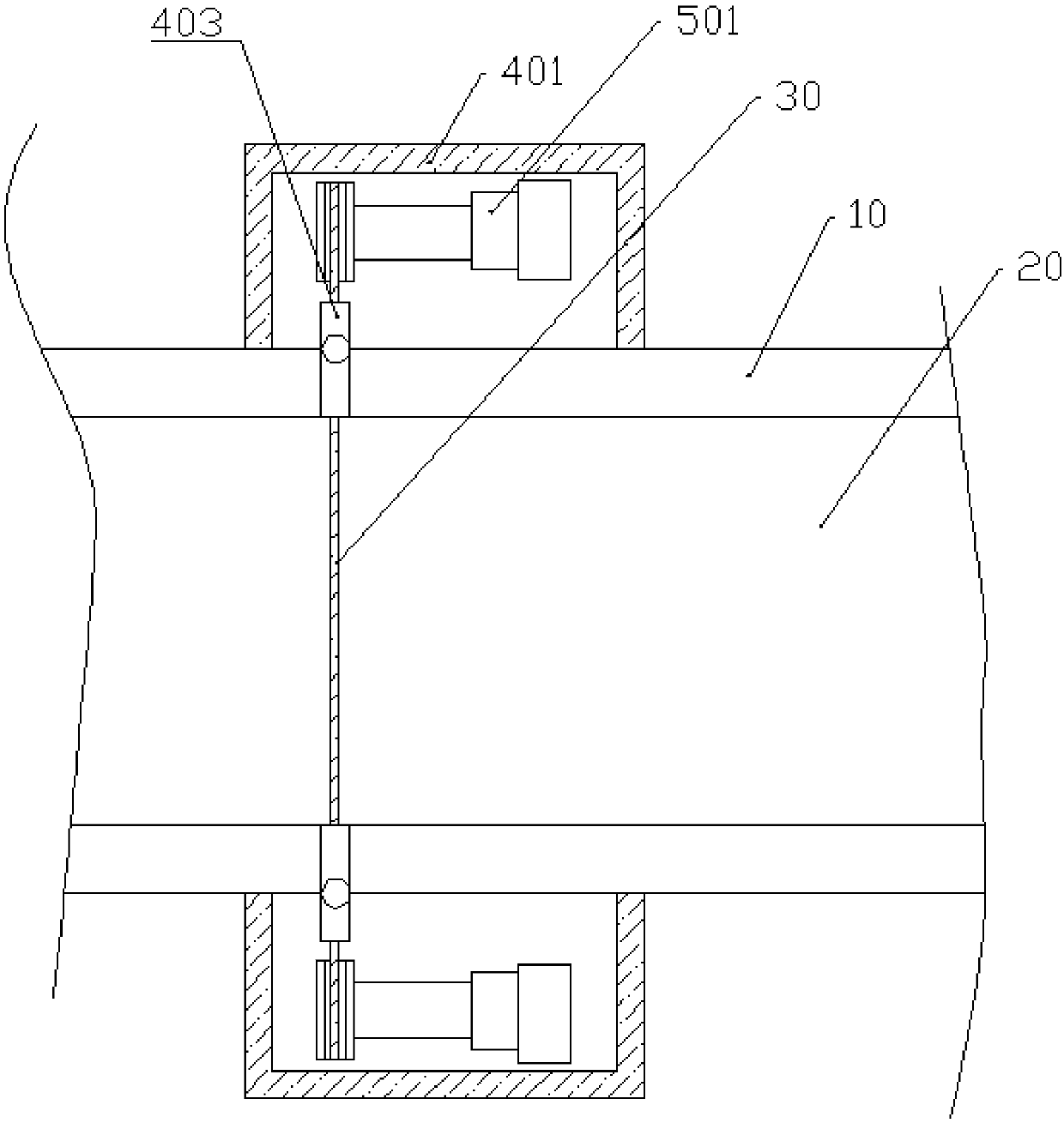

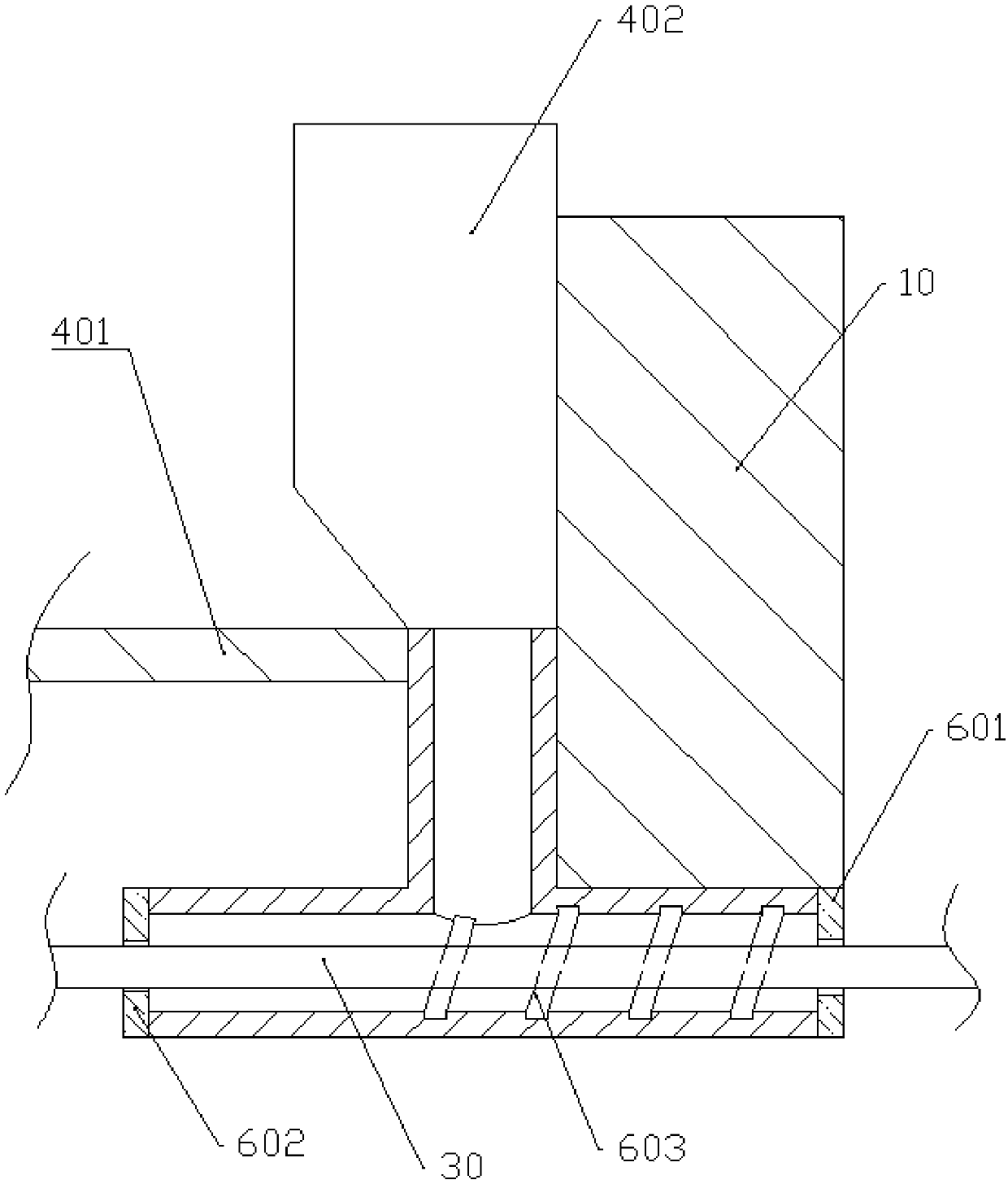

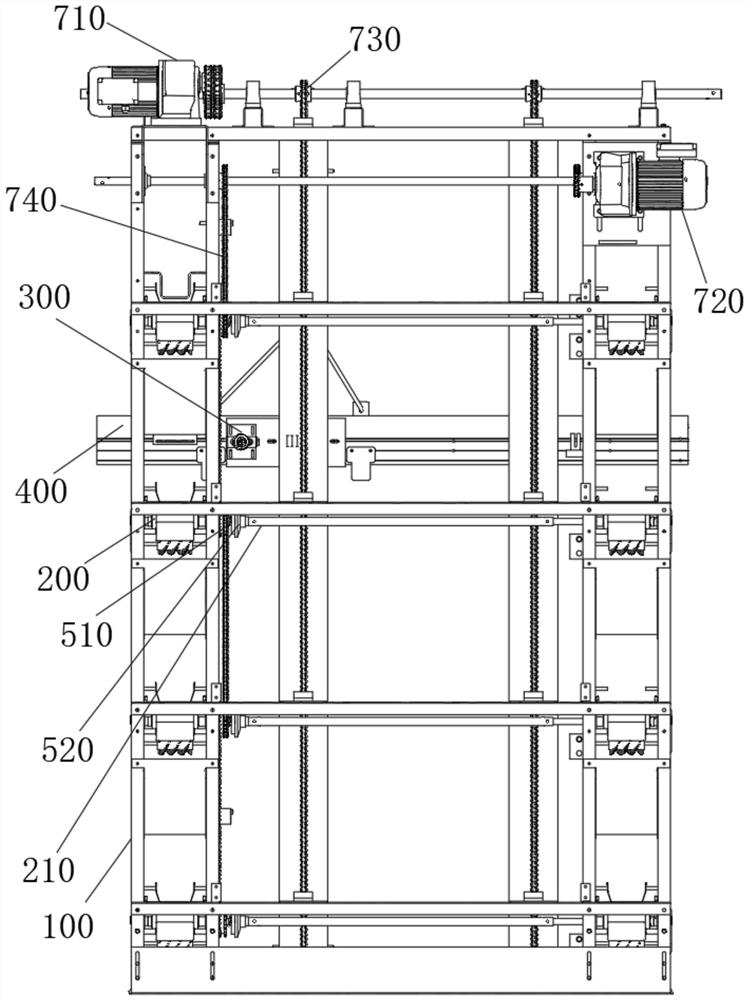

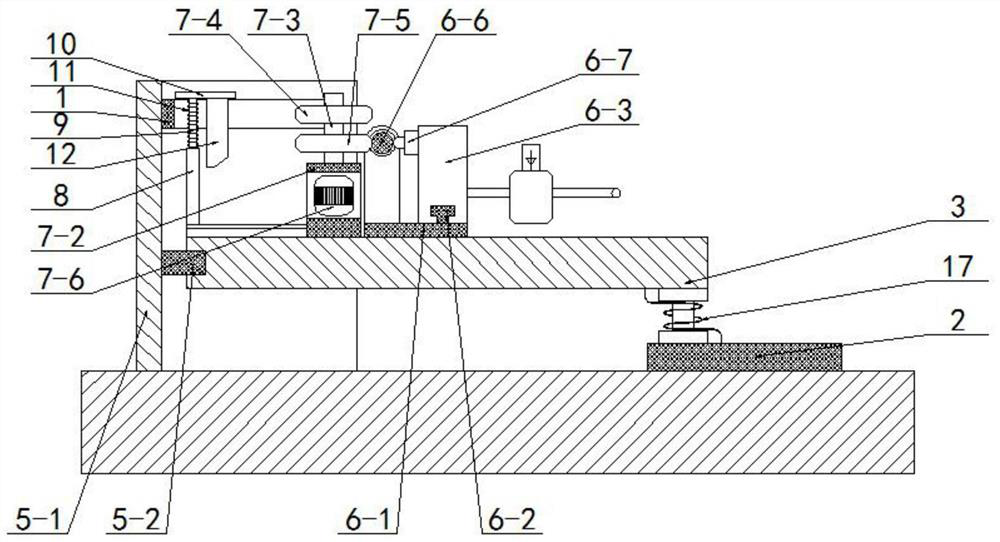

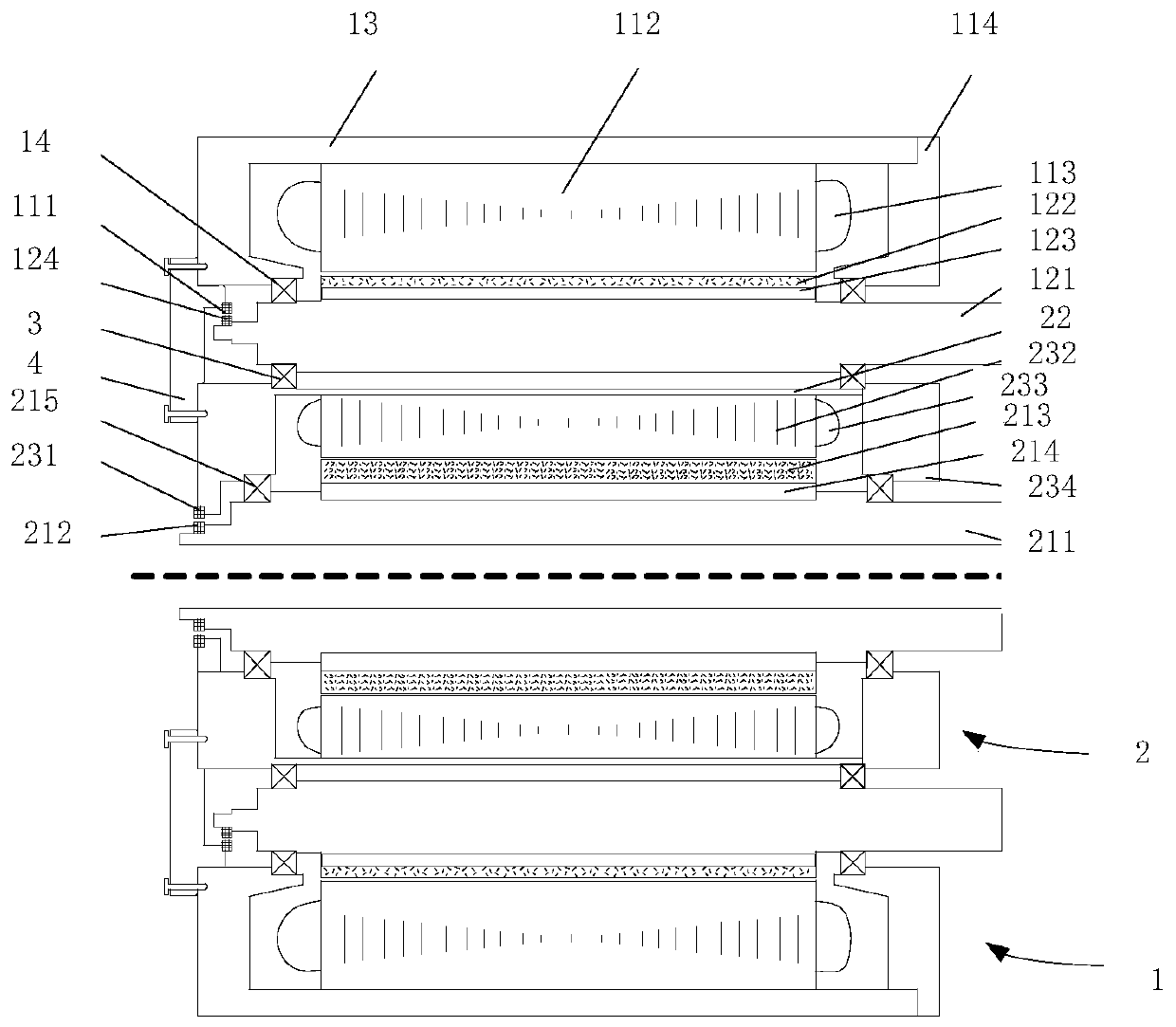

Variable-size RV reducer planetary gear stress measurement device and method

The invention discloses a variable-size RV reducer planetary gear stress measuring device and method. The device comprises a strain measuring device, a planetary gear mechanism, a planetary gear adjusting mechanism, a planetary gear carrier displacement mechanism, a gear ring bracket displacement mechanism, a sun gear shaft displacement mechanism, a torque braking device and a torque driving device. The strain measuring device is used for measuring strain of a sun gear and a planetary gear of the planetary gear mechanism, the planetary gear adjusting mechanism is connected with the planetary gear and used for adjusting the position of a planetary gear shaft, and the planetary gear carrier displacement mechanism is arranged on the lower portion of the torque braking device and used for adjusting horizontal displacement of a planetary gear carrier. The sun gear shaft displacement mechanism is arranged on the lower portion of the torque driving device and used for adjusting horizontal displacement of a sun gear shaft and the torque driving device, and the gear ring bracket displacement mechanism is connected with a gear ring of the planetary gear mechanism and used for adjusting vertical displacement of the gear ring. According to the invention, measurement of tooth root stress of planetary gears with different sizes and different specifications is realized.

Owner:NINGBO UNIV

Headlight

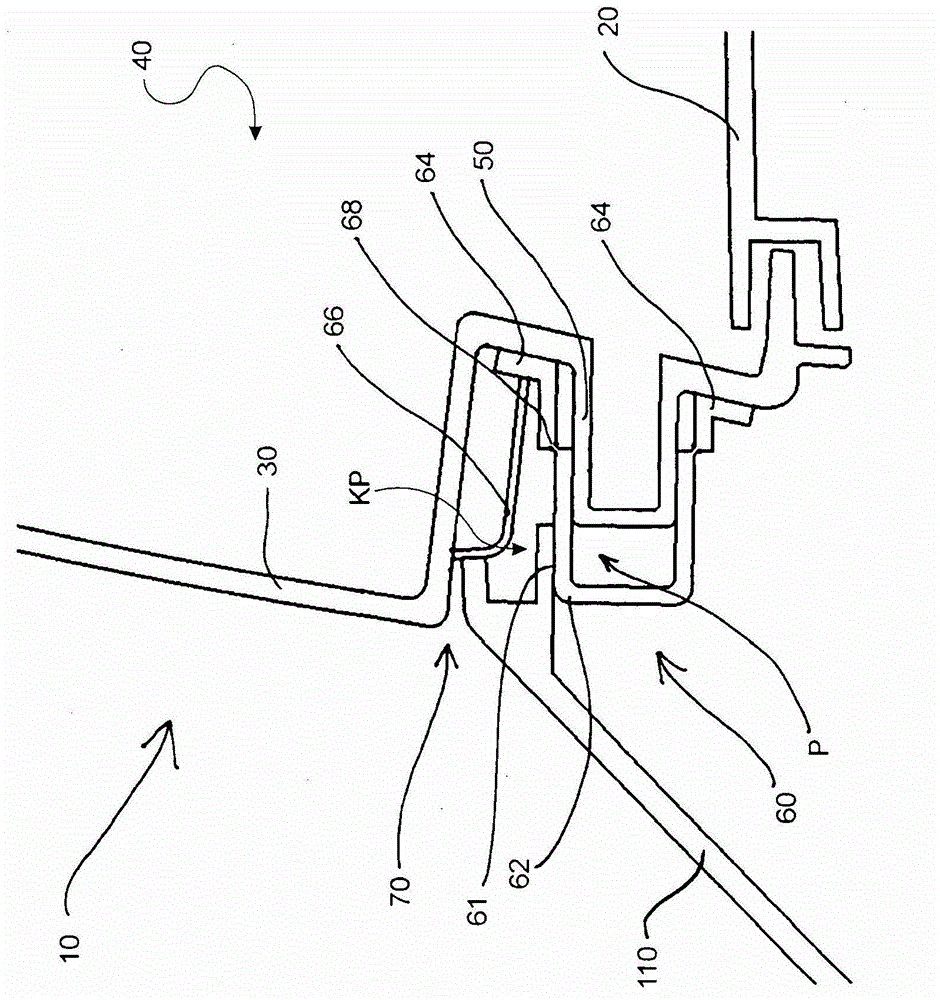

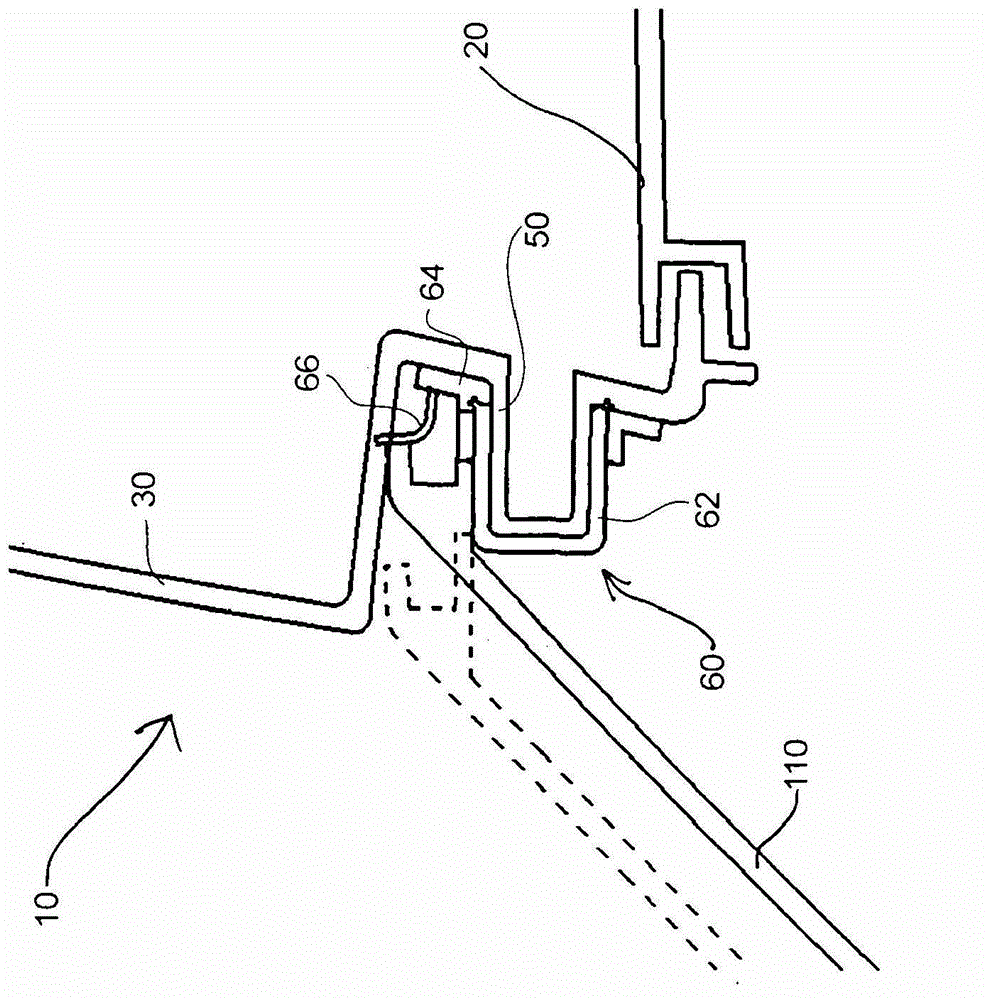

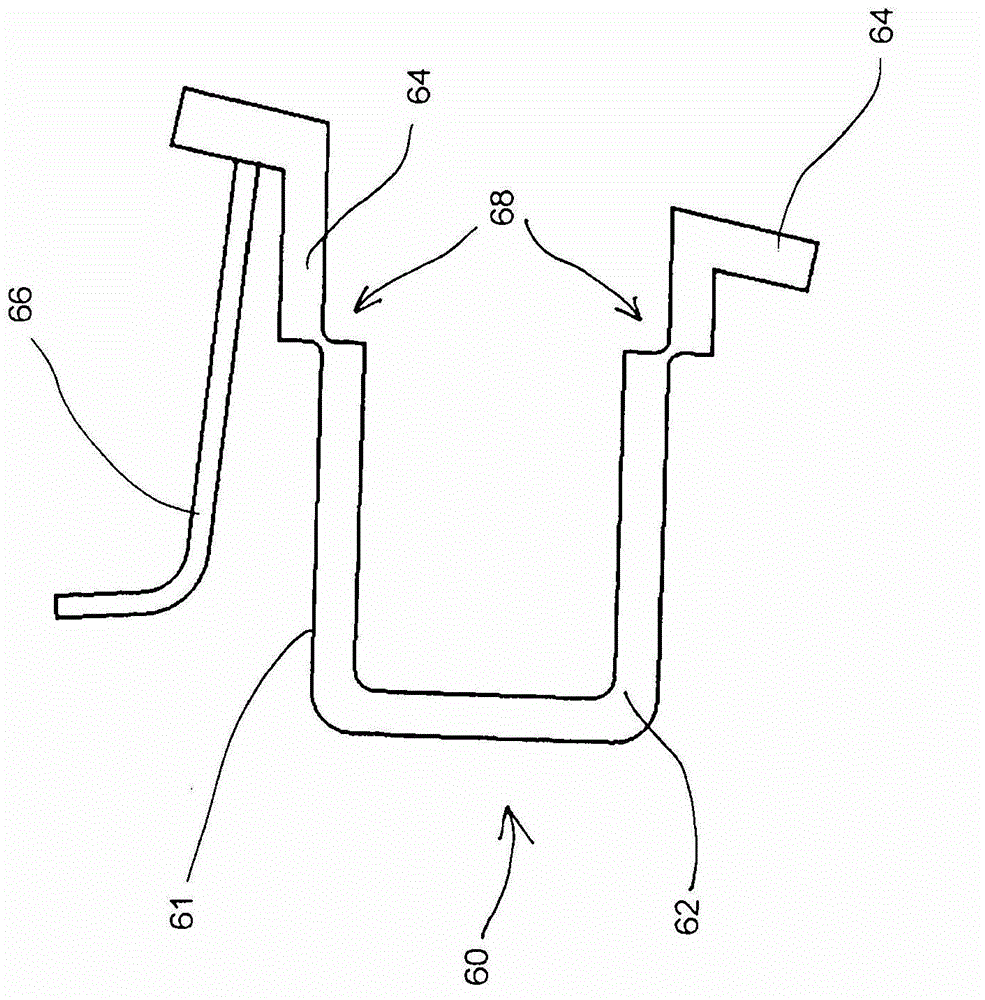

ActiveCN102862505AAvoid damageExtended service lifePedestrian/occupant safety arrangementOptical signallingRisk strokeMechanical engineering

The present invention relates to a headlight (10) used for an automobile (100), comprising a housing (20) and an enclosed lens (30) which both enclose one inner cavity (40) of the headlight (10); and at least one supporting rib (50) arranged outside the inner cavity (40) and connected with the enclosed lens (30), wherein the supporting rib (50) is provided with a supporting component (60) with at least one supporting portion (62), the supporting portion can support one vehicle body (110) of the automobile (100), and the supporting portion (62) can move along a buffer stroke (P) on the supporting rib (50) relative to the supporting rib (50).

Owner:海拉有限双合股份公司

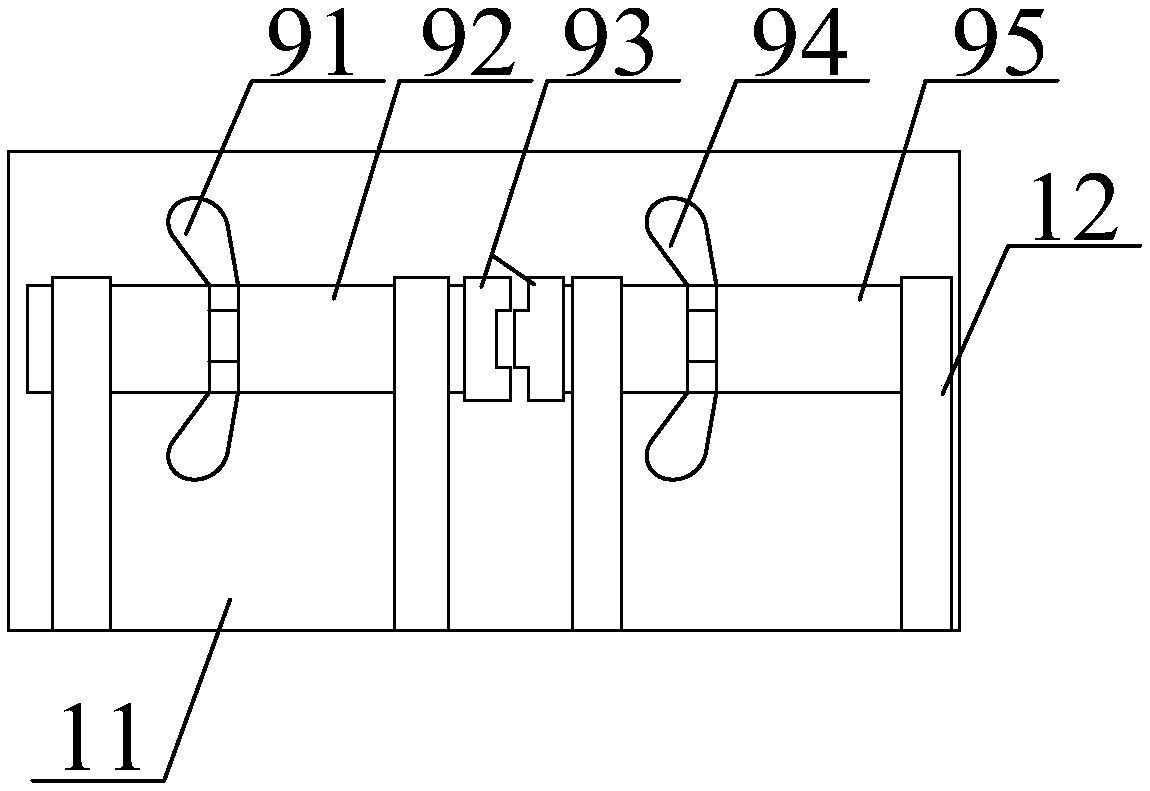

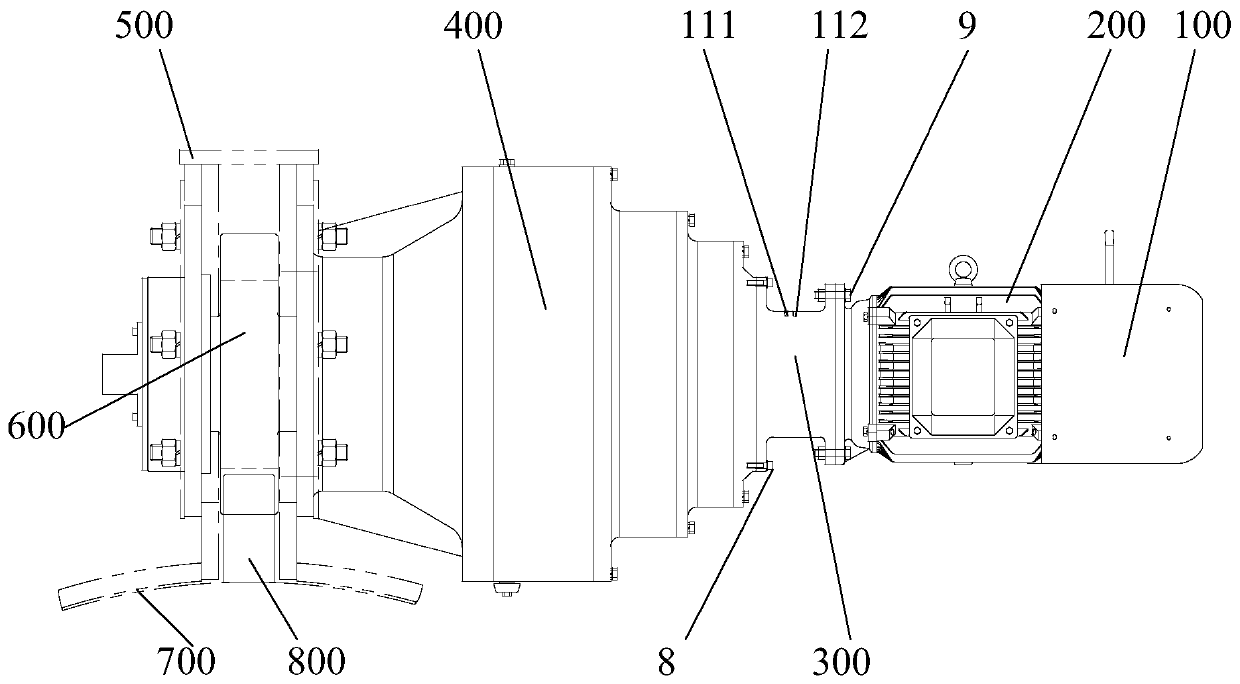

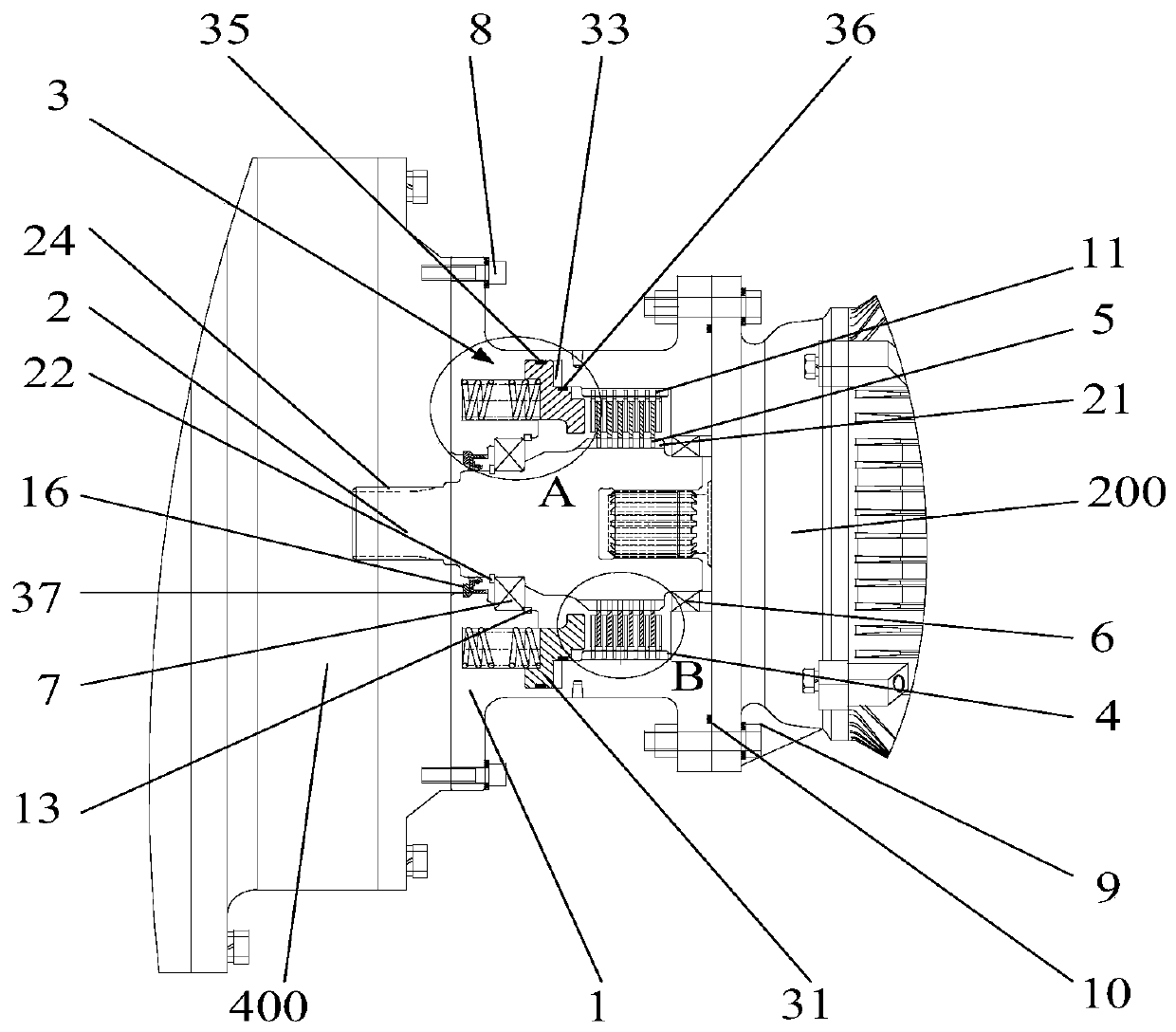

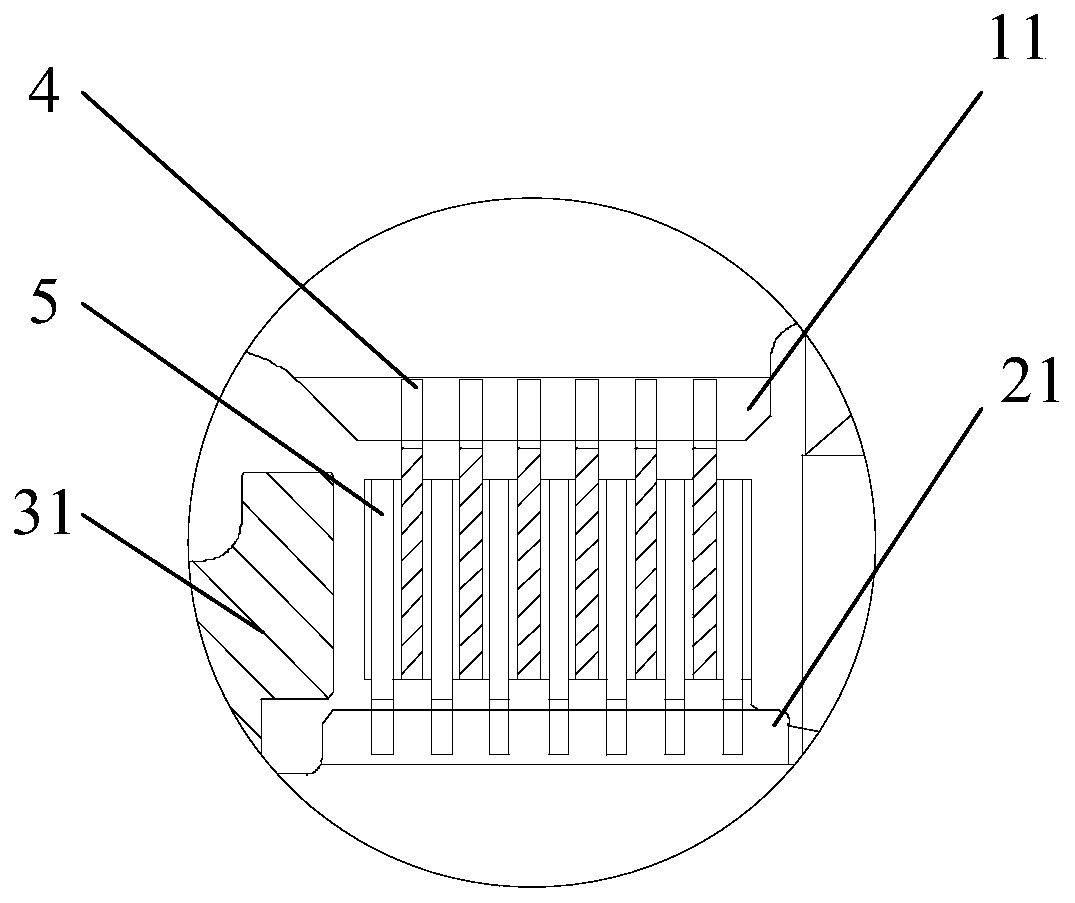

Energy-saving box type centrifugal fan

ActiveCN109488618AAchieve connectionRealize simultaneous operationPump componentsPump controlImpellerDrive wheel

The invention provides an energy-saving box type centrifugal fan. The energy-saving box type centrifugal fan comprises a mounting seat, an air inlet, open grooves, a dividing and combining mechanism,a buffering seat, a rotating motor, a driving wheel, a flat belt, a centrifugal mechanism, an air outlet, a box body, a bearing seat, a driven wheel and a positioning pin. Through arrangement of the centrifugal mechanism and the dividing and combining mechanism, the dividing and combining mechanism is pushed to drive a driven shaft to move leftwards to achieve sliding block type connection of a coupler. A driving shaft drives power to the driven shaft, and therefore a first centrifugal impeller and a second centrifugal impeller rotate at the same time, and the flow speed of air is improved. The two centrifugal impellers are adopted, so that the defect that the length of a box body behind the impellers influences the air sucking effect in the prior art is overcome. A rotating draught fan and the buffering seat is arranged, the buffering seat is additionally arranged at the bottom of the rotating motor, and therefore direct contact between the rotating motor and the box body is avoided,and vibration and noise during working are effectively reduced.

Owner:深圳市志誉科技有限公司

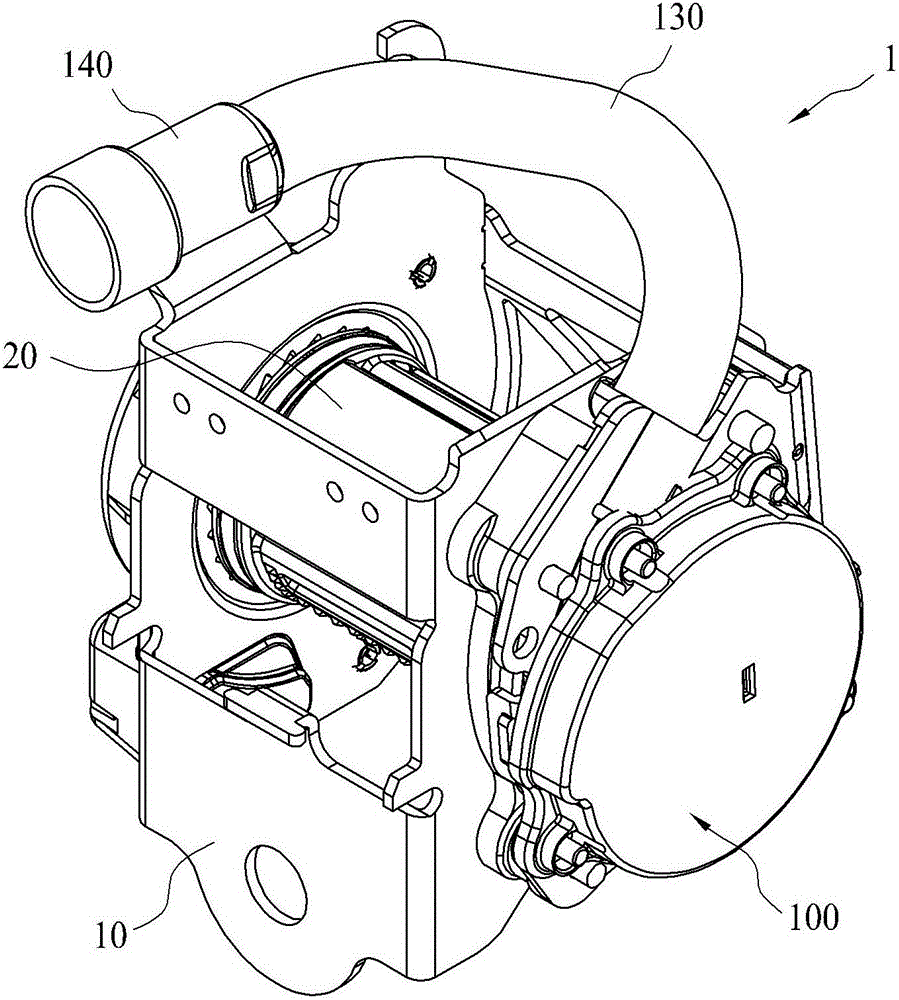

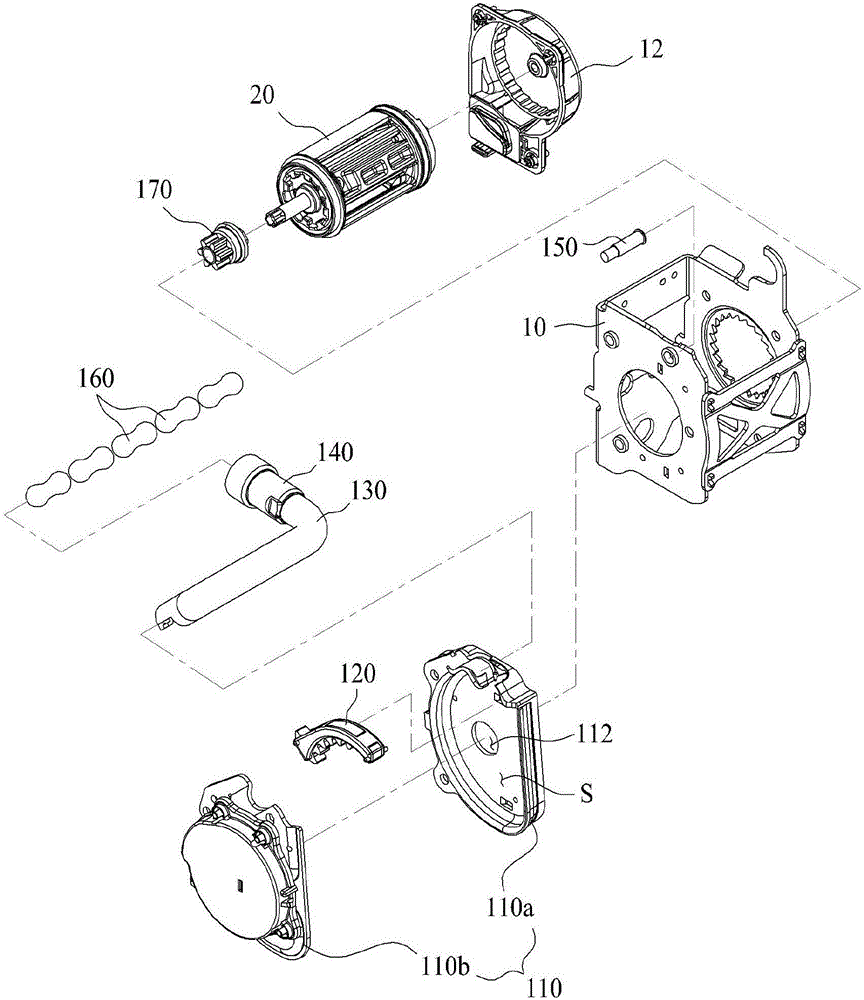

Pretensioner having fracture connection-type rack gear

A pretensioner having a fracture connection-type rack gear, according to the present invention, comprises: a housing having a receiving space; a pinion gear which is provided in the receiving space, and which is connected to a rotation shaft of a spool having a seat belt webbing wound thereon, and is rotated by the rotation of the spool; a micro gas generator for generating explosive power in response to an impact from outside; a transport pipe, one end of which is connected to the micro gas generator, and the other end of which is formed with an opening so as to be connected to the receiving space; a plurality of ball members which are provided in the transport pipe, and which are transported to the receiving space by the explosive power of the micro gas generator; and a rack gear which is provided in the receiving space in a fixed state so as to be fixed by a fixing part, and which is engaged with the pinion gear as the fixing part is fractured by the ball members transported to the receiving space by the explosive power of the micro gas generator, and which rotates the pinion gear by means of the remaining thrust of the ball members in a direction in which the webbing is introduced.

Owner:WOOSHIN SAFETY SYST CO LTD

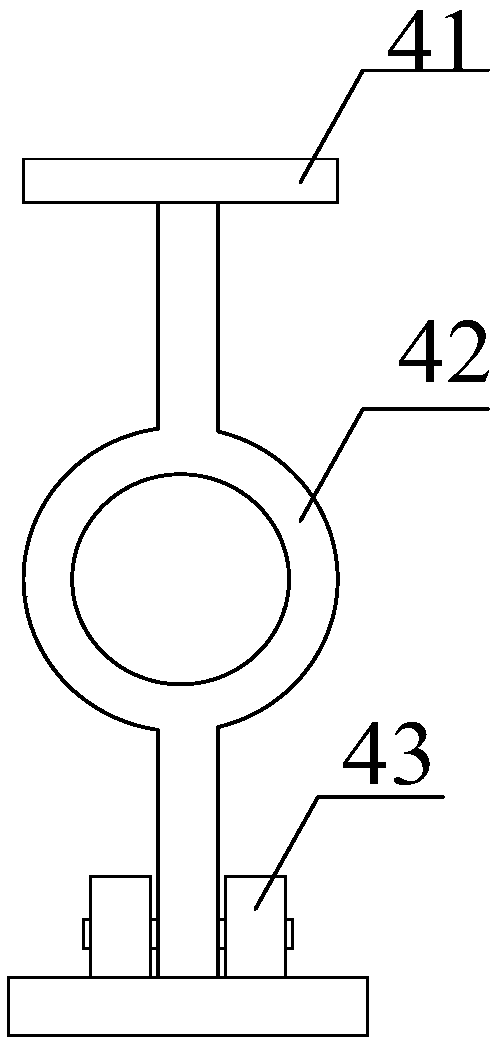

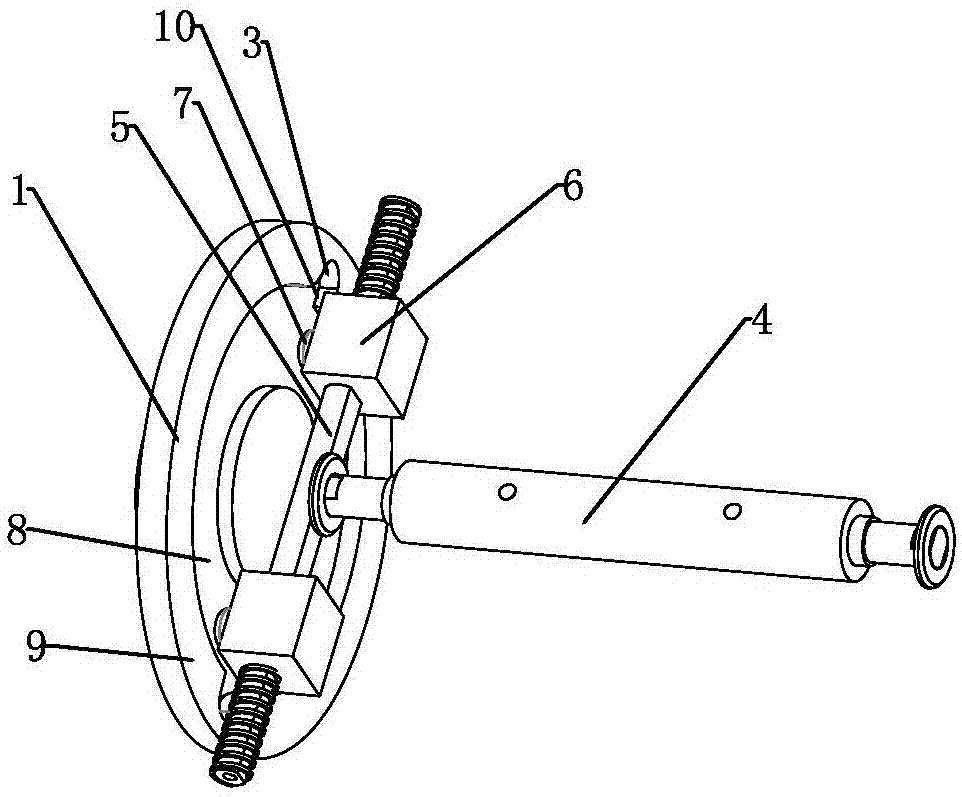

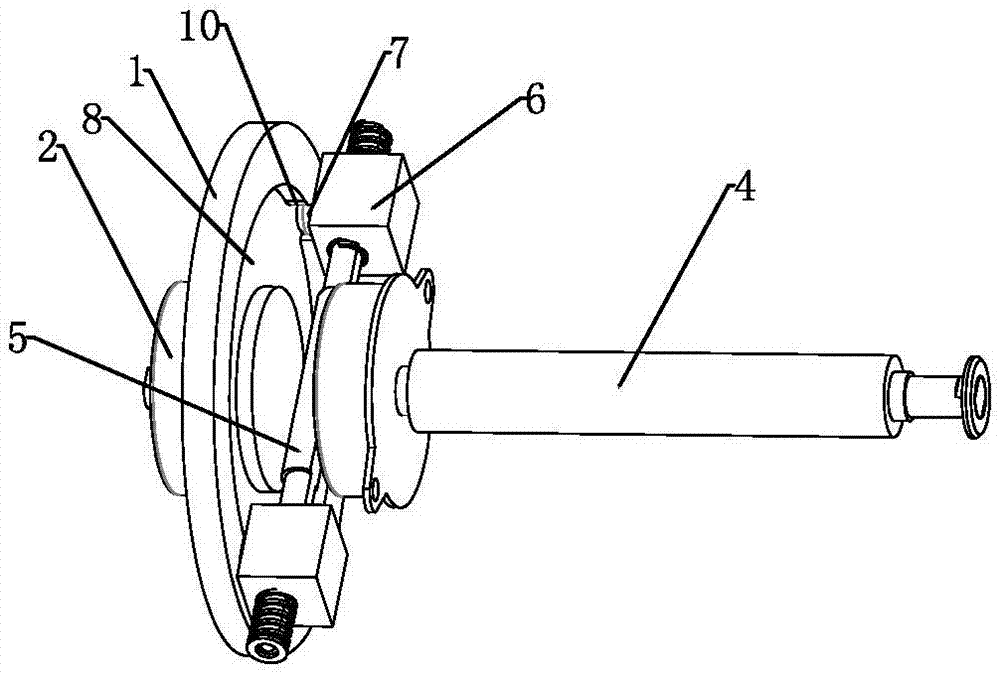

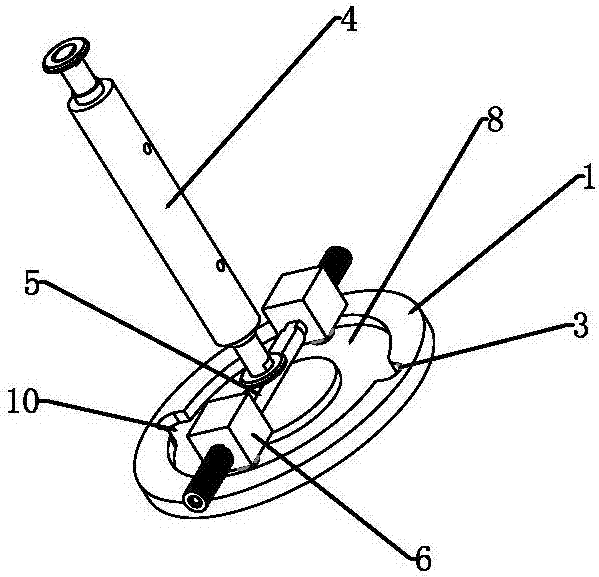

Centrifugal clutch

The invention relates to a centrifugal clutch which comprises a driven shaft end plate and a damper arranged on the driven shaft end plate. Clamping grooves are formed in the driven shaft end plate, and a driving shaft is arranged on the face, opposite to the clamping grooves, of the driven shaft end plate; one end of the driving shaft is connected with a sliding rod; the sliding rod is provided with a balance weight in the axial direction in a sliding mode and a spring used for making the balance weight reset; and the balance weight is provided with clamping columns capable of entering the clamping grooves. The centrifugal clutch has the advantages of good engagement and disengagement effects, simple structure and the like.

Owner:广东奥硕智能装备有限公司

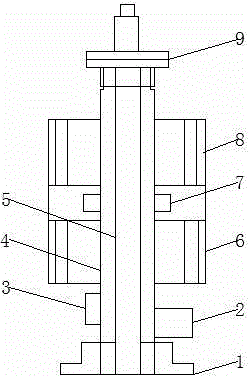

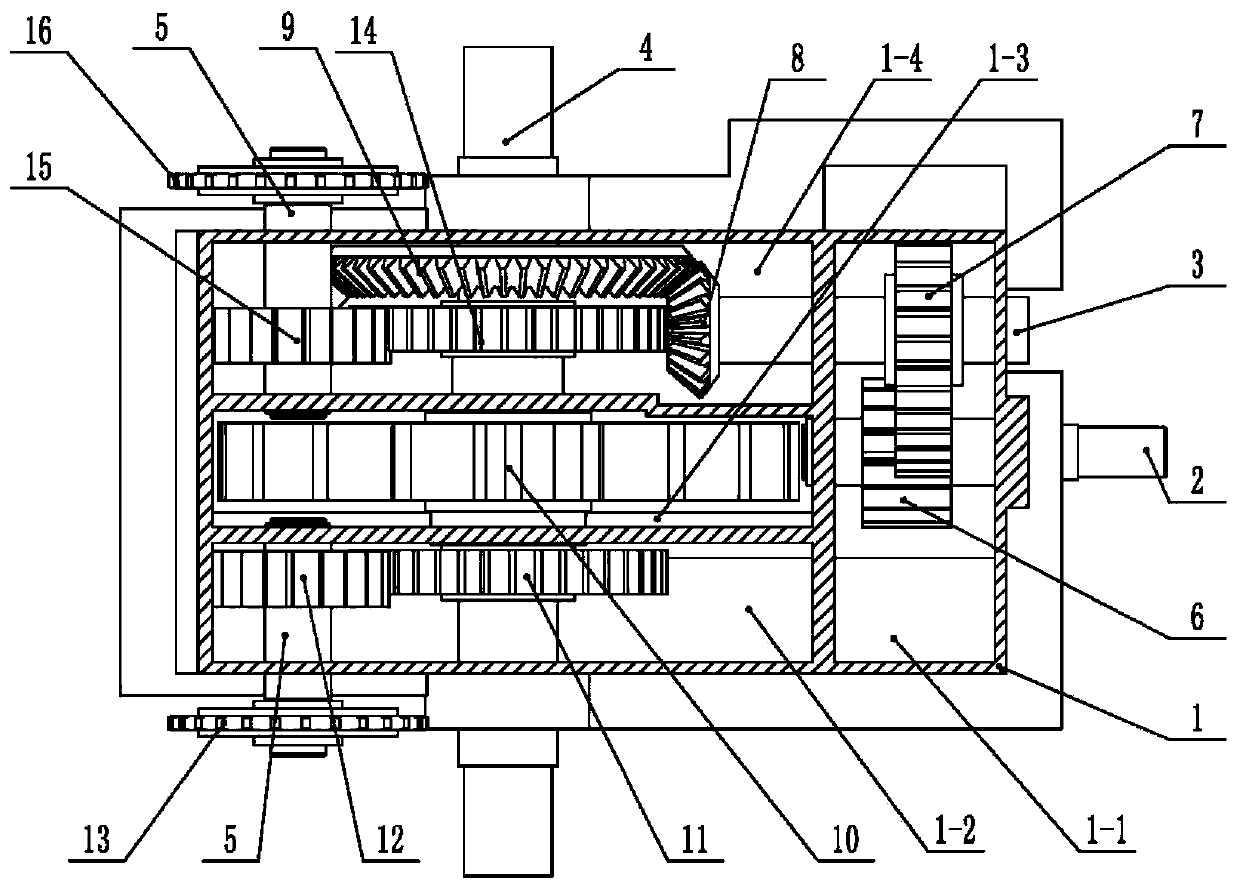

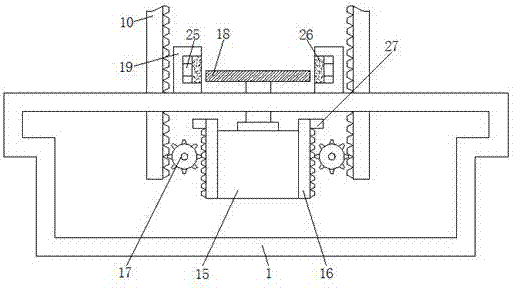

Brake device for lifting system of self-elevating ocean platform

InactiveCN109736280AAchieve meshingAchieve emergency brakingArtificial islandsUnderwater structuresEngineeringElectromagnetic brake

The invention discloses a brake device for a lifting system of a self-elevating ocean platform, and belongs to the field of ocean engineering. The brake device includes a shell, a main shaft, a driving assembly, outer friction plates and inner friction plates. One end of the shell is used for being fixedly installed on a gear box of a lifting system. The other end of the shell is used for being fixedly installed on a motor of the lifting system. The main shaft is rotatably mounted in the shell. The inner friction plates are sleeved on the outer peripheral wall of the main shaft in an axial sliding mode. the outer friction plates are inserted into the inner circumferential wall of the shell in an axial sliding mode, the outer friction plates and the inner friction plates are alternately arranged at intervals, one inner friction plate is arranged between every two adjacent outer friction plates, the driving assembly is arranged in the shell, and the driving assembly is used for driving the outer friction plates and the inner friction plates to be meshed together. When the electromagnetic brake of the self-elevating ocean platform lifting system fails, emergency braking of the self-elevating ocean platform lifting system is achieved, and the reliability of the lifting system of the self-elevating ocean platform is improved.

Owner:WUHAN MARINE MACHINERY PLANT

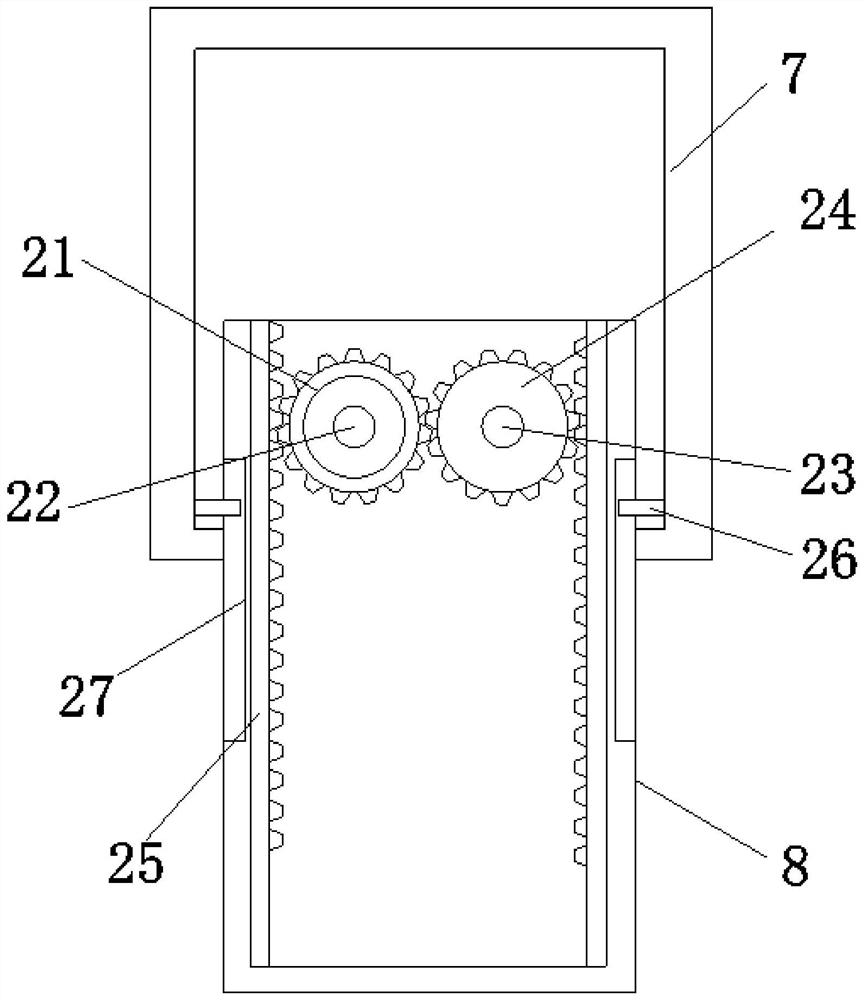

Suspended rack rail transport vehicle driving device

PendingCN109910922AMeet the use requirementsCompact structureElectric motor propulsion transmissionRack railwaysEngineeringVehicle driving

The invention discloses a suspended rack rail transport vehicle driving device. Motor power is input through an input shaft, and through multi-stage deceleration, a pair of rollers roll along an I-shaped rack rail and an output gear is meshed with a rack below the I-shaped rack rail to synchronously drive a suspension frame to move along the I-shaped rack rail. The suspended rack rail transport vehicle driving device is compact and simple in structure and novel in design, adopts an intermediate open gear output structure, simultaneously outputs the power through the gear and the rollers, and meets using requirements of a suspended rack rail transport vehicle under large-slope and branched multiple working conditions; in addition, through compartments in a shell, the output gear is isolatedfrom transmission gears, so that normal lubrication of the transmission gears is guaranteed.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

Physical mechanics demonstration device

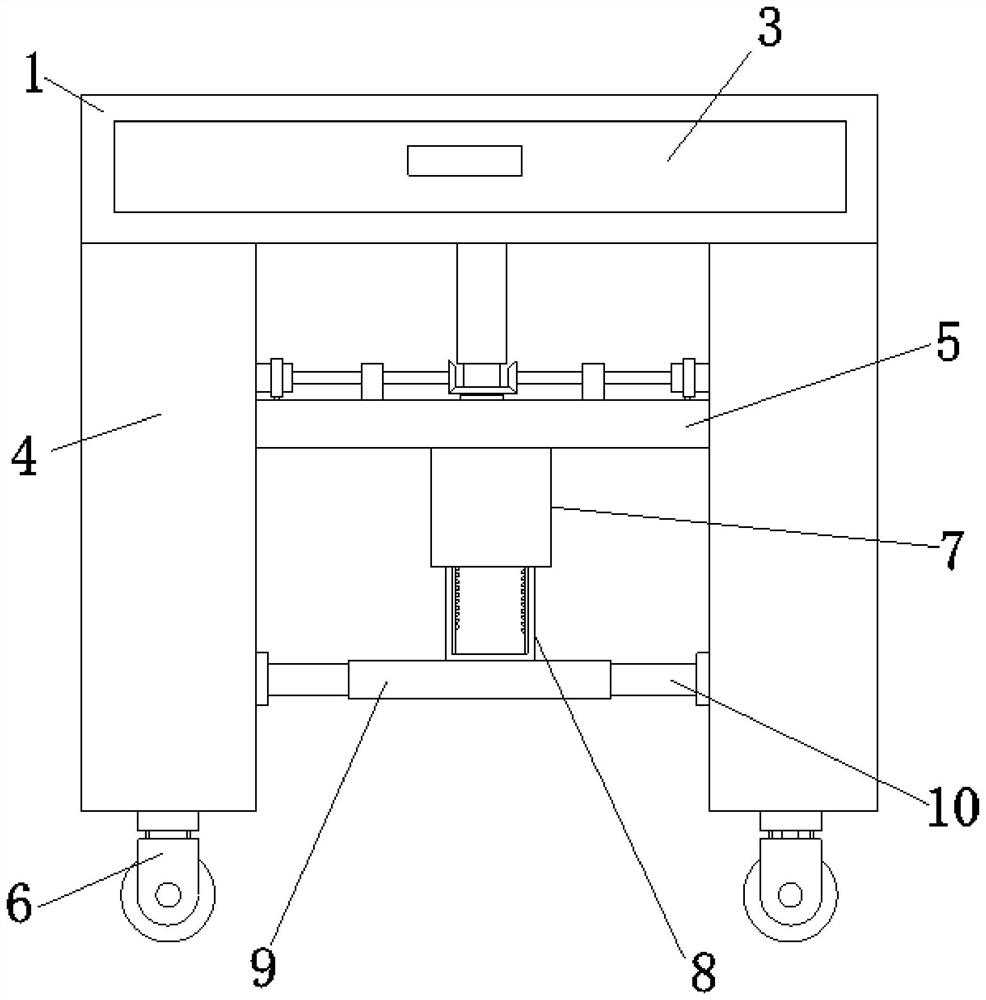

InactiveCN114519950AHeight adjustableImprove scalabilityEducational modelsEngineeringMechanical engineering

The invention relates to the technical field of education, and discloses a physical mechanics demonstration device which solves the problems that an existing physical mechanics demonstration device is inconvenient to move, so that the portability is poor, meanwhile, the height is fixed, the height cannot be adjusted according to operators with different heights, and the practicability is not high. A containing groove is formed in the demonstration operation table, a containing cabinet is inserted into the containing groove in a penetrating mode, supporting columns are symmetrically arranged on the two sides of the bottom end of the demonstration operation table, every two adjacent supporting columns are connected through a supporting plate, two universal wheels are symmetrically arranged at the bottom end of each supporting column, and a mounting box is arranged at the bottom end of each supporting plate. A lifting rod is arranged below the mounting box and is of a U-shaped structure; through the design of the height adjusting mechanism, the height of the demonstration operation table can be conveniently adjusted according to the height of an operator, the operator can conveniently carry out force demonstration work, and meanwhile the work fatigue degree of the operator is reduced.

Owner:黄灵万

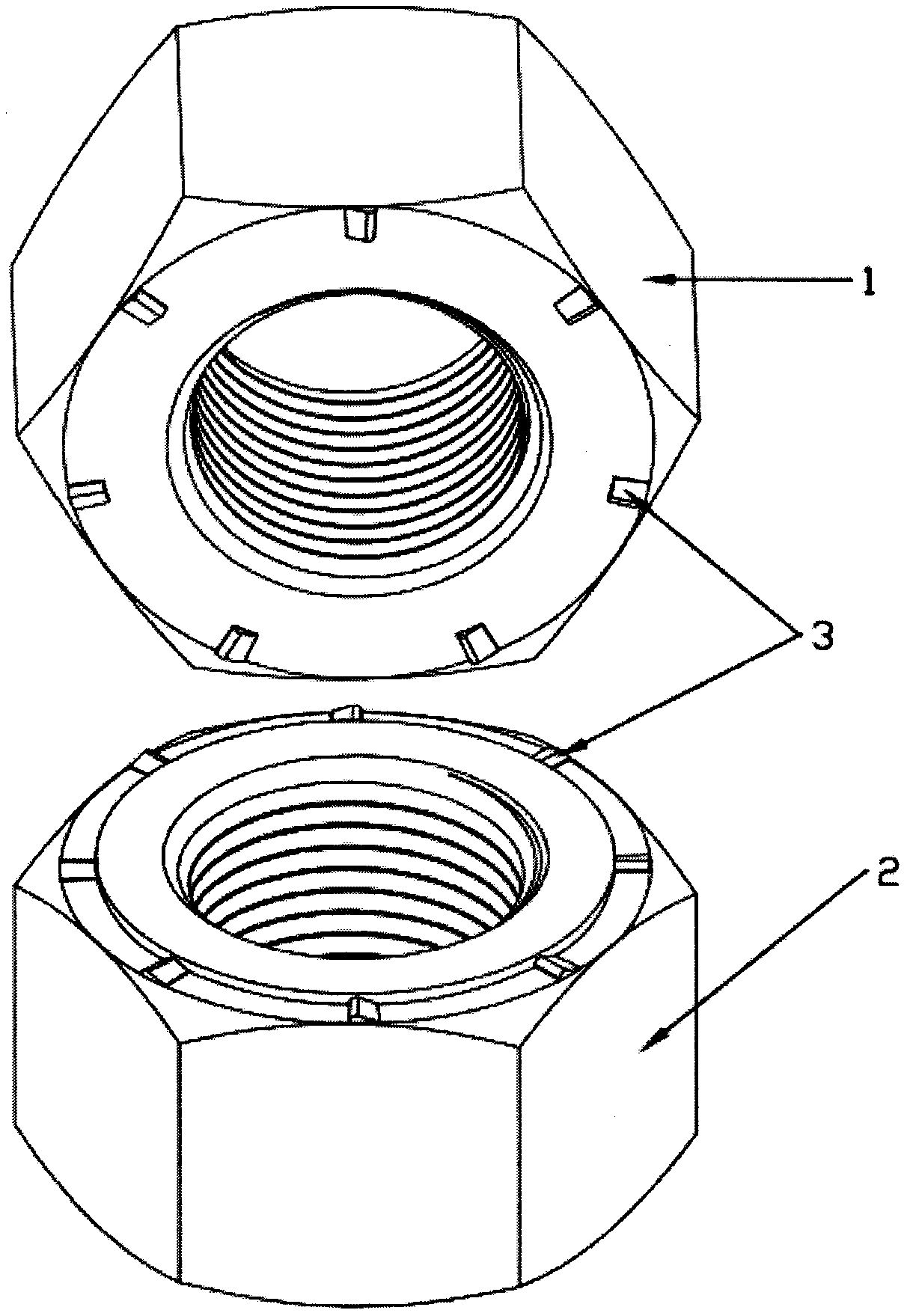

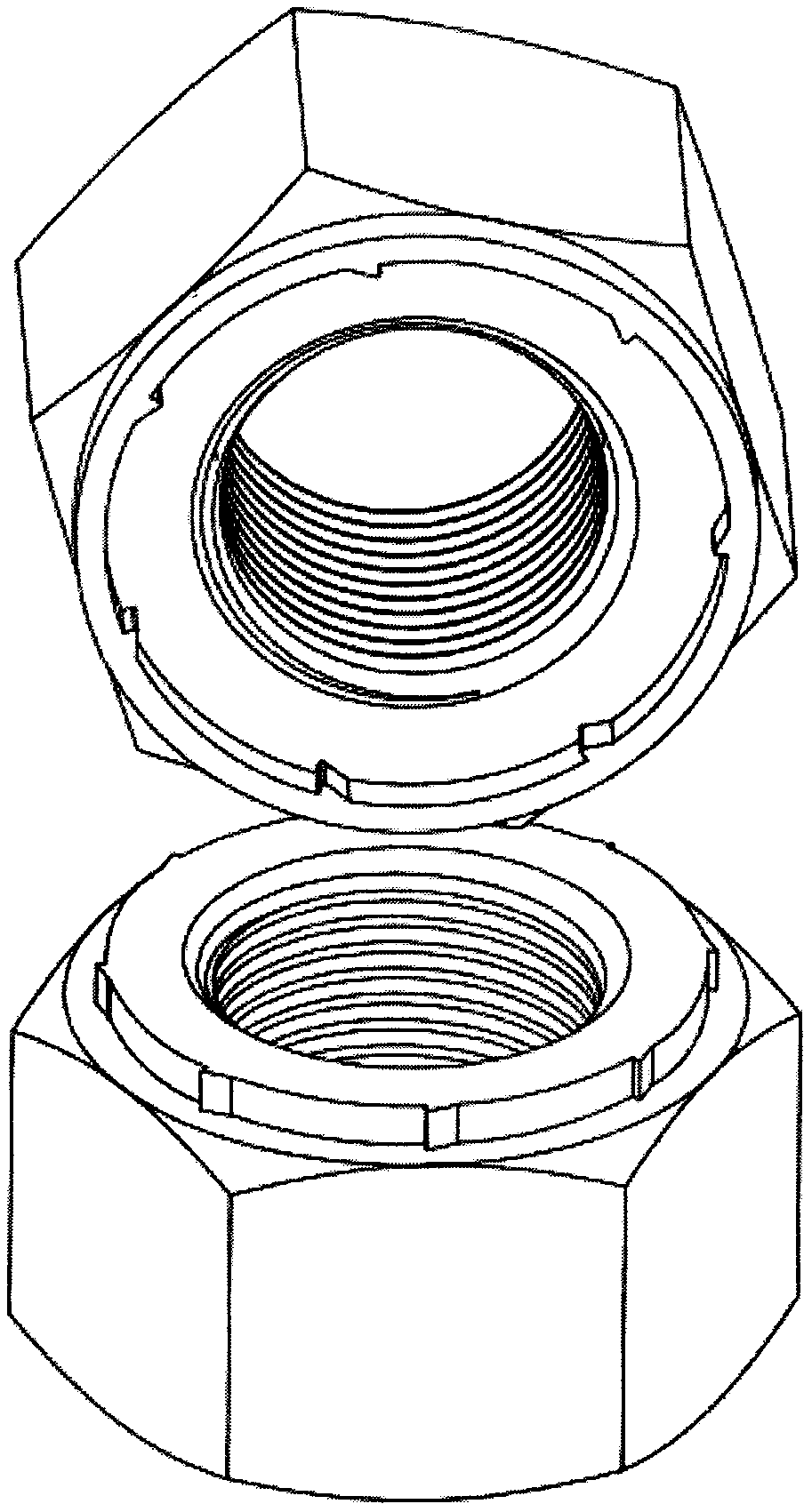

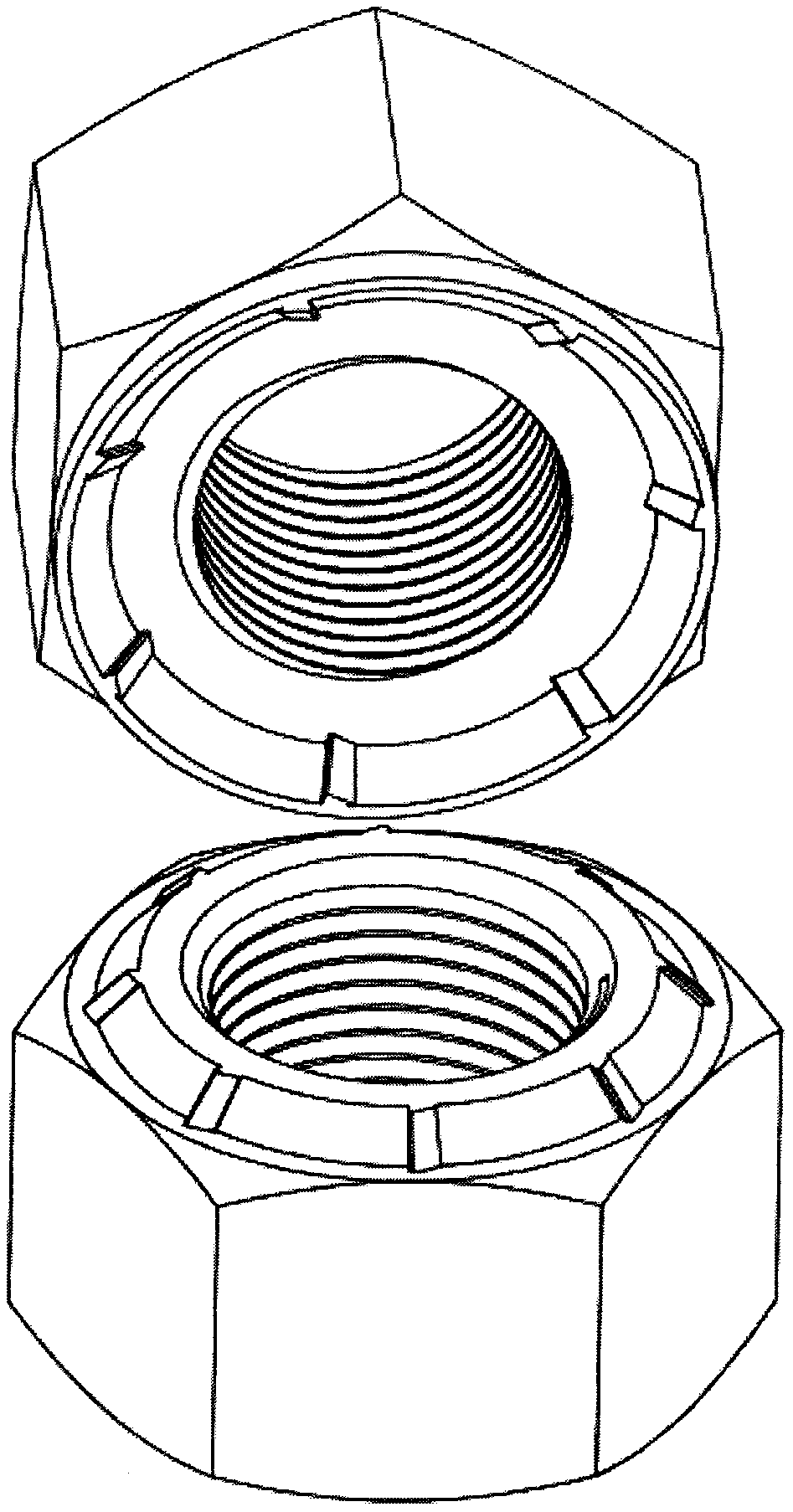

Differential ratchet type anti-loosening double nut

ActiveCN109681511AAvoid reverse rotationImprove anti-loosening performanceNutsBoltsTooth numberEngineering

The invention discloses a differential ratchet type anti-loosening double nut composed of an upper nut body and a lower nut body. The upper nut body and the lower nut body are provided with ratchets,and the ratchets of the upper nut body and the ratchets of the lower nut body are different in tooth number. A set of ratchets are engaged every time when the upper nut body and the lower nut body relatively rotate by a small angle, relative loosening between the double nut bodies is effectively prevented, and the defect that a traditional double nut achieves loosening preventing only through friction force is overcome.

Owner:杨天啸

Fruit and vegetable fresh-keeping slow-release equipment

InactiveCN111616212ARealize reciprocating sprayingReduce laborFruit and vegetables preservationAgricultural scienceAgricultural engineering

The invention discloses fruit and vegetable fresh-keeping slow-release equipment. The equipment comprises a square plate and is characterized in that the square plate is fixedly connected with a pesticide barrel, the pesticide barrel is fixedly connected with a water pump, the square plate is fixedly connected with a first vertical plate, the square plate is fixedly connected with second symmetrical vertical plates, the first vertical plate is fixedly connected with a sensor, the second symmetrical vertical plates are fixedly connected with corresponding sensors respectively, the square plateis fixedly connected with a shell, the square plate is fixedly connected with a slow release mechanism, and the square plate is fixedly connected with a turning mechanism. The invention relates to thefield of fresh-keeping equipment, in particular to the fruit and vegetable fresh-keeping slow-release equipment. Fruits and vegetables can be kept fresh conveniently.

Owner:QILU UNIV OF TECH +2

Device for machining semi-arc long groove

InactiveCN104475853AEasy to replaceAchieve positioningPlaning/slotting machinesEngineeringMilling cutter

The invention discloses a device for machining a semi-arc long groove. The device comprises a supporting plate, a first rotary rod, a second rotary rod, a slide block and a planer tool, wherein the first rotary rod is connected with the supporting plate through screw threads; a first threaded through hole is formed in the supporting plate in the longitudinal direction; a through hole is formed in the supporting plate in the transverse direction; a first slide groove is formed in the lower part of the supporting plate; a slide block is positioned in the slide groove; a threaded post is arranged in the first slide groove; a second slide groove and a second threaded through hole are formed in the slide block in the longitudinal direction; the width value of the second slide groove is greater than the outer diameter value of a threaded rod; the planer tool is detachably connected with the first rotary rod; the first rotary rod is a threaded rod; a first bevel gear is arranged on the bottom part of the first rotary rod; a second bevel gear is arranged on the end part of the second rotary rod; the first rotary rod is meshed with the second rotary rod by the gears; a locking nut is arranged on the threaded post. The defects of complex mounting and high manufacturing cost caused when the semi-arc long groove of a current workpiece is required to be processed by mounting a milling cutter with a special shape on a milling machine are overcome.

Owner:CHONGQING ZHONGFANG RUBBER & PLASTIC

Rotary separation drive rotary flow wormwood cleaning device

ActiveCN108816920AEasy loading and unloadingSimple structureDrying solid materials without heatCleaning using liquidsCouplingEngineering

The invention belongs to the technical field of cleaning instruments, and discloses a rotary separation drive rotary flow wormwood cleaning device. The cleaning device comprises a cleaning tank, the lower surface of the cleaning tank is fixedly connected with legs, the lower surface of the cleaning tank is fixedly mounted with a gear motor through a mounting rod, and the position at the bottom wall of the cleaning tank corresponding to an output shaft of the gear motor is provided with a mounting hole. A first bearing is fixedly connected in the mounting hole in the sleeve mode, a rotating shaft is fixedly connected in the first bearing in the sleeve mode, the bottom end of the rotating shaft extends out of the first bearing to be fixedly connected with the output shaft of the gear motor through a coupling, the top of the side of the rotating shaft is provided with a rotary cleaning mechanism, and the middle of the rotating shaft is provided with a separate drive mechanism. By means ofthe rotary cleaning mechanism, cycling feeding, discharging and cleaning of the device can be achieved, an operator can conducts feeding and discharging conveniently by means of driving of the gear motor, and the cleaning device is simple in structure.

Owner:无锡艾之缘生物科技有限公司

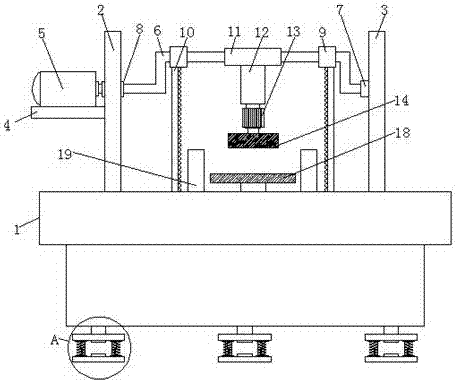

Wood plate grinding device

InactiveCN107756163ARealize large frequency vibrationNot easy to cause blockageGrinding machine componentsPlane surface grinding machinesPulp and paper industryDevice failure

The invention discloses a wood plate grinding device which structurally comprises a box frame, a pedal, a support plate, a motor, a grinding visual frame and a polishing device, wherein the pedal is arranged in the lower left corner of the box frame, the bottom of the support plate is connected on the surface of the upper corner of the box frame in a gluing mode, the end, away from the pedal, of the support plate, is embedded into the grinding visible box, the support is adjacent to the motor, and the motor is fixedly connected on the upper end face of the box frame. The swinging of a wigglerdrives small-frequency vibration of a vibrator, so that a small amount of ground wood chips are sieved. If ground wood chips are multiple, the pedal drives a pulling device, so that big-frequency vibration of the vibrator is achieved, the sieving speed is accelerated, and the shaking frequency of equipment can be adjusted according to the amount of fallen wood chips. The wood plate grinding deviceis convenient to use, and low in equipment failure rate, and doesn't easily cause blocking of chips. Meanwhile, the wood chips are further processed and stirred, and the wood chips are reused.

Owner:台州市黄岩赵兴工艺品有限公司

Double-station efficient edge grinding machine for couplers

InactiveCN107042435AReduce vibrationAvoid noiseEdge grinding machinesGrinding carriagesEngineeringTime-Consuming

The invention discloses a dual-station high-efficiency edging machine for a shaft coupling, which comprises a base, and a symmetrical first baffle and a second baffle are fixedly connected to the top of the base, and one side of the first baffle is arranged There is a support plate, and one end of the support plate close to the first baffle is fixedly connected to the outer surface of the support plate, the top of the support plate is fixedly connected to the first motor, the output end of the first motor is fixedly connected to a folding rod, and one end of the folding rod Through the first baffle plate and extending to the outside of the first baffle plate, a first bearing is provided at the place where the folding rod passes through the first baffle plate, the inner wall of the first bearing is fixedly connected with the outer surface of the folding rod, and the outer surface of the first bearing is connected to the outer surface of the first baffle plate. The outer surface of the first baffle is fixedly connected, and the outer surface of the second baffle is fixedly connected with a second bearing. The present invention makes it possible to realize the upper and lower double-station machining as a whole, shortens the overall consumption time and improves the work efficiency when machining large batches of shaft couplings.

Owner:方瑞松

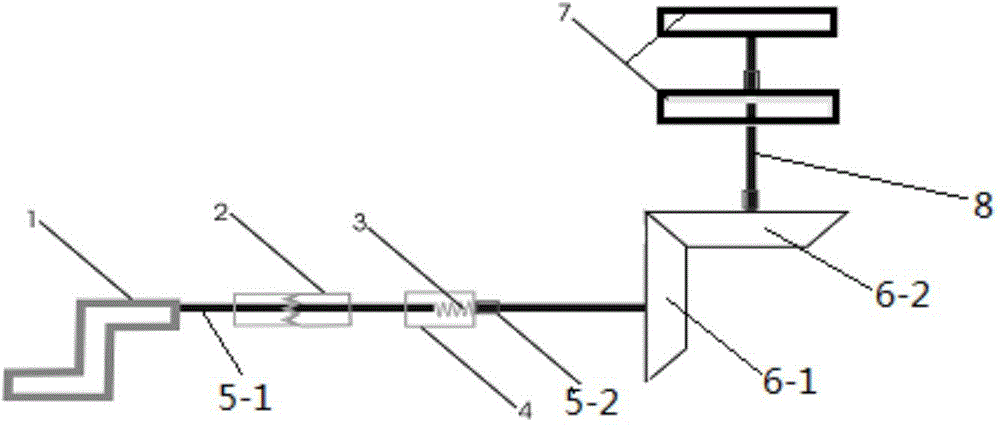

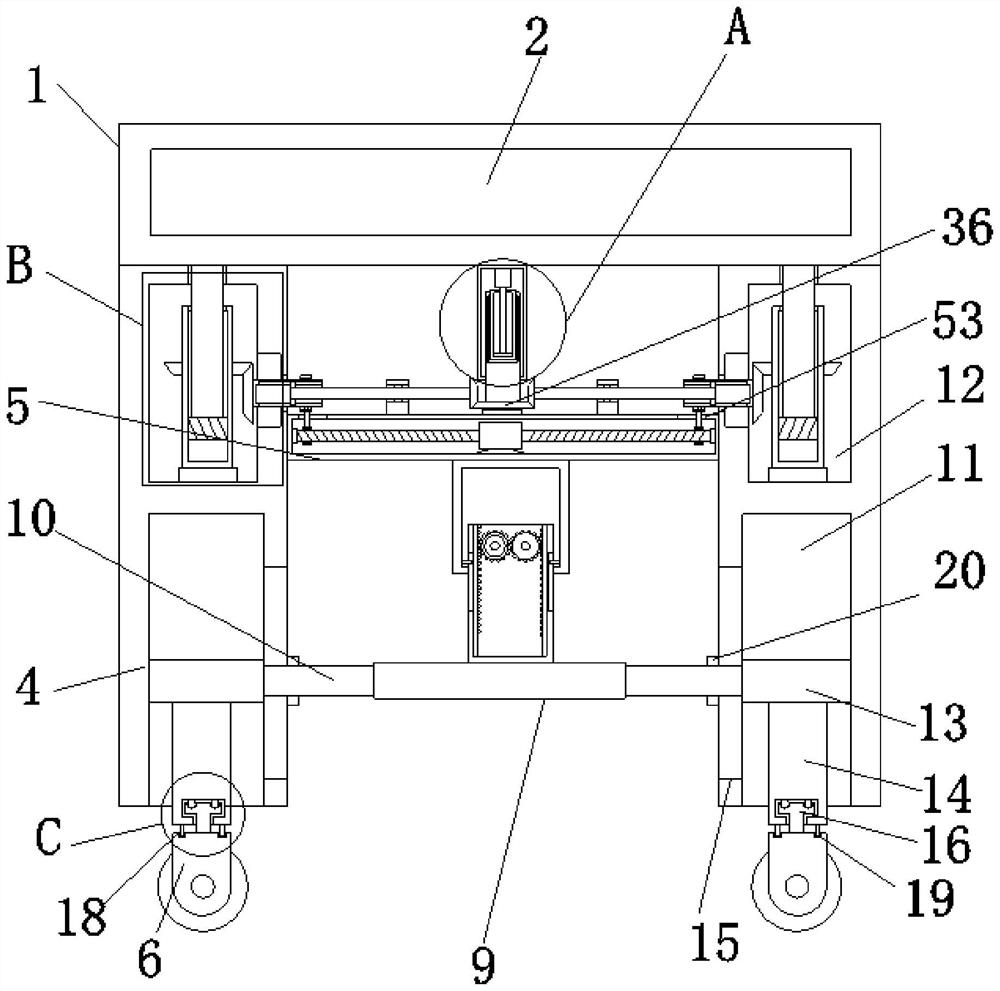

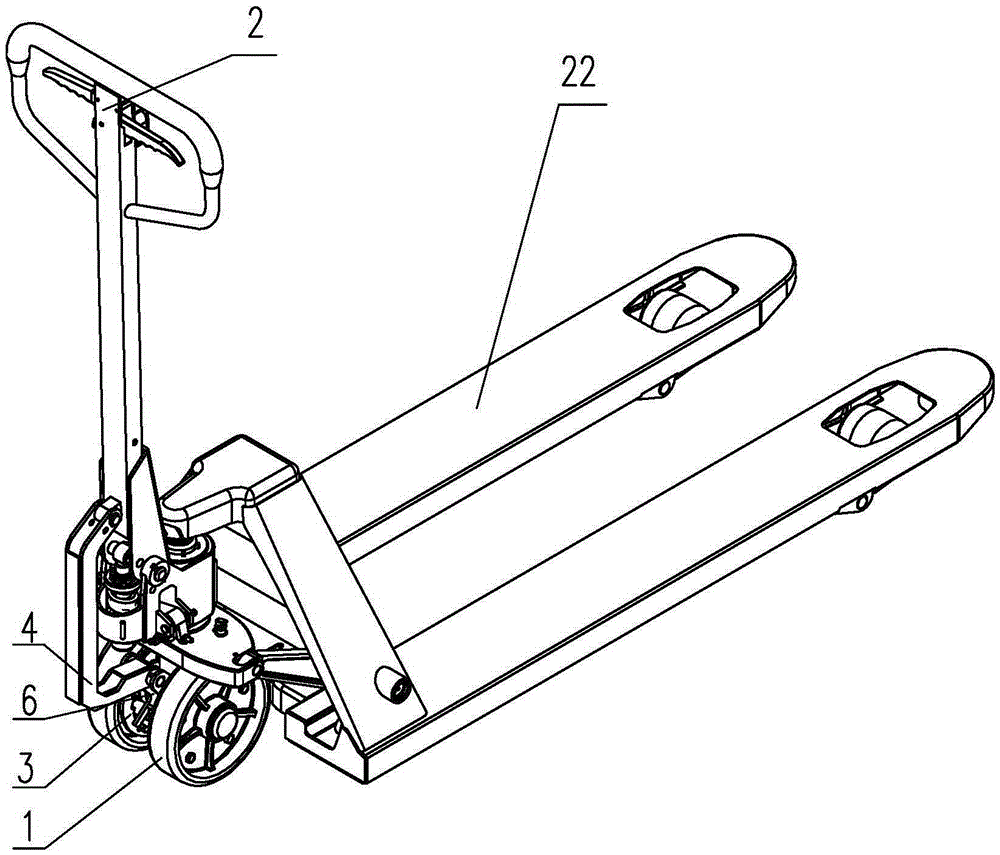

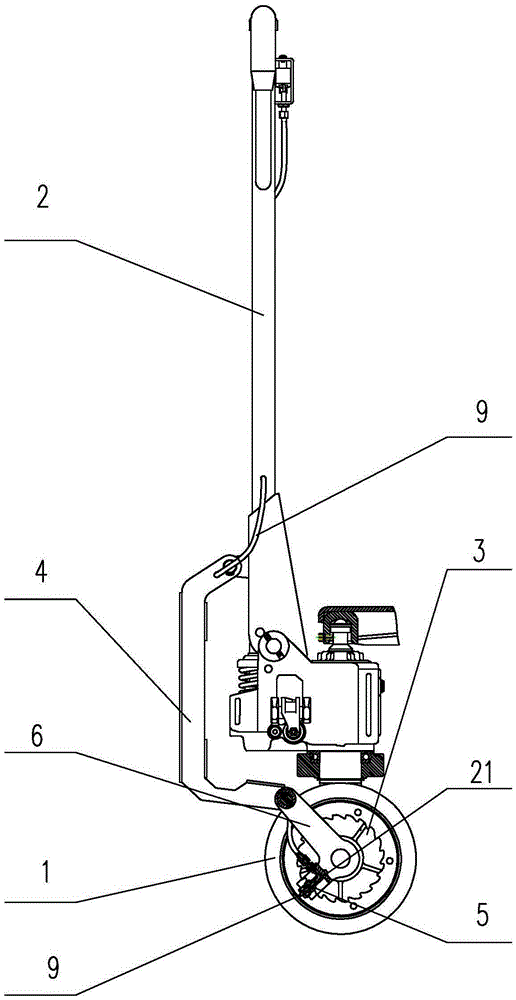

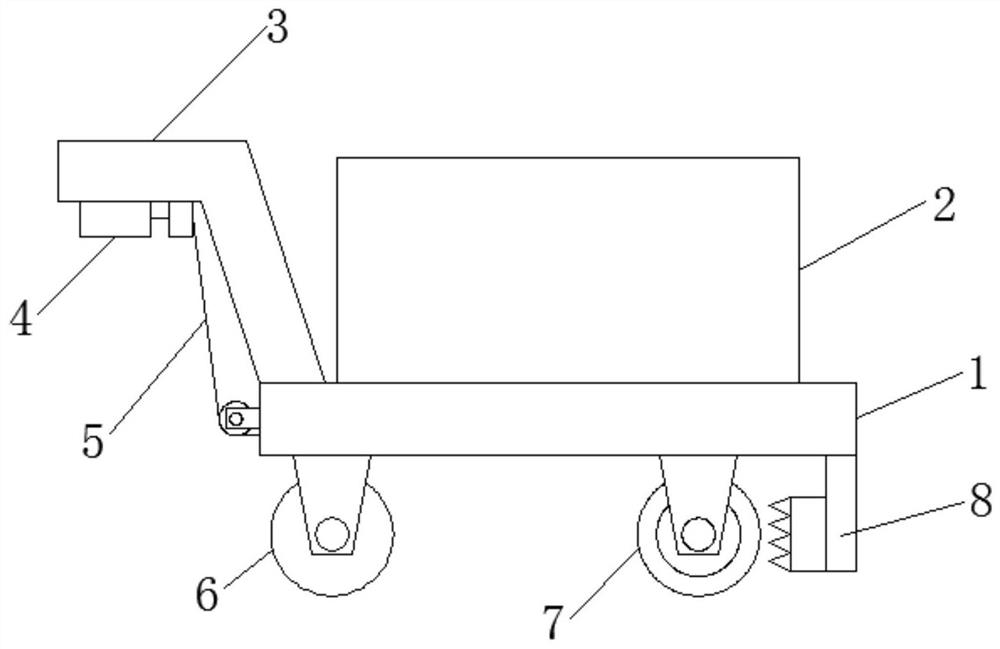

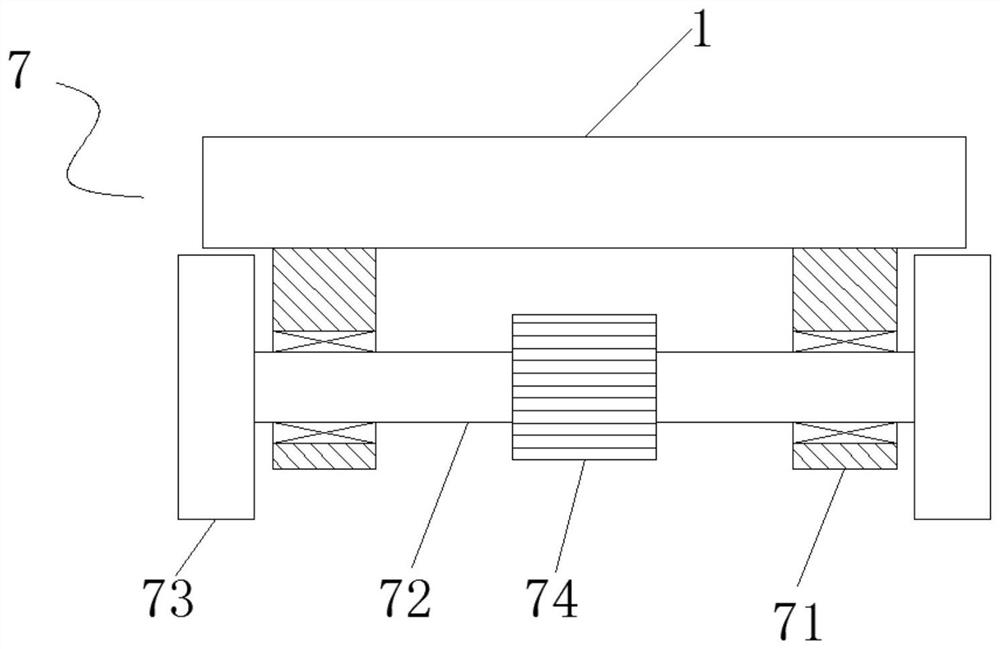

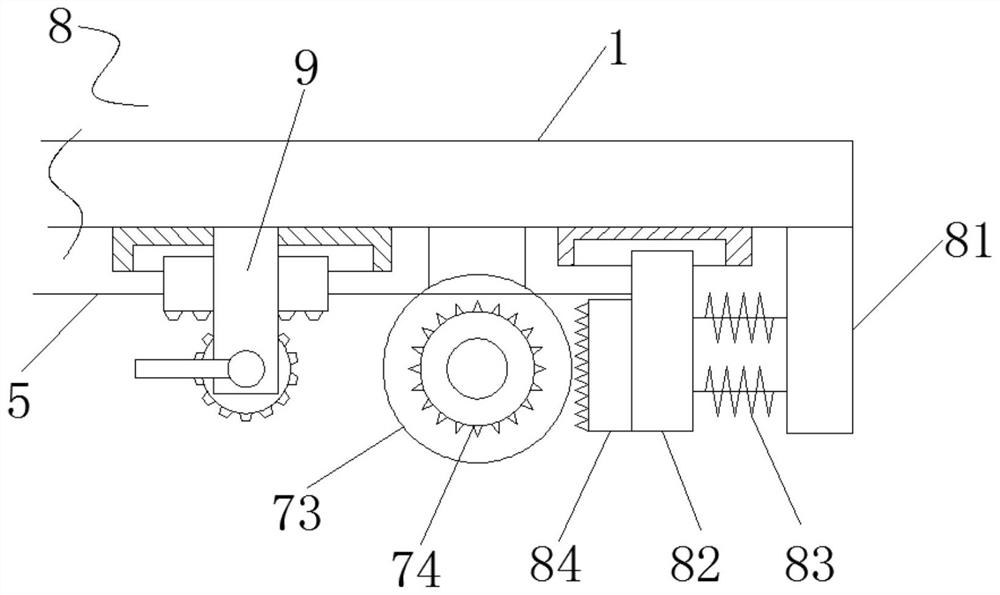

Manual pallet jack with power assisting device

ActiveCN105329285ASimple structureEasy to operateHand carts with multiple axesHand cart accessoriesDrive wheelRotation - action

The invention discloses a manual pallet jack with a power assisting device. The manual pallet jack comprises two driving wheels (1), a handle (2), a pressing rod (4) hinged to the handle (2) and a driving mechanism capable of converting rotation actions of the handle (2) into rotation actions of the driving wheels (1) and is characterized in that the driving mechanism comprises inner ratchet wheels (3) fixed on the driving wheels (1) and capable of driving the driving wheels (1) to rotate, shifting rods (5) used for shifting the inner ratchet wheels (3), shifting forks (6) used for converting up-and-down actions of the pressing rod (4) into rotation actions and transmitting power to the shifting rods (5) and a control device used for controlling the shifting rods (5) and the inner ratchet wheels (3) to separate and match; a controller of the control device is arranged on the handle (2). The manual pallet jack with the power assisting device is simple to operate and high in reliability.

Owner:NINGBO RUYI

Sheet splicing device

InactiveCN108015864AEasy transferBroaden applicationWood veneer joiningGlue vesselsWood veneerWood processing

The invention relates to the field of wood processing, and particularly discloses a sheet splicing device. According to the technical scheme, a glue coating mechanism and a power mechanism are arranged in the device, the power mechanism can drive a glue coating rope in the glue coating mechanism to move in a reciprocating mode, glue in a glue coating pipe is transferred to splicing surfaces of board-shaped wood during the reciprocating movement process of the glue coating rope, so that uniform coating of the board-shaped wood splicing surfaces is realized, then the splicing surfaces of the twopieces of the board-shaped wood are abutted, so that splicing of the plate-shaped wood is achieved, and due to the fact that the glue on the splicing surfaces of the board-shaped wood is uniformly coated, the splicing strength of the board-shaped wood can be effectively improved.

Owner:重庆丰胜天家具有限公司

Self-regulation load bearing device realizing treatment assisting function

The invention discloses a self-regulation load bearing device realizing the treatment assisting function. The self-regulation load bearing device comprises a base and a connecting shaft, wherein a limiting rotation wheel is connected to the front surface of a second mounting plate through a rotation shaft, a tension cog belt matched with a first gear and the limiting rotation wheel is arranged atone end of a hook, an electric push rod is arranged in the middle of the upper surface of the base, vertical rods are symmetrically arranged on the upper surface of the base, a movable block is arranged on the outer side of each vertical rod, a control switch is arranged on the front surface of the movable block on the left side, a drive motor is arranged on the opposite faces of the two movable blocks, an output shaft of the drive motor is provided with a concave wheel and a second gear, the concave wheel is connected with the tension cog belt, and the concave wheel is positioned at the rearside of the second gear. For the self-regulation load bearing device realizing the treatment assisting function, the tension cog belt is adopted for replacing a weight for realizing pressuring, the load bearing effect of the weight can be achieved, the tension is stable, no swing occurs, meanwhile, the drive motor is utilized for realizing adjustment, and the operation is convenient.

Owner:WUXI NO 9 PEOPLES HOSPITAL

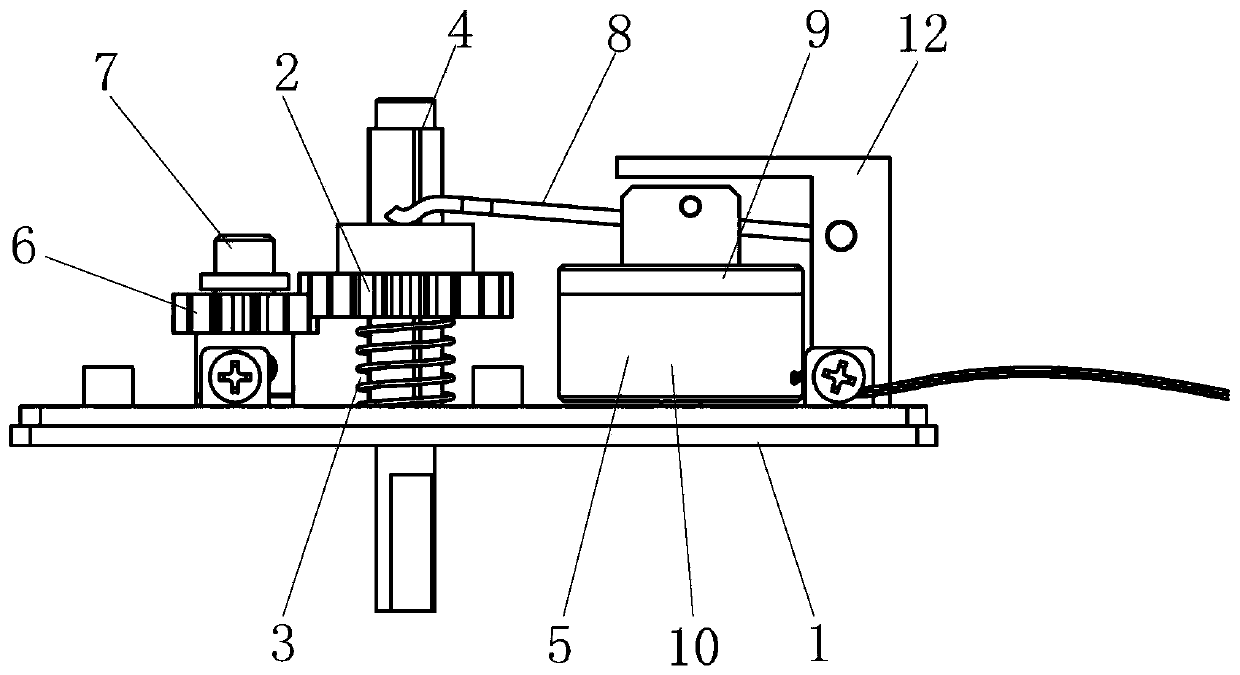

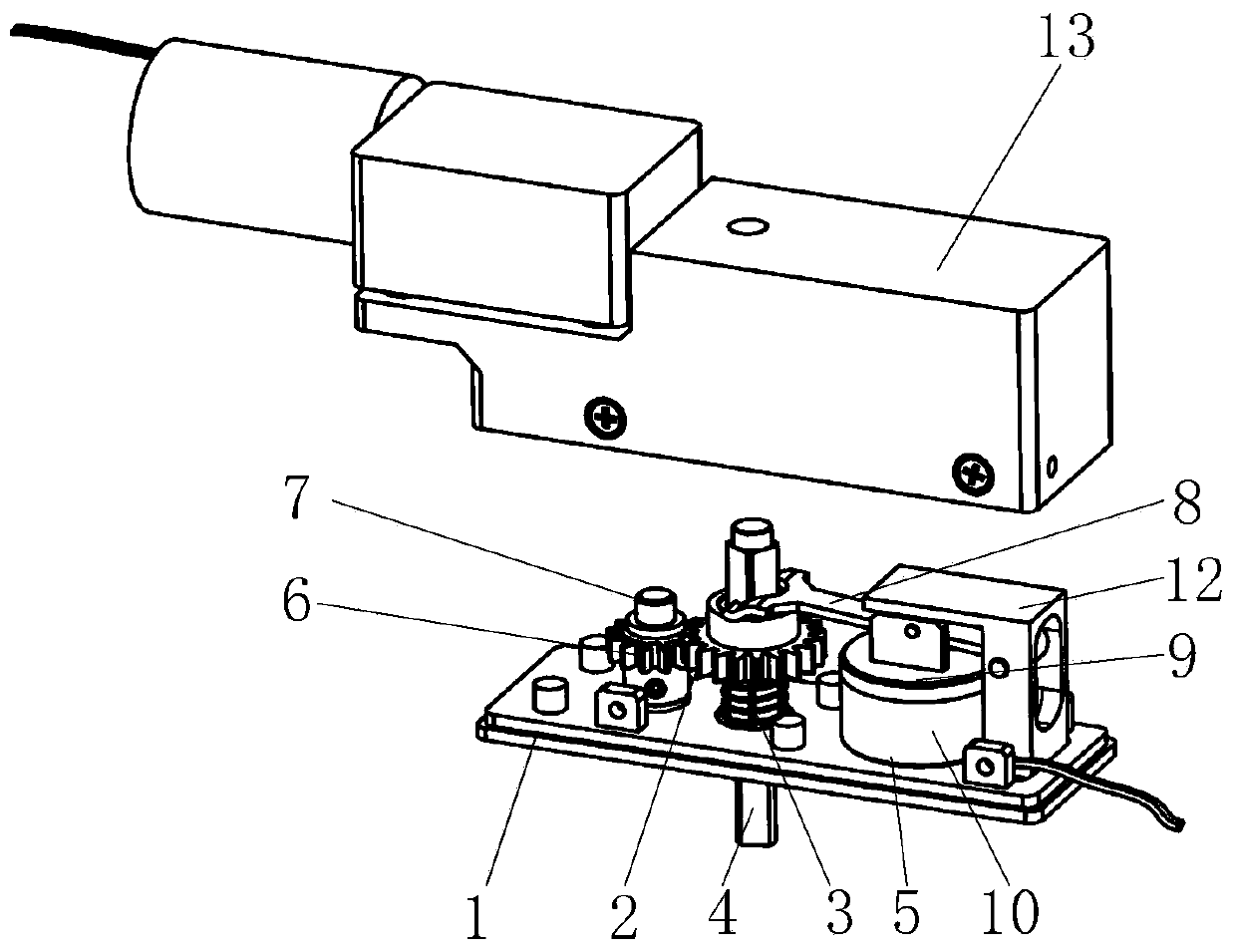

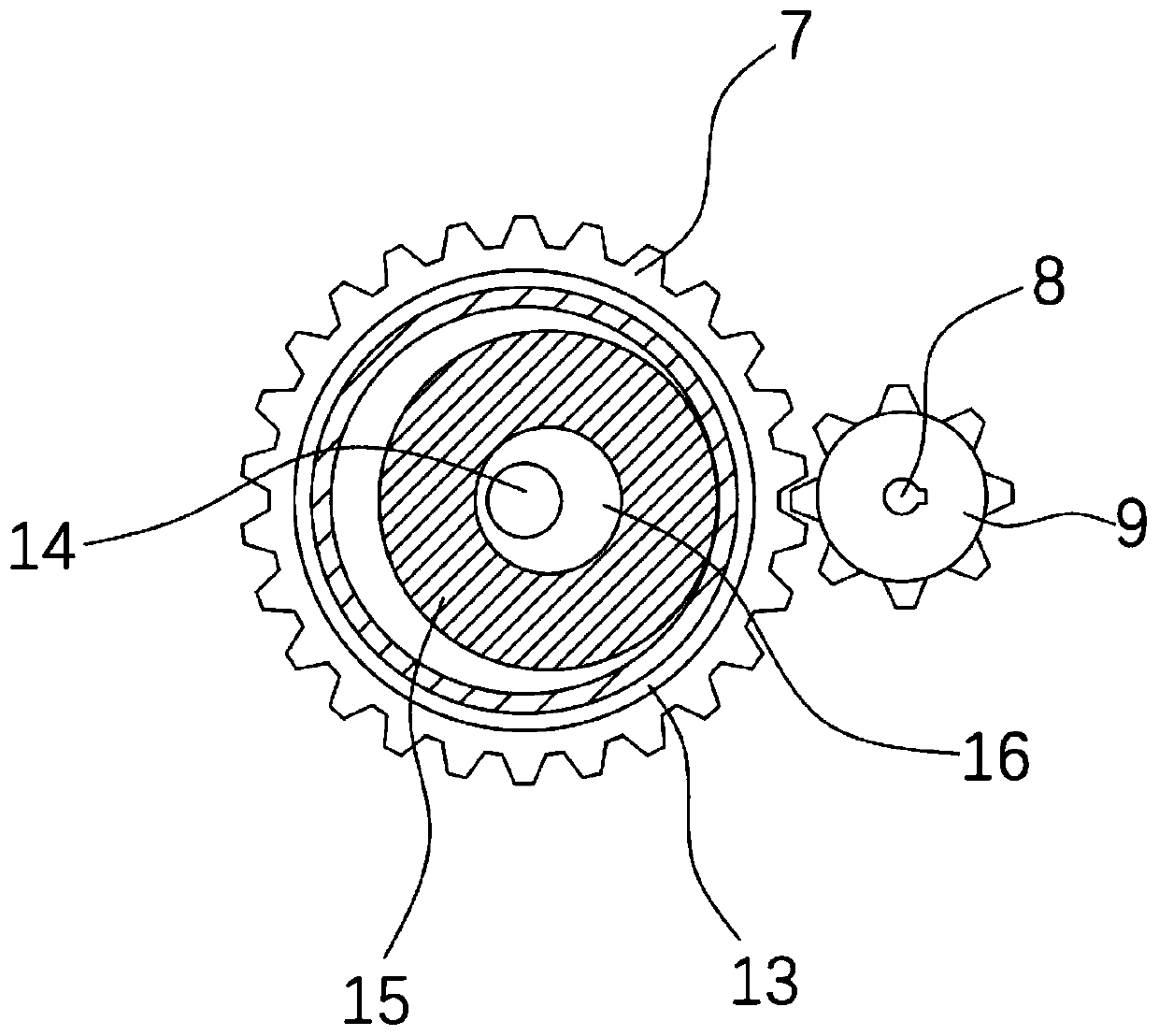

Egg collector clutch device

PendingCN112268074AEasy to achieve meshingEasy to achieve separabilityInterengaging clutchesBird housingsDrive wheelControl engineering

The invention discloses an egg collector clutch device. The egg collector clutch device comprises a clutch nylon wheel, a clutch double-chain wheel and a clutch driving mechanism. The clutch nylon wheel is installed on a shaft of an egg belt driving mechanism and moves axially along the shaft, and the clutch driving mechanism is arranged on a central egg line corresponding to a clutch driven wheel. When the central egg line moves to a corresponding layer of egg belt, a pressing wheel at the end of the clutch driving mechanism pushes the clutch driven wheel to enable the clutch driven wheel tobe meshed with a clutch driving wheel. When the central egg line moves away from the corresponding egg belt driving mechanism, the pressing wheel at the end of the clutch driving mechanism is separated from the clutch nylon wheel, the clutch nylon wheel is separated from the clutch double-chain wheel, and the egg belt driving mechanism stops running. The egg collector clutch device is simple in structure, the accuracy requirements for processing and installation and the like are not high, and the egg collector clutch device is capable of achieving meshing and separation of the clutch device easily and low in cost.

Owner:青岛大牧人机械股份有限公司

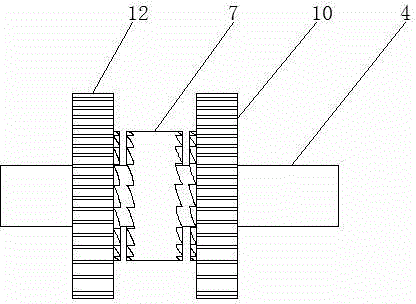

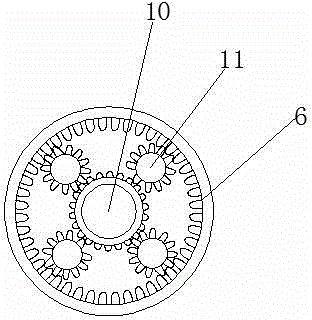

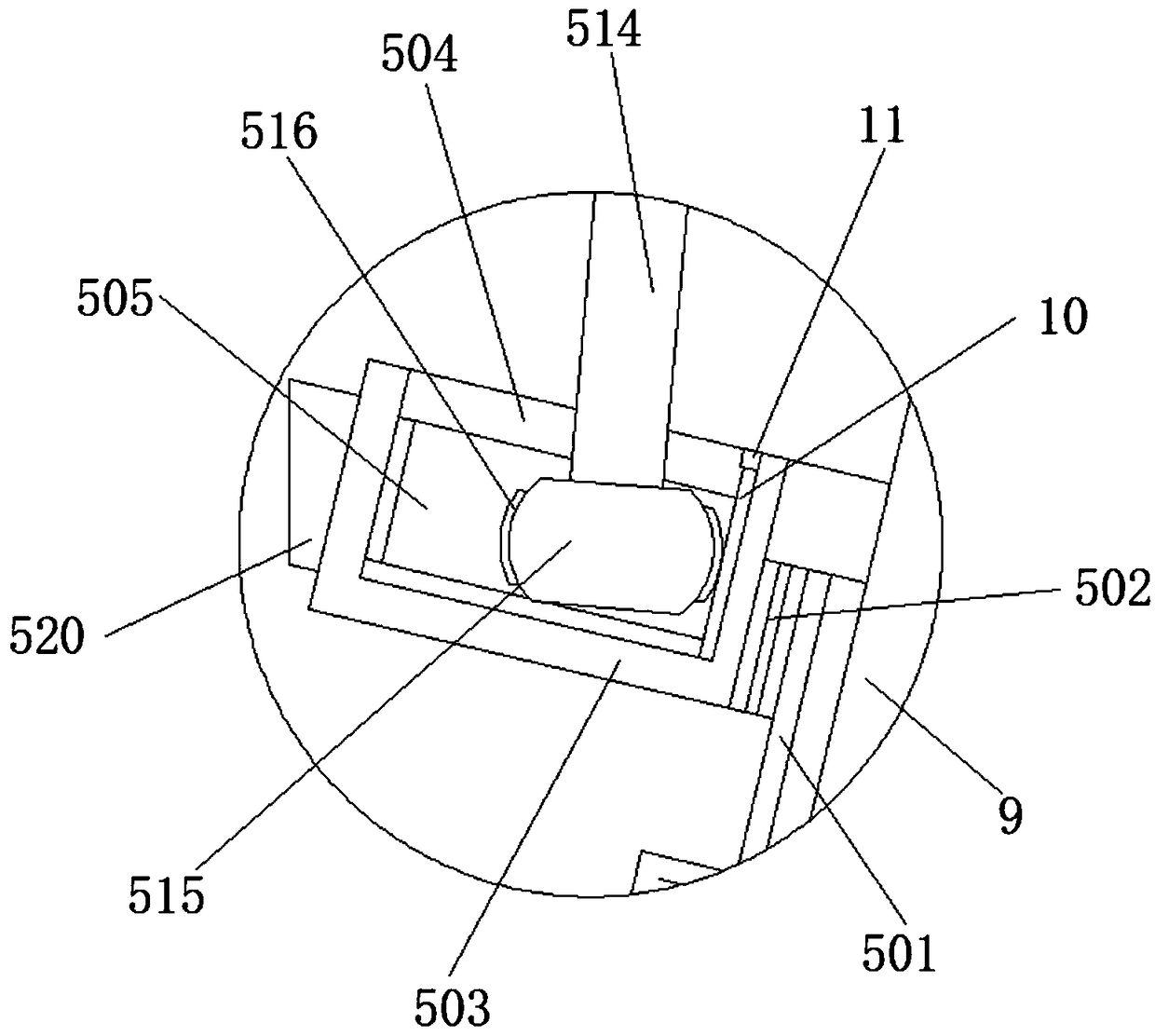

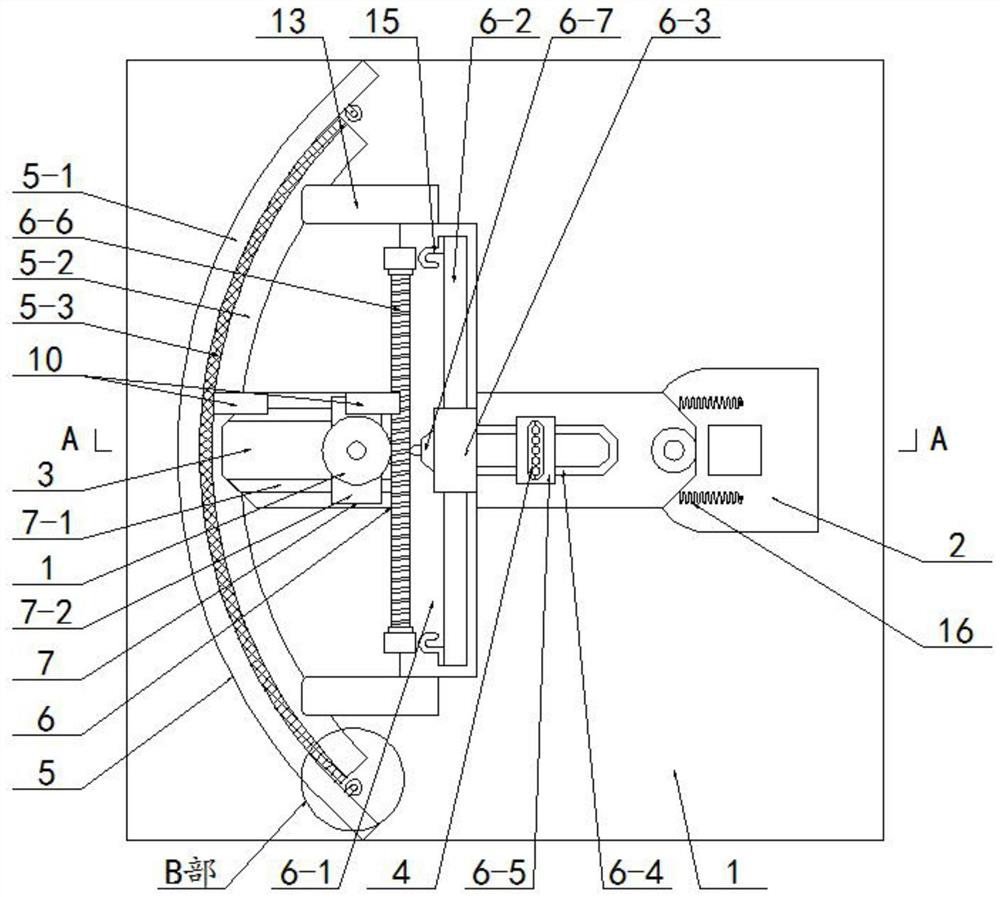

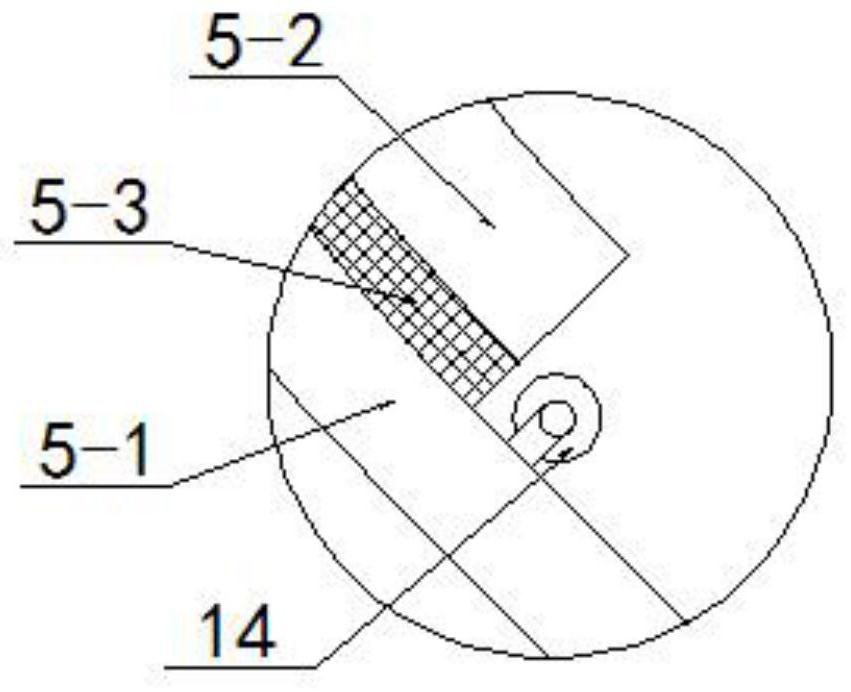

A Thin-Wall Pipe Circular Cutting Mechanism Applicable to Different Wall Thickness

ActiveCN109226873BAchieve meshingOvercomes the disadvantage of requiring large rotary equipmentTube shearing machinesShearing machine accessoriesFixed frameGear wheel

The invention discloses a thin-walled pipe ring cutting mechanism suitable for different wall thicknesses. The ring cutting mechanism comprises a round fixed frame. An outer tooth ring is fixedly connected with the outer surface of the round fixed frame. An annular slide rail is fixedly connected with the outer surface of the round fixed frame. A slider is slidingly connected to the annular sliderail. A telescopic mechanism is installed on the slider. The output end of the telescopic mechanism is fixedly connected with a fixed frame. A motor is fixedly connected with the fixed frame. By arranging a multi-stage speed reduction mechanism, the meshing of the outer tooth ring and a planet gear is realized, the circumferential movement of a cutting plate can be driven during cutting, the ringcutting mechanism is suitable for large-aperture thin-walled pipes, and the defect that large-aperture thin-walled pipes need large rotating devices in a traditional technology is effectively overcome. Through the internal and external matching of a cushion block stop piece and a cushion block, the two-point type fixing of the two sides of the cutting plate is realized, it is avoided that the thin-walled pipes are indented under the effect of extrusion force during cutting and cutting is not completed.

Owner:徐州市瑞泰钢管有限公司

Pulling device of foam fire extinguishing device

ActiveCN113442983AFast fixationQuick breakClimate change adaptationFire rescueEngineeringStructural engineering

The invention discloses a pulling device of a foam fire extinguishing device in the technical field of fire extinguishing equipment, the pulling device comprises a cart and a foam fire extinguishing device body, a push rod is welded to one end of the top of the cart, a wire winding mechanism with a self-locking function is installed on the push rod, a rope is wound on the wire winding mechanism, a universal wheel and a directional wheel mechanism are installed at the two ends of the bottom of the trolley respectively, and the end, away from the winding mechanism, of the rope is connected with a snapping mechanism for fixing the directional wheel mechanism. A rope is released or stored through the winding mechanism, so that an outer spline body on the clamping mechanism is engaged with or disengaged from an outer spline wheel in the directional wheel mechanism, meanwhile, a fixing block is driven to rotate to abut against and disengage from the ground, and therefore the directional wheel is rapidly fixed and disengaged.

Owner:江苏南源消防工程有限公司

A clamping transmission device for finishing a positioning pin

ActiveCN113732949BImplementation orientationAchieve meshingGrinding drivesGrinding machinesEngineeringMechanical engineering

A clamping transmission device for finishing a positioning pin, the invention relates to the technical field of positioning pin tooling, which comprises a base, a bracket, a mounting bracket and a clamping claw, wherein a bracket is fixedly arranged on the front side wall of the base, and the right end of the mounting bracket is The bearing is screwed on the bracket, and the clamping claw is set on the mounting frame; it also includes an arc guide assembly, a linear guide assembly, and a drive assembly, wherein the arc guide assembly is fixedly arranged on the front side wall of the base, and the arc guide assembly is The guide assembly is arranged on the left side of the installation frame, the linear guide assembly and the drive assembly are fixed on the installation frame, and the drive assembly is arranged between the arc guide assembly and the linear guide assembly; it is provided with two sets of guide structures with different running trajectories It is driven by a set of adjustable driving parts, so that it is convenient to drive the clamping parts of the equipment with different motion trajectories, so as to realize the finishing production of the workpiece.

Owner:河南经济贸易技师学院

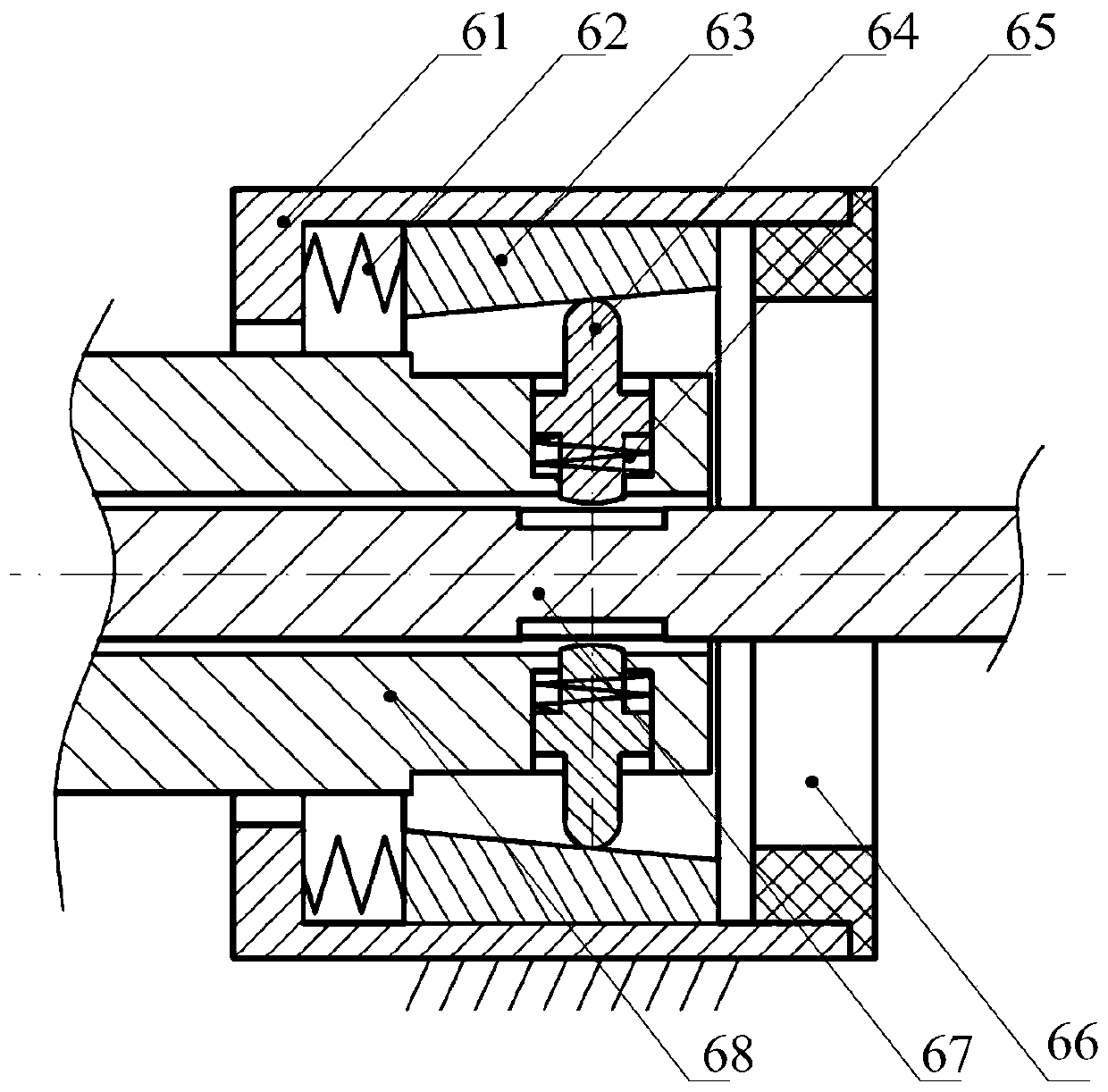

A clutch device for dual motors

ActiveCN107733152BAchieve high power outputDoes not occupy axial dimensionMechanical energy handlingControl powerPower switching

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

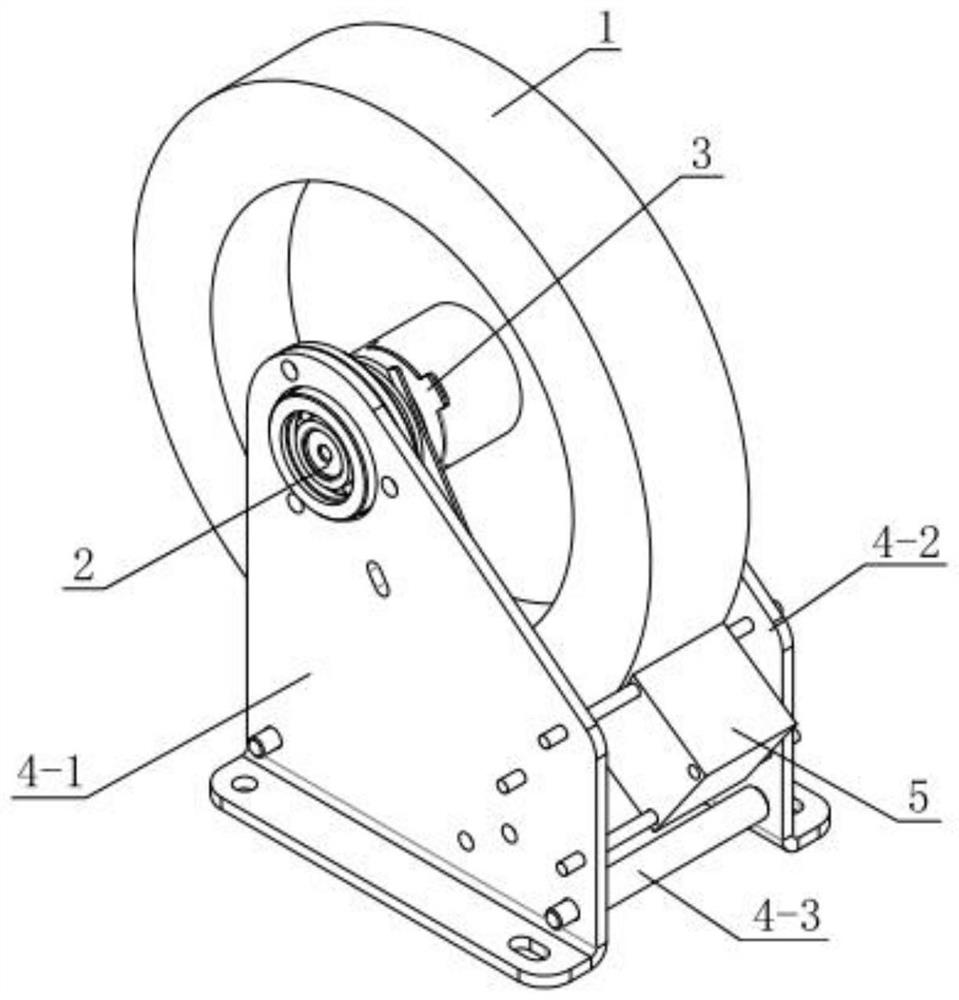

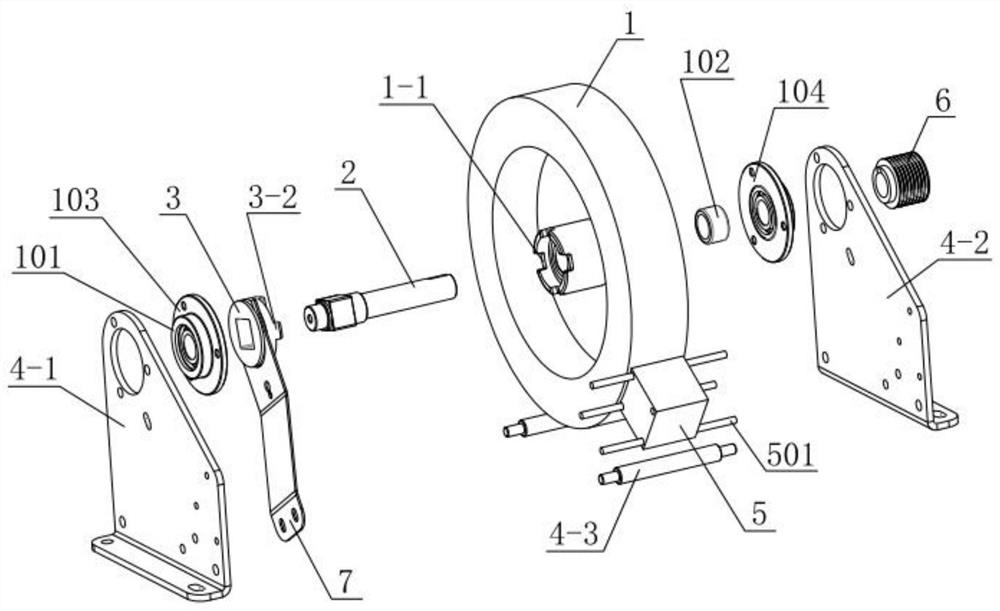

A kind of one-way two-way flywheel and its adjustment system

ActiveCN112402894BEasy to useLow costMuscle exercising devicesMovement coordination devicesCouplingFlywheel

The invention provides a single-direction flywheel and its adjustment system, which belong to the field of fitness equipment. The single-direction flywheel includes a flywheel body, a central shaft and a coupling. A one-way bearing is embedded in the center of the flywheel body, and the central shaft passes through the The one-way bearing is provided, and the coupling is movably sleeved on the central shaft to realize engagement and separation with the flywheel body. The single- and two-way flywheel adjustment system includes: a single- and two-way flywheel and a shifter assembly, the shifter assembly includes a spring fork, an adjustment handle and a shifter cable, the spring fork is set on the coupling, and the adjustment handle can be rotated to set; the shifter The pull wire is used to connect the spring fork with the adjustment handle, so as to control the loosening and tightening of the spring fork through the adjustment handle, and then drive the shaft coupling to move along the central axis. The present invention can realize the switching between the one-way mode and the two-way mode of the single-bidirectional flywheel through the adjustment system, that is, two exercise modes can be realized through one exercise bike, which is convenient to use and can reduce the cost.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD +1

Automatic mechanical device for recycling metal machining excess materials

ActiveCN111890115AAchieve meshingAchieve separationGripping headsMaintainance and safety accessoriesGear wheelMetal machining

The invention relates to an automatic mechanical device for recycling metal machining excess materials. The automatic mechanical device comprises a fixing column, the lower end of the fixing column isfixedly connected with the top face of a base plate, the eccentric position of the bottom face of the base plate is connected with the top face of a bearing plate through a rotating shaft, a power device acting on the rotating shaft is arranged on the bottom face of the base plate, the bottom face of the bearing plate is connected with the upper end of a sleeve through a bearing, a bevel gear isfixedly installed at the lower end of the sleeve, a motor is fixedly installed on the bottom face of the bearing plate, the output end of the motor faces downwards and is fixedly provided with a gear,a tooth groove meshed with the gear is formed in the periphery of the sleeve, a plurality of screws are arranged below the bevel gear, the screws are connected with the bearing plate through bearingpedestals, a swivel nut is installed on the periphery of each screw in a threaded mode, a limiting groove is formed in the top of each swivel nut, a fan-shaped block is arranged on the bottom of eachswivel nut, and an electromagnet connected with a power circuit is arranged on the bottom of each fan-shaped block. The device can be used for recycling the excess materials on a magnetic metal machining site in real time, can also be used for roughly classifying the magnetic metal excess materials after the magnetic metal excess materials are gathered, and can also be used for grabbing and movingmagnetic metal.

Owner:青岛正大正电力环保设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com